CONTENTS DEAR CUSTOMER...

Page 2

- Image

- Text

2

AOGV V. 1.01AOGV V. 1.01

CONTENT

DEAR BUYER! ………………………………………………………3

1. ATTENTION………………………………………………………………………………..3 2. COMPLETENESS……………………………………………………. ………………………………………….4 3. GENERAL INSTRUCTIONS …………………………………………………………………….. 4 4. SAFETY REQUIREMENTS …………………………………………………….4 5. DEVICE CONSTRUCTION …………………………………………………………………… …………..7 6. PREPARATION FOR WORK ………………………………………………………………7 7. OPERATION PROCEDURE ……………………… ……………………………………………..7 8. INSTRUCTIONS FOR INSTALLATION, MAINTENANCE …………….8 9. WARRANTY …………………………… …………………….9 10. RULES OF PACKAGING, TRANSPORTATION AND STORAGE …………..10 11. ACCEPTANCE CERTIFICATE …………………………………………………… 11 13. POSSIBLE PROBLEMS AND METHODS FOR THEIR ELIMINATION……….11

DEVICE STRUCTURE ………………………………………………………12

INSTALLATION DIAGRAM OF HEATING SYSTEM …………………………………..13

Advantages

The main advantages of gas boilers, for which owners of private houses choose them, are:

- Use of natural gas - a cheap energy source.

- Possibility to warm water and air in the room.

- An automated system that does not require close attention.

To understand the principle of operation of the automated mechanism, you can look at the instructions. If you have any questions, feel free to call to get detailed advice. If necessary, a service to call a technician to your home is available. Usually our employee explains the principle of using gas equipment. Owners need to follow these simple steps:

- Open the gas tap and set the thermostat knob to position “0”;

- To start the system, press the magnetic valve button and bring the piezo lighter;

- As soon as the pilot lights up, you can set the regulator to the desired position.

Servicing gas boilers is a very responsible job, and this service should not be neglected. There is a certain percentage of dangerous problems that occur, so it is better to take advantage of the professionalism and experience from.

To solve your problem, you can call a specialist. Fill out the form, briefly describe your problem and we will call you back for a consultation.

Free consultation

. DEVICE STRUCTURE…

Page 7

- Image

- Text

AOGV V. 1.01

7

AOGV V. 1.01

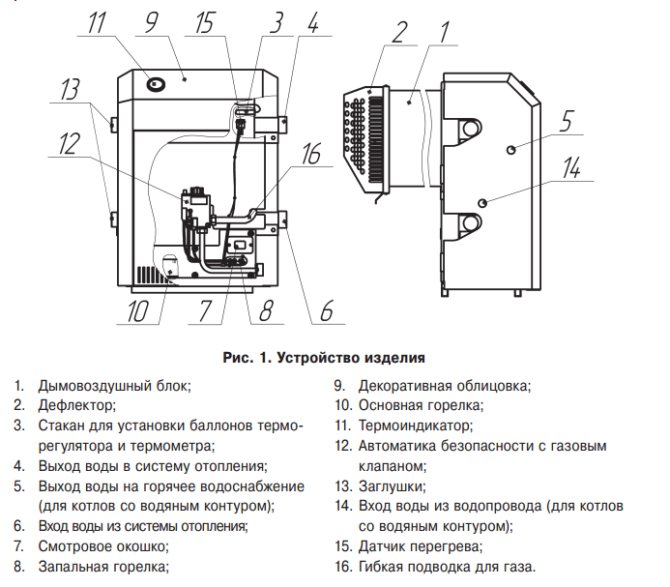

5. DEVICE STRUCTURE

5.1. The device is a welded structure that forms throughout the entire

the diameter of the water jacket bordering the combustion chamber. At the bottom of the boiler, in the opening of the combustion chamber, a gas burner device with controls is installed.

At the top of the device there is a gas outlet pipe for removing combustion products from the firebox.

On the back surface of the device there are threaded pipes intended for connecting the device to the heating system. Regulation and maintenance of the set temperature is ensured by a thermostat that modulates the flame of the main burner, equipped with a knob with divisions, which is installed on the front panel of the burner.

6. PREPARATION FOR WORK

6.1. after connecting the device to the gas supply system and filling the heat

carrier of the heating system, employees of a specialized service center or local gas management must adjust and check for operation of the safety automatics and temperature control, and also check the tightness of all threaded connections on the gas pipeline of the device and up to it.

6.2. Before igniting the gas burner, check for the presence of draft according to clause 4.3. in the absence of

If there is no draft, it is prohibited to ignite the gas burner device.

7. OPERATION PROCEDURE

For AOGV based on “630 EUROSIT” and injection burner (see Fig. 1)

7.1. Open the gas valve on the gas supply line. 7.2. initial position of the round control handle 3 (Fig. 4) in the “high” position

turned on" (

). turn control knob 3 counterclockwise to

ignition position (

).

7.3. press the control handle all the way and, without releasing it, for 10-60 seconds,

press the piezo igniter button 4 until a flame appears on the pilot burner.

After igniting the pilot burner, the control handle must be held pressed for 60 seconds, then gradually released. if the flame goes out, repeat points 7.2.-7.3. no earlier than 1 minute (or after a spontaneous click inside the automation) by increasing the time of pressing control handle 3.

7.4. To turn on the main gas burner, turn control knob 3

counterclockwise to positions 1-7. maximum temperature 80

ºС te-

fruit carrier corresponds to the number 7 on the control handle (subject to the conditions of clause 8.4.).

7.5. To turn off the main gas burner, turn control knob 3 to

clockwise to position (

). in this case, the pilot burner will hold

live the flame.

7.6. To completely turn off the gas supply to the pilot burner, turn the handle

control clockwise to the “off” position (

).

Installation of Lemax wall-mounted boilers

There are much fewer wall-mounted models than stationary ones. But they are still present on the market, so let’s look at the distinctive features of these units:

- The operation of a gas wall-mounted boiler depends on electrical energy. It is equipped with Italian automatic equipment. When using the device, you do not need to resort to auxiliary adjustment; it is enough to take care of a stable voltage in the network;

- use of high-quality components. Italian automation is installed with the ability to connect room thermostats to the control unit. There is also protection against reverse draft overheating and soot formation. The only drawback is the lack of an anti-freeze function and pump jamming. The combustion process occurs through a modulating burner. Due to this, the productivity of the boiler is significantly increased and gas consumption becomes economical. The device also includes a safety group, a circulation pump, a pipe draft sensor;

- functionality. Owner reviews indicate that Lemax double-circuit wall-mounted gas boilers work flawlessly. But in the comments about the work of floor-standing models you can sometimes find complaints.

Construction of a Lemax Patriot parapet boiler

. Horizontal sections of heating system pipelines are…

Page 9

- Image

- Text

AOGV V. 1.01

9

AOGV V. 1.01

8.7. Horizontal sections of heating system pipelines must be

install it with a slope of at least 10 mm per 1 m towards the heating radiators and from them to the device. This is done to ensure free release of air when filling the system with water and eliminate the occurrence of air locks.

8.8. pipelines, heating radiators and their connections must be

sealed, water leaks are not allowed.

8.9. Do not drain water from the device and heating system during the non-heating period, i.e.

This leads to accelerated corrosion and premature failure of the device. Add water to the expansion tank as it evaporates.

8.10. To avoid clogging (contamination) of the device and the heating system on

In the return pipeline in front of the device, it is recommended to install a slag separator (slag dump, dirt dump) and periodically clean it.

8.11. supervision of the operation of the device is assigned to the owner, who is obliged

keep it clean and in good condition, check and clean the chimney in a timely manner.

8.12. Annual preventive inspection, maintenance and repair of equipment

It should only be carried out by qualified employees of the local gas authority or an organization servicing household gas appliances.

8.13. It is prohibited to operate the device when the heating system is full.

system with ethylene-containing liquid. The hardness of water for filling the heating and hot water supply system should not exceed 5 mmol eq/l

1)

. failure to comply with these requirements will result in

termination of warranty obligations.

9. WARRANTY OBLIGATIONS

9.1. The warranty period for the operation of the device, if required,

th annual preventive maintenance and consumer compliance with the conditions of transportation, storage, installation and operation - 36 months from the date of sale. The service life of the device is 14 years.

9.2. In case of failure of the device during the warranty period,

tation subject to the requirements of clause 9.1. The consumer has the right to free repairs, and in the case of a manufacturing defect of the heat exchanger, to replacement of the device.

Warranty repairs of the device are carried out by specialized service centers or gas services. Based on the results of the repair, a warranty repair certificate is issued.

9.3. The manufacturer is not responsible and does not guarantee operation

device in the following cases: – non-compliance with installation and operation rules; – if installation and repair of the device were carried out by persons or organizations on

this is not authorized

2)

;

1) water hardness is expressed in mmol equiv/l (1 mmol equiv/l corresponds to 20.04 mg/l Ca2+ cations or 12.16

mg/l MD2+ cations). There are soft water (total hardness up to 2 mmol equiv/l), medium hardness (2-10 mmol equiv/l) and hard water (more than 10 mmol equiv/l).

2) RESOLUTION of September 29, 2003 No. 170 on the approval of the rules and standards for the technical operation of living

Advantages and disadvantages

Let us note the key advantages of Lemax solid fuel boilers:

- unpretentiousness to the type and quality of fuel - brown, white, hard coal, as well as coke and wood are suitable;

- boilers are compact in size;

- safety at work;

- Impact protection thanks to thermal insulation materials;

- the top loading door makes it easy to load coal and other fuels;

- with proper care, a boiler made of high-quality steel and cast iron will last for many years;

- corrosion resistance;

- high performance;

- You can purchase a gas burner and a volatile draft regulator for the boiler;

- low price;

- This unit comes with a three-year warranty.

The main disadvantages of Lemax solid fuel equipment:

- the efficiency of such boilers is lower than that of a pyrolysis or pellet boiler, the efficiency is only 80%;

- The fuel in such products burns out very quickly, so you have to load them very often.

if the control card for installing the boiler is not completed...

Page 10

- Image

- Text

10

AOGV V. 1.01AOGV V. 1.01

– if the control coupon for installation of the boiler is not filled out (there is no seal of the organization

tions);

– if the warranty card does not contain the stamp of the trading organization and

Date of sale;

– if mandatory annual maintenance of the device has not been carried out; – in case of mechanical damage and broken seals; – when scale and burnout form on the walls of the heat exchanger.

9.4. The service life of the device is 14 years. 9.5. the company reserves the right to make changes that do not worsen

operational characteristics.

9.6. Work related to technical and preventive maintenance is not

are guaranteed.

10. RULES OF PACKAGING, TRANSPORTATION AND STORAGE

10.1. The devices are supplied in manufacturer's packaging. 10.2. The devices are transported by road, water and rail

transport in accordance with the rules for the transportation of goods in force for a specific type of transport.

10.3 The devices are transported only in a vertical position, sudden shaking

Hibbing and edging are not allowed. When transporting, it is necessary to ensure that the devices are securely secured against horizontal and vertical movements.

10.4. Packed devices must be stored vertically. 10.5. Uninstalled devices are stored in the manufacturer's packaging.

Storage conditions for devices in terms of exposure to climatic factors are 4 GOST 15150-86.

11. CERTIFICATE OF ACCEPTANCE

Steel gas heating water heating apparatus.

Factory number _____________________________________________________

device model ___________________________________________________________________

complies with GOST 20219-74 and is recognized as suitable for use

The device is tested for strength and tightness by hydraulic pressure

0.2 MPa (2 kg/cm

2

)

Date of manufacture _________________________________________________________________

plant representative ________________________________________________

Otk _____________________________________________________________________________________ m.p.

personal fund.

5.5.2. installation and dismantling of gas pipelines, installation of gas appliances, apparatus and other gas-using equipment, their connection to gas pipelines, apartment water supply and heat supply systems is carried out by specialized organizations.

Comments

Select → I found the instructions for my water heater here! #manualza

- Click →

An instruction is a paper that is usually read in two cases: 1. When there is nothing to read. 2. When everything is already broken.

Manualza!manualza.ru

Still not with us?

Recommendations for use - how to turn on a gas boiler correctly

Before lighting the Lemax boiler, you need to make sure that there is water inside it and other elements of the heating system. Next, they check the level of traction and select the most optimal algorithm of action. Its formation is influenced by the power of the equipment and the presence of automatic units. The Lemax boiler is classified as non-volatile, so the problem of how to ignite a Lemax gas boiler is solved using conventional piezo ignition. Some models have a special traction sensor, which ensures safe operation of the device.

Prices

- ServicePrice

- Engineer visit during working hours from 8:00 to 22:00

- Within a small concrete ring 2000 rubles.

- Tariff for visiting a site outside the small concrete ring, per km. in both directions 30 rub.

- Departure on holidays ×1.5

- Departure after hours from 22:00 to 8:00 am ×2

- One-time maintenance of a gas boiler

- Wall-mounted (up to 49 kW) 4500 rub.

- Wall / floor condensing (up to 60 kW) 6000 rub.

- Wall / floor condensing (61-140 kW) 8000 rub.

- Floor-standing with atmospheric burner (up to 59 kW) RUB 5,500.

- Floor-standing with atmospheric burner (60-99 kW) 6500 rub.

- Floor-standing with atmospheric burner (100-150 kW) 8500 rub.

- Floor-standing with forced-air burner (up to 29 kW) RUB 6,000.

- Floor-standing with forced-air burner (30-59 kW) RUB 7,000.

- Floor-standing with forced-air burner (60-119 kW) RUB 8,000.

- Floor-standing with forced-air burner (151-359 kW) 10,000 rub.

- Floor-standing with forced-air burner (120-249 kW) Negotiable

- Floor-standing with forced-air burner (over 250 kW) Negotiable

- Annual maintenance of a gas boiler (1 routine + 1 emergency visit)

- Wall-mounted (up to 49 kW) 13,500 rub.

- Wall / floor condensing (up to 60 kW) 15,000 rub.

- Wall / floor condensing (61-140 kW) 17,000 rub.

- Wall / floor condensing (151-359 kW) RUB 19,900.

- Floor-standing with atmospheric burner (up to 59 kW) RUB 14,500.

- Floor-standing with atmospheric burner (60-99 kW) RUB 15,500.

- Floor-standing with atmospheric burner (100-150 kW) RUB 17,500.

- Floor-standing with forced-air burner (up to 29 kW) RUB 15,000.

- Floor-standing with forced-air burner (30-59 kW) RUB 16,000.

- Floor-standing with forced-air burner (60-140 kW) RUB 17,000.

- Floor-standing with forced-air burner (140-249 kW) RUB 20,000.

- Floor-standing with forced-air burner (over 250 kW) Negotiable

- Adding a scheduled departure RUB 5,000.

- Adding an emergency exit RUB 3,000.

Reviews of Premium Nova boilers

Buyers quite often choose boilers of this series for the reason that they represent equipment that has been improved. This is how it differs from the options described above. The main positive feature is the presence of an automation system. The model is volatile, but if we consider it from the point of view of ease of use, it wins. Buyers like that the device can be set to operating mode with the necessary parameters. The temperature of the coolant will depend on the temperature inside the room. Automation will monitor and adjust parameters that were manually set by the user. According to buyers, this feature is not only a plus, but also provides ease of use.