Often people are freezing from the cold in their homes and cannot determine the cause of such an unpleasant phenomenon, believing that an inefficient heating system is to blame. In fact, the problem is often not this, but the fact that heat quickly leaves the room - both through the walls and ceiling, and through such seemingly insignificant structural elements as doors and windows. Experts say that windows are the main source of cold air entering the house. Doors take second place after them. And in order to reduce heat loss, along with high-quality thermal insulation of walls, ceilings and floors, you should insulate doors and windows yourself. This is what we will discuss in our article today.

Traditional methods of insulation

If the budget is limited, then we often insulate wooden windows for the winter with improvised materials. A brief overview of budget insulation methods:

- If the windows do not close tightly, use self-adhesive rubber seals of suitable thickness. You can purchase them at any hardware store. There are times when the glue does not stick well. In this case, use a hairdryer or fan heater.

- Toilet paper is soaked in water, wrung out and stuffed into the cracks. Painting tape is placed on top.

- Using cotton wool, foam rubber or tow, the joints between the frames and sashes are clogged, after which they are sealed with tape.

- A relatively cheap but reliable material is self-adhesive foam rubber, or polyethylene foam. It simultaneously has the properties of insulation and adhesive tape. Sold in rolls, like tape.

- The cracks are covered with plasticine or regular window putty. But the method has a big disadvantage - it is difficult to remove them from the window in the spring. This method is used only in extreme cases.

Correct application of sealant

The main advantages of silicone sealants are their resistance to temperature changes, a high level of adhesion to wood, glass and painted surfaces, and excellent thermal insulation when insulating plastic windows.

Procedure for working with sealant

When sealing window units, you need to know how to apply it correctly.

First, we clean the surface of the window glass from dirt and rust, degrease it, and sand it.

Then you can apply a layer to the surface in the form of a continuous line.

If it drips in a place where it shouldn’t be, you can wipe it off with a damp cloth or rag.

You can start forming the seam within

5 minutes after applying it.

It is better to do this with gloves; you cannot go naked, since the sealant contains acid, as mentioned above. You can also make a seam using a spatula. Remaining liquid can be wiped off with plain paper. But if the composition has already begun to harden, then it can now be removed only with the help of a solvent or mechanically.

You also need to know that it completely hardens after 20 minutes, after which it is not recommended to straighten the seam or redo it.

We would like to give you some more useful recommendations when insulating windows with silicone:

- the most suitable seam width will be 5-30 mm ;

- the depth of the applied seam must be twice as thick as its width;

- If you need to make a very deep seam, use sealing tape that sticks.

- Be careful not to use silicone on synthetic surfaces, copper, lead or brass.

Using heat-saving film

One way to insulate wooden windows for the winter is to use heat-saving film. If condensation and ice appear on the inside of the window glass in winter, this is a sign of low thermal insulation properties. The problem is typical even for modern double-glazed windows. The film is installed on the inside of the frame, parallel to the glass.

It simultaneously performs two actions: it prevents heat loss in the form of infrared radiation and creates a thermal insulating layer of air between the film and the glass. It makes it possible to avoid the effect of “crying windows”.

Installation of thermal film is simple and quick. First of all, the frame is cleaned and degreased, and double-sided tape is glued around the glass. Conventional film is sold folded in two layers (the layers are separated before use).

The film is glued to the tape so that it covers the entire glass. They pull it on, not paying attention to the wrinkles that form. In this case, you should ensure that the edges of the film are securely seated and that no bubbles form. After this, hot air from a hair dryer is blown onto the film. Under its influence, it stretches and smoothes out.

How to seal windows with sealant. How to seal cracks in windows yourself for the winter (video)

A significant part of the heat from the room escapes through the windows. To maintain warmth and comfort in the house, you can install new window structures, but this is not always affordable. Therefore, owners of houses and apartments are thinking about how to seal their windows for the winter. To do this, you can use available tools,

Using a sealant

which are traditionally used for insulation and require removal when warming occurs, or with modern means that provide reliable sealing and can last for more than one year.

A cleaned window will prevent heat from escaping

Heat leaves the home not only from the cracks between the frames and glass, but also in the form of infrared radiation. Clear glass has a low level of transparency to infrared rays that transmit heat. A dirty window, becoming not too transparent, increases the spectrum of infrared radiation. Therefore, before the winter cold sets in and the time comes to choose a good insulation product, you need to wash the glass.

It is necessary to wash the window both inside and outside, using products containing ethyl or ammonia. These products will help you avoid unsightly stains and perfectly clean the glass from grease stains. In addition to the glass, you should also wash the frames on which various window sealing products will be glued.

Using improvised means for insulation

Windows can be sealed using old proven methods using means that are always at hand:

- old newspapers or paper. The newspaper is moistened with water, and the resulting mass is placed in the cracks. The whole thing is sealed on top with cut strips of paper, which are moistened and smeared with soap. The disadvantages of this simple method of sealing windows are the need for removal in the spring, paper sticking, removal of pieces of paper along with window paint, which will require painting the window frame;

- cotton wool and strips of fabric. Instead of soaked paper, it is better to insert cotton wool or pieces of foam rubber into the cracks. This method is especially good when the gaps are very large. It is better to stick strips of white fabric on top, which are soaked in a soap solution or, once wet, rubbed with soap. Fabric strips come off frames more easily without stripping the paint;

- paraffin. It is better to use this product for insulation in the presence of small gaps. First, the paraffin is melted, the resulting mass is drawn into a syringe and poured into the crevices. For larger cracks, you can insert a rope into them, and then pour melted paraffin on top;

- foam rubber and paper tape. For large gaps, foam rubber must be glued along the entire perimeter of the window sash, which will help close the sash tightly. You can also insert foam rubber into the gaps between the sashes, and stick paper tape on top, which is very easy to remove from the window frame in the spring.

Insulating windows with paper and soap

This method is one of the oldest and is used quite rarely. Newspaper paper is torn into pieces, moistened in water and all the cracks between the frames are sealed with the resulting mass. Before you insulate wooden windows for the winter with your own hands, you should prepare the necessary tools: a knife, a flat-head screwdriver or a metal ruler. When all the cracks are sealed, strips of paper and adhesive tape are glued over them. You can also use fabric. The strips of paper must first be lubricated with moistened soap, which will allow them to be securely attached to the surface. The method is relatively cheap, but has one serious drawback - removing the paper without damaging the window frames is problematic. Often windows have to be repainted.

How to insulate Soviet windows. How to insulate wooden windows?

If you are in no hurry to replace still-good wooden windows with newfangled plastic ones, then perhaps you are right - repairing and insulating wooden windows will cost less if you do the work yourself!

Let's justify the decision

The “untwisted” unique thermal insulation of PVC windows is inferior in terms of similar thermal characteristics to conventional double-leaf frames.

Let me clarify! This speech does not include “Soviet” windows of high-rise buildings with centimeter gaps. We're talking about carefully crafted double-leaf frames.

The higher thermal insulation qualities of double wooden frames are due to:

- a large volume of air enclosed in the “space between the frames”;

- “decoupling” the frames from each other through the same air gap.

Double wooden frame

In addition, the following factors may influence the choice of insulation:

- replacing windows in a rented apartment may not be economically viable;

- wooden windows are better for you and you like them more;

- you don’t want to “inhabit” plastic in your apartment;

- insufficient financial resources.

The conclusion suggests itself - we won’t change it, it’s better to just do the insulation of wooden windows with our own hands.

How can we not do it?

We suggest considering several “barbaric” methods:

- Use tape to seal. Consequences: the adhesive from the tape remains perfectly on the frames. Therefore, it is better to use construction tape. Disadvantage - it can peel off due to drafts.

The functional disadvantage of such methods is that the frames will not open.

- Use window putty. Consequences: unsightly appearance, destruction of putty in the heat.

- Tamp the cracks with rags or, better yet, foam rubber. Cover the top with tape or paper strips for additional thermal insulation and DIY decor.

Insulation “on the go”

These methods are an extreme case when it is not possible to properly do winter insulation with your own hands, there is no time, money, or your hands are not growing properly.

Optimal insulation

Let's use other low-budget modern solutions to insulate wooden windows. The necessary materials are always freely available at an affordable price. We will need:

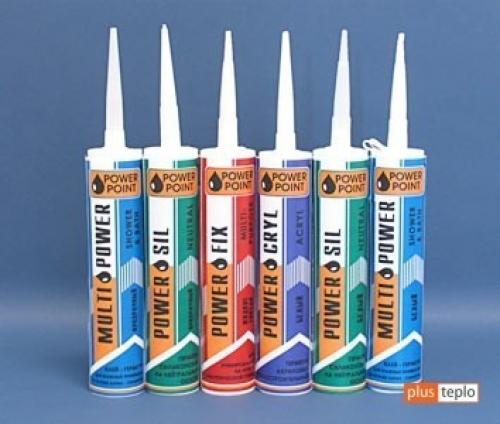

- Silicone sealant. We choose a transparent frost-resistant (for the winter) option for interior work.

Silicone sealant

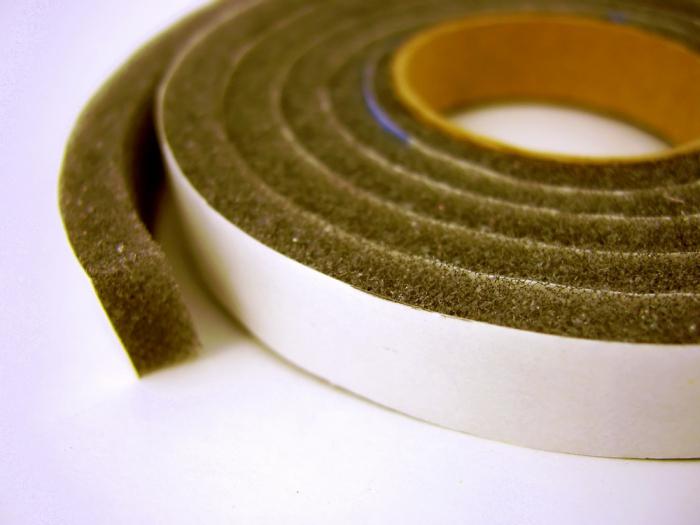

- Rubber seal for windows and doors with a sticky self-adhesive base. To correctly determine the required footage, we measure the perimeters of all frame sashes. Add 0.5 m to the total length (just in case). We divide the resulting value by two, since this seal is sold in a double version.

Double self-adhesive seal

We insulate glass seats

The draft finds its way not only between the sashes of old frames, but also through the junction of the glass and the frames. Therefore, window restoration for the winter begins with sizing the glass. This can only be done efficiently by removing the glass.

The technology is like this:

- carefully remove the glazing bead;

We remove the glazing bead...

- take out the glass;

- clean the seat in the frame and wipe the edge of the glass;

- properly coat the sealant in the corner of the “quarter” of the frame;

- nail the bead into place.

- remove excess sealant.

If you don’t want to do so many things with your own hands, we make it simpler, but at the expense of quality.

We simply apply sealant to the junction of the glass and the frame in the form of a thin strip, and then rub it into the seam with a spatula or finger. If the insulation is done correctly, the draft on the glass should stop.

Sealing glass with sealant

Using the first or second method, we glue all the glass on the internal and external old frames.

We insulate frame sashes

The sashes, or more precisely the places where they adjoin the frames, are the widest paths for drafts. Therefore, we will block them using a rubber window seal.

Restoration is done correctly like this:

- With our own hands we clean the gluing areas from dust and old layers of paint. It is also advisable to degrease the base surfaces with alcohol or solvent before gluing the seal;

- we study the degree of fit of the sash to the frame in order to determine whether the seal will fit between it and the frame when the window is closed;

Both the internal and external parts of the window are insulated

- If the gap is sufficient, we glue the seal with our own hands along the entire perimeter of each sash. For small gaps, it may be necessary to cut a groove into which the seal will fit.

- The edges of the seal can be additionally secured with small nails.

Predicted result

The result of the above actions will be high-quality insulation of windows for the winter, which, without losing their functionality, will be able to open safely. There are other ways to insulate wooden windows, for example, “advanced” Swedish technology.

Insulation scheme using Swedish technology

But the above-mentioned restoration and “packing” of windows for the winter perfectly combines efficiency, ease of implementation and low cost. And the Swedish technology, although simple, requires additional equipment and a larger amount of work.

Insulating windows with foam rubber

This type of insulation is similar to the first. The only difference is in the material used, that is, instead of paper they use foam rubber. It is necessary to familiarize yourself with the installation technology before insulating wooden windows for the winter. Expert advice is not at all necessary, since the technique is quite simple, and any errors can be easily eliminated.

Strips of foam rubber are sold at any hardware store. Compared to paper, their dismantling is simple. You can also stick strips of paper, pre-lubricated with soap, on top of them.

Insulation with polyurethane foam

The best advice on how to insulate windows for the winter will certainly be given by specialists. Using polyurethane foam is one of the most effective methods. In recent years, it has become widely used both in construction work and in everyday life. All cracks, chips and other defects are covered with polyurethane foam. After the cavity is filled with foam, it is allowed to dry. The excess is cut off with a regular knife.

When foam is used outside, all areas must be plastered. This must be done because the foam crumbles in the sun and turns into dust. In general, the material is reliable and durable.

How to insulate windows for the winter: instructions and step-by-step technology

The silicone-based method requires more effort than conventional crack sealing, but it is the most effective. This is due to the fact that the method allows not only to minimize heat losses, but also to improve the overall sound insulation of windows.

The technology is as follows: the places where the glass is attached are insulated with silicone. First of all, the frames are removed from the hinges and placed on the floor, after which the glazing beads are dismantled. You will need a flathead screwdriver for this, but a knife will also work. It is important to be extremely careful as the beads may break. It is advisable to purchase spare ones in advance. After dismantling them, the glass is removed. All work should be carried out with gloves, as there is a high probability of cutting yourself.

The place where the glass was previously located is cleaned of all kinds of contaminants and filled with sealant. At the next stage, the glass is put back, after which they pass the sealant a second time and hammer the glazing beads back. Upon completion of the work, the frame is hung back. In parallel with insulation, it is recommended to repair the frame: remove old paint, fill cracks, install high-quality locks. In the question of how to insulate wooden windows for the winter, every little detail plays an important role.

Tip: It is best to use a clear sealant as it will not be noticeable if it gets on the glass.

Do-it-yourself insulation of plastic windows

Considering the fact that plastic windows are becoming more and more widespread these days, we will start by looking for the answer to the question of how to insulate plastic windows for the winter with our own hands.

Thermal insulation of slopes

The insulation process should begin with the slopes. Along the contour of the frame, they need to be treated with a special deep penetration primer, after removing the paint, in order to increase the resistance of the material used during the construction of the walls. When insulating windows in a wooden house, the slopes are treated with drying oil.

When the primer is completely dry, install PVC overhead slopes.

Although they are quite inexpensive, they significantly increase the thermal resistance of the entire structure as a whole. The cavity formed inside the slope is filled with any insulation: flax tow, polyurethane foam, polyurethane foam, etc. Advice! To fill a cavity in a PVC slope, you cannot use mineral wool, as it will quickly gain moisture and lose its thermal insulation properties.

Increasing the heat-saving performance of glass

Glass is an amazing material that perfectly reflects infrared rays. However, even with the thinnest layer of dust and dirt, this property is reduced. That is, the cleaner the glass, the more sunlight will penetrate into the room through it, and the warmer it will be. Hence the advice: before the onset of cold weather, wash the glass until it squeaks and wipe it thoroughly with paper, and, if possible, seal it, thereby preventing dust from getting on it.

To increase the heat-saving performance of glass, the inside of the room can be covered with self-adhesive, naturally transparent. Even the cheapest self-adhesive perfectly reflects infrared radiation and adheres well to glass; it will definitely last until spring.

Do-it-yourself window sill insulation

The cause of additional heat loss in the room may be an incorrectly installed or damaged window sill. Often a so-called “cold bridge” appears under it, through which flows of cold air freely penetrate into the room.

To reduce heat loss, carefully inspect the window sill, especially from below. If you find even the slightest crack, blow it out with foam. A homemade rag roller attached to the bottom along the entire length of the structure also gives a good result.

Eliminating cracks

When exposed to different temperatures, wooden frames often crack. Before insulating wooden windows for the winter, all these cracks should be sealed.

The following materials are used for this:

- melted paraffin;

- sealant;

- putty for wood;

- a mixture of sand and flour in a ratio of one to three.

There are other methods, but they are less common. If you use any of them, the windows will have to be repainted.

Insulation of windows along the perimeter of the frames

In general, window insulation is the sealing of cracks where the window sashes adjoin the window frame. Sealing of joints can be achieved using rubber tubes with an adhesive base, foam rubber tubes, polyurethane foam and other materials.

One of the most effective ways to place a seal is to glue it to the transom of the window along its entire perimeter. When the window closes, the seal will bend and block the cold air flow from the street. It is important to ensure that the frame bends the seal and does not slide over it.

If the frame is wide enough, then the seal is glued in several rows. To securely fasten it, it is nailed along the edges with small nails. This will prevent the material from peeling off. It is important to carefully inspect the frame before insulating the windows for the winter. Insulating wooden windows using weather stripping can result in them not closing. Therefore, sometimes the frame needs to be trimmed so that the seal does not push the sash forward, as a result of which the window does not rest against the adjacent sash.

This method is most effective when used in conjunction with placing windows on silicone sealant. One of the main advantages of the method is that once winter passes, it is not necessary to dismantle the entire seal, so it can be used for several years.

Types of window sealants

There are many window sealants, among which we highlight:

- acrylic;

- silicone;

- vapor permeable;

- polyurethane;

- thiokol.

Acrylic is used to fill gaps between surfaces made of stone, concrete, brick, wood and other materials. And due to the fact that the composition does not contain solvents or other toxic substances, it can be used both outdoors and indoors. But most often it is used to seal assembly seams, due to its resistance to ultraviolet radiation.

Also, this type is very practical and is not at all afraid of vibrations, frost, and other atmospheric phenomena. The seam of the acrylic seal can be painted or plastered without any problems, thanks to its smooth surface. When interacting with metal, it does not cause rust.

Polyurethane sealant is also widely known. It is perfect for filling joints and gluing surfaces. In a frozen state, it has excellent sound and heat insulation properties, penetrating deeply into cracks, and has good adhesion strength to many surfaces, such as glass, wood, plastic, concrete. It should be taken into account that this type of sealant contains harmful substances, so you need to be careful and use it only outdoors.