Today, an increasing number of people, when arranging their suburban area, decide to place a swimming pool here. As a rule, this pool is not very large in size, but it is quite attractive and you can plunge into it at any time when it is no longer possible to be in direct sunlight. However, every pool must have impeccable waterproofing, which largely determines its durability. This article will reveal all the features of waterproofing technology, as well as list possible methods and types of this process.

You have started building a swimming pool for your summer house with your own hands and have reached the stage of waterproofing it. Here you should know and understand that waterproofing protects the pool structure from water leakage. If the structure allows water to pass through, it will drain out of the pool in just a few minutes.

During the construction of this structure, cement is used, but this material allows water to pass through, so it is recommended to make high-quality waterproofing.

Advantages and disadvantages of waterproofing swimming pools

No one wants their pool to leak water, and it is for this reason that a whole range of work is carried out to protect the structure from water leakage. At the same time, many people are faced not only with the advantages of waterproofing, but also with its disadvantages.

Advantages:

- some materials are able to tightly seal cracks and chips;

- long service life;

- materials do not deteriorate when exposed to water.

Flaws:

- some materials are not durable and reliable;

- waterproofing may deteriorate if there is an uneven surface;

- chips and cracks may appear.

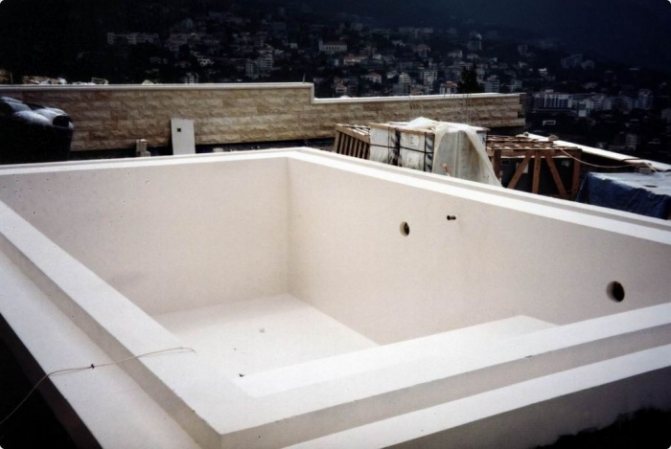

Stages of internal waterproofing

When processing the inside of a swimming pool, it is very important to follow a strict sequence of work. The instructions below will allow you to do everything yourself. Do-it-yourself pool waterproofing includes the following steps:

- Cleaning the concrete frame from dirt and dust. For thorough cleaning, use construction or portable vacuum cleaners. It is very important that the surface being treated is perfectly clean: the quality of future waterproofing directly depends on this.

- The cracks in the pool are opened and treated with a joint sealant. Sealing tape is used for joints.

- After processing the seams of the pool, the entire inner surface of the font is plastered. In addition, the walls are impregnated with a moisture-resistant composition, and a screed made from a self-leveling self-leveling mixture is poured onto the bottom.

- When the plaster has dried, a primer is applied over it. It can be applied with a brush or roller. The impregnation dries in about 4 hours (depending on the manufacturer and layer thickness). After complete hardening, you can begin applying the next layers.

- Impregnating a concrete pool with penetrating waterproofing increases its strength. To dilute the composition, use water; you need to add enough liquid so that the mixture has the consistency of thin sour cream. The proportions of the components are written in the manufacturer's instructions. It is better to use exactly the proportions indicated on the package.

- Using a wide, thick brush, apply the mixture onto the prepared concrete. When impregnating, special attention is paid to the entrance holes for communications, seams between walls, joints and cracks.

- When applying waterproofing to a pool under tiles, it is very important to carry out comprehensive measures. The waterproofing “pie” consists of penetrating and coating solutions. After the penetrating impregnation has dried, the font is treated with a five percent solution of hydrochloric acid, after which it is washed off. When the water dries (about 30 minutes), the font is washed with a five percent solution of soda ash. After these treatments, the concrete is ready for mastic application.

- After treating concrete with waterproofing, you should not step on it and it is not even recommended to touch it. In addition, it is necessary to maintain the temperature inside it above zero for three days. Therefore, it is optimal to carry out work in late spring or summer, when frosts are not expected.

- To prevent the applied layers from cracking or peeling off, they are moistened for three days. Places that will be subject to constant water pressure are moistened for 10-15 days. To do this, use a spray of water. Also, at the time of drying, the font is covered with polyethylene, which will retain particles of moisture inside the pool.

- After 10-15 days, it is necessary to carry out a test filling of water. To do this, fill the font and leave water inside for 10 days. If there is no leak, the pool is drained, cleaned and left to dry.

When the waterproofing has been checked and dried, you can begin tiling. Decorative finishing of the pool is made of mosaics or tiles.

Treatment with liquid rubber

Liquid rubber is a mastic based on bitumen and polymer additives. The material has a high degree of adhesion to concrete, and most importantly, liquid rubber perfectly protects the font from water penetration. The material is applied to the walls of the pool by spraying. It is optimal to treat the font with several layers of liquid rubber. It is most convenient to apply the material with a compressor, but you can also use a brush or roller; such processing will take much more time.

Note! Liquid rubber combines the characteristics of membrane and liquid waterproofing, which makes it extremely effective. When treated with such mastic, a cast impregnation is formed on concrete without seams or cracks. The coating has a pleasant surface, similar to PVC membranes, while it has a very high fabric strength. You can safely apply a decorative finish to the liquid rubber, or you can leave the pool like that. Today there are many varieties of such mastics of all colors, which allows them to be used as a finishing coating, saving on tiles.

Before treating the pool with rubber materials, you need to level the surface and thoroughly degrease it. Then, using a compressor or a brush (if self-processing), the rubber is evenly distributed over the concrete so that it covers all the walls.

Waterproofing with liquid glass

Liquid glass is made from sodium and potassium silicates. Waterproofing of swimming pools with such material is carried out during the construction of the swimming pool. Liquid glass is mixed into the concrete itself at the construction stage. Dilution proportions: 1 to 100 (1 liter of glass per 100 liters of solution). This inclusion makes the body of the reservoir durable and more resistant to mechanical loads. The main advantage of adding glass is increasing the water-repellent properties of concrete.

Liquid glass can be applied to the pool body and after construction, directly to the concrete. For such purposes, waterproofing coatings are produced with the same composition as in the additives for the solution. Such materials have high waterproofing rates. In addition, liquid glass protects concrete from fungi, temperature, destruction and ultraviolet radiation. Liquid glass has a low cost, and to treat the pool you will need little material, since it has low consumption. The coating is very easy to use, so you can process it yourself with this material.

Applying glass is very simple; the technology includes the following work:

- Surface preparation. Before treating with any coating, the concrete must be cleaned; the surface under liquid glass must be rough, so if it is smooth, it must be degreased. This measure is necessary for good adhesion.

- Dilute the solution. The solution must be prepared strictly following the instructions; the recipe and proportions must be indicated on the packaging.

- After complete mixing, the composition is applied to the concrete. When the first layer dries a little, you can apply the second. Rollers or brushes are used for processing.

- Applying the final finish. Any type of decorative finish can also be applied to liquid glass.

Liquid glass is unique in that it can be added at the concrete mixing stage. This will free you from waterproofing work in the future.

PVC film

Today, PVC films are very popular in waterproofing concrete pools. The material is highly durable, and most importantly, it is absolutely waterproof. In addition to waterproofing functions, the film acts as a decorative layer. Therefore, if you want to save on finishing, you should take a closer look at PVC materials.

Films differ not only in color, but also in thickness, strength and design. The material is available in various patterns and imitations. On the construction market you can find PVC films with tile or mosaic patterns. The color of the films is very intense, and thanks to the protective layer, the coating does not fade during prolonged contact with ultraviolet radiation. For this quality, the material is often used in outdoor outdoor pools.

Installation and repairs using film are indistinguishable from waterproofing with coatings. First, the pool is cleaned and dried. After this, fixing tapes and film holders are attached.

Important! The film is mounted on geotextiles, this increases the service life and quality of the coating. In addition, the layer reduces the friction of the PVC film on the concrete, thereby maintaining its integrity.

After placing the fasteners, spread the film and weld it with a special apparatus. This method is considered the most reliable and simple.

Methods and types of waterproofing pools

Today, there are two main types of insulation: internal and external.

The first option involves treating the inner surface of the structure with certain waterproof materials, protecting the pool from the inside so that water does not leak out.

The second type of insulation is to prevent groundwater from reaching the outer surface of the pool.

Internal waterproofing:

During the work, it is necessary to repair all cracks and chips through which water may leak. To do this, the following work should be done:

- clean the concrete surface from dirt and dust;

- cracks must be treated using special materials to seal the seams;

- joints must be sealed with sealing tapes;

- the surface is leveled, after which it is primed;

- applying additional sealing layers.

External waterproofing:

At this stage of work, special waterproof materials of the adhesive type are purchased. They are distinguished by their reliability and elasticity, which is necessary for protection from groundwater.

As a rule, the walls of the pool along its perimeter are dug out and cleaned of dirt. Where the concrete coating has begun to deteriorate, thorough cleaning is also carried out. Cracks are treated using pre-prepared waterproofing materials.

Types and purpose of waterproofing

According to the method of arrangement, pool waterproofing is divided into:

- waterproofing the outer walls of the pool;

- waterproofing the inner surface of the pool.

Waterproofing from the outside is carried out to ensure protection of concrete from the destructive effects of free moisture. This type prevents the destruction of the walls, ensures their waterproofness and reliability. The outer layer of waterproofing is laid at the initial stage of construction of the structure or in the event of its planned overhaul.

Waterproofing of the pool from the inside is carried out before finishing it. This layer of insulating material prevents moisture from penetrating into the concrete. Most often, internal waterproofing is carried out using the coating method.

Materials for waterproofing swimming pools

Today, professional builders use several types of materials to effectively insulate a pool structure. Below are examples of the most common options.

PVC film

This is a membrane coating system, the main advantages of which are lightness, affordable price, resistance to chemicals, frost resistance, etc.

PVC membranes combine insulating and decorative functions. Today there are many different types of such films, so choosing the most suitable option will not be difficult.

However, over time the PVC membrane can become damaged. This often happens due to the fault of those people who use the pool carelessly.

Liquid rubber

It is considered an innovative material , which has already proven itself as a reliable waterproofing element.

This mastic is sprayed onto the surface of the structure, which gives it excellent insulating properties.

Liquid rubber is used for both external and internal waterproofing. The structure will be reliably protected from corrosion and mechanical damage.

Disadvantages include intolerance to exposure to ultraviolet radiation . Liquid rubber should never be applied to a wet surface.

Liquid glass, special mastics and cement

The most famous mastics are Penetron, Izofast, Idrosilex Pronto, Tenabit-M and many others. This material allows you to create a durable layer that will not allow water to pass through. The concrete coating of the pool becomes resistant to mechanical stress.

Another waterproofing option is liquid glass, which is an aqueous solution containing sodium silicate. This material allows you to extend the life of the structure by filling all cracks and chips with a reliable solution.

A cement layer is also often used to waterproof swimming pools. Such mixtures easily adhere to any surface and are characterized by high strength. In addition, the installation process will be a fairly simple job for any builder.

The disadvantages include the fact that such insulation can quickly become unusable, after which water will begin to leak through minimal cracks and pores.

Requirements for internal waterproofing of a swimming pool

When constructing swimming pools, it is necessary to take into account the influence of water: its direct impact on the lining materials and the increased load from the inside on the frame of the structure itself. Therefore, appropriate requirements are imposed on waterproofing materials: in addition to the fact that they must reliably retain water, it is necessary that they have increased strength characteristics that allow them to withstand temperature changes and mechanical stress.

The material used to waterproof the pool bowl from the inside must have good strength characteristics and at the same time be elastic. Not all of the materials on the market meet such requirements. The pool bowl is mainly constructed from reinforced concrete or monolithic concrete. Brick is used much less frequently for these purposes. All these materials require additional protection from the inside against water penetration.

There are two more options - using a protective layer of film or using a ready-made plastic bowl. In the latter case, the base itself is a waterproofing agent. But the most reliable pool design will be if it is built from concrete - this material is the most relevant, and will be discussed below.

Protecting the pool surface from the inside from moisture penetration must be done very carefully. Any deviations from the technology are fraught with leaks and destruction of concrete as a result of dampness. In addition, the material will mold. All this will inevitably lead to the need for expensive repairs.

Therefore, when arranging waterproofing of the pool from the inside, you should not save. Moreover, for reliability, it is better to use several protection methods simultaneously.

The insulating layer of the pool bowl is constructed in compliance with the following conditions:

- 100% waterproof;

- elasticity combined with strength;

- good resistance to hydrostatic and dynamic loads;

- excellent adhesive properties;

- chemical resistance to microorganisms and inorganic substances contained in water (for example, chlorine-based preparations).

When waterproofing a concrete pool from the inside, it is necessary to choose a material that is environmentally friendly. In addition, it must successfully withstand temperature changes and ultraviolet radiation.

Recommended articles to read:

- Pool liner: characteristics and installation methods

- Children's play tents: features and selection rules

- PVC film for the pool: types and installation methods

How to correctly calculate the consumption of materials?

Even the approximate consumption of materials cannot be calculated if you have never encountered the waterproofing of swimming pools.

In this case, it is better to contact specialists who will help you understand this issue. The only thing to remember is that it is better to take the material with a small margin. If there is too much of it, you can apply it in two layers, if the design technology allows.

For example, the approximate cost of PVC film is 2800-3900 rubles per roll. The same amount of plastic film will cost 1000-2200 rubles. Based on the price and area of your pool, you can approximately calculate how much you will spend on all the necessary materials.

Pool finishing with mosaic

Ceramic finishing of the pool requires large financial investments. Therefore, such technology is not included in the list of budget operations. However, finishing the pool with mosaics is highly environmentally friendly. It is designed for long-term use. The aesthetics of the coating completely justify all the costs of creating a mosaic.

The operation of the pool bowl differs in its specific conditions. Therefore, in order to finish the pool with mosaics at a high level, high-quality auxiliary materials are required. The technological process of such an operation has characteristic features. However, a person who has extensive experience in tiling various rooms with ceramic tiles can easily cope with this task. He will not need the help of professionals; everything can be done with his own hands.

Finishing a pool with mosaics occurs in several stages. Each of them requires a professional approach, attention and accuracy. The reliability of the design, as well as its attractiveness, depends on this.

Materials required to complete the job

Since a pool is a structure that is constantly in water, according to sanitary and hygienic standards the following is added to it:

- chlorine;

- sea salt;

- chemical compounds.

When changing water, temperature changes may occur. Moreover, they are sometimes very significant, sometimes very sharp. Prolonged contact with water, the action of chemicals, temperature fluctuations require that the finishing of the pool with mosaics be carried out with high-quality materials that differ in their characteristics.

Choosing finishing tiles

Considering future operation, the selection of tiles should take into account several important parameters:

- increased strength;

- water resistance;

- low porosity;

- heat resistance;

- do not react to the effects of aggressive chemicals, especially chlorine;

- environmental friendliness;

- should not emit toxic substances;

- safe when walking (increased friction coefficient);

- easy maintenance;

- attractive look.

In accordance with the requirements, mosaic finishing of the pool can be made from the following materials:

- porcelain;

- glass;

- porcelain stoneware;

- glazed clinker.

The pool bowl, decorated with smalt mosaic and special glass tiles, looks great. Of course, you can decorate the walls with natural stone. However, this will require large financial investments. Moreover, the natural material does not look very beautiful under water; the cladding takes on a gloomy appearance.

Note! Any size of ceramic tile can be used. However, ceramics with dimensions exceeding 15 centimeters are completely unsuitable for finishing work. Small-sized ceramics are more resistant to bowl deformation.

Many people consider the pool a place to spend leisure time. However, this is not quite true. This is a design that requires constant visual supervision. The technical condition, as well as the hygienic component, must always meet established standards. That is why the mosaic finishing of the pool should have a color that will help facilitate such control. Professionals recommend finishing the bowl with dark ceramics, which will hide water contamination.

Suitable grout, choice of tile adhesive

Installation of tiles and grouting work can only be carried out in the presence of special mixtures that differ in their performance. They must have several mandatory qualities:

- increased adhesion;

- elasticity;

- water resistance;

- frost resistance;

- heat resistance;

- inertness to aggressive media (chlorine);

- antifungal protection.

Manufacturers of adhesive compositions must indicate on the packaging the main characteristics of the composition. Usually, in the description of the glue, “pool” is always written. Sometimes you can see the word "aqua". These inscriptions help you choose the right mixture.

Finishing a swimming pool with mosaics is usually done using waterproof cement mixtures. Compositions based on epoxy resin are used for grouting joints. High technical parameters fully justify the cost of these materials.

Important! You should not buy cheap glue if it does not have the required characteristics. The ceramic finish will quickly begin to deteriorate. Major repairs will be required, which will cause large financial losses.

Calculation of the number of tiles

The consumption of materials required to decorate the pool bowl is carried out similarly to the calculation of tiling of other bases. If this is a monotonous cladding, you will need to determine the total area of the entire surface. To this result, taking into account the laying method (straight, diagonal), 10-15% is added. This additive goes to waste when the tiles are adjusted.

Artistic decoration of a swimming pool with mosaics requires a combined approach when calculating ceramics. The consumption of tiles when creating panels is carried out piece by piece. To design the background, the total area is taken or the number of packs is calculated. All calculations occur after determining the tile format, as well as marking the areas to be tiled.

The square of the thicket is the basis for calculating the required amount of tile adhesive. Its consumption is indicated on the packaging. The basis is one square meter. The amount of grout mixture is determined taking into account the dimensions of the tile, its thickness, and the width of the joints.

Technological process of foundation preparation

To carry out independent finishing, you must first carry out two operations:

- waterproofing;

- alignment.

Good to know! Even the most durable, waterproof tiles cannot ensure the tightness of the bowl.

Waterproofing

To make the structure airtight, it is necessary to waterproof the walls of the pool and its base. In outdoor pools it is performed from the inside and outside. Thanks to waterproofing, the structure receives reliable protection from groundwater. Leakage of liquid from the thicket into the soil is eliminated.

For waterproofing, a technology is selected using materials that will not complicate the installation of ceramics:

- Penetrating compounds. They begin to crystallize after getting into microcracks in a concrete base, for example “Penetron”.

- Polymer cement mixtures. This is a coating material consisting of cement and sand. To improve quality, special plasticizers are added.

- Membranes. The mastic is based on rubber with reinforcing fabric laid on it.

These insulating materials differ in their positive and negative characteristics. They are selected for independent waterproofing, taking into account the condition of the surface.

Plastering and leveling

In order for the mosaic finishing of the pool to be of high quality, it is necessary to first level the walls using plastering. The technological process completely repeats similar operations in other areas.

On a note! After leveling plastering, it is necessary to cover the base with another insulating layer. It will protect the plaster, as well as the floors, from possible gaps when previous layers were applied.

Before you start laying tiles yourself, the insulating layer must be primed. This operation can be avoided if you use an insulating compound that does not require the application of a primer.

Technology of working with tiles

If you choose the right material, laying ceramics can be done using several methods:

- with offset;

- straight;

- monotonous;

- artistic.

To ensure complete safety when using the pool, it is better to use a combined finish.

Structural combinations, lighting combinations

Finishing the pool with mosaics creates the attractiveness and beauty of the entire structure. It is better to cover the underwater part with light mosaic. This will allow you to visually monitor the purity of the water, as well as ensure that there are no foreign objects in the pool.

Craftsmen recommend finishing the surface of the pool walls in the form of horizontal stripes of the same color, and the tone should be different.

A certain width of the stripes will make it possible to monitor the fullness of the pool from a great distance.

Above-water areas, especially horizontal surfaces intended for walking, are covered with ceramics, which have a coefficient of friction exceeding 0.75. Clinker tiles are considered the best for this type of work. Areas under water are covered with smooth tiles. It is very easy to maintain.

Finishing a pool with mosaic is used for surfaces not covered by water. The seams between the tiles are highly dense, the coefficient of friction increases, and walking becomes absolutely safe. Matrices with small chips make it possible to independently finish various oval surfaces. Such connections are much safer than any corner joints.

How to glue ceramics

Finishing the pool with mosaics occurs in a certain sequence:

- walls are lined;

- underwater terraces are closed;

- sides are mounted;

- process shaped elements.

After these operations, the tiles are laid on the floor, previously cleared of debris. The technological process for installing ceramics inside a pool is not much different from finishing work on other surfaces.

It is necessary to start gluing ceramics from the center of the wall. The adhesive layer is easily applied with a special flat spatula. Excess mixture is removed with a special spatula-comb. The same layer of adhesive should cover the back side of the tile. Then the product is pressed tightly to the base, a rubber mallet is taken and the entire surface is tapped. Installation of mosaics inside the bowl, if the material is selected correctly, is carried out using a similar technology for finishing any surfaces.

We rub the seams

You can start making the seams and filling them with grout mixture three days after the installation of the ceramics is completed. The bottom of the pool is covered with plastic film. It will protect the seams prepared for grouting, when the joints are being prepared, and when the grout mixture falls. Elimination of gaps on the floor is done after completion of the grouting work.

Summarize

To finish a large pool, turn to professional finishers. Working hours are established by contract. The technology for producing such work is practically no different from the design of a small bowl. Therefore, you can do such work on your own plot yourself, if you follow the technologies described above and adhere to these recommendations.

Preparing the pool surface for waterproofing

Whether it is external or internal waterproofing, you will need to prepare the surface of the pool before proceeding with the actual installation of insulation materials. Preparation includes several points:

- Removing ceramic tiles or other old coverings.

- Removing loose concrete using a jackhammer.

- Thorough cleaning of the pool surface.

- If there are cracks or chips, it is necessary to make fines (small grooves) along their entire length, then clean them with a brush.

The surface of the pool should be as clean and level as possible. This is the only way you will achieve good results and high-quality insulation.

Preparing the pool bowl for waterproofing work

The hydroprotection of a pool must be approached especially carefully and thoughtfully. Any error is fraught with leakage, concrete dampening, the formation of fungus, and so on. Repair work and correction of these phenomena is a labor-intensive and expensive procedure. Therefore, you should not skimp on the quality of the material.

To increase the effectiveness of waterproofing, it is recommended to use several methods. For example, a solution of silicates with liquid glass, a coating mass with deep penetration impregnation, acrylic-based compositions with mastic, and so on.

You can, as an option, use not two methods, but more. But be sure to adhere to the styling technology. The coating that is applied to the bottom of the pool tank must meet all of the following requirements:

- Have the highest levels of moisture resistance.

- Be strong and flexible at the same time.

- Have high performance in withstanding dynamic and hydrostatic loads.

- Have good adhesion.

- Be resistant to biological effects in terms of destruction of the base by various microorganisms.

A special composition for waterproofing must have good resistance to ultraviolet radiation, be safe for health, temperature influences and other weather factors.

The following waterproofing materials meet all these requirements:

- Liquid rubber.

- Deep penetration impregnations.

- Polymer membranes.

You can use all the means at once or limit yourself to any two. As for the finishing coating, mosaics with ceramic tiles have not lost their relevance. They last a long time, if not forever, are completely inert to chemicals, safe for humans, and easy to care for.

Before finishing, a moisture-resistant layer is applied to the surface of the bowl. It is optimal and most effective to use coating mastic under facing tiles.

Installation of pool waterproofing

At the initial stage, the external insulation of the pool is performed. It should be done with sufficient margin around the edges so that the waterproofing can then be placed on the wall and attached to the internal insulation. As for the materials, they have already been discussed in this article. You can choose PVC film, liquid rubber, bitumen, etc.

As a rule, the selected material is applied in 2-3 layers. In some cases, even 4 layers are allowed, this will be much more effective and reliable.

At the second stage, internal waterproofing should be performed. To do this you need to adhere to the following rules:

- The pool bowl must dry after filling with material during the external insulation process, and it is also necessary to plaster the structure bowl.

- For internal waterproofing, an elastic mixture is used, which is applied to the internal surface in 1-2 layers.

- To avoid leaks, the mixture should be evenly distributed around the entire perimeter of the pool.

- Once the waterproofing has dried, you should definitely check the pool for leaks. To do this, fill the bowl with water and observe whether water flows out of the pool or not.

It is worth understanding that waterproofing a pool is necessary, first of all, for yourself. A swimming structure will last for many years only if its waterproofing is done competently, efficiently and in accordance with the rules that you could learn from this article.

How to waterproof a pool under tiles

External work on insulating the bowl does not depend on the finishing method, and therefore does not limit the choice of material. Since most pools in suburban areas are open structures located in recesses, roll and film waterproofing remains the most popular for them.

The design of the pool is monolithic. In no case is a phased construction allowed, and, accordingly, alternate waterproofing of the bottom and then the walls.

Find out how to heat your pool water.

The following link describes the water aeration system: .

You can see prices for pumps for waterfalls in the country here.

Internal insulation under tiles usually includes two stages, since the penetration of moisture, and even more so the appearance of condensation, will lead to the destruction of the finish. Therefore, waterproofing with film materials is immediately excluded.

Work is carried out during the construction of formwork for the pool. Roll and film material is spread along the outer border of the future concrete bowl, the seams must be welded and not taped.

- The concrete surface is cleaned. Seams and cracks, if any, are opened and treated with seam sealants. The joints are sealed with sealing tapes or cords.

- The walls of the pool are leveled with waterproof plaster, and the bottom is leveled with a self-leveling cement composition. If tile finishing is intended, this is a mandatory procedure.

- The surfaces are primed with a primer, the layer should dry for 3–4 hours.

- Using a brush or spray, a penetrating composition is applied. Maximum attention should be paid to seams, connections to communications and cracks.

- Concrete walls and bottom are treated with 4-5% hydrochloric acid, washed with a stream of water, and then treated with a solution of soda ash (4-5%) to neutralize.

- Lastly, coating mastic is applied in a layer of 3–4 mm. If liquid waterproofing is used under the tile, then after the first layer has dried - after 6 hours and no later than 24 hours, the surface is reinforced with a mesh, and then the second layer is applied on top. To increase adhesion, after the same 6–10 hours, the surface is treated with fine-grained sand.

- It is prohibited to walk on the bottom of a pool covered with a waterproofing compound for three days or even more. Concrete surfaces must be moistened for at least 3 days, and the bottom and part of the walls in contact with water - up to 14 days. The wetted concrete is covered with film.

- After the mastic layer has completely dried, you can begin laying the tiles.

Waterproofing work cannot be carried out at temperatures below zero. The same applies to the entire drying period.

The video describes in detail the technology of pool waterproofing: