The basement can be used in different ways. But, in any case, it must have the necessary technical characteristics that allow it to maintain the reliability of the entire building structure for a long time and simplify its operation.

Since the basement is located below the zero level, it is primarily affected by negative environmental factors, and its structures begin to suffer from corrosion and collapse.

The main enemy of building structures is moisture, which is always present in the soil. In addition, the soil accumulates water well from precipitation, where it often accumulates in the area of the foundation.

If the basement from the inside is not protected from moisture by waterproofing or it was made with deviations from building codes and regulations, then there is a high probability of water penetrating into concrete blocks and brickwork with their subsequent destruction. Therefore, during the construction of any building, it is necessary to install high-quality waterproofing of reinforced concrete and other structures in accordance with technical requirements, and also not to forget about the mandatory organization of wall drainage.

Waterproofing the basement from the inside allows you to solve the problem of protecting those parts of the building that are below the zero level, as well as the entire building, since it is on the basement part that the entire structure is supported.

Waterproofing the basement should begin during its construction and be carried out outside the building, in parallel with the installation of drainage. For this purpose, modern rolled materials, PVC membranes, coating compounds, as well as “liquid” rubber are used, which will ensure high quality and durable insulation.

The performance properties of waterproofing are often negatively affected by the use of cheap materials from unverified manufacturers. In addition, qualified personnel are required to carry out this work. Inept use of construction technologies leads to moisture leakage through the waterproofing and the appearance of dampness in the interior of the basement.

In most cases, poor quality work is discovered already during the operation of the building, and it will no longer be possible to change anything with the help of external work. Therefore, in such cases, it is necessary to waterproof the basement from the inside.

Types of waterproofing

Currently, the most effective methods of waterproofing include:

- applying special mixtures to the internal walls of the basement (penetrating insulation);

- sealing leaks and microcracks with sealants;

- sealing cold seams;

- applying “liquid rubber” to the internal surface of structures;

- injection of sutures and cracks;

- injection of waterproofing solutions into the soil adjacent to the foundation of the building;

- the use of mineral compositions for coating.

In order to get the greatest effect, builders often combine different waterproofing methods, which complement each other, improving the final result, allowing for absolute isolation.

Method of penetrating basement waterproofing

This method is characterized by the formation of a waterproofing layer directly in the mass of concrete or brickwork, and not on their surface. Using penetrating systems, it is possible to obtain high-quality wall insulation without damaging the internal structure of the basement structures.

Using the penetrating waterproofing method, even wet concrete can be treated, from any side. Therefore, when repairing foundation leaks, this method is the most effective and quite simple. Properly performed waterproofing in this way will strengthen the seams of the foundation blocks and stop the filtration of moisture through concrete and brick walls.

The service life of penetrating waterproofing is similar to this parameter of concrete building structures. This is because the insulating material penetrates directly into the internal structure of the concrete, rather than remaining on its surface. The microcrystals formed in the pores of the building material have a high degree of protection against water penetration and are resistant to other aggressive influences.

Penetrating materials contain special cement, additives and quartz sand. Therefore, they can also be used for application to the surface of building structures that are in direct contact with water. They are also ideal for protecting the foundation from moisture when it is not possible to eliminate its effects from the outside. Penetrating waterproofing also allows you to solve the problem of high groundwater, protecting the lower elements of building structures from it.

The principle of operation of such insulation is based on the interaction of the hydrophobic liquid of the insulating material with moisture. When they interact, a chemical reaction occurs, during which a penetrating layer of insoluble sulfates is formed. Such liquids are even added to concrete to increase its water resistance.

Before starting waterproofing work using this method, it is necessary to open the pores of the material. To do this, the structure is ground or chemically milled.

Hydrophobic liquid has a valuable property. Penetrating into concrete, it leads to the formation of crystals in its pores, which continue to grow until they no longer come into contact with moisture. If water begins to seep into the structure of the material again, the crystals begin to increase in size again until the pores are completely sealed.

Using the penetrating waterproofing method has its limitations:

- Penetrating solutions should not be used in weak concrete structures. It is recommended to check the strength of concrete using a Schmidt hammer, making calculations based on the magnitude of its rebound from the concrete. The minimum strength of the material must be at least 150 units. The indicator obtained in practice is compared with the building’s passport data, after which appropriate conclusions are drawn;

- It is not recommended to install waterproofing in this way even if there are voids of various origins in the foundation blocks with a diameter greater than 0.3 mm. Often such defects cannot be determined visually, so it is best to use special ultrasonic devices for this.

Technology for waterproofing in the basement

Waterproofing in the basement, regardless of the technology chosen, always begins with preparing the surface to be treated. The concrete base is thoroughly cleaned of dust and dirt; if there are any defects, they are eliminated. Those areas of the structure where weakened concrete is visible must be replaced - the loose areas must be dismantled and filled with a high-strength cement-sand mixture (grade M500).

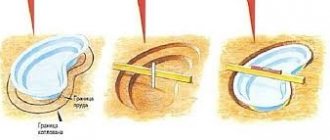

If there are cracks or seams on the surface, then they are embroidered along the entire length to a width and depth of up to 25 mm, then treated with a primer and filled with a penetrating mixture.

Before you begin waterproofing your basement floor yourself, you need to understand what the process entails, depending on the method used.

- Waterproofing the basement floor from groundwater with penetrating compounds. This method will be effective only if the rules for applying the mixture are followed. The base is carefully prepared, cleaned and degreased so that the pores absorb the composition well. The most effective way to clean the floors and walls is with a water jet. It is also recommended to scratch the concrete with a wire brush to enhance adhesion. Before treatment, the surface should be well moistened and then, after applying the penetrating composition, periodic moistening of the coating will be required so that the hardening process occurs evenly. Waterproofing a concrete floor in a basement in this way can be carried out even in the presence of leaks, since high humidity only has a positive effect on the properties of penetrating mixtures, increasing their hydrophobicity.

- Waterproofing of basement floors and walls with coating mastics. This method is capable of cutting off capillary moisture, but in the case of close proximity to groundwater and frequent floods, it will not cope with leaks. The surface treatment process begins after it has been cleaned and primed with a primer. Bitumen, bitumen-polymer mastics or cement-polymer compositions are applied in a layer of 3 mm, then after it hardens (after 4 hours), the procedure is repeated 2-3 times. Wide brushes or rollers are used for coating. It is very important, when carrying out such waterproofing in the basement, to avoid gaps in order to obtain a continuous coating as a result.

- Roll waterproofing of a concrete floor in a basement begins, as in any other case, with surface preparation - cleaning, applying a primer and subsequent drying. If the material will be attached to mastic, then it is applied in a strip larger than the width of the roll. After laying, the insulation surface is rolled with a roller, applying maximum pressure. Laying is carried out with an overlap of 17 centimeters and with the obligatory approach to the walls. You can also fix such waterproofing in the basement using the fusing method using a torch.

- Injection. As a rule, this basement floor waterproofing is carried out by specialists, since it will be problematic to carry out the work yourself. The process begins with an analysis of the premises, identifying problem areas and defects in the design. Next, holes are made in a checkerboard pattern on both sides (in each case the number is calculated individually) and packers are inserted. Under pressure, a waterproofing compound is injected through the packers, and then they are removed. Waterproofing the basement floor from groundwater by injection is completed by treating the surface of the walls and basement floor with plaster mortar.

Regardless of which technology for waterproofing the floor above the basement, walls and screed you choose, it is advisable to obtain qualified advice, and in the best case, entrust all manipulations to specialists.

Sealing of utility service entry points

With the existing waterproofing of a structure, it is necessary to pay special attention to the condition of the seams and places where utility lines enter. If moisture penetrates through them, then each such element must be cut and re-caulked using cement-polymer compositions that ensure reliable sealing of such places. Such sealants are best applied using the layer-by-layer compaction method.

In order to obtain high-quality waterproofing using expanding sealants, it is necessary to correctly install the grooves in the concrete structure and apply an insulating compound at all seams and joints between floor slabs and walls. At the same time, you must remember to thoroughly clean the grooves with compressed air or a special brush, removing from them the smallest inclusions that can worsen the tightness of the sealant to the concrete.

If moisture appears on a building structure during waterproofing work, it is necessary to react to it correctly. It is best to eliminate its effect on the sealant using special powder formulations that can harden within 8 minutes. When there is strong water pressure, use pressure sealants that can harden within 20 seconds.

Sealing of utility service entry points

The most vulnerable places in the basement are the places where pipes, cables and other communication systems enter. Existing joints of structures made of different materials will sooner or later lead to the formation of gaps through which moisture will begin to penetrate into the room.

Constant leaks will lead to the formation of efflorescence and stains on the walls, and peeling of the existing plaster. Such formations lead to an increase in the cost of maintaining the building and become a headache for the organization involved in its repair.

To prevent such processes, it is necessary to think through the sealing of all joints at the construction stage and carry it out in accordance with all building codes and regulations.

To perform waterproofing work efficiently, it is necessary to take into account the type of materials from which the joining structures are made, the possibility of performing insulation outside the room, and the temperature conditions of the basement.

The main condition for obtaining absolutely airtight joints and seams is the correct choice of insulating material. Simply sealing the places where utility lines enter with cement mortars will not give the desired result. Over time and under the influence of moisture, such places will leak again.

Only the use of special sealants will allow you to avoid returning to this problem for a long time. Such sealants include compounds on a multicomponent basis, swelling cords, hydroseals and more.

Technology for waterproofing communication entry points

Sealing a concrete unit with an adjacent sleeve:

- A groove is made around the sleeve;

- A swelling cord is wound around the sleeve;

- The remaining gaps are sealed with expanding sealant.

Use of “pressure” sealing compounds during active leakage:

- You can squeeze out moisture from the waterproofing area using injection solutions;

- Then the joint between the structures is filled with ordinary expanding mortar.

Sealing the joint between the sleeve and the pipe:

- A groove is made around the sleeve;

- The swelling cord is laid;

- The remaining leaks are sealed with expanding compounds. If there is a strong leak, use a pressure sealant.

As additional protection, you can use injection joints and seams.

Waterproofing with Liquid Rubber solution

This method of creating reliable waterproofing can be used to repair already rebuilt buildings and structures that are under construction.

Before starting work on waterproofing with “liquid” rubber, the walls and floor of the basement are thoroughly cleaned so that the insulating material reliably “sticks” to the surface. It must be remembered that “liquid” rubber hardens very quickly when outdoors, since it contains a special emulsion and a coagulating solution.

This type of waterproofing is based on latex, which has excellent elasticity. In addition, this material is fireproof and does not release chemicals hazardous to humans into the environment. The consistency of rubber resembles glue. When applied to the surface, a kind of seamless membrane is obtained that will block moisture from entering the room.

After cleaning the surface of the walls and floor, “liquid” rubber is applied to the surface with the calculation of the ground level. If there is a possibility of water rising above the zero level, it is recommended to screed the floor.

Methods for waterproofing a basement floor

Waterproofing the basement against water penetration using quality materials can be done after the house is completely built. Of course, all such protective measures applied indoors will not be able to completely replace external insulation, but as an additional water barrier they can cope with the task assigned to them.

Let's look at ways to waterproof walls and floors in the basement.

- Coating insulation. It is carried out using bitumen and polymer mastics, as well as compositions made on the basis of Portland cement.

- Impregnating (penetrating) waterproofing of basement floors and walls. The technology involves the use of penetrating mixtures that penetrate deep into the structure of concrete and give it hydrophobic qualities.

- Roll insulation. This technology uses adhesive and weld-on materials, membranes, and films. When waterproofing a basement floor in this way, you must first level the surface and fill the seams and cracks with cement mortar.

- Injection. Such waterproofing of the floor from the basement allows you to cope with groundwater even when the outside insulation is of poor quality and there are leaks inside the room. The technology itself is complex and requires special equipment and extensive operational experience.

The most effective way would be to carry out a complex of works: waterproofing the floor above the basement, the walls and floor of the basement itself, and carry out protective measures outside the foundation, with the arrangement of high-quality drainage and blind area.

Each of the above-described technologies for waterproofing the inside of the basement has its own characteristics; certain steps must be followed. Violating any rule or neglecting any action will result in the quality of the insulation being reduced. It is advisable that waterproofing in the basement be carried out by specialists who know all the features of the process, the properties of insulating materials and have experience in carrying out work of this kind.

Injection waterproofing

One of the newest and most reliable methods of waterproofing basements is the injection method. With its help, you can waterproof a room in its interior, which eliminates the need for excavation work and the influence of the temperature factor on the quality of the building’s protection from moisture.

This method of waterproofing is used not only in basements, but also in underground parking lots, tunnels and other structures whose outer walls are in direct contact with the ground.

The injection method is based on the use of special polymer materials that are pumped into seams, other voids and leaks under pressure. This method is very reliable. Its only drawback is the high cost and the need to use equipment. Only qualified workers who can accurately follow the technological process can work with injection formulations.

The following can be used as polymer injection materials:

- Polyurethane compositions (foams). They are well suited for sealing active leaks and utility lines. This material can also be used in brickwork, as well as in rubble walls and concrete blocks. Polyurethane can expand in volume up to 40 times when interacting with water. At the same time, the composition penetrates into all microcracks and pores, ensuring reliable insulation of the building structure from water.

- Epoxy compounds (resins). Most often, this sealant is used to seal seams and cracks during building shrinkage, since their appearance is associated with deformation of reinforced concrete structures. We will also use epoxy sealant in the case of local elimination of leaks in a brick structure.

- Polyacrylate resins (gels). They are used for injection of expansion joints and cracks in structures subject to intense subsidence and dynamic load due to unstable soils (soils with a high clay content).

- Acrylic compositions. Used in injection methods for waterproofing basements. Acrylic penetrates well into concrete and brick, has a high degree of adhesion and is elastic enough not to form microcracks during mechanical deformation.

- Cement compositions. Used as an injection method to repair cracks in concrete structures.

Additionally, micro-cementation of soils (strengthening the soil/foundation) using a cement mixture can be distinguished as a separate group. It consists of Portland cement and special mineral fillers. They are diluted with water or have a ready-made composition. In this case, cement is responsible for the adhesion of all mineral particles in the composition to each other, and fillers increase the strength of the material and its elasticity.

Why is waterproofing needed?

The ground floor or basement floor, as a rule, is mostly located below ground level. This means that the walls are in contact with the ground. For the construction of the underground part, prefabricated reinforced concrete (FBS blocks (see Basement from FBS blocks - fast, reliable, durable)) or a monolithic structure made of reinforced concrete are usually used.

Destruction of the basement without waterproofing

Although this material has a strong, but still porous structure. The foundation will become reliable when the foundation is protected from moisture penetration from all sides. If this is not done, then there is a risk of unpleasant and dangerous factors appearing.

- Moisture from the soil, precipitation, and nearby groundwater easily penetrate through concrete capillaries into the body of the basement structure and then reach the main walls.

Ground floor with high groundwater level

- If the walls and floor are not protected from water, then after some time its harmful effects will lead to oxidation and rusting of the fittings.

- Seasonal temperature changes and periodic freezing/thawing of water in concrete will disrupt the structure of the material, which will significantly reduce the strength of the entire base.

Cracks in the foundation

- In other words, neglect of waterproofing is fraught with subsidence of the building, cracks in the blocks, weakening and gradual destruction of the monolith.

- In addition, a damp foundation is a breeding ground for various microorganisms, fungus, mold, and, accordingly, an unhealthy, humid atmosphere in the room.

Dampness and mold in the basement

In a dry climate or in sandy soil, when the location of groundwater (see How to find out the groundwater level on a site: instructions) is below the foundation level, only coating insulation is sufficient. But today we will talk about the full protection of the foundation and base with our own hands, using modern materials that reliably protect the surface.

Coated mineral-cement insulation

Using coating materials, mineral-cement waterproofing creates a sealed coating that will protect concrete and reinforcement of building structures from corrosion. The composition of such insulation is quite simple: a dry cement-polymer mixture reinforced with polymer fibers.

If there is a possibility that cracks may form on its surface over time, you can additionally treat this area with elastic waterproofing.

The waterproofing suspension of the coating material is an environmentally friendly product, simple and economical to use. It is usually applied to the surface by spraying or painting. At the same time, when hardened, it is highly waterproof, frost-resistant and has a long service life.

You can choose any waterproofing material yourself. But, if possible, it is better to listen to the opinion of experts in order to eliminate possible mistakes.

Basement waterproofing materials

Nowadays, manufacturers offer an incredible amount of different materials, thanks to which the basement is waterproofed from the outside and directly into the room itself from groundwater. Conventionally, they are all divided according to the principle of influence and method of application.

- Coating insulating mixtures. These include a large number of different emulsions, compositions based on bitumen and cement-polymer.

- Pasted insulation is presented in the form of roll materials, which are fixed to the structure using bitumen or glue.

- Water repellents. This is a relatively new product; you can waterproof a basement using impregnation on your own, but the hydrophobic properties of the coating are significantly reduced after 2-3 years.

- Penetrating basement waterproofing. A good way to protect concrete structures. The product penetrates into the micropores of concrete, making it more durable and creating a barrier against water.

You should consider in more detail all these types of waterproofing for basement treatment in order to make the right choice.