- 4664

- expanded polystyrene insulation foundation

A foundation without insulation and waterproofing is a source of discomfort for the inhabitants of the house: it draws cold from the ground floor, moisture and mold rise into the living rooms.

Soil water, precipitation, and other aggressive factors negatively affect the foundation of the house, destroying concrete and other building materials. In winter, the foundation freezes; in the spring, after thawing, it can crack.

One of the most economical thermal insulation options is foundation insulation with extruded polystyrene foam.

Even cheaper is ordinary polystyrene foam, but it is inferior to EPS in terms of density/strength; a thicker layer of insulation will be required.

It is better to waterproof and insulate at the construction stage. If this is not done in a timely manner, or the heat/waterproofing materials have become unusable during long-term use, the foundation and basement of the residential building should be treated.

Why choose expanded polystyrene?

The modern building materials market offers a considerable selection of different insulation materials. Why, when choosing foundation insulation, should you give preference to expanded polystyrene? There are several reasons for this:

- High frost resistance.

- Excellent thermal insulation properties.

- Low cost.

- Low vapor permeability.

- Easy to process and install.

Like any other material, it also has certain disadvantages. But they are either completely insignificant or easily eliminated. For example, polystyrene foam does not have high mechanical strength - even relatively low pressure can damage it. But the problem is easily solved by installing additional protection. In addition, opponents of this material emit flammability. However, what is the risk of polystyrene foam catching fire underground? Of course, such a danger is completely excluded.

What you will need for installation

Before you start insulating the foundation with extruded polystyrene foam, you should prepare the following tools:

- shovel;

- knife;

- hacksaw;

- Master OK;

- yardstick;

- wide spatula;

- a coarse brush for cleaning the foundation.

As you can see, no expensive or highly specialized tools are required to complete the entire job. Everything you need is either available in every household or can be purchased for a few hundred rubles. In addition, the work cannot be completed without materials such as:

- expanded polystyrene of suitable thickness;

- waterproofing material (mastic, waterproofing without powder or construction polyethylene);

- cement;

- sand;

- plaster;

- glue.

The choice of insulation should be taken seriously - the effectiveness of insulation depends on it. For the southern regions, material with a thickness of 50 millimeters is suitable. Residents of the middle zone are better off giving preference to 100 mm polystyrene foam. Well, residents of the northern regions will have to spend money on 150 mm sheets. In addition, it is worth paying attention to the edges. On sale there are sheets with smooth edges and locks. The former are a little more expensive, but they ensure high reliability of the joints - cold bridges do not form here. Therefore, it is better to overpay a little - the costs will be recouped by the high quality of thermal insulation.

When choosing a waterproofing material, proceed from your financial capabilities. Hydroisol is much more expensive, and its heavy weight makes transportation and installation difficult. But it is stronger and can last much longer. Polyethylene is cheap, light and compact, but has relatively low strength.

Any glue will do, the main thing is that it adheres reliably and does not contain organic solvents - otherwise the polystyrene foam will be damaged.

We begin excavation work and leveling of the foundation

First of all, you will have to arm yourself with a shovel and expose the foundation. This is perhaps the most difficult part of the job.

The depth of the trench should allow working with the lower layer of the foundation. And the width ensures the convenience of working in it.

After completing the excavation work, it is advisable to leave the foundation and plinth open for 24-48 hours (in hot, dry weather, 10-12 hours is enough). The stuck soil should dry out - then it will be easier to remove. Taking a coarse synthetic brush in your hands, walk over the entire surface, removing not only the soil, but also crumbled concrete (this often happens during long-term use).

After this, you need to level the working surface. Expanded polystyrene is a sheet material. Therefore, applying it to a surface with protrusions will not work - the sheets will not fit tightly to each other, forming cracks.

For leveling, a regular solution is suitable. You should take high-quality cement (grade M400 or higher) and sand in a ratio of 1:4. Having diluted them with water to the consistency of thick sour cream, the solution must be applied to the surface, eliminating all irregularities. If a very thick layer is needed for leveling, then the solution will have to be applied in several passes, giving each layer 2-3 days to dry. When applying a thick layer at a time, there is a high risk that it will simply slide off.

After completing the leveling, it is advisable to allow the solution not only to set, but also to dry completely - 28 days. But if this is not possible, you need to wait at least 10-14 days for most of the moisture to evaporate. Otherwise, in winter, the temperature of the foundation will drop below zero and the water will freeze, which contributes to the rapid destruction of concrete.

Insulating the foundation of a house with polystyrene foam - installation instructions and tips

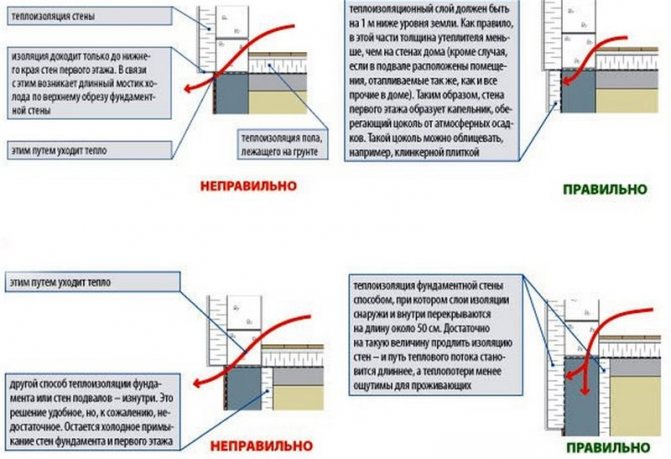

When planning the insulation of a private house, special attention is paid to the choice of technology. The material, the method of its installation and further surface treatment are carefully selected. However, along with the external walls and roof, little attention is paid to the foundation of the building, although it is often the cause of the main heat losses.

Why should you insulate?

In modern construction, the foundation not only serves as the basis of the entire building, but also must perform reliable heat and waterproofing functions. This is discussed at the design stage, when the following factors are taken into account:

- Seasonal temperature chart and soil freezing level.

- Amount of precipitation.

- Maximum height of groundwater rise.

All these indicators are taken into account when insulating the foundation and waterproofing it. However, if the house has already been built and the level of heat loss is high, it is necessary to insulate the building from the outside. Since about 20% of thermal energy is lost through the foundation, this issue should be approached carefully.

In a building, the foundation plays the role of a thermal barrier between the interior and the soil. The microclimate not only in the basement and basement rooms, but throughout the entire house will depend on the quality of its thermal insulation. For insulation, it is not enough to insulate the internal walls - this will not have much effect on heat retention.

Only a professionally planned set of measures will help create an effective thermal barrier. To do this, you should perform the following activities:

- Design a groundwater drainage system from the foundation. To do this, it is best to install a ring circuit of drainage pipes with water discharge outside the site.

- Make a storm drain on the roof of the house to prevent precipitation from entering the soil near the house.

- Insulate the base of the foundation.

For thermal insulation, you can use several types of materials, but polystyrene foam is often chosen.

Foam plastic is the best choice

The result is a rigid structure, which is characterized by elasticity and a low thermal conductivity coefficient - 0.045 W/m*C. But at the same time, foam plastic is weak to fracture. The main advantages of foam plastic over other thermal insulation materials are affordable cost, easy processing and ease of installation. Therefore, it is most often chosen as the main one for insulating the foundation. In addition, it will play the role of a damper between the foundation and the ground. If the latter consists of clay, then in combination with a high groundwater level, soil layers shift, which leads to destructive mechanical effects on the foundation.

Work order

It is best to plan the installation of foam plastic sheets in the summer season - by this time the soil will have completely dried out, groundwater will not interfere with excavation work. First, it is necessary to carry out preparatory activities.

A trench is dug around, the depth of which should be greater than the freezing level of the soil, but less than the total height of the foundation. The width can be different - it is necessary for comfortable work.

The next stage is waterproofing the wall surface. Most often, factory-made liquid bitumen mastic is used. Having pre-mixed the solution, carefully coat the foundation. After 5-6 days, you can begin installing the foam.

Next, the bottom is carefully compacted, leveled and covered with a sand cushion.

The thickness of the foam sheets is selected according to the climate zone, but cannot be less than 50 mm. Otherwise, the insulation efficiency will be low. For ease of installation, foam sheets are prepared in advance - cut according to optimal cutting.

Next, starting from the bottom of the wall, installation begins. It is possible to achieve an increase in thermophysical characteristics if the installation is carried out using liquid nails or special organic-based glue. The sheets are joined to each other, and the junction is treated with bitumen mastic and insulated with tape. After installing the sheets, the foundation is covered with sand and compacted.

This is a general description of the technology for insulating facades with foam plastic. There are several practical tips that can simplify the installation process and improve the performance properties of the insulating layer:

- It is recommended to install a soil drainage system before installing the foam.

- Instead of factory-made mastic for waterproofing, you can prepare it yourself. Bring construction bitumen to a viscous state and gradually add gasoline or diesel fuel. The proportion is 1 to 1.

- If you plan to install several layers of foam, then the joints of each of them should not coincide with each other.

The use of this technology will significantly reduce the cost of heating the house in winter and establish a comfortable temperature and humidity level in the basement. The main task in this case is to correctly calculate the optimal thickness of the thermal insulation layer and adhere to the installation technology.

Protecting the foundation from moisture

The next step will be to protect the foundation from moisture. Precipitation, groundwater - all this leads to the fact that with constant contact with wet soil, concrete will absorb moisture. As mentioned above, this can cause rapid destruction of the foundation. To prevent this from happening, you need high-quality waterproofing.

Some experts recommend using mastic - it reliably closes the pores of concrete, preventing moisture from entering. But working with it is not very convenient - you need to constantly heat the container, and application takes quite a lot of time.

Therefore, many people prefer to use waterproofing or construction polyethylene. The first is carefully melted with a gas burner, after which it is glued to a flat surface. The second is fixed using reliable solvent-free glue. In any case, waterproofing work should be carried out carefully. It is advisable to make an overlap of at least 10-15 centimeters. The edges of roofing felt are fused, while those of polyethylene are glued with wide tape.

Read more about do-it-yourself foundation waterproofing here.

How to insulate a foundation with polystyrene foam

Stages of work:

- preparation of the base. It must be cleaned of dirt and dust;

- purchase of polystyrene foam. When purchasing a material, you should take into account its density and layer thickness;

- waterproofing works;

- fixing the material to the underground part of the base. The slabs are secured using a special glue, which is applied around the perimeter of the slab and in the center. There is a pause of a minute, after which the slabs are firmly pressed to the foundation.

How to insulate a foundation with foam plastic? By analogy with the previous material, since there is no difference between them.

Let's start laying polystyrene foam

Only after this the insulation of the foundation of the house from the outside begins.

The process itself is not complicated and takes minimal time. But for this you need to carry out appropriate preparation.

Measure the height and width of the foundation, calculating the required number of whole sheets of insulation, as well as the optimal trimming of the corners and top ones. Soft polystyrene foam is easily cut with a hacksaw, and the edges can be trimmed with a knife. If there are no locking connections, make sure that the edges are as smooth and neat as possible - then it will be possible to install the thermal insulation without gaps.

Laying is done directly on the waterproofing layer. The sheets should be laid from bottom to top, starting from one of the selected corners. In this case, the insulation should protrude slightly from the edge in order to reliably close the corner.

When installing, it is advisable to use high-quality glue. You can also use dowels, but in this case the formation of cold bridges is inevitable, significantly reducing the thermal insulation properties of the insulation. In addition, they will damage the waterproofing material. And to secure it in a concrete foundation, you will need a powerful drill or even a hammer drill.

The laying technology is simple - the sheets are stacked one on top of the other in such a way that the gaps between them are minimal. Pay special attention to the corners. If you have to lay thin material in two layers, try to do it in such a way that the sheets of the second layer lie on the seams of the first.

Extruded polystyrene foam for facade insulation

It is quite difficult to insulate a house from the outside on your own, especially for a person without special education and prior experience. It is better to entrust the work to a team of professional specialists who can perform high-quality insulation and make the foundation more stable in the effects of low temperatures. Using expanded polystyrene, you can achieve the desired result with minimal costs, which is due to the affordable price of this material and the ease of its use.

High-quality polystyrene foam has a large number of advantages that set it apart from other insulation materials:

- Excellent thermal insulation properties.

- High level of compressive strength.

- Good moisture and frost resistance.

It is used in various fields to achieve set goals: insulation of many parts of the house, laying roads, in complex engineering structures. Insulating the foundation from the outside will be an excellent solution for those who want to retain the maximum amount of heat inside the house and achieve significant savings on utility bills. Insulating the outside of a house with polystyrene foam does not require much time and is one of the most cost-effective methods.

The use of this material will prevent the development of harmful fungi and mold. In this case, there is no need to apply additional measures aimed at protecting the slab from the negative effects of high humidity or sudden temperature changes. It is enough just to secure it correctly and accurately determine the optimal thickness.