Properties

The dry construction mixture consists of special cement, quartz sand of a certain granulometry, and patented active chemical additives.

- Peneplug blocks access to water within 40 seconds after application.

- The material expands upon contact with water, closing the leakage cavity.

- Peneplug is intended for short-term waterproofing and is not washed out by water.

- Suitable for underwater use.

- The material can be used in the cold season.

- It is characterized by a short setting time (40 seconds at the temperature of the added water +200C), and the ability to expand.

- Used in combination with Penecrit and Penetron materials.

- The material is environmentally friendly and radioactively safe.

- Approved for use in domestic and drinking water supply. Certified for use in construction.

Differences between penetrating materials and membrane materials ↑

A variety of technologies are used to waterproof building structures. There are many types of materials that are suitable for protecting concrete: roofing felt, Lysol, polymer resins and others. They all work on the same principle - they create a water-repellent film through which moisture does not seep.

Waterproof membranes are less effective than changing the structure of the material itself. Over time, they peel off and lose their properties. If the waterproofing work was not initially carried out carefully enough or the base was not properly prepared, the service life of such materials does not exceed several years.

Unlike conventional roll and coating waterproofing, penetrating compounds do not create surface films that cut off water. They impregnate concrete from the inside, working to strengthen its structure and change its properties. The resulting crystals are connected to the material at the molecular level, and their detachment is impossible.

Types of materials of the Penetron system

Instructions for use of Peneplag

Preparing the concrete surface before using Penetron system materials

Clean the concrete surface from dust, dirt, oil products, cement laitance, efflorescence, shotcrete, plaster layer, tiles, paint and other materials that prevent the penetration of active chemical components of the Penetron system materials.

Clean concrete surfaces using a high-pressure water jet or other suitable mechanical method (for example, a wire brush). Treat smooth and polished surfaces with a weak acid solution and rinse with water for an hour. Remove excess water formed on a horizontal surface after working with a high-pressure water jet unit using a special vacuum cleaner.

Pressure leak cavities (for working with Peneplug and Waterplug materials) should be cut using a jackhammer to a width of at least 25 mm and a depth of at least 50 mm with an expansion inward (if possible in the shape of a “dovetail”). Clean the internal leak cavity from loose, peeling concrete.

Preparation of Peneplag composition

Mix a handful of Peneplug dry mixture with water in the following proportion: 150 grams of water per 1 kg of Peneplug material (Waterplug), or 1 part water per 6 parts Peneplug material (5 parts Waterplug material) by volume. The optimal water temperature is +20º C. Depending on the activity of the leak, the proportions may vary. If the leak is severe, reduce the amount of water added to the mixture to the following proportion: 1 part water to 7 parts Peneplug material (6 parts Waterplug material) by volume. The type of prepared solution is “dry earth”. Prepare such an amount of solution that can be used within 30 seconds (for Peneplug material) and 2-3 minutes (for Waterplug material), since solutions set very quickly.

- A small leak needs to be expanded to dimensions of 20x20 mm in the shape of a “dovetail”. The wide part of the groove should be on the outside.

- If there is no water supply at the time of work, then the cavity must be moistened abundantly.

- The working composition of Peneplag is prepared in a ratio of 4:1 with the addition of water. A portion is prepared for one leak at a time.

- Peneplug is placed into the cavity in one step. The mixture is formed into a cone and placed into the cavity with a sharp edge.

- The cavity must be filled halfway with the material and pressed firmly for a minute.

- The effect of Peneplag lasts only for a short time, so the remaining part of the cavity must be filled with a long-acting waterproofing compound Penecrit.

- Finally, the leak is treated with a layer of Penetron.

Operating principle of the Penetron material

The action of the Penetron material is based on four main principles: osmosis

,

Brownian motion

,

reactions in the solid phase

and

surface tension forces of liquids

. The active chemical components of Penetron interact with the components of set concrete.

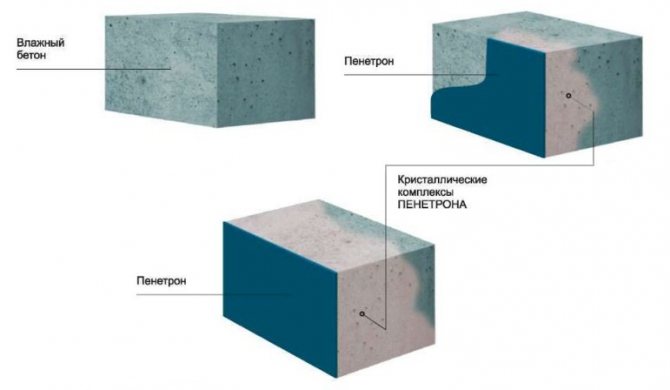

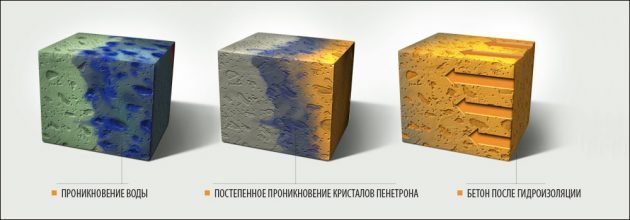

The dry Penetron mixture is mixed with water and the resulting solution is applied with a brush to the wet concrete surface. As a result, a high chemical potential is created on surfaces treated with Penetron solution, while the internal structure of concrete retains a low chemical potential. Osmosis tends to equalize the potential difference; osmotic pressure occurs. Due to the presence of osmotic pressure, the active chemical components of the material penetrate deep into the concrete. The higher the humidity of the concrete structure, the more effective the process of penetration of active chemical components deep into the concrete body. This process occurs under both positive and negative water pressure and continues until the chemical potential on the surface and inside the concrete is equalized. The penetration depth of active chemical components in a continuous front reaches several tens of centimeters.

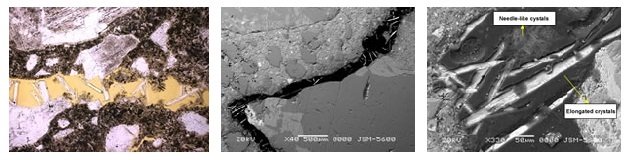

The active chemical components of the Penetron material, penetrating deep into the concrete body, dissolving in water, react with ionic complexes of calcium and aluminum, various oxides and metal salts contained in concrete. During these reactions, more complex salts are formed that can interact with water and create insoluble crystalline hydrates - formations in the form of needle-shaped, chaotically located crystals. The network of these crystals fills capillaries, microcracks and pores up to 0.4 mm wide. In this case, the crystals are an integral part of the concrete structure.

Microscope images show needle-shaped crystals filling a crack in the concrete body.

When water disappears, the process of crystal formation stops. When water appears (for example, with an increase in hydrostatic pressure), the process of crystal formation resumes, that is, concrete after treatment with the Penetron material acquires the ability to “self-heal”.

Consumption

Peneplug consumption is 1.9 kg/cubic dm.

Instructions for use of Penetron materials

Album of drawings for designers

You can find out the price and buy Peneplag in Moldova and Tiraspol in our store or by calling our contacts.

| Property | Index | |

| 1 | Appearance | Free-flowing gray powder without lumps or mechanical impurities |

| 2 | Humidity, %, by weight, no more | 0,6 |

| 3 | Setting time, min., beginning, not earlier | 1 |

| 4 | Setting time, min., end, no later | 4 |

| 5 | Bulk density in standard uncompacted state, kg/m3 | 1100±50 |

| 6 | Adhesion strength to concrete, MPa, not less | less than 2.0 |

| 7 | Material waterproof grade, W, no less | W16 |

| 8 | Compressive strength, MPa after 24 hours | 6,0 |

| 9 | Compressive strength, MPa after 7 days | 14,0 |

| 10 | Compressive strength, MPa after 28 days | 17,0 |

| 11 | Frost resistance grade of the material, cycles, no less | F400 |

| 12 | Ultraviolet | has no effect |

| 13 | Application: surface temperature, ° C, not less | +5 |

| 14 | Operating temperature, ° C | in accordance with concrete operating standards |

| 15 | Material storage conditions | in rooms of any humidity from -80 to +80 |

| 16 | Guaranteed shelf life of the material, months, not less | 18 |

Penecrit

Dry building mixture "Penecrite" refers to the Penetron system of penetrating waterproofing materials used for waterproofing prefabricated and monolithic concrete and reinforced concrete structures. Designed for waterproofing cracks, seams, joints, interfaces, abutments, and service entries in statically loaded prefabricated and monolithic concrete structures.

Description of the material "Penecrete"

Dry construction mixture consists of special cement, quartz sand of a certain granulometry, patented active chemical additives, used for waterproofing seams, joints, cracks, junctions in concrete TU 5745-001-77921756-2006.

Cracks, seams, joints, etc. are fined, moistened, and primed with Penetron solution. The fine is filled with Penecrit solution and treated with Penetron solution.

Purpose of the material "Penecrete"

"Penecrete" is used for waterproofing cracks, seams, joints, mates, abutments, and service entries in statically loaded prefabricated and monolithic concrete structures.

Penetcrete is a very plastic material, does not shrink and bonds well to concrete.

Peculiarities

“Penecrete” is characterized by high strength, no shrinkage, and has good adhesion to concrete, metal, brick and natural stone. Used in combination with Penetron.

The material is environmentally friendly and radioactively safe. Approved for use in domestic and drinking water supply. Certified for use in construction.

Areas of application of Penetron materials

Use Penecrit together with other materials of the Penteron system:

- for reliable waterproofing of wells made of prefabricated reinforced concrete rings,

- for waterproofing the foundations of buildings under construction, including waterproofing a house, waterproofing a cottage;

- for waterproofing communication inputs;

- for waterproofing tanks and reservoirs,

- for protection against exposure to water and aggressive environments of fire tanks

- for tanks for storing drinking water using liquid rubber;

- for waterproofing parking lots and parking lots;

- for waterproofing seams, including expansion joints;

- for waterproofing swimming pools and sports facilities;

- for waterproofing floor screeds.

Video instruction

Specifications

| No. | Material characteristics | Meaning | Measurement methods |

| 1. | Appearance | Free-flowing gray powder without lumps or mechanical impurities | TU 5745-001-77921756-2006 |

| 2. | Humidity, %, by weight, no more | 0,6 | TU 5745-001-77921756-2006 |

| 3. | Setting time, min: beginning, no earlier than end, no later | 40 90 | TU 5745-001-77921756-2006 |

| 4. | Bulk density in standard uncompacted state, kg/m³ | 1300±50 | TU 5745-001-77921756-2006 |

| 5. | Adhesion strength to concrete, MPa, not less | 2,0 | TU 5745-001-77921756-2006 |

| 6. | Compressive strength, MPa | TU 5745-001-77921756-2006 | |

| in 7 days in 28 days | 20,0 25,0 | ||

| 7. | Material waterproof grade, W, no less | W14 | TU 5745-001-77921756-2006 |

| 8. | Frost resistance grade of the material, F, no less | 400 | GOST 10060 |

| 9. | Ultraviolet | has no effect | Art. SEV 5852-86 |

| 10. | Applicability for drinking water tanks | allowed | Hygienic certificate TU 5745-001-77921756-2006 |

| 11. | Application: surface temperature, ° C, not less | +5 | TU 5745-001-77921756-2006 |

| 12. | Coating operating temperature, ° C | in accordance with concrete operating standards | TU 5745-001-77921756-2006 |

| 13. | Material storage conditions | In rooms of any humidity at temperatures from -80 to +80 | TU 5745-001-77921756-2006 |

| 14. | Guaranteed shelf life of the material, months, not less | 18 |

Operating principle of the Penecrit material

The action of the Penekrita material is based on the same principles as the action of other materials of the Penetron penetrating waterproofing system, namely the use of a special patented chemically active additive. The chemically active additive is soluble in water, but the product of its interaction with cement stone and further crystallization is insoluble in water. Dissolved in water, ions of a chemically active additive penetrate through micropores into the internal structure of concrete and crystallize there, as a result of chemical reactions, forming a reliable barrier to water. Let's look at the process using the example of using the Penetron dry mixture.

The active chemical components of the Penecrit material penetrate deep into the concrete. The penetration depth of active chemical components in a continuous front reaches several tens of centimeters, and in some cases can reach one meter. Chemically active components penetrate concrete regardless of the direction of water pressure, in other words, they can penetrate against the direction of water flow.

The network of these crystals fills capillaries, microcracks and pores up to 0.5 mm wide. In this case, the crystals are an integral part of the concrete structure.

Advantages of penetrating waterproofing Penetron:

- Penetrating waterproofing is not subject to mechanical wear, since the concrete itself has waterproofing properties.

- The service life of waterproofing is equal to the service life of concrete, and due to waterproofing of concrete, this period increases.

- There is no need to completely dry the concrete; Penetron materials are applied to a damp surface.

- Thanks to the penetrating properties of Penetron, a concrete structure can be processed from any side, in other words, when processing the foundation, there is no need to dig it out - Penetron applied from the inside will protect the concrete from water and from the outside.

- Penetrating waterproofing "Penetron" has unique properties of self-healing through cracks, pores and other defects that inevitably appear on any concrete structures during operation, with an opening of no more than 0.5 mm.

- Penetron does not affect the basic physical parameters of the concrete mixture: mobility, strength, setting time, etc., with the exception of water resistance. Concrete treated with Penetron retains vapor permeability and the concrete “breathes.”

- The cost of waterproofing work using Penetron materials is lower than when using traditional technologies.

Manufacturer's warranty

The Penetron waterproofing materials plant guarantees the compliance of Penetron system materials with Technical Specifications 5745-001-77921756-2006 “Penetron dry waterproofing dispersed systems mixtures”, as well as all modern standards. The Penetron waterproofing materials plant guarantees that the Penetron system materials contain all components in their appropriate proportions. The use of Penetron system materials must be carried out in strict accordance with the Technological Regulations for the use of penetrating waterproofing materials of the Penetron system.

Carrying out work on waterproofing concrete structures (instructions)

Download link

Technological regulations

Download link

Materials for design and working drawings of units

Download link

Technical specifications

To increase the effectiveness of using the Penetron Admix additive, you should study its technical characteristics presented in the following table.

| Appearance | gray powder, free of impurities, uniform consistency |

| Humidity | no more than 2.5% |

| Possibility of increasing the water resistance grade | no less than 4 points |

| Increasing the compressive strength of concrete | 10% |

| Increasing the frost resistance of concrete | for at least 100 freezing cycles |

| Resistance of the material to various acids | present |

| Resistance of concrete to alkalis | There is |

| Resistance of the treated material to the action of light and dark petroleum products | Present |

| UV resistance | Eat |

| Possibility of use for forming reservoirs for storing drinking water | Allowed |

| Acidity of the environment where the use of treated concrete is allowed | 3-11 pH |

| Operating temperature range | -60…+130°С |

| Storage requirements for Penetron Admixa | at temperatures -60…+50°С, at any humidity level |

| Shelf life of the material | 1.5 years |

Waterproofing technology

Before treating the surface, it is moistened, after which Penetron Admix is applied in two layers using a brush. Approximate consumption – 2 kg of powder per 1 sq. m.

Concrete after waterproofing with Penetron

Waterproofing brick walls

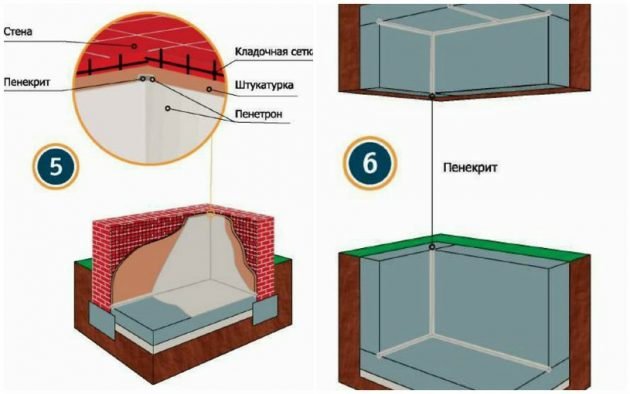

First, brick walls are plastered using masonry mesh (layer thickness 40 mm), after which they are treated with waterproofing. Mixture consumption – 800 g per 1 sq. m.

Waterproofing Penetron Admix on a brick wall

Caring for concrete after treatment

After applying waterproofing, the concrete surface is protected from sub-zero temperatures and mechanical influences for at least three days. The surface of the structure must remain wet at all times. To do this, it is constantly moistened with water and covered with plastic film, which prevents excessive evaporation of the liquid. The treated structure is allowed to be finished, which can be done after 28 days.

Caring for concrete after waterproofing

Related video: Penetron Admix

Publications on the topic

Plasticizers applicable for the production of cement mortar

Application of antifreeze additives in concrete

Technical parameters and application possibilities of M400 cement