In what case should collector-beam connection of radiators be preferred?

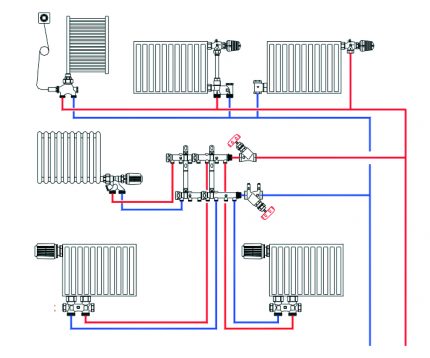

Radiant heating distribution is preferable for large areas of heated private houses (as well as in modern apartments when pipes are laid along the floor). When the goal is not to save money and it is necessary to maintain the aesthetic component of the interior. In other respects, this is one of the best (if not the best) heating layout schemes.

All pipes in the system run through the floor screed and do not interfere with further finishing of the room. Nothing sticks out anywhere. Radiators are connected from the floor, or better yet, from the wall. After installation, we will only be able to observe the heating radiators themselves and no additional pipes on the walls.

This wiring got its name by analogy with its appearance. Pipes radiate from the collector group to the radiators. Hence the name collector-radiant heating system.

Beam wiring: features and elements

The radial type of heating system wiring is a well-thought-out and effective design, consisting of several main elements, presented:

- A boiler designed to transfer coolant through pipes to heating radiators. The power indicators of the installed equipment must be taken into account with a percentage increase for heat losses in the gas radiant heating system.

- Circulation pumping equipment that allows forced movement of the coolant through a closed heating system. In the process of choosing the model and design of the pump, the height and length of the pipes that create hydraulic resistance, as well as the design and type of radiator batteries, must be taken into account.

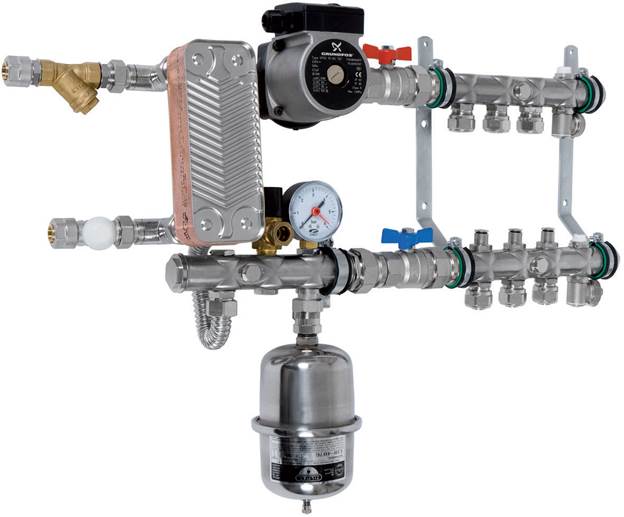

- Comb and collector. The installation of gas radiant heating requires the mandatory installation of combs or a collector, which is responsible for the process of distributing the coolant throughout all heating devices in the system.

Horizontal radial heating distribution diagram

Modern brass, steel or polymer manifolds used in radiant heating systems are often equipped with additional elements of thermostatic or shut-off-regulating properties, which allows the individual flow of coolant to be distributed over each individual circuit.

Equally important is the presence of an automatic air removal mode and standard thermometers that facilitate the operation and maintenance of the heating system.

In recent years, the installation of special external and internal, so-called built-in cabinets, within which elements of the radiant heating system are mounted, has become very relevant.

The principle of organizing a beam circuit

One of the central elements of the beam system is the collector unit. If you are going to do heating in a house with several floors, then the collector should be located on each level.

During installation, collectors are placed in a collector cabinet, where a convenient system for positioning this element is provided for subsequent maintenance or adjustment.

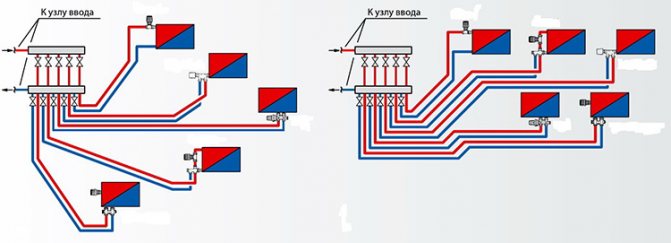

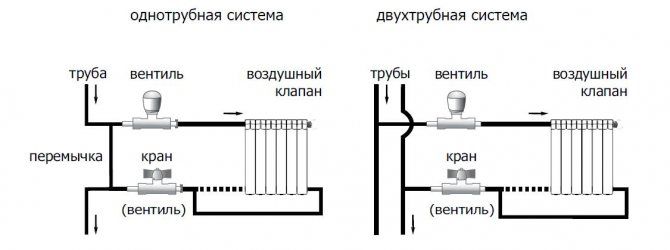

The radial wiring diagram is used for one- and two-pipe systems. The first option assumes that the supply and collection of coolant is carried out by one collector. The second option involves the use of two collectors for supply and return

The indisputable advantage of the radial system is the minimum number of connections, which has a positive effect on the hydraulic stability of the entire heating system. The central working body is the boiler.

To ensure high efficiency and safety, the owner needs to take into account the power of the unit, the consumption of thermal energy by heating devices and the heat loss of the system. This must be done regardless of what type of fuel the boiler operates on.

An increase in the length of the pipeline when creating radial distribution is fraught with a slight increase in heat loss, which also needs to be taken into account for power balance.

In single-pipe radial distribution of heating circuits, the supply of coolant prepared for heating devices is carried out by the same collector, which collects the return and sends it to the boiler (+)

Choosing a circulation pump

Radial piping is used mainly in horizontal circuits with bottom coolant supply. It requires a circulation pump that stimulates the movement of heated water through numerous branches.

Controlled coolant circulation makes it possible to reduce the temperature difference at the inlet and outlet of the heating circuit. As a result, it is possible to increase heating efficiency, making the system more compact and less material-intensive.

When selecting and installing a circulation pump, you need to take into account a number of features, using which you can achieve high efficiency of the entire system.

This unit is selected according to several important parameters, including:

- productivity, m3/hour;

- head height, m.

To correctly select a circulation pump for these parameters, you need to take into account the diameter of the pipes, their length and height relative to the level of the pumping unit. When drawing up a heating system installation project, these parameters are calculated in advance.

Rules for installing a circulation pump

By adhering to the recommendations below, you can achieve high heating efficiency and safety:

- circulation pumps with a wet rotor are installed so that the shaft is horizontal;

- the device with a thermostat should not be close to hot surfaces (radiator or boiler) so that the readings are not distorted;

- as a rule, it is installed on the return section of the pipeline due to lower temperatures. Modern models can also be installed in the supply line, withstanding high temperatures;

- The heating circuit must be equipped with an air bleed mechanism. If there is none, then the pump must have an air vent;

- should be located as close as possible to the expansion tank;

- Before installing the pump, it is recommended to flush the system to remove solids;

- Before starting the pump, fill the system with water;

To avoid becoming a victim of excessive noise, select a pump in accordance with the performance of the heating system.

Is it possible without a pump?

Of course, you can save money and not buy a pump, air vents for bleeding air, sensors, etc. But a beam system with natural circulation requires compliance with several not very convenient conditions.

Experts recommend this option in extremely rare cases. Firstly, you will need to install wide diameter pipes. Secondly, the expansion tank must be installed at the highest point of the facility.

To save on components, you can do without a pump, but this is only possible if a number of conditions are met and only for small buildings

This option is suitable for a cottage or other modest-sized object, providing enough heat. The choice between natural circulation and forced circulation must be made at the design stage.

What is a radiant heating scheme?

The beam system is essentially an evolution of the two-pipe system. Not as significant, but still an evolution. There are also two pipes here: supply and return. The only difference is that each battery receives a pipeline from the distribution manifold. The collector is the same as that used when installing a water heated floor.

Let's now highlight the strengths and weaknesses of each heating scheme

Features and diagrams of a beam system in an apartment building

The main difficulty of using a collector-radial circuit in an apartment building, in which the coolant is supplied according to a traditional vertical two-pipe circuit, is the influence of the radial circuit of an individual apartment on the heat load of the apartments above, in which this circuit is not implemented. Such apartments will not receive enough heat.

There are some ways to connect the collector to the common house system without harming the neighbors.

Use of a heat exchanger in a radiant system

The heat exchanger has no hydraulic resistance and is connected like a simple radiator through which the coolant passes without the participation of a circulation pump.

Option for connecting the collector to central heating via a heat exchanger

Heat flows passing through the collector circuit in which the heat exchanger is installed do not mix with the central heating coolant.

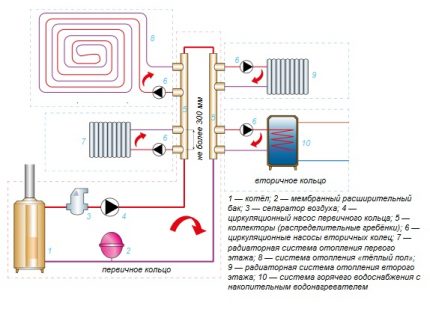

Connection with primary-secondary rings

With this connection, the central heating system of the house serves as the primary ring, and the collector-radiant heating system plays the role of the secondary ring.

The connection is made to the pipeline coming from the convector.

The algorithm for constructing such an insert is as follows:

- To directly supply coolant to the collector, the first cut is made at a distance of 30 cm from the radiator jumper.

- The return contour line is cut in at a distance of 60 cm from the jumper.

- Shut-off valves are mounted on the tie-ins.

- A three-way valve and pump are installed.

- A valve is mounted on the return pipe, through which coolant flows in only one direction.

Hot water passes through the collector through loops of the circuit, then part of it is supplied to the central heating return pipe, and part is returned to the collector through a three-way valve. This valve is responsible for the distribution of coolant.

With this scheme, the coolant is withdrawn evenly, without creating a vacuum in the central heating pipeline and without changing the heat balance of the apartments.

To insert into the common heating riser of a residential building, individual design and permission from the management company are required.

Pros and cons of the beam system

It is best to weigh all the pros and cons before installing a heating system and decide in advance which system will suit you best. Of course, the beam system has its own characteristics, which also need to be taken into account. Let's start with the negative points.

Disadvantages of the beam system

- This system has, perhaps, only one drawback - it is a larger number of elements in its design. In particular - pipes. It also uses more fittings;

- A large number of elements in a given system can increase repair costs. A conventional heating system has a lower estimated cost and is cheaper to repair.

A radiant heating system for a private home requires a more correct approach when connecting all heating devices, since violation of the connection rules is fraught with frequent breakdowns of the system as a whole.

Pros of the beam system

But all of the above loses its significance against the background of the general advantages of a radiant heating system. In a very short period of time, a properly designed and installed beam system:

- It will more than pay for itself. It also has a lot of useful and convenient features;

- When using a radiant heating system, you can have a differentiated approach to heating in each room. This approach allows you to more efficiently distribute heat in your home, which entails very large energy savings;

- This system is also convenient in that during its repair you can get unhindered access to pipe connections, which speeds up the identification of problems and their elimination;

- In a traditional heating system, hiding pipes is not very easy. The radial system allows pipes to be hidden from view either in the walls or under the floor. If this system is installed correctly, then no components or wiring will be noticeable;

- The correct radial distribution scheme allows you to effectively distribute heat throughout the entire area of your home.

Advantages of a collector heating system

Thanks to the independent connection (see diagram above), it is possible, if necessary, to turn off one radiator without turning off the others and, especially, the entire heating system. This is not necessary to repair a failed radiator, but it is possible that you simply do not need to heat any room for some time. Then your boiler will work more economically. Why turn off radiators, other than repairs? You never know. For example, where I live there is high groundwater, which is why cellars are not built. One of my neighbors made one room cold by wrapping a blanket around the radiators in that room to store vegetables and other supplies. With a radial connection scheme, it would be enough to screw the corresponding valve on the collector...

Another plus of the collector circuit is the ability to hide pipes in the floor, in walls, behind a suspended ceiling... so as not to “cling” to them with your eyes:

Another plus is the use of pipes in this connection of approximately the same length, the same diameter and the absence of intermediate connections. The same diameters ensure a uniform pressure drop. The same length gives the same coolant flow through each radiator. Well, the absence of unnecessary connections reduces installation time and the risk of leaks.

Components for the collector system

The set of elements of a radiant heating system is similar to that of a conventional tee system. For both of these systems, the main element is the heating boiler. In order for the radiant system to be effective, you need to carefully approach the issue of selecting the power of the heating boiler. When choosing a boiler, you need to take into account the area of the heated room, but it is also important to take into account heat loss.

The wiring of the radiant heating system also includes a pump that circulates the coolant. The radiant heating system does not work by gravity. Therefore, the vast majority of radiant heating systems have a circulation pump in their design. The pump must also be located in the correct location. Let's move on to the second very important element of the radiant heating system - the collector.

This element is nothing more than a distribution device. With the help of a collector, coolant is supplied to all segments of the heating system. The Collector includes numerous elements of shut-off equipment that allow you to differentially regulate the temperature of the living space, right down to individual radiators in the rooms. As a rule, the collector is mounted in a separate panel or in a cabinet, which fits perfectly into the interior and is not an eyesore. Now separately about circulation.

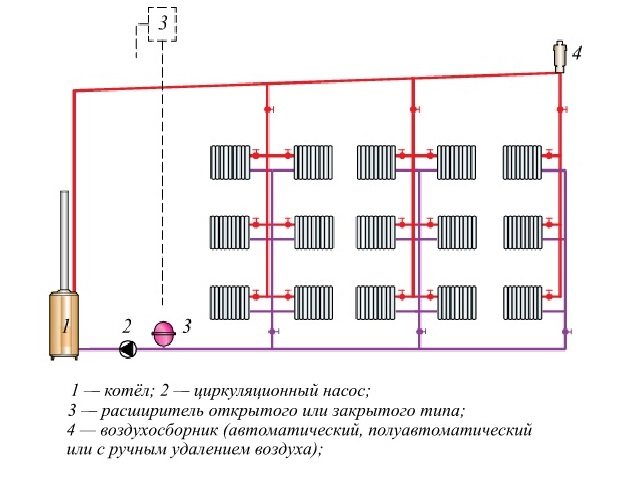

Two-pipe heating system with overhead wiring: get ready to hide the pipes

When designing small cottages on one floor, it is advisable to use a scheme in which the coolant is supplied from above to the radiators. From the boiler, the hot liquid rises up the supply riser and then falls through the pipes to the batteries. And the “return” is carried out below through all the radiators.

Top distribution of a two-pipe system with forced (closed type expander is installed at any point) or natural (open type expander installed from above) circulation.

The biggest disadvantage of overhead wiring is the unpresentable appearance of the supply line located under the ceiling and the cost of “masking” it. There are several ways to hide a pipe:

- under suspended ceilings or ceiling trim;

- in ceiling niches, plasterboard boxes;

- in the attic. With this option, the costs of pipe insulation increase significantly;

- vertical sections are usually hidden in artificial projections imitating columns.

If the circulation of liquid occurs due to gravity, the pipes in the attic will have to be insulated in any case: there should be an expansion tank at the highest point of the system. It is needed to compensate for the increase in the volume of hot coolant.

The disadvantages of such wiring will have to be taken into account both when performing calculations and during installation:

- limitation of the minimum pipe diameter due to the high resistance to natural circulation;

- most modern radiators are not suitable due to their small cross-section;

- The slopes of the pipes must be strictly maintained, otherwise the heating will not work correctly.

Heating circulation methods

The heating system can have several types of coolant circulation. These include:

- Forced circulation method;

- And natural.

With the natural type of circulation, the coolant is spontaneously distributed through convection throughout all elements of the heating system. To ensure the best circulation in a natural way, large diameter pipes are used in the heating system. The natural method of coolant circulation, due to its lower efficiency, has some limitations on the area of the heated room. Typically this method is used in small private homes.

The forced circulation method has long proven itself very well. Today on the market you can find a huge number of circulation pumps that are very compact and very efficient. These pumps have a fairly long service life. When installing a radiant system, it is important to correctly adjust the coolant circulation speed. The pump can be installed both on the supply and return side. Using a circulation pump, you can supply coolant to a fairly decent height. When selecting a pump, this parameter must also be taken into account.

Today, forced circulation, due to its undeniable advantages, is undoubtedly the most popular method of transferring coolant. The advantages also include the very affordable cost of circulation pumps.

Rules and diagrams for installing a radiant heating system

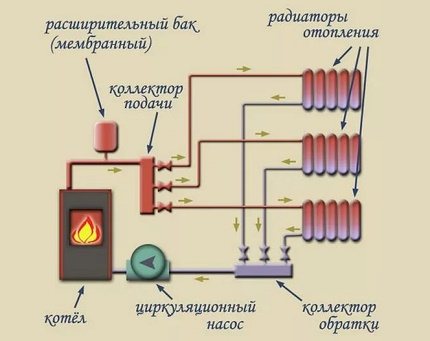

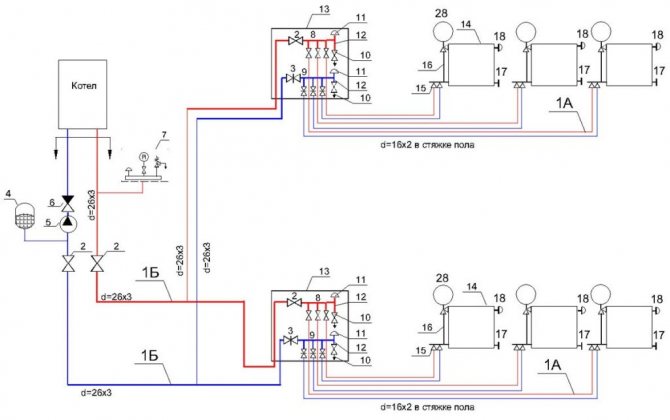

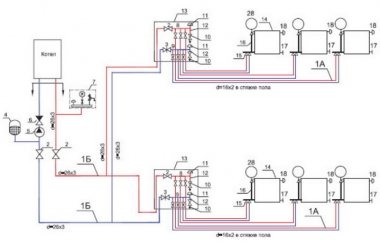

Look at the diagram:

From the boiler (K) the supply pipe goes to the collector (the pipe directed upward from the boiler - if you look at the diagram). A pump is installed on this pipe (in fact, it is better to place the pump on the return line in front of the boiler, but let’s leave this up to the conscience of the diagrammers for now).

From the collector, supply pipes go to the radiators (in the diagram they are in the form of “springs”). And from the radiators the pipes return to the return collector, from which there is a common return to the boiler. The pipes that connect radiators to collectors are the easiest to hide...

When designing a radial system, the following must be taken into account: the lengths of the pipes going to the radiator or vice versa must be within 20 m.

The following diagram also shows a radiant heating system:

Typically the manifold pipes are 3/4″, that is, this is the size for connecting to the boiler. And the radiators are connected to the manifold with 1/2” pipes.

We lay out the pipes on the subfloor (floor slabs, etc.), enclose the pipes themselves in thermal insulation and fill them with a cement screed 5...7 cm thick:

As a result, pieces of pipe will protrude from the screed with a length necessary and sufficient for connecting radiators.

Important! If the collector and radiators are on the same floor, then most likely the collector will be higher than the radiators. Therefore, air will accumulate in it. To prevent this from happening, automatic air vents are installed on the collectors - both supply and return.

However, Mayevsky taps are also provided on radiators to remove air.

Another option for installing a beam system:

Here the collector is on the first floor or in the basement, the radiators are on the next floor. In this case, the pipes from the collector are attached to the walls of the lower floor and lead through the ceilings to the radiator installation sites.

Another diagram of a radiant heating system - the collector operates on two floors:

With this scheme, you need to take care of the power of the circulation pump - so that it is able to pump the coolant to both floors. It is better to install a separate collector on each floor and install a separate pump for each, so that each pump can be controlled independently of the second.

Let's summarize. The radiant heating system does not spoil the appearance of the premises and is good in various technical parameters. So, so...

radiant heating system

The variety of building heating schemes that exist today makes it easy to choose the optimal heat supply option. However, not all of them can be quite effective in providing heat to houses with a complex configuration or multi-room layout. And in difficult projects, the modern radiant heating system has proven itself well, although not very popular yet, but gradually gaining recognition among specialists and property owners.

Unlike others, this scheme provides for individual heating of each of the installed heating devices, i.e. both supply and removal of coolant are carried out in parallel through pipes separately connected to the radiator. Externally, the configuration of this system resembles rays diverging in different directions from a heat source, which gave it its name.

Radiant heating can be organized with one or two pipes. The second option is most widely used, characterized by higher heat transfer rates and, consequently, greater efficiency.

Figure 1 – General diagram of a radiant heating system

Where to start installation?

Typically, all construction activities begin with thoughtful design. Typically, a drawing is created first. To design a radiant heating system, it is necessary to make a similar drawing with all elements and dimensions. If this drawing cannot be made by hand, then it can be ordered from a design organization.

The beginning of the design always begins with an assessment of the room in which the radiant heating system will be installed. It is advisable to do this in the early stages of construction, before finishing work has yet been carried out on the premises. It is better to immediately hide the elements of the heating system in the walls or under the screed. The drawing must detail all elements of the heating system and where they will be located. It is also advisable to provide more detailed information about the heating devices, since the system as a whole will be designed on the basis of this data. It is advisable to indicate the exact volume of heating devices and what materials they are made of. Using this information, you can accurately calculate how much coolant will be used in the heating system.

A very important point to pay attention to is additional heat loss. In a radiant heating system, the length of the pipes is slightly higher than in a conventional two-pipe system, and this factor is also important to take into account when designing and calculating a radiant heating system.

The drawing must also include a plan for laying communications for the heating system. It must also indicate all measuring instruments, as well as adjusting and locking elements. The drawing also indicates all additional elements that can be used in the installation of the heating system. Detailed information about this additional equipment and its installation is also described step by step.

Convective types of heating radiators

The second type of heat transfer to the surrounding space is convection.

The essence of convection is that a layer of air in contact with a heated surface is heated by this surface:

Scheme of indoor convection

As is known from physics, warm air has a lower density than cold air, so it begins to rise upward, along the way giving up its heat to colder layers of air and unheated surfaces (walls and ceilings). At the same time, the warm air cools, becomes more dense and again falls to the hot surfaces of the heating devices, from which it heats up again. And this circulation occurs continuously. The result of convection is the mixing of warm and cold air and an increase in room temperature.

The disadvantage of the convective method of heat transfer is that the temperature distribution in the room along the height is uneven: the air temperature is higher near the ceiling, and lower near the floor.

If a heating device emits most of its heat using the convective method, then such a device is called a convective type device (convector).

Convective type devices are plate and tubular convectors, most steel panel radiators, and finned tubes.

In fact, the division of heating devices by type is arbitrary, because most heating devices give off heat simultaneously both by radiation and convection.

What equipment and materials to use

There is no universal design for radiant heating, so the use of equipment and materials in such a scheme will depend on the choice of a specific heating circuit design option. This could be standard heating with radiators or, for example, a warm water floor.

In general, the following basic equipment is required for radiant heating:

- collector block (comb);

- external or wall-mounted manifold cabinet;

- circulation pump;

- pressure gauge;

- air valve;

- thermostat;

- shut-off and control valves;

- rotameters;

- mixing units;

- membrane expansion tank.

In terms of volume, the tank is selected to be 10% larger than the total volume of coolant in the system.

To install a radiant heating circuit, additional elements are also required.

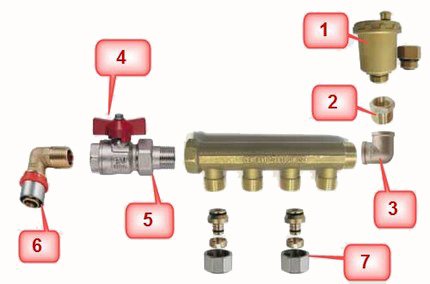

Additional parts for connecting the manifold

- Air vents.

- Adapters.

- Corners.

- Cranes.

- Sgony.

- Fitting.

- Fittings.

For the construction of heating beams, it is better to use cross-linked polyethylene pipes in coils.

Remember! Pipes must be flexible so as not to make unnecessary connections, tensile strength and have good heat resistance.

The diameters of the installed pipelines are selected taking into account the parameters of the equipment to which they are connected (outputs of the central main line, manifold comb). Most often, pipes with a diameter of 20 mm to 32 mm are used.

The manifold kit can be equipped with useful devices - servos.

Servo drive for heating manifold

These devices make the heating system “smart”, automatically maintaining the specified heating parameters through the control unit.

Comparison with other heating wiring diagrams

Heating systems have been improved over the decades and the wiring diagram is no longer at all similar to their predecessors. In modern homes, we have long moved away from classic wood-burning stoves - modern people need automation and do not need unnecessary worries with heating the house.

Single pipe system

In this type of wiring, one pipe is used, which goes sequentially to the heating radiators, from one to another and returns to the heating boiler. A circulation pump can be used to move the coolant through the heating pipes.

Two-pipe system

Unlike a single-pipe system, in a two-pipe system the heating radiators are connected in parallel. A pipe with hot coolant goes to each heating radiator and a pipe with cooled liquid goes out. A circulation pump can be used to move the coolant through the heating pipes.

Radial heating system diagram: features of application in a two-story house

The heating circuit with a distributor (this is radiant) is very convenient and effectively suitable for installation in a two-story house. The thing is that this heating system for a private two-story house involves an individual supply of coolant from the distributor to various heating devices .

One- and two-pipe heating systems

Thanks to the design features, as well as thoughtfulness, the rooms in the house (including those on the second floor) heat up much faster than when using a more affordable single-pipe heating system. And aesthetically, this heating scheme is very good, because the hot coolant supply and return lines can be hidden under the floor covering.

The main (but not the only) advantage of the radiant heating scheme is the absence of multiple connections on the pipes (this also helps to simplify installation work). Also, such a system assumes the most uniform distribution of heat throughout the entire line, without losses and other troubles.

Radiant heating systems with natural and forced circulation

As a rule, the Leningradka heating system in a two-story house is not preferable today, since it does not allow achieving maximum heating and saving rates.

It is being replaced by a double-circuit radiant system, which can be installed with both natural and forced circulation of the coolant along the main line. It should be noted that both of these methods have their own characteristics, which are important to consider before starting installation yourself.

Radiant heating system

- Natural circulation (gravity heating system) is not used as widely today as it was 10-15 years ago. The decline in popularity is due to the fact that the instructions for such systems imply the use of large-diameter pipes, which is not always possible.

A two-pipe heating system with natural circulation must also be equipped with an expansion tank, which acts as a compensator for the expansion of the coolant. Installation of such equipment is carried out at the highest point of the house and, at times, this is quite inconvenient.

But, be that as it may, it is the natural circulation in the two-pipe heating system of a two-story house that allows you to save money. Such a dual-circuit system does not require the installation of additional equipment, in particular, expensive pumps.

Natural circulation heating system

Advice: If the property is used, for example, as a summer house or it is some kind of long-term construction where there is no electricity, then natural circulation in the heating system will be the most appropriate solution. Even without automation and additional pumping of coolant, the house will always be quite warm and cozy.

- Forced circulation systems have become widespread today. Just 5-10 years ago, such a heating option was not approved by consumers due to its high cost. Today, when the price of automation and equipment has decreased, everyone can afford two-pipe heating systems with forced circulation.

The main advantage and feature of forced circulation is the artificial “pushing” of the coolant through the pipes. This process is carried out using special equipment - a pump - installed in the supply or return line.

It should be noted (and this can be seen in many photos and videos on the network) that two-pipe heating systems for two-story country houses with forced circulation are not at all demanding on the geometry of the house, the length of branches and the hydraulic resistance of pipelines. Automation also helps maintain optimal temperature in the premises of the house.

Forced circulation heating system

Automatic collector-beam system

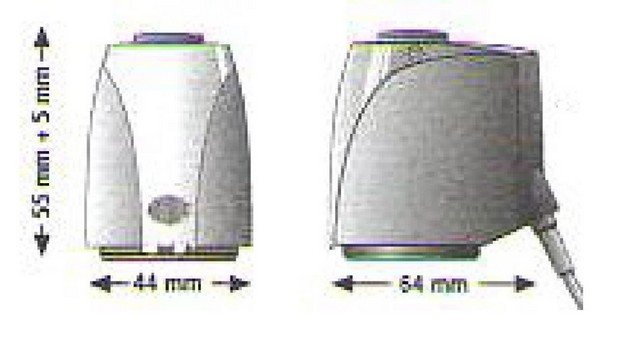

The supply of coolant to radiators connected via radial wiring can be made automatically adjustable. In this case, instead of a plastic manual control cover (position 4 in the figure “Complete manifold block”), a small-sized electromechanical servo drive is installed on the thermal valves of the return manifold (position 2 in the figure “Complete manifold block”), connected by a cable to an analog thermostat or controller. Radiators are connected to heating pipes without any fittings at all (ball valves can be installed).

Dimensions of the thermal valve servo drive.

Such a scheme has increased capital costs, while simultaneously providing an increased level of comfort. The user-desired air temperature can be set from the control panel of the room thermostat, the signals of which are processed by servo drives on the thermal valves of the return manifold. The system can be controlled by a so-called chronothermostat, which provides the user with the ability to set a temperature control program for a week, differentiated by day of the week and time of day.

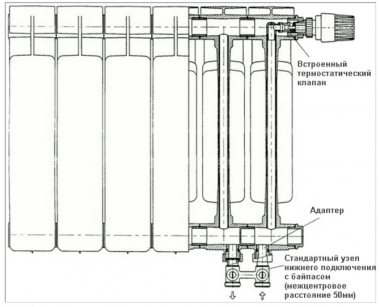

Decide on the type of radiators

A room in which radiators are connected from the bottom and the pipelines are hidden under the floor benefits from an aesthetic point of view. But at the same time you need to decide on the type of radiators and connecting unit. The option recommended by experts is complex radiators with a bottom connection and a built-in top thermal head. But these are expensive options.

It is possible to supply a “regular” radiator with different connection units.

There are connecting units with a lower thermal head, and options with an upper regulator. It can be used without a thermal head but with shut-off (balancing) valves. In a radial circuit, minimalism is acceptable and workable - only the connection point is on the radiator, and the balancing valves are on the collector.

Another option is conventional radiators connected diagonally (supply from above, return from below) with conventional taps and thermal head.

Radiation types of heating radiators

The first type of heat transfer is radiation (radiant). With this type of transfer, heat is transferred by thermal (infrared) rays (since any heated surface emits infrared rays). The property of infrared rays is such that when they pass through the air, they do not heat it, but they heat other objects (floor, walls, furniture, etc.). And these surrounding objects become sources of heat.

Radiation (radiant) radiation from a heating device

The radiation type of heat transfer ensures a uniform air temperature in the room, which creates a healthy and comfortable climate in the room.

Accordingly, radiators that transmit the bulk of their heat through infrared radiation are usually called radiation-type devices.

Radiation-type devices (from top to bottom): cast iron radiators, aluminum radiators, warm water floor, steel tubular radiators

Radiation types of heating radiators are sectional cast iron radiators, tubular radiators, and some models of panel radiators. Heating devices of this type also include wall panels and heated floors.

What kind of pipes and fittings are used?

Only solid pieces of pipes should be located under the floor. For laying, metal-plastic pipes supplied in coils, as well as polymer multilayer PEX and PERT with an oxygen barrier, can be used. But experts agree that metal-plastic with an aluminum layer is the most reliable option both in terms of strength and resistance to oxygen penetration.

To avoid large leftovers from the bays, it is advisable to calculate all the lengths of the lines in advance, then select the bays in the store. Purchasing bays of 50 meters, as a rule, entails extra costs.

Under the casing, it is possible to leave only crimp tees for metal-plastic, if necessary, which experts call “eternal.” Direct joining of pipes is not allowed.

Applicable diameters

As a rule, a system that includes up to 5 radiators is connected from the boiler (from the branch line) with a diameter of 20 mm for metal-plastic. If there are 5 or more radiators, then 26 mm will be required (32 for polypropylene), but the area heated from the collector should not exceed 120 - 150 sq. m.

If the area is more than 120 square meters, then most likely you will need larger connection diameters for the collector itself, but this is already being analyzed by specialists and calculations are being made.

Each radiator is connected from the collector using metal-plastic pipes with a diameter of 16 mm, as a rule. In some cases, with beam lengths greater than 40 meters, it is recommended to make them with a diameter of 20 mm in order to reduce the overall hydraulic resistance.

For example, here is a hydraulic connection diagram for a manifold system. 26 mm are used (from the boiler), 20 mm to the collector, 16 mm to the radiator.

Main stages of installation

A frequently used method of laying heating according to a radial scheme is bottom routing, with pipes installed in the floor screed. Therefore, it is better to carry out this work during new construction or reconstruction of a house and in the absence of a finished floor covering.

Main stages of work:

- preparation of the subfloor base;

- laying pipes and a layer of insulation (penoplex or polystyrene foam);

- fastening pipes to the base with mounting tape or plastic clamps;

- installation of an expansion tank;

- installation of circulation pumps;

- installation of automatic balancing valves for air removal;

- hydraulic tests of the installed system.

The work is completed with a pipe screed, which will serve as the basis for the finished floor.

Screeding device for heating pipes

When pouring concrete, pipes must be kept under pressure. Coolant at operating temperature is supplied only after the solution has completely hardened.

What do experts recommend?

When installing radiant heating, you must follow the advice of the experts:

- air vents must be installed both on the direct and return flow of the collector;

- The optimal location for installing the compensation tank is on the return pipeline, before the circulation pump.

- It is better to install circulation pumps on each circuit.

Installing pumps on the return line, where the coolant temperature is lower, will slightly increase their service life.

Circulation pumps in the heating system

Equipping a home with a radiant heating system, despite its apparent complexity and cost, in fact, if all technologies and recommendations are followed, will be a winning solution both in terms of energy efficiency and the comfort provided.