Fiberglass pipes are long hollow elements made of fiberglass with a constant cross-section, designed to move any working medium through them or to protect cables placed inside for various purposes. Production on an industrial scale has been established since the mid-1950s, but truly widespread distribution begins two to three decades later.

Fiberglass pipes are universal products that have found application in many areas of construction and industry.

Story

The mid to late 1980s of the 20th century saw an increase in the production and use of large diameter underground composite pipes. Technological advances in the filament winding process, corrosion resistance, and strong market factors have contributed to the popularity of fiberglass pipe. Definitions of what constitutes a large diameter pipe can vary, but in general sizes range from 12 to 14 inches.

Composite or fiberglass pipe is used in a wide range of industries such as power generation, petrochemicals and seawater desalination. Fiberglass pipe resists corrosion, has a long life cycle, often exceeding 30 years, and is a better alternative to steel and other metal alloys, ductile iron and concrete. According to statistics, more than 60,000 km of large-diameter pipes are in operation worldwide.

Pipes based on various resins

Depending on what resins are used to produce pipes, their performance characteristics change significantly.

Therefore, when choosing materials of this class, be sure to check what type of fiberglass is offered to you:

Fiberglass on PEF

- Fiberglass on PEF (polyester resins) is chemically neutral, it is resistant to various substances, and is indispensable when laying pipelines for the oil refining industry. But it is worth saying that these pipes are not designed to operate at high temperatures (maximum 95 degrees) and pressure (up to 32 atmospheres).

- Epoxy binder used in the production of fiberglass pipes gives them increased strength. Such large-diameter fiberglass pipes are capable of operating at ultra-high pressures (up to 240 atmospheres), and the temperature limit reaches 130 degrees. Another feature of the material is minimal thermal conductivity, due to which there is no need for additional thermal insulation (the pipe practically does not give off heat). Products of this class are significantly more expensive than PEF-based pipes.

Scope of application of fiberglass pipes

Fiberglass pipes are widely used in various industries and households.

They have proven themselves to be excellent in the following areas:

Fiberglass pipe

- The oil industry, where fiberglass pipes are used to organize not only the transportation of minerals (main lines), but also to support all technological processes, starting with oil or gas production.

- Chemical and medical industry. Chemical neutrality and resistance to any aggressive influences make the material indispensable for transporting acids, alkalis, and other liquids and mixtures.

- In the housing and communal services system, fiberglass pipes are used for laying cold and hot water supply lines and installing heating systems.

- Energy - in this industry, the material is widely used in the construction of pipelines operating under high loads.

The share of use for domestic purposes is gradually increasing; the possibility of using this material should be considered, because the repair-free (failure-free) service life of such pipes exceeds 50 years.

Production of fiberglass pipes

At the present stage, we practice the production of fiberglass pipes using two main technologies - centrifugal molding and continuous winding.

Depending on the number of structural layers of material, performance characteristics may differ significantly:

Characteristics of fiberglass pipes

- The most inexpensive are simple single-layer pipes. The structural layer of fiberglass is not protected by additional coatings.

- Double-layer pipes have an outer protective shell, which significantly increases the resistance of the product to ultraviolet radiation and various aggressive environments.

- Three-layer fiberglass pipes have an additional strength layer located between the main structural material and the protective shell. Such products are characterized by increased strength and can be used at high internal and external pressures. But it is worth considering that the cost of such pipes is quite high.

Thermal expansion and contraction

A fiberglass pipe has different thermal expansion in the diagonal and axial directions. In the circumferential direction the thermal expansion is approximately the same as that of steel. However, in the axial direction the thermal expansion is approximately twice that of steel.

The relatively low modulus of elasticity of fiberglass pipe is an advantage that should be considered when designing a piping system. Since the thermal forces are smaller, the restrictive equipment (guides, anchors) does not have to be as strong and heavy as for steel pipelines. There is some increase due to the finite pressure load on the piping system, but experience has shown that this change in length does not need to be taken into account when designing a fiberglass piping system. Composite piping systems can handle thermal shock between maximum rated operating temperatures if the pipe connections are not mechanical.

Types and features of composite pipes

Pipes made of composite materials are made using special fiber impregnated with a specific resin. Accordingly, several types of products are distinguished depending on the substances from which they are produced:

- Fiberglass is the most accessible and inexpensive material, the mechanical characteristics of which depend on the degree of reinforcement, i.e. The fibers are laid either along the axis or around it. Pipes can be used in various fields depending on the wall thickness and the set of resins included in the raw material;

- Carbon fiber - this expensive material is not available to a wide range of consumers, but due to its high strength and elasticity it is used in the space sector;

- Basalt fiber - when combined with plastic and adding epoxy resins, it is possible to obtain an elastic, durable and water-resistant pipe.

For the production of composite pipes, not only epoxy, but also polyester and phenolic resins are used. The choice of material and technique directly depends on the industry in which and under what conditions the pipeline will be used. When purchasing, you should take this point into account by studying the documentation for the pipes.

Characteristics

Fiberglass pipes have the following advantages:

- long service life due to excellent resistance to corrosion and chemical attack (salt water, CO2, H2S, solvents, thermal and oil water);

- ease of handling and light weight (approximately ¼ the weight of steel);

- require less personnel and equipment for installation;

- quick installation thanks to fittings and reduced installation costs;

- Improved flow characteristics due to smooth internal lining and reduced material resistance.

Areas of application and marking of fiberglass pipes

The advantages of fiberglass products have led to their distribution in various fields of activity. Massive application has been found in:

- oil industry. The ability to maintain high corrosion resistance under the influence of aggressive environments (oil, solutions, formation waters) and high specific strength make it possible to give preference to fiberglass products over steel and polymer ones;

- coal industry. Low weight and ease of installation, low flammability and combustibility, non-toxicity of combustion products, resistance to corrosion, and the absence of damaging fragments in a methane explosion play a role here;

- energy. Resistance to high pressure makes fiberglass essential for pipelines;

- housing and communal services. Fiberglass products are used to equip sewerage, land reclamation and utility systems.

Fiberglass pipes are suitable for installation of household water supply and sewerage systems

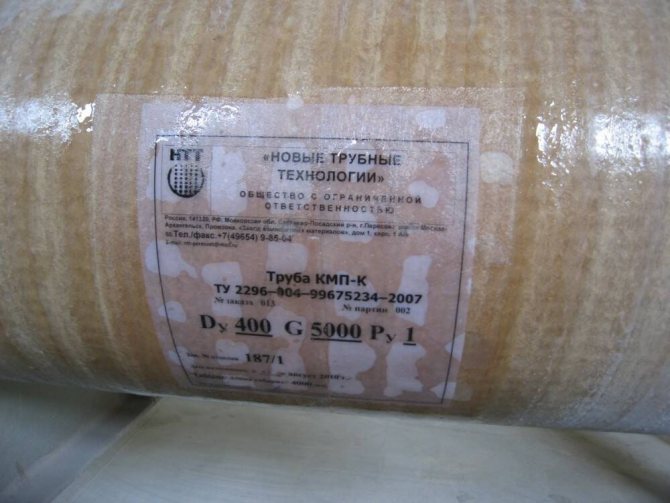

Fiberglass products are marked as follows:

- A – are intended for pumping working media with various abrasive inclusions;

- G – for hot water supply systems with energy carrier temperatures up to 75º C;

- P – for the water supply network, including that supplying drinking water;

- C – universal purpose. The working environment may have different acidity;

- X – capable of transporting chemically active liquids and gases.

Fiberglass pipes: technical characteristics

The main reason for the increasing use and popularity of fiberglass is the key benefits such as high strength-to-weight ratio, dimensional stability, good mechanical properties, ease of installation, reduced installation and maintenance costs, and overall durability under extreme conditions. Another benefit of fiberglass pipe is that it has a smoother interior surface than traditional building materials. The smooth internal bore resists large deposits and can produce high service fluid flow throughout the life of the project.

Many considerations must be taken into account when designing a large diameter underground pipe: local soil conditions, groundwater depth, burial and living loads, deflection due to error and operating temperatures, fluid velocity and pressure, head loss due to turbulent flow, hydraulic hammer, pressure on bending and pulsation pressure. Designing a proper underground piping system is a complex process that involves extensive calculations - product design should always be carried out by qualified engineers.

Characteristics of pipes made of composite materials

Composite fiberglass pipes are in demand on the market for one reason - they have good characteristics and can be used even with constant exposure to negative environmental factors. Among the physical properties of such products are:

- High strength - the pipe will compete with a classic steel structure, while its weight is several times less;

- Resistance to high temperatures - up to 140 degrees, while the product has minimal thermal conductivity. When transporting hot water in winter, losses will be insignificant;

- The pipe can be used in the presence of vibration and shock loads - under highways, railways, since mechanical damage is excluded;

- Corrosion resistance – traditionally, the service life of pipes made of composite materials is about 50 years;

- Smooth inner surface, which affects hydraulic resistance;

- Installation can be carried out in any weather conditions, even in frost; it takes a minimum amount of time to assemble one joint;

- Although the price of the products cannot be called low, taking into account the mechanical characteristics and long service life, the savings are obvious.

Composite materials are not subject to corrosion, and no plaque forms on the inner surface, so you don’t have to worry about clogging the pipeline. Products can be installed regardless of the type of soil and physical activity.

Composite fiberglass pipe

FRP pipe manufacture uses a variety of epoxy and vinyl ester resins and, where necessary, corrosion barriers to achieve optimal performance for any application. A wide range of temperatures and pressures allows you to best match the fiberglass pipe to the requirements of a specific application.

High-pressure fiberglass pipes are time-tested as they have been used in harsh environments for decades and have proven their durability and value. The first samples appeared more than 40 years ago.

Advantages of fiberglass composite piping systems:

- increased resistance to corrosion/abrasion when exposed to strong acids;

- high strength;

- pipe spans are similar to steel counterparts;

- high quality polyvinyl chloride for higher temperatures and longer piping distances;

- optimal replacement for steel pipes with external or corrosive internal coating.

Fiberglass pipe diameters range from 1 to 72 inches.

Characteristics of fiberglass pipes and scope

Fiberglass pipes are still slowly being introduced into our communication networks, and the main reason for the slowdown is the high price of a fiberglass pipe. But the record anti-corrosion resistance and virtually impenetrable qualities of fiberglass pipes as conductors of water and sewerage cannot but attract private builders. In the long term, fiberglass (other names are glass-polymer, as well as fiberglass-reinforced) pipelines will provide lasting savings due to the elimination of items for repairs and replacement of rusty metal and worn-out components from the estimate. In practice, domestic data is still scarce, but the fact of high strength and stability of fiberglass pipes has long been recognized - in Europe these pipes have been in use for more than half a century, and in the USA, fiberglass composite pipes have been known since 1944.

Fiberglass is a composite material with a relatively low density, but at the same time uniquely strong. The composite contains quartz sand, reinforcing glass fiber and binding additives: epoxy and polyester resins. Pipes from different manufacturers differ in the type of binder additive, as well as in the nuances of production technology aimed at enhancing the desired qualities based on the future operating conditions of the fiberglass pipeline. Of the two main widely known additives - epoxy and polyester resins (phenolic ones are also used, but to a limited extent), polyester ones are used more often, and as a result the pipe becomes completely invulnerable to the aggression of acid and alkali, and corrosion in a saline environment becomes absolutely impossible. Coating the pipe with epoxy resins is a marking on GRE pipes; the presence of polyester binders can be seen by the GRP marking. It must be said that the technical qualities of pipes made with epoxy resins are radically different from those for pipes made with polyester resins.

The standard pipe production scheme is winding roving on a solid base, continuous mode. In this case, it is possible to use various fibers - basalt, glass or even expensive carbon (for the space industry and aircraft construction). The widespread use of fiberglass is associated precisely with its low cost and availability, although basalt fiber provides many times more strength and elasticity (as well as water and heat resistance) of the final product compared to glass roving. The method of reinforcement is also important - laying the fiber along the axis or around the central axis. Standards for fiberglass pipes and installation manuals are developed regionally, in Russia this is GOST R53201-2008. The threads are reinforced with a special compound and impregnated with a mixture of resins with crushed glass fiber and quartz sand.

Two modern pipe production technologies: centrifugal molding and continuous spiral winding (for 3-layer pipes), allow the production of multi-layer pipes. The bonding of the layers to each other is based on polymerization at high temperatures, which also gives the pipe additional resistance to various influences. Two or three additional layers add strength and stability to the pipes in harsh environments. A single-layer pipe has one layer of fiberglass with a structural binder; the two-layer pipe is reinforced with an internal protective layer for working in conditions of UV radiation or an external one for working in aggressive environments. A three-layer pipe includes a strength layer between the structural and protective layers. Pipes with internal coating are distinguished by markings, which indicate the scope of application of the pipe: for drinking water supply, systems with chemically active contents and abrasives, for hot water supply and others.

The operation of fiberglass pipes has shown more than just advantages, for example, with massive forces across the fibers, the crack resistance of large diameter pipes is sharply reduced. When laying an oil pipeline, this is critical and is therefore optimized by complex technical additions to the pipe design (corrugated sealing layers inside). But in the context of laying networks and installing heating equipment on a private plot, the strength limits of conventional single- and double-layer pipes are super-optimal, as well as their corrosion and chemical resistance, so the only “minus” can be considered the price of the pipes.

The main advantages of pipes made of fiberglass composites:

Microbiologically induced corrosion

This vulnerability is a common problem in industrial processes due to the presence of microbes. This eventually leads to the formation of gaps, with pockets of oxygen and ion concentrations, allowing corrosion to progress. If not treated with a fiberglass repair kit, piping systems will be significantly weakened, often creating holes in the pipe walls, leading to leaks and loss of fluid. Treatment can be accomplished by protecting the pipelines with cathodic protection or chemically treating the fluid, which itself may be susceptible to corrosion. Either of these methods requires additional costs, which may only delay failure.

Application area

A popular manufacturer of fiberglass pipes, Amiantit, produced a trial batch of pipes in the late sixties of the last century. Over the decades, the manufacturer has managed to reach the global level and now fiberglass reinforced plastic (GRP) pipes deserve attention due to their quality and reliability. This is due to the fact that the pipes are made using a special method - continuous spiral winding. As a result, they are not subject to corrosion and become very resistant to acids and environments. In addition, unlike standard metal pipes, fiberglass pipes are easy to handle - the weight of the products is many times less than heavy metal ones. Therefore, if there are any doubts about whether to buy fiberglass or traditional metal pipes, most companies choose durable and practical materials for laying fiberglass pipes.

In just forty to fifty years, the leading company of the same name for the production of fiberglass pipes managed to take not only a leading position, but also become a step higher.

The scope of application of fiberglass pipes is quite wide; they can be used for laying sewerage and drainage systems, as well as for fire fighting, transporting drinking and industrial water. Pipes can be laid at power plants and for the removal of any type of waste.

In addition, fiberglass pipes are widely used for laying almost any type of communications:

- trunk lines;

- sewer networks for any purpose;

- water supply;

- laying gas and oil pipelines.

Popular Amiantit factories take into account the interests of each consumer when producing their products - you can purchase fiberglass pipes of different diameters, lengths and designs, as well as additional components and fittings. In addition, the production process is adjusted in such a way as to satisfy the requirements of any buyer and produce customized pipes.

The diameter of a standard fiberglass pipe ranges from one hundred to three thousand seven hundred millimeters, and the length can reach eighteen meters. The use of such pipes is permitted in six pressure classes and three strength classes. Thanks to these indicators, we can confidently say that fiberglass pipes are not only efficient. The high durability of the products is also noted.

Fittings and accessories

Fiberglass pipe accessories are made from epoxy and vinyl ester resins. These adhesives provide the best corrosion resistance and temperature performance.

Fittings include flanges, couplings, tees, reducers, drain pipes, repair kits, fiberglass repair kit and more. Fiberglass pipes are designed for heavy duty applications and are suitable for a wide range of chemicals as specified in the Fiberglass Chemical Resistance Guide.

All fittings come with a pipe or flange connection for easy field installation. Prices for fiberglass pipes include all accessories necessary for installation and range from 4,350 to 47,900 rubles per linear meter, depending on the diameter.

Advantages and disadvantages of fiberglass pipes

The spread of fiberglass products is associated with the following advantages:

- duration of operation;

- light weight, which simplifies transportation and installation;

- low coefficient of thermal expansion;

- ease of installation;

- non-corrosion and inertness to aggressive environments;

- wear resistance;

- strength;

- resistance to temperature fluctuations in the range from - 65º C to +155º C;

- relatively low cost;

- environmental friendliness.

Note! One disadvantage of fiberglass products is their low stability under significant loads across the fibers, which leads to the formation of cracks. Therefore, to enhance the tightness from the inside, a special corrugated layer is applied.

The advantages greatly outweigh the disadvantages, which, rather, can be attributed to the peculiarities of use.

Pipe installation can be done using the socket method, which is simple