What's happened. Differences from open

The essence of the operation of a closed-type heating circuit is simple: the liquid heats up, expands and enters the main line. Excess water goes into a separate container, and as the temperature drops, it returns back to the system. There is a constant pressure inside the thermal block, which allows rational control of the entire process

Closed-type heating systems are very popular; its most important advantage is the absence of open interaction with the external environment. Air promotes rapid depreciation of pipeline elements and reduces the efficiency of the system, which occurs in open-type thermal systems.

Nowadays, a closed heating circuit, in which forced circulation operates, works successfully in most private households.

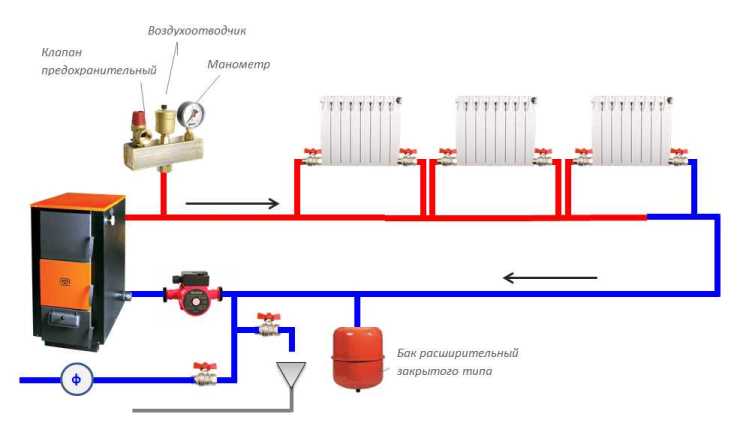

A closed loop consists of elements:

- Heat generator (boiler running on solid or liquid fuel, gas, electricity);

- Radiators, heated floors;

- Pump;

- Sealed membrane type container;

- Elements that allow you to relieve excess pressure (pressure gauge, air vent, protection valve);

- Filter;

- Control and balancing fittings;

- Pipes;

The main blocks can be equipped with additional elements, such as:

- collector;

- Containers;

- Automation relays.

The operation of a closed heating system consists of moving warm water (under pressure 1-2.2 bar) from the heating boiler to radiators that are located in the rooms. Volume adjustment is done using a membrane that is attached to the container. All contents are isolated from the external environment.

Pressure adjustment is done using an air vent operating in automatic mode. The second safety element is the burst valve, which is activated if the pressure in the system exceeds critical levels (usually about 3.5 bar).

The mud trap is mounted on the back side of the line (in front of the heat generator), its task is to accumulate sludge from the heating circuit. Another important block is the pump; it supplies water and can work in both directions.

Advantages:

- No contact with air. Complete isolation of liquid from the outside world.

- Environmental safety, no fumes.

- You can use antifreeze in your work.

- The pipes used are inexpensive and of small cross-sections.

- There is no unnecessary heat loss, energy is saved.

- The risk of air locks is reduced; water “works” at a higher temperature and pressure.

- Easy to adjust

Small-diameter pipes are easily hidden in the wall or under drywall, which is an important factor in the arrangement of residential premises.

Pressure in a closed heating system

Three types of pumps are used in closed heating circuits. They are differentiated by the pressure of the water column:

- 4;

- 6;

- 8 meters

Accordingly, the pressure is distributed in proportions:

- 0,4.

- 0,6.

- 0.8 Bar.

For a private household with an area of about two hundred square meters, a pressure of 4 meters is sufficient. If the area is three hundred square meters, then a 0.6 bar pump will be required, and if the area is more than 500 square meters, then a pressure of 0.8 bar will be required. All pumps are marked with technical indicators. The pressure is relatively low, there are also safety valves, an explosion in closed thermal circuits is impossible.

Expansion tank for closed system

How does an expansion tank work?

The expansion tank is selected based on the calculation of the volume of liquid in a closed heating system. When boiling, water increases in volume by an average of 5.5%, respectively, and the volume of the container should have one tenth of the total volume of the coolant. The expansion tank helps eliminate too much water, which is extremely important in terms of safety.

The design consists of two blocks:

- The body is made of stainless steel.

- Membrane.

One part of the container is filled with air, and excess water enters the lower compartment. As the temperature rises, the membrane contracts, regulating the flow of liquid. The container is mounted next to the boiler; it is an effective tool for preventing circuit breakout and accidents.

Membranes are:

- Stationary;

- Replaceable

The first type of membrane cannot be changed; the replacement membrane is made of rubber, and you can replace it yourself. Such elements are mounted on the flanges of the container.

Advantages and disadvantages of heating systems

The main advantage of an open system is reliability and simplicity. In addition, it is cheaper than closed.

Pros:

- easy installation;

- ease of operation and maintenance;

- no noise;

- does not require power supply;

- even heating of the room;

- no pumps needed;

- installation does not require special skills.

Due to the increased diameter of the pipelines, open heating takes up a lot of space and has an unsightly appearance.

More information about a reliable heating system:

Minuses:

- low efficiency;

- slow movement of liquid through pipes;

- You cannot use alternative coolants, only water;

- due to leakage, it is necessary to add fluid;

- air entering the system leads to operational interference and rapid wear;

- The water in the expansion tank and pipes may freeze.

The closed system is used in most private apartments due to its compactness.

. Advantages:

- thanks to the tightness, you can use antifreeze and protect pipes from freezing;

- small pipe diameter;

- aesthetics;

- no need to take into account the level of inclination of pipelines;

- thanks to the high speed of the coolant, the room warms up very quickly;

- not subject to corrosion;

- there is no need to constantly monitor the fluid level;

- easy temperature adjustment.

Read also: installation of a closed heating system in a private house.

Comparison of closed and open heater:

Flaws:

- requires electricity to function;

- pumps can create additional noise;

- the slightest depressurization entails the entry of air into the coolant, which is fraught with malfunctions and breakdowns;

- The membrane expansion tank has quite large dimensions.

How to fill a closed system

Work begins with isolating all heating devices from the mains. Cranes are used for this. The hydrogen supply is turned on, the circuits are gradually filled, and the air gradually escapes.

After the pressure reaches one bar (we monitor the pressure gauge readings), we stop the hydrogen supply and activate the pump to remove the remaining air. One by one, you should unscrew the taps and bleed air using Mayevsky’s device. After this, the boiler and pump are started, we warm up the coolant and once again purify the batteries. After this operation, the pressure rises to 2.2 bar, the temperature in the boiler does not exceed 85 degrees Celsius.

The system is reliably protected from air penetration, however, it is impossible to remove 100% of all air. Over time, it becomes hot and can cause blockages, leading to malfunction. The Mayevsky tap is an effective means of eliminating excess air. Separators that are located in the circuit itself are also actively used.

For more efficient operation, a thermostat is used on all closed circuits; it allows serious energy

Closed system and its differences

This is a heating structure in which the circulation of the coolant through the pipes is forced using a specialized pump , and its operation requires a connection to the electrical network. The working principle of a closed installation is almost the same as an open one:

- The coolant is heated in the boiler .

- Then the pump pushes out the heated coolant

. - The heated water flows through all heating devices , which leads to heating of the air in the room. Pipes in the house can be installed as you wish, circulation through them is carried out using a pump.

- After a certain period of time, the cooled coolant returns back to the boiler.

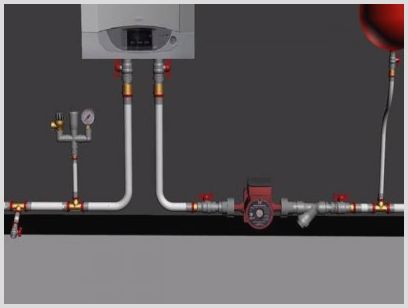

For good functioning it is also necessary to install an expansion tank , thanks to which the pressure can be controlled. Qualified engineers advise giving your own preference to membrane tanks. It makes it possible to reduce or increase pressure in a short time, which is critical for a closed installation.

Reference! In the case of installing a closed heating system , the pipes can be positioned in different ways, because circulation will occur due to the operation of the pump.

- normal installation.

- It is not necessary to monitor the fluid level .

- Antifreeze can be used .

- Requires connection to a stable electrical network.

- It is recommended to connect an emergency power supply.

- Expansion membrane tanks are quite voluminous .

- In order for the pump to operate quietly, the technical room should be soundproofed.

Popular closed system schemes

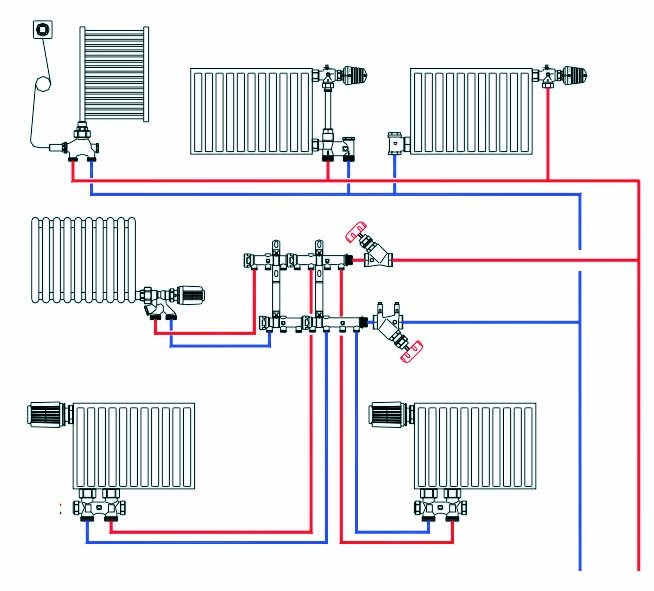

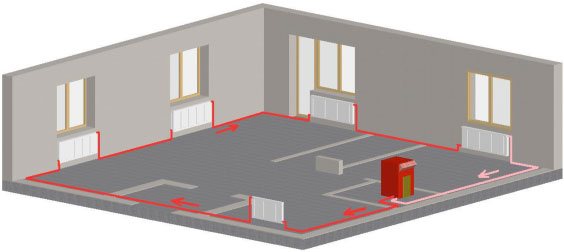

Wiring in heating blocks exists:

- Radial.

- Two-pipe.

- Single-pipe.

Radial

Each radiator autonomously receives its own portion of the coolant; they are all connected to the same source. The beam arrangement is reliable, easy to install and maintain. The wiring is installed in the floor. Pipes are used with a cross-section of sixteen millimeters. The furthest pipes are used up to 22 mm. The cross-section of the boiler line is 26 mm (DN 20).

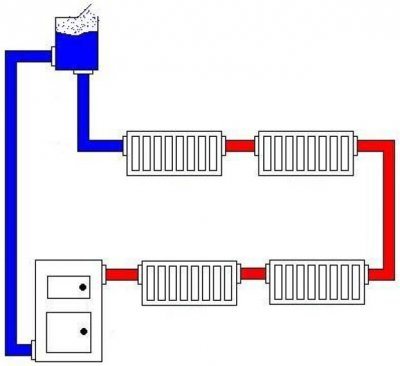

Two-pipe

The heated coolant circulates. This model of a closed heating system is the most popular and exists in 80% of properties. A variation of the two-pipe arrangement is the Tichelman loop (passing). In this case, cooled water flows in the same direction along with hot water.

This arrangement is simple and reliable, and it is also very easy to install. In private houses up to 220 sq. meters (2 floors), it is recommended to use pipes DN 16, as well as 20 mm. In this case, the outer diameter is 22 - 25 mm

The Tichelman loop is not easy to install; too many pipes have to be installed and the cost increases for this reason.

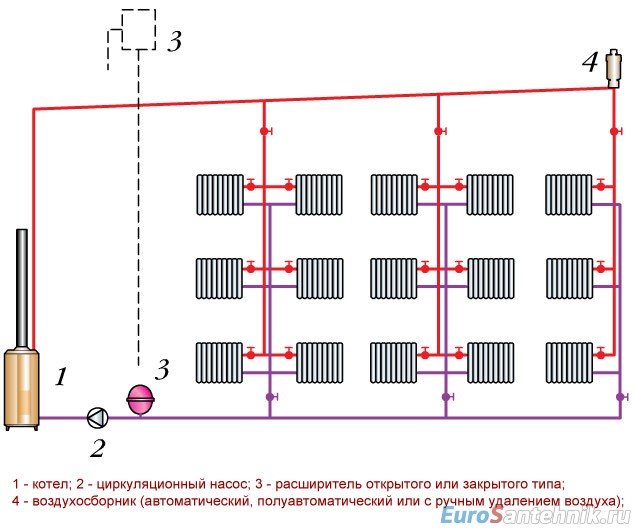

Single-pipe

The batteries in a single-pipe closed heating system interact with one main line. It is present around the entire perimeter of the room. The disadvantage of such a system is that remote batteries receive the least amount of thermal energy. Water moves only through this pipe. There is a horizontal single-pipe circuit (the third name is “Leningradka”. There are also vertical models, water is distributed from risers, most often found in low-rise country houses. The optimal number of batteries for such a scheme should not exceed five. If the layout is vertical, the building can be up to three floors high The single-pipe circuit is quite “picky”; it must be configured by a specialist with experience.

Open heating system

An open system is a heating structure in which the coolant moves naturally in accordance with the laws of thermodynamics. Its operation does not require a special pump that would create forced circulation of heated water, so connection to the electrical network is not required. Principle of operation:

- The water is heated in boiler.

- The heated water begins to move up the vertical pipe due to the phenomenon of convection .

- It passes through all pipes and radiators, giving off its heat to the rooms. Pipes in a house are usually placed on a slope so that the liquid moves in a horizontal plane under the influence of gravity.

- At the end, the cooled water is returned back to the boiler, heated again, after which the heating cycle is repeated .

A so-called expansion tank is placed in an open installation . The fact is that liquid expands when heated, and in case of severe overheating it can damage radiators. In a closed installation, this problem is solved by reducing the pressure using a pump.

Attention! The tank is used to store superheated water, to stabilize pressure , and also to remove excess liquid when there is too much water in the heating installation.

Advantages and disadvantages

Pros:

- Easy operation and maintenance.

- No need to connect a quiet pump.

- All rooms are heated evenly .

- The installation starts and stops quite quickly .

- No connection to the electrical network is required (except when an electric boiler is used for heating).

- Installation does not require complex engineering skills from the master.

Photo 1. Expansion tank for heating, volume - 100 l, power - 950 W, .

Minuses:

- Before starting operation, installation of an expansion tank is required.

- The pipes must be located in a special way in the house (otherwise the water will not circulate).

- If air enters, damage to the installation may occur due to mechanical damage and/or corrosion.

- In winter, due to severe frosts, freezing will occur.

- After turning on, you will have to wait for the liquid to heat up to the desired temperature.

- should be constantly monitored .

- as a coolant .

How to turn an open system into a closed system

There are often options when an open heating system is converted into a closed one. To successfully implement your plan, you must first change the container by installing a “return” with a thermostat in it. A filter is mounted in front of the pump, the old container is dismantled and removed. Using welding, it is easy to convert the system into a closed circuit that will be attached to the new container.

Such manipulations should be carried out together with the installation of the pump. Additionally you should put:

- pressure gauge;

- valve;

- air vent

Closed and open heating system using example diagrams

Closed and open heating systems are considered the main schemes used for heating residential buildings. The open heating system is the most popular among convective circulation systems. The operation of this system is based on thermodynamic laws. An area of very high pressure is formed at the outlet channel of the boiler, under the influence of which the heated liquid moves through the pipeline, gradually releasing heat energy.

Having cooled, the coolant

flows back into the boiler, where it is heated again. Similarly, a system with convective circulation does not stop operating. In such a design, only water can be used, because antifreeze used for heating evaporates very quickly.

Boiler for closed system

The closed system operates with a wide variety of fuels and boilers; in this regard, such units are universal. Before choosing a boiler, it is necessary to carry out appropriate calculations of the heating system. The power of the boiler directly depends on the number of square meters that will have to be heated. Or rather, from heat loss at home. There are special formulas; the calculation itself is not difficult. There are boilers:

- Single-circuit.

- Dual-circuit.

- With a boiler.

It is recommended to remember: not all coal boilers are designed for pressure above 1 atm. Especially homemade ones. When switching to a closed heating system from an open one. This should be kept in mind.

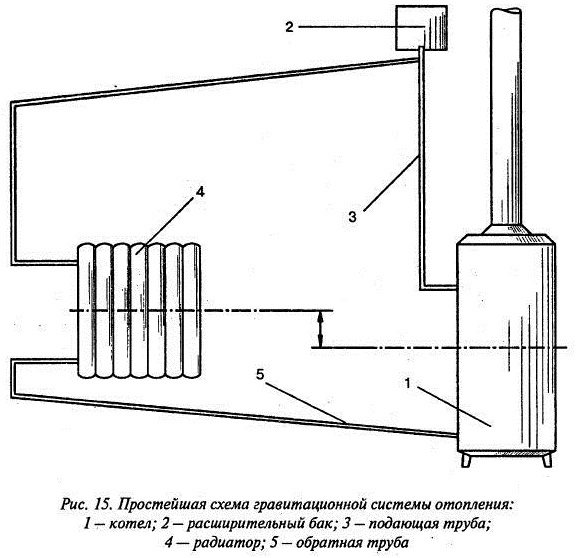

Operating principle

The gravity heating system of a private house includes:

- Heating radiators;

- Supply pipeline;

- Return pipeline;

- Heat generator;

- Expansion tank.

The principle according to which a heating system with natural circulation works is as follows: once inside a gas or solid fuel boiler, a certain amount of water begins to heat up and rise up through the pipes. During this process, free space appears at the bottom of the pipeline, into which cold liquid rushes. After passing through the radiators, the water cools and rushes down. Its movement is hampered by friction, but slopes help solve this problem. This operating principle is the simplest, but most effective.

Open or closed system. What's better?

Closed systems are beneficial to use, but not all settlements have an uninterrupted supply, for example, of electricity. In winter, this can lead to trouble.

Open and closed heating systems have their own advantages and disadvantages; the palm cannot be given to either of them. Professional correct installation of an open system can also guarantee a long period of trouble-free operation. The choice is determined by the specifics of the object and the region itself where the house is located.

If you want to achieve maximum savings, then you should look towards a closed system. Through precise control, costs can be reduced to a minimum. If you want the simplest option possible, then perhaps an open heating system is your choice.

Pros and cons of an open system

Advantages:

- Simple installation, repair and maintenance;

- Silent movement of the coolant - a closed circuit does not have this feature, since the pump is constantly noisy;

- Energy-independent operation with natural circulation of the working fluid;

- Another difference between an open heating system is the ability to install boilers of any type;

- Low cost of materials and equipment.

Negative points:

- Evaporation of the coolant means the impossibility of pouring antifreeze or other antifreeze into the system, because such a solution increases the risk of harm to residents;

- The need to constantly monitor the coolant level in the tank, which is inconvenient at night or when you need to leave home;

- Heating solutions that are still open are characterized by high inertia in operation, which is corrected by installing a circulation pump and bypass;

- For a “warm floor” system, the open circuit option without a pump is not suitable due to complex pipe routing and increased hydraulic resistance.