- home

- Chimney inspection, chimney report

- Fireplace installation

- Installation of fireplace stoves

- Chimney repair

- Design

- Installation of a chimney for a gas boiler

- Covering a bathhouse (steam room)

- Engineer consultation

- Chimney inspection in Moscow and the Moscow region

- Grounding installation for a gas boiler and for the home

- Ceramic chimneys (choice, features, technology)

- Fireplace cladding Superisol and Silka

- Choose a fireplace lining

One of the main documents that the gas service requires to start gas is the Certificate of Inspection of Smoke and Ventilation Ducts. This act is necessary for a reason - because your Safety and proper operation of gas equipment, first of all, depends on a properly installed chimney and the necessary air exchange in the room where the gas equipment is located. And since gas is an explosive and poisonous substance, it is therefore necessary to make chimneys and ventilation ducts efficiently and airtight so that there is no carbon monoxide entering the house. That’s why inspection reports were introduced so that competent organizations could issue conclusions.

Before issuing a water certificate for operation

If the equipment requires any tests and inspections, then before drawing up this act all such procedures must be carried out and completed.

As a rule, new equipment is checked for defects, defects, defects, malfunctions, as well as whether it complies with the regulations and standards adopted by the enterprise, labor protection and fire safety requirements.

All these procedures are carried out by a specially created commission, consisting of at least two people, which is appointed by a separate order by the head of the organization.

Basic rules for drawing up a water act for operation

This document does not have a unified, mandatory form, so it can be compiled either in free form or according to a template developed and approved within the enterprise. The act can be written on a regular A4 sheet, or on the organization’s letterhead.

It must necessarily include information about the enterprise where the equipment is being put into operation, as well as detailed information about its name, technical characteristics, conditions of use, etc. The more complex the equipment, the more detailed information about it needs to be recorded and the more points the act may contain.

This document must indicate the compliance of the introduced equipment with the internal requirements of the organization and legal standards, and also record the presence of comments or identified malfunctions. If the facts of defects are confirmed, then a special defect report must be drawn up for the equipment and the equipment cannot be put into operation until the defects are eliminated.

It should be remembered that after signing the act of putting the equipment into operation, the manufacturer’s warranty begins to apply to it.

Boiler room commissioning procedure

After successful installation and commissioning work, the boiler room is put into operation, which can be divided into two points:

- Actual

, when the installation physically “turns on” in normal mode, indicating readiness for further operation to provide the consumer with heat and/or hot water supply. - Documentary

, during which specialists prepare the necessary package of as-built documentation, and also receive official permission to operate the boiler room on an ongoing basis.

certified to work with boiler installations, which allows us to obtain the necessary permits quickly and completely legally.

How are documents collected and submitted? To begin with, a statement is being prepared stating that the installation has been inspected and allowed to be put into operation as usual. The application is attached to the established package of documents and sent to the supervisory authorities. Next, it is necessary to ensure that the boiler room is inspected by designated persons, and also to obtain an admission certificate for permanent industrial operation

.

After receiving the certificate, all work is considered completed - the boiler room is allowed to be used on a permanent basis.

Instructions for writing a water act for operation

- In the first part of the document, its name is written, and its essence is also briefly indicated (in this case, “about the commissioning of equipment”). The line below indicates the locality in which the act is created and the date: day, month (in words), year. Then the composition of the commission that checked the equipment is entered: the positions of the employees are entered, as well as their last names, first names, and patronymics. Here you should also make a reference to the order of the director who appointed the commission (indicate the full name of the enterprise, surname, first name, patronymic, manager, number and date of the order).

- The main part is to certify the fact that the equipment has been examined and inspected by the commission. Here you need to enter its name, serial number, technical characteristics, name of the manufacturer, place of manufacture of the equipment, etc. options. The regulations, laws, documents on the basis of which the inspection was carried out and its timing are also recorded here.

- The third part of the document contains information about the condition and quality of the equipment being put into operation. If it is in good condition, then this should be noted; if it has any defects or malfunctions, then this should also be indicated. If there are any comments, they must be included in the act with all the details. Next, you should add a clause about the commissioning work carried out, as well as that the equipment meets all safety requirements (fire, technical, environmental, industrial).

In conclusion, in this part, a separate paragraph needs to summarize that the equipment has passed the test and is ready for use.

The penultimate part of the document contains conclusions on the entire above procedure. If there are no complaints about the equipment, then here you need to enter that the equipment will be put into operation on such and such a date at such and such an address (the address of the enterprises where it will be used is indicated).

If there are complaints, then you should write “not ready for use until identified defects are eliminated.” Next you need to add a warranty clause.

After entering all the information into the act, links to all annexes to it with numbers and dates are included.

The act must be certified by the signatures of the inspection commission. The document can also be certified by a seal, but not necessarily, since since 2016, the presence of a seal for legal entities is not a legal requirement, but is voluntary.

Certificate of commissioning of a gas boiler

General provisions on the delivery to the Customer and admission into operation of new and reconstructed thermal power plants.

The procedure for delivery to the Customer and admission into operation of new and reconstructed

thermal power plants are regulated by the following documents:

1.

Rules for the technical operation of communal heating boiler houses, approved by order of the Ministry of Construction of Russia No. 251 dated November 11, 1992.

2.

Rules for the technical operation of thermal power plants, approved by order of the Ministry of Energy of Russia No. 115 dated March 24, 2003.

3.

Rules for the design and safe operation of steam boilers with a steam pressure of no more than 0.07 MPa (0.7 kgf/cm2), hot water boilers and water heaters with a water heating temperature not higher than 388 K (115 °C), approved by order of the Ministry of Construction of Russia No. 205 dated 28.08..92

4.

Guidelines for the admission into operation of new and reconstructed electrical and thermal power plants, approved by order of the Ministry of Energy of Russia No. 32 01-05/105 dated 04/05/02.

5.

Construction norms and rules SNiP 3.01.04-87, approved by Decree of the USSR State Construction Committee No. 84 of 04/21/87 “Acceptance into operation of completed construction facilities. Basic provisions".

6.

Construction norms and rules SNiP 3.05.05-84, approved by Decree of the USSR State Construction Committee No. 72 dated 07.05-84.

"Technological equipment and technological pipelines." These Regulatory Documents regulate only the procedure for delivery to the Customer and admission into operation of heating equipment.

The procedure for delivery to the Customer and admission into operation of new and reconstructed electric drive systems is regulated by Chapter 1.8. “Acceptance testing standards” of the General Rules of Section 1, approved by Order of the Ministry of Energy No. 150 of 04/09/03 of the Rules for the Construction of Electrical Installations.

The main stages of electrical installation work are reflected in the general forms of acceptance documentation, see Instructions for preparing acceptance documentation for electrical installation work VSN 123-90, approved by the USSR Ministry of Installation and Special Construction on December 24, 1990.

General provisions for the delivery to the Customer and admission into operation of new and reconstructed thermal power plants are as follows:

Commissioning, commissioning, initial launch of gas wall-mounted boilers

Dear customers, we draw your attention to the fact that commissioning and commissioning of gas boilers by a specialized organization is one of the main conditions for manufacturers to provide a warranty on equipment! Without the appropriate mark on the warranty card, the warranty may be denied.

Commissioning work on a wall-mounted gas boiler, as well as its initial start-up and commissioning, are a key factor in the further long, stable and safe operation of the equipment and heating system as a whole.

In addition, commissioning of the boiler by a certified service department that has undergone special training is one of the key conditions for providing a warranty on the boiler from the manufacturer. Since, in order to carry out commissioning work, according to the recommendations of boiler equipment manufacturers, it is first necessary to check the heating system as a whole, to identify errors made during the installation of the boiler itself and the smoke exhaust pipe, errors in the electrical wiring, errors in the installation of plumbing connections to the boiler and boiler piping, errors in wiring heating systems, errors made by installers of gas services (gas leak, incorrect operation of the meter) to detect these gross errors, the specialist performing commissioning of a wall-mounted gas boiler requires knowledge in the following areas:

- Knowledge of fire safety rules and regulations.

- Knowledge of electrical safety rules and regulations.

- Knowledge of norms, rules, and operating standards for indoor gas equipment.

- Knowledge of the basic requirements of manufacturers for the installation of gas wall-mounted boilers and smoke exhaust pipes.

- Theoretical and practical knowledge of the basic schemes, types and topology of heating system pipe distribution.

The most common problems that arise when the boiler is connected incorrectly or independently:

The TOP-KOTYOL company offers its customers affordable, qualified assistance in the initial setup and first start-up of gas equipment.

Required documents

List of documents.

To obtain permission to operate a boiler room and gas equipment for commercial or economic purposes, you must submit a corresponding application to Rostechnadzor.

The following documents will be required:

- documents confirming the commissioning of gas boilers;

- gas tolerances;

- in the case of capital construction of an object, papers are provided for the land plot used for development (extract from the Unified State Register or long-term lease agreement);

- action plan for containment and elimination;

- receipt confirming payment of state tax;

- papers confirming the availability of reserve finances in case of the need to eliminate an accident;

- permitting documents, regulations granting the right to operate technical equipment and confirming its compliance with technical standards;

- the position of industrial control of the enterprise;

- a list of all control, automation and monitoring devices for equipment operation;

- a copy of the contractual agreement on cooperation between the enterprise and ASF;

- certificates of workers granting them the right to operate and maintain boiler equipment and gas boilers;

- copies of insurance contracts for employees of public production organizations.

The commissioning service for a wall-mounted gas boiler includes:

- Diagnostics of the condition of the heating system, identification of errors in the installation of pipes, radiators, check valves, shut-off valves and other factors negatively affecting the operation of the gas boiler and heating system

- Checking the correct installation of the wall-mounted boiler and smoke exhaust pipe

- Checking the condition of the electrical connection of the boiler (checking the presence of grounding)

- Checking the tightness of the gas pipe and in-house gas equipment (gas meter, gas valve), checking the presence of gas, removing air lock and welding debris from the pipe

- Connecting the wall-mounted boiler to the electrical circuit (via a voltage stabilizer, if available), connecting the gas supply and dielectric coupling

- Checking the main mechanisms of a wall-mounted boiler (circulation pump, smoke exhaust fan, gas valve)

- Initial activation of the boiler and setting of operating parameters taking into account the area of the room, the length of the smoke exhaust pipe and the personal wishes of the customer (if possible)

- Setting the boiler gas valve taking into account its power and heating area. Checking compliance with norms and regulations of gas pressure in the gas main during boiler operation (in dynamics)

- Instructing the user on the basics of using gas heating equipment, operating conditions, precautions, actions during an accident

- Filling out the boiler passport with a note on the work and tests performed

Grounding a gas boiler.

Installation of grounding for gas boilers in Moscow and the region + material + protocol (act), registered with Rostechnadzor e. laboratories.

Prices depending on the selected material:

Material - galvanized steel | price from 12500 rub.

Material: copper-plated steel | price from 13,500 rub.

Material: stainless steel | price from 16,000 rub.

Installation carried out with resistance measurement and laboratory conclusion (protocol/report) provides a guarantee of compliance with the requirements for connecting the boiler.

Installation of materials with high corrosion resistance ensures long service life of the grounding*

* The technology for installing factory electrodes makes it possible to install one modular vertical ground electrode, which reduces the volume of excavation work, therefore there is no need to dig a trench on the site.

Checking the existing ground loop for the boiler. Departure + resistance measurement + act/protocol: Price from 5000 rub.

When a heating system based on a gas boiler is installed in a private country house, then to connect it the gas service requires grounding, i.e. - in order to ensure safe operation and uninterrupted operation, the boiler is grounded - carried out by a deliberate electrical connection of its body (through a grounding bus) with a ground electrode and compliance with the requirements for resistance, conductors and electrodes. The implementation of these measures provides protection against electric shock, fire protection, and protection of expensive circuit boards.

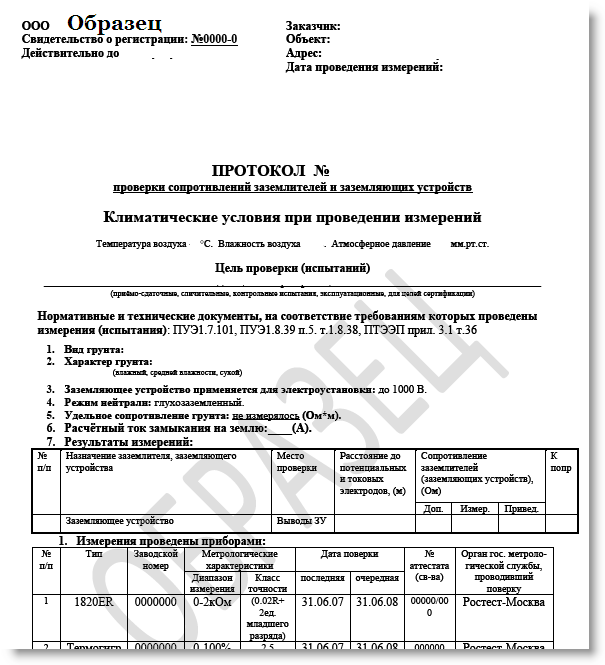

Confirming documents on compliance of grounding for a gas boiler with standards.

The main documents confirming that the grounding of a gas boiler meets the requirements is the protocol (“Protocol for checking the resistance of grounding conductors and grounding devices”) of the electrical measuring laboratory and a copy of its registration certificate, certified by a blue seal. A protocol is often mistakenly called an “act.” The protocol indicates the last name of I.O. customer. Object: Residential building. Address. Date of grounding test. Climatic conditions (air temperature, humidity, atmospheric pressure). Purpose of verification. Type of soil. The nature of the soil. Neutral mode. Purpose of the grounding device. Place to check resistance. Distance to test electrodes. Resistance (measured, permissible, given). Correction factor Conclusion on compliance of grounding resistance with the requirements for gas boilers.

Grounding switch for gas equipment.

To install high-quality grounding, suitable for issuing a protocol (certificate), installation work should be carried out with a device for measuring resistance. How long is required to install the ground electrode(s) to ground a gas boiler that complies with the requirements? It all depends on the resistivity of the soil in which the installation will be carried out. If we consider the use of a factory-made modular kit, then in soil with very low resistivity a 6-meter grounding electrode may be sufficient, but this option rarely works; most often, a vertical grounding electrode is installed using a 9-15 meter grounding kit, which is driven in from one or several points, depending on soil conditions and area used. For example, the cost of installing a ground loop in dry clay will be much less than in dry sand. The final length and configuration of the ground electrode/s is determined in the process of carrying out work and measuring (with a device) the resistance to current spreading. For those who install grounding professionally, it is much easier. Typically, installers take several dozen rods and their accessories with them to the site, rather than a set of a certain length. If you buy a ready-made grounding set of some fixed length, then after installation and measurements, it may turn out that there are not enough rods or there are extra rods left.

Resistance standards: The gas service requires that the resistance be no more than 10 ohms.

Work order:

- choosing the optimal location for the grounding device

- soil development (if required)

- start of installation

- step-by-step measurements with a resistance device during the installation of a modular ground electrode

- completion of work upon receipt of the required inspection result

- registration and issuance of documents on the condition of grounding for a gas boiler.

Do-it-yourself grounding installation for a gas boiler in a private house.

If the installation is carried out independently, is such grounding suitable for obtaining a protocol (act) for a gas boiler? To answer this question, you should call an electrical laboratory to check the resistance to current flow. When the parameters comply with the standards, documents are issued; if there is no compliance, you need to increase the length or number of electrodes in the grounding device at home.

After installation and connection of the grounding device - in accordance with clauses 1.7.82, the main potential equalization system is performed. For example, if a gas pipe has an insulating insert at the entrance to the building (boiler room), only that part of the pipeline that is located relative to the insulating insert on the side of the building is connected to the main potential equalization system.

Checking resistance.

Measurements must be carried out by qualified personnel, with the issuance of appropriate documents. The resistance test for commissioning the ground loop for a gas boiler in the private sector (house, cottage) is carried out for compliance with standards, followed by the issuance of a protocol (act) by the electrical measuring laboratory. The required current flow resistance for volatile gas heating equipment should not exceed 10 Ohms. Measurements are carried out using measuring equipment. There are a number of ways to measure the resistance of grounding devices (GDs). The most common method is measurements using a 3-wire circuit.

Also, during commissioning and during operation, monitoring the condition of the charger must be carried out by checking the execution of the connection elements of the grounding conductors with the grounded elements, the corrosion state of the charger elements,

Wire cross-section for boiler:

If the word “wire” for a boiler means a power supply cable, then according to the PUE, it must have copper conductors and consist of: phase (L), neutral working (N) and neutral protective (PE) conductors. The cable cross-section must correspond to the design load - but not less than the value specified in the PUE table (7.1.1.). If the word “wire” means a grounding conductor laid in the ground, the minimum permissible cross-sections for various materials are indicated in GOST R 50571.5.54 - 2013 (Table 54.1). For example, according to this table: Copper stranded wire (D=1.7mm for each wire) installed in the ground should have a minimum cross-sectional area of 25 mm2, addition (d): if experience shows that the risk of corrosion and mechanical damage is extremely low, a section of 16 mm2 can be used.

Service life of grounding.

Corrosion-resistant materials provide long-term protection against the aggressive destructive effects of soil. Factory materials [grounding kits] with increased resistance to external influences are parts made of copper-plated and stainless steel. When performing grounding for a gas boiler (and not only), you should take into account the minimum available standard diameters of metal pins for vertical installation: for stainless steel - this value is no less than 16 mm, for steel with galvanic copper coating (copper-plated steel) - no less than 14 mm. Professional work for the trouble-free installation of factory components in hard and soft soil requires the presence of a power tool with an impact force of 25 J.

Mechanized work and corrosion-resistant materials provide: • High corrosion resistance and, accordingly, a long service life of the grounding device; • Installation of one long ground electrode, depending on ground conditions, can provide low resistance to current flow; • When installed in this way, unlike a multi-electrode circuit, a horizontal grounding conductor is not needed - accordingly, this leads to a reduction in excavation work. • The resistance of the grounding device does not depend on changes in climatic conditions;

Areas where our electrical laboratory operates; Moscow; Balashikha; Bronnitsy; Dzerzhinsky; Dmitrovsky district; Dolgoprudny; Domodedovo; Zhukovsky; Ivanteevka; Istrinsky district; Korolev; Krasnoarmeysk; Krasnogorsk district; Krasnoznamensk; Leninsky district; Lobnya; Losino-Petrovsky; Lytkarino; Lyubertsy district; Mozhaisk district; Mytishchi district; Noginsk district; Odintsovo (Odintsovo district); Pavlovo-Posadsky district; Podolsk; Pushkinsky district (Pushkino); Ramensky district; Reutov; Ruzsky district; Fryazino; Khimki; Chernogolovka; Schelkovsky district; Elektrostal.

Electricity supply and gas boiler.

Why can a volatile gas boiler go out periodically? One of the reasons for the shutdown may be periodic potential surges on the neutral wire (relative to the ground). Some boiler models “perceive” the potential at “zero” as an emergency and turn off. For the same reason, phase-dependent models are not started from portable generators, in which there are two 110V phases and no “zero”.

Information for the document

In practice, very often the subject of civil transactions is various equipment. Equipment is rented, purchased, donated, etc. An integral part of such contracts is the act of putting equipment into operation. The legislation does not contain rules that regulate the process of drawing up an act of commissioning equipment. But the Civil Code of the Russian Federation contains some rules that regulate the procedure for accepting goods or services (for example, Articles 513, 720 of the Civil Code of the Russian Federation). These standards also apply to the act of putting equipment into operation. How and when to draw up this document and what features it has.

Features of drawing up a receipt

When the act is drawn up

In accordance with current legislation, drawing up an equipment commissioning certificate is not mandatory. But in practice, this document is always drawn up. This is primarily done in order to avoid further problems associated with equipment defects.

Important : if equipment is sold or transferred to a third party on the basis of other civil transactions, then it is necessary to draw up an act of putting the equipment into operation. Also, this document must be drawn up in cases where the operation of the equipment was stopped for the purpose of repair and resumed some time later: a commissioning certificate is drawn up when the equipment is resumed.

Drawing up such a document is an additional guarantee for both parties. This document is drawn up after the transfer of equipment and after its installation. In some cases, the act is also drawn up directly at the time of concluding the contract.

Parties to the act

Many people are interested in the question of who should sign the equipment commissioning certificate. Since this document is an integral part of the relevant agreement, it must be signed by the parties to the transaction or their authorized persons.

Important : very often a special commission is created to check the operation of the equipment. In these cases, the act of commissioning the equipment must be signed by all members of the commission.

Moreover, if the opinion of one of the commission members differs from the opinion of others, a corresponding entry is made about this in the document.

What needs to be included in the act

The legislation does not provide for a mandatory form of commissioning act. Accordingly, the parties may provide any information they consider necessary. The content of the act largely depends on the specifics and features of the equipment that is transferred on the basis of the transaction. Of course, there is no single form for the commissioning act, but the following information must be indicated in the text:

- brand, year of manufacture and name of equipment;

- date of equipment inspection;

- place of inspection and location of the equipment (if the equipment was tested in another place and is located in another);

- description of the conditions for using the equipment;

- other information and special conditions.

What is being checked

When drawing up the act, the following is checked:

- serviceability of equipment;

- his job;

- accommodation conditions;

- compliance of this equipment and its operating conditions with established technical safety standards and other regulations.

If during the inspection any malfunctions or any inconsistencies with established standards and legal requirements were discovered, then a corresponding entry is made in the text of the drawn-up report.

Please note: If during the inspection violations or malfunctions were discovered that make the operation of the equipment impossible, then in this case the equipment cannot be used: a corresponding entry is made about this in the text of the equipment commissioning act.

If the above faults are detected, they must be eliminated: the equipment can be used only after the detected faults have been eliminated. The responsibility for troubleshooting lies with the owner of the equipment, unless otherwise provided by the relevant agreement.

Important : after troubleshooting, the equipment must be re-tested: in this case, a new act of putting the equipment into operation is drawn up. If, based on the results of the secondary inspection, no malfunctions were found, a corresponding entry is made about this in the text of the report, and operation of the equipment is permitted.

Phased commissioning of the boiler plant

You may also be interested in

Fire sensors for boiler rooms. How to choose?

Any boiler room, regardless of its configuration and equipment, is a potentially dangerous technical room, therefore, during its production, special attention should be paid to safety issues, especially fire safety. Without automation and control mechanisms that negate most risks, the boiler room simply will not be put into operation.

We are not always able to make money installing a heating system. It often happens that the client has assembled the entire system independently or by a familiar installer and installed the boiler. But in this case, only those who have undergone training and received the appropriate certificate have the right to guarantee it.

The technician needs to come and check the correct installation, the presence of all the necessary components, then start the system and check the safety of operation. Then set up the programmers and other control devices and perform hydraulic balancing of the system.

Commissioning does not involve installation work; everything should already be hanging and in place. Before leaving for commissioning, it is recommended to refresh your memory of the features of the boiler model that you will be dealing with. Find and review the service instructions and drawing of the boiler being serviced, and take them with you.