Basalt wool is designed primarily to serve as insulation and retain heat in our homes in winter and keep cool in summer. The remarkable properties of the material allow it to be used on a large industrial scale, as well as in civil engineering. Basalt wool is widely used when carrying out work on thermal insulation of objects, and in addition serves as an excellent soundproofing tool.

Modern designers, when creating a new project, are very wary of new advertised building materials. This is due to past mistakes, when the construction complex sought to produce square meters in accordance with the tasks of the planned economy, without caring at all about the materials used, and without thinking about their impact on humans.

Recently, doctors have been sounding the alarm, expressing the opinion that the use of low-quality materials in the housing complex leads to asthma or, even worse, causes cancer problems. Particularly sensitive is the issue of using various heat-insulating materials; as a rule, they are covered with building structures and can affect us completely unnoticed.

Is basalt wool harmful to health?

Gaining enormous popularity as a heat and sound insulating material, we increasingly argue: is basalt wool harmful to human health or is its use absolutely harmless? The question is not an idle one, and our review is intended to understand how realistically the use of such material can be dangerous to human health.

City residents are increasingly thinking about the environmental safety of our living environment. Outside the windows of our homes, dozens of factories produce products, burning tons of gas and oil products, polluting the atmosphere with harmful substances. What can we say about the endlessly growing fleet of cars that undergo annual maintenance, but strangely leave behind clouds of black smoke exceeding all imaginable CO2 standards.

Nevertheless, all these harmful exhausts are carried somewhere into the distance by the wind, CO2 evaporates into the vast atmosphere and generally happens somewhere in the city with them, and not with us - our brain is lulled into a stream of consciousness. We worry much more about ourselves and our loved ones, we monitor proper nutrition, counting the numbers of preservatives on jars.

We are concerned about what the tiles, wallpaper, floors, and furniture in our home are made of. When planning the construction of a cottage or intending to carry out a long-planned renovation, we are increasingly taking a more responsible approach to the choice of noise and heat insulation materials. Understanding that we will have to live and come into contact with these substances for many years. For example, everyone knows that careless handling of glass wool leads to serious consequences, ranging from discomfort from needles to allergic reactions.

Here it’s probably worth taking a break and saying a few words about what this prickly material, familiar from childhood, is like.

Glass wool or basalt wool, which is better?

Glass wool is a fibrous mineral material. Nothing more than one of the types of mineral wool. In the production of glass wool, raw materials are used that are exactly the same as those that serve as a component of ordinary glass. Often recycled, collected material or waste from the glass industry is used. But wait, if this is a mineral material, then where is the danger, please explain to me, glass wool or basalt wool, which is better?

We know of three modifications of fibrous heat insulators made from mineral components:

- glass wool;

- basalt wool;

- slag.

If everything is clear with the first, there are no problems with the third either, it is made from molten blast furnace slag, and in fairness, we note that it is rarely found on construction markets, then I think it’s time to find out what the second is made of.

Basalt wool or mineral wool, which is better?

Basalt wool is an artificially produced, inorganic material. It is made by melting natural minerals and further forming them into a fibrous structure. Natural mineral - volcanic stone of basalt rock. That is why we can often hear the definition of mineral stone wool . Accordingly, the question of basalt wool or mineral wool, which is better, after finding out that they are the same thing, disappears by itself.

How dangerous is mineral wool?

How harmful is mineral wool to health? What is its danger? Many people have heard that mineral wool is harmful. But when it comes to insulating a house, right during work, the dangers of mineral wool are ignored.

They underestimate it and when placing this insulation, they put it anywhere.... On the other hand, many people are so afraid of mineral wool that they refuse to use it right away.

Let's look at the hazards that are present in mineral wool and insulating materials, and decide where and how best to use this heat insulator.

How is mineral wool produced?

Mineral wool can be made from various rocks. But mainly it is made from basalt and blast furnace slag. The exact composition of mineral wool fibers is usually not disclosed.

The inclusion of blast furnace slag significantly reduces the cost of production. Because of this, cotton wool contains impurities of iron and other metals. Therefore, the melting point of stone wool often drops to 800 degrees C.

Mineral wool is a popular building material; its mass production is established in many countries. It is mainly used as insulation.

Stone fibers are bought from large manufacturers by many small companies, which create insulation boards with special properties from them, for example, dense and strong mats, foil insulation, strapping materials, low-density rolls...

How microfibers bind

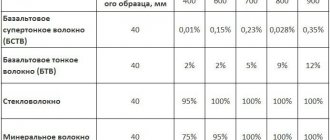

The connection between stone fibers in the insulation is achieved by adding phenol-formaldehyde or melamine-formaldehyde resin. Mineral wool constantly releases a dangerous substance - formaldehyde. The stone fibers themselves can be of different sizes. Including the microscopic one. And in this way, stone wool is similar to asbestos, which is banned in many countries due to the great danger to human health. Also, due to the presence of asbestos in the composition, slate is also prohibited.

How dangerous are the fibers and formaldehyde in mineral wool?

What dangers do microfibers pose?

Scientists believe that asbestos causes cancer. It contains a lot of fibers with micron sizes - 2 - 5 microns and less. They are dangerous carcinogens and affect the cells of the respiratory organs. At the same time, a person does not feel anything, but over time they cause cancer.

Scientists believe that there are much fewer microscopic fibers in mineral wool than in asbestos. Therefore, she is not so dangerous. These are precisely the statements that can be found about mineral wool.

Its production and use are not prohibited in any countries. You can find out what is the difference between ecowool and how it is used

How to provide protection against fibers

No one denies the presence of danger in mineral wool in the form of microfibers. But it is impossible to stop production and prevent the use of the heat insulator for economic reasons, such statements can be heard from management officials.

There are restrictions on the use of mineral wool.

Its use is not recommended without special protective sheaths designed to prevent contamination of the environment by fibers that are carried in the air.

There are usual recommendations for use - do not use this insulation indoors in an open form, and also use it outside only in protective shells or in the form of a too dense mat that cannot be blown through with a stream of air.

The usual area of application is outside the premises under a vapor-permeable membrane in the “ventilated facade” system, or under a layer of plaster in the “wet facade” system. In the roof and floors, but closed from the living space with waterproofing membranes. How to insulate walls with mineral wool - read on the website.

Formaldehyde is a dangerous substance

Formaldehyde in high concentrations is poisonous. But it is constantly present in small quantities in the air; somewhat larger concentrations are almost always found indoors.

Formaldehyde resins are used to produce plywood, and it is used to make furniture. In the home, there are usually sources of formaldehyde - wood wardrobes, for example.

Scientists state the maximum permissible concentration of this substance in the air is 0.05 milligrams per cubic meter.

How much formaldehyde is released from cotton wool?

It is believed that one square meter of mineral wool surface releases 0.02 milligrams of formaldehyde per hour.

If the air exchange in the room is 30% per hour, even with maximum use of mineral wool, the accumulation of dangerous concentrations will not occur, there are such statements.

But since the sources of this substance complement each other, the presence of one more is not desirable.

Lack of ventilation (air exchange) in a home is dangerous.

Thus, due to the “formaldehyde” factor, it is recommended to use mineral wool only outside residential premises, or to divert the ventilation stream outside, which ventilates the insulation layer. For example, underground air ventilates the insulation layer through vents. How to insulate floors with mineral wool

Conclusions about the dangers of mineral wool

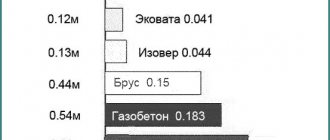

Scientists' conclusions about the dangers of mineral wool boil down to the fact that it is advisable to prevent its use indoors. It should be used only on a stream of air going out, and only in a sealed shell that prevents the spread of fibers, or in tightly glued versions (density more than 80 - 120 kg/m3, for different wind zones).

As you can see, the use of mineral wool insulation in construction is mainly carried out in accordance with these recommendations. The use of mineral wool for insulating roofs and ceilings is always accompanied by the installation of a vapor barrier on the side of the home.

With reverse partial pressure in summer, the penetration of air from the dangerous insulation into the building is blocked by this vapor barrier, or is hampered by the walls of the building when the material is located outside on the wall. Additional information about the use of mineral wool for roof insulation

Basalt wool - how do they do it?

The technology for making fiber from stone is “borrowed” from Mother Nature. One day, on the Hawaiian Islands, researchers found strange fibers, which later became known as “Pele’s Hair.” In honor of the beautiful girl Pele, the goddess of fire among the ancient settlers. Fibrous materials were produced as a result of volcanic eruptions. The formations resembled cotton wool made from thin threads of volcanic rocks. It was they who became the “progenitors” of modern heat-insulating material.

For the first time, such a substance was prepared artificially from rocks in 1897. in the United States of America. The production of basalt wool is not far removed from the natural work of the volcano, and to this day is based on the same principle. The rock is heated in furnaces to 1500 °C. As a result, a fiery liquid molten substance is formed, from which the threads that serve as the basis of fibrous wool are drawn.

Okay, we figured it out, all materials are mineral, although they are obtained artificially. What is the difference between glass wool and stone wool? Does using these materials mean we are at risk? Or are there differences? And the most incomprehensible thing is, if the material is mineral, then why is basalt wool harmful to health? What is this, speculation or rumors?

We found out that igneous rocks serve as raw materials. By the way, both dormant and active volcanoes can boast large deposits of basalt. Foreign - Etna and Vesuvius. In Russia - the Kamchatka and Kuril Mountains. These minerals and their derivatives, cotton wool, are truly harmless. But formaldehyde resin is used to bind the fibers together. It is this that contains phenols.

Characteristics of basalt wool

First of all, let's find out what this material consists of. It includes a base (fibers obtained from molten basalt). This rock is an absolutely safe raw material, which has found application not only in construction, but also in medicine. Binding components, which are resins, and special impregnations are added to the base, improving the following qualities of the material:

- durability;

- low thermal conductivity;

- fire resistance;

- safety of use;

- sound insulation and others.

However, among all types of basalt wool, there are also those that are produced without following technology. As a rule, these are cheap materials that do not meet quality standards. They can be dangerous for the consumer.

Basalt wool phenol formaldehyde

Phenol production in the world amounts to more than 10 million tons/year. Phenol is considered one of the strongest industrial pollutants. Phenol is a toxic substance dangerous to animals and humans. Phenol is very difficult to undergo even biological purification. With all this, it serves as an indispensable component in the production of phenol-formaldehyde and epoxy resins, widely used in construction and everyday life.

It is phenol, being exposed to the destructive effects of drafts, precipitation moisture and temperature changes, that negatively affects the physical condition of a person. Of course, the fibrous structure also makes its contribution: when exposed to certain factors, cotton wool contributes to the formation of fine and sharp dust, which in turn negatively affects our lungs and mucous organs during breathing.

The best basalt wool

Now that we have identified the main “enemy,” everything falls into place. It turns out that the matter is not in the material, but in the absolutely precise ratio of components and following the established technological process. And the question of what is the best basalt wool can be answered with confidence - the one that was produced in compliance with the technological chain and complies with quality certificates.

In this case, the main rule for purchasing material is to carefully check the origin of the product. Any product has maximum permissible standards for the content of harmful substances, so do not be afraid to use basalt wool where they are not exceeded. The main well-known manufacturers today:

- Rockwool (Rockwool Scandic thickness 50mm, Rockwool Light Butts thickness 50mm), light butts 1000x600x50 mm

- TechnoNIKOL Rocklight thickness 50mm, Technolight extra 1200x600x100 mm

- Paroc thickness 50mm

- Isover thickness 50mm

- Knauf thickness 50mm

- Ursa thickness 50mm

- IZOVOL thickness 50mm

- Beltep thickness 50mm

- BASWOOL thickness 50mm

Basalt wool characteristics

A few words about the characteristics of the volcanic rock basalt. In the future, this will help to get a better picture of the remarkable properties of mineral wool produced from its raw materials:

- Hardness on the Mohs scale from 5 to 7

- rock density 2.60 - 3.10 g/cm3

- specific gravity 2.6-3.11 g/cm3

- specific heat capacity 0.84 J/kg•K at 0°C

- abrasion 1-20 kg/m²

- rock melting from 1100-1250°C

- The compressive strength of rock stone reaches 400 MPa

Production of crushed stone, production of basalt wool, stone casting, paving slabs, paving stones, decorative facing elements, concrete mix filler, this is not a complete list of magma uses. Building materials made from basalt have become widespread and have gained immense popularity.

What is the difference between glass wool and stone wool?

Let’s go back and clarify again: what is the difference between glass wool and stone wool, if these are two similar mineral materials? In the first case, the source is glass, in the second, stone. The difference, as they say, is obvious. In addition, in glass wool, the fiber particles are longer and more likely to break off and end up on the skin and in the human respiratory tract.

Basalt wool has a shorter fiber length; they are interconnected randomly and break less. The structure is more dense with high strength, with less shrinkage, holds its shape well and does not crumble.

Common myths about stone wool

Fibers enter the lungs and harm health

Basalt fibers should not be confused with glass wool, which has a lower density - its fibers are easily separated and can penetrate into the human lungs. Basalt wool is denser and stronger, so its fibers cannot enter the respiratory system.

Harmful substances enter the atmosphere

Production is carried out using resins, so many are confident that they release formaldehyde into the environment. However, the resin undergoes special processing, and its amount in cotton wool is no more than 2-3 percent. Accordingly, it practically does not get into the air. And some manufacturers have completely abandoned the use of resins and produce absolutely environmentally friendly materials based on basalt fibers (Basfiber is one of them).

The material is dangerous during installation

It is believed that this material can cause allergic skin reactions and a negative reaction if it comes into contact with the eyes or mouth. This myth is again associated with the well-known glass wool and with those who continue to confuse these two materials. Glass wool can cause severe irritation and allergies, unlike high-quality basalt wool. Moreover, when laying wool, builders follow safety regulations, working in respirators, gloves and goggles.

The cotton wool becomes damp and mold grows in it

According to the latest myth, basalt fibers quickly accumulate moisture and serve as a breeding ground for fungus and mold. In fact, many manufacturers treat their products with water-repellent impregnations. And even at high humidity, their moisture absorption level is only a few percent of the total volume. In addition, an antiseptic is added to the composition of a high-quality product, which prevents the appearance of microorganisms.

Basalt wool application

German designers from EDAG have developed a concept car

, basalt fiber was used in the production of the body. According to experts, the material turned out to be light, durable and environmentally friendly, and most importantly, it is cheaper than aluminum and even carbon-plastic.

Mineral wool, which is based on basalt threads, acquires truly irreplaceable qualities: the wool is porous, temperature-resistant, excellent vapor permeability and neutral to chemical environments.

Properties

- basalt wool has a porous composition, the pores reach 70% by volume, often even more. When the pores are filled with air, wool is characterized by low thermal conductivity.

- temperature resistance is considered almost the most basic indicator of heat-insulating materials; this is of great importance in the thermal insulation of equipment used in industry. Operation of which often occurs during elevated temperature conditions. Temperature resistance is determined by the temperature at which the material is exposed, without changing its technical parameters.

- Vapor permeability - there is a good microclimate in the home and it is easy to breathe when the material allows water vapor molecules to pass through the pores. As we mentioned, basalt wool is a tangle of interconnected pores. They do not trap air or steam. Vapor permeability allows the cotton wool to always remain dry.

- basalt wool is neutral to oils, solvents and other organic compounds. Alkalis and acids also do not have a destructive effect, which indicates the high chemical resistance of cotton wool.

Thanks to its remarkable properties, the scope of application of basalt wool is constantly expanding and is finding wider application each time:

- heat and sound insulation;

- basalt wool for the chimney;

- fire protection in civil and industrial facilities;

- for a bath, for a sauna, for a change house;

- thermal insulation of power machines, pipelines;

- as a means of insulation in public catering: gas, electric stoves, frying ovens;

- insulation during the reconstruction of buildings, in work with flat roofs;

- insulation of high and low temperature mechanisms;

- interlayers for household and industrial refrigerators;

- in multilayer sandwich panels during the construction of light buildings

Is mineral wool dangerous as insulation?

Mineral wool: how dangerous is this insulation to health? According to a number of experts, one of the most harmful building materials is mineral wool. Mineral wool is used for heat and sound insulation of residential premises everywhere. Some experts believe that the components included in its composition - mineral fibers, resins that bind them, which reduce the moisture absorption of the impregnation - cause serious diseases of the respiratory tract, eyes, and skin in people. The Association of Russian Thermal Insulation Manufacturers insists on the safety of its products. Builders, however, continue to use this thermal insulation material, which causes so much controversy. And officials don’t even try to figure out whether residents of mineral wool houses are endangering their health.

Today, the main share of the domestic market of thermal insulation materials is occupied by producers of mineral

cotton wool. Mineral wool, especially slabs and sandwich panels based on it, are quite popular insulation in Russia. Where to buy mineral wool? Anywhere. Mineral wool is sold on any construction market, including on specialized websites on the Internet. Mineral wool is used for insulating pipes, utility rooms or houses from almost all sides: for insulating the walls of a house (outside and inside), facades, ceilings, attics, attics, loggias, as well as for sound insulation and noise insulation.

At the moment, you can buy mineral wool from various manufacturers on the Russian market. There are many of them, including Russian and Ukrainian factories; mineral wool production is established in Zheleznodorozhny, Kstovo, Kharkov and other cities. There are different types of mineral wool: foil, that is, with foil, acoustic mineral wool, in addition, various products made from it - pierced mats, thermal insulation cords, sandwich panels, slabs, cylinders, it is also sold in rolls (rolled), etc. Mineral wool is produced in different sizes and densities.

However, many foreign and Russian construction companies refuse to insulate their facilities with mineral wool. Firstly, due to the widespread and cheaper prices of competing insulation materials (silicate fiber, expanded polystyrene foam, polyurethane foam, polyethylene foam, etc., as well as insulation based on plant raw materials), and secondly, because of the harm, in their opinion damage caused by mineral wool to the environment and human health.

Is mineral wool the scent of death?

People began to argue and write about the dangers to human health and the environment from mineral wool relatively recently. Previously, it was believed that mineral wool as insulation was completely safe, environmentally friendly and non-flammable. And these qualities compensated for the fact that the price of mineral wool is higher than that of some other thermal insulation materials. But now a number of ecologists, doctors, and builders have begun to argue that the safety of mineral wool is, to put it mildly, exaggerated. In their opinion, the fibers contain carcinogenic components, and the binding material is phenol-formaldehyde or melamine-formaldehyde resin, which releases free formaldehyde, as well as phenol - highly toxic substances, in fact, are poisons for the human body.

Manufacturers of mineral wool, for their part, claim: the phenol-formaldehyde binder used in the technological process is found in mineral wool in small quantities and in the so-called bound, polymerized state, which does not pose a threat to humans if the established rules of installation and use are observed. Confirmation of this, they say, are the current SEZ certificates and other environmental certificates obtained after testing materials in Rospotrebnadzor and other regulatory organizations.

However, the head of Rospotrebnadzor, Gennady Onishchenko, is very wary of mineral wool insulation. “All the requirements that apply to it must be applied to mineral wool. If elementary technology is violated during its manufacture and construction regulations are violated, then the use of such materials can lead to very serious health consequences,” Onishchenko said in an interview with Nezavisimaya Gazeta. – A person moves to a new apartment, he gets headaches, his blood pressure goes up, he can’t find a place for himself. When we start checking, we find many violations of technology in the finishing materials - the release of the same formaldehydes. It comes to the point that we give orders to tear everything off and redo it again. But this is when the person complained. But most don’t complain.”

According to doctors, phenol is very quickly absorbed into even intact areas of the skin of the human body. Almost immediately after the substance enters the body, phenol begins to affect the brain, causing short-term excitement, and possibly paralysis of the respiratory center. Even tiny shares of this component cause a person to cough, headache, nausea, and loss of strength. More serious poisoning can lead to fainting, corneal insensitivity, seizures, and cancer. People who live for a long time near a source of phenol may have children with physical and mental disabilities.

As for formaldehyde, according to a number of experts citing ongoing research, some mineral wool samples can emit up to 0.02 mg of this component per square meter of slab surface per hour. Taking into account the fact that in a residential area there are quite a lot of other sources of this highly toxic substance (chipboards, plywood, etc.), as well as taking into account its supply from street air, the maximum permissible concentration (0.05 mg/m³) of formaldehyde can be exceeded in repeatedly.

“Phenols, dirt, dust strike the microecology of the human body, destroying beneficial microorganisms. The biocenosis is disrupted, and as a result, numerous inflammatory processes occur, says Evgeniy Zharov, Doctor of Medical Sciences, professor, gynecologist, specialist in reproductive health, leading researcher at the Central Clinical Hospital of the Russian Academy of Sciences. “As a result, 20% of married couples in the country are infertile, 10-15% of births are premature, the number of defects in newborns and perinatal mortality are growing.”

Ecologists who carried out an examination in the Moscow region, next to a plant owned by a large well-known company, say: the smell emitted by the enterprise is pungent and unpleasant. And their measurements of soil and air showed a high concentration of toxic phenol. According to them, in some varieties of mineral wool, especially cheap ones, you can clearly smell a vile and poisonous aroma, reminiscent of ammonia.

By the way, at factories producing mineral wool, workers are required to undergo regular medical examinations, primarily from an otolaryngologist, dermatologist, pulmonologist, and ophthalmologist. Most often, workers who neglect safety measures develop diseases of the skin (dermatitis) and the anterior part of the eyes, and lesions of the upper respiratory tract (rhinitis, pharyngitis, laryngitis). In the USA and Europe, a study was conducted of mortality among workers at mineral wool and fiberglass production plants. Some researchers have allegedly identified an increasing trend in the incidence of lung cancer: the longer a person has worked in mineral wool production, the higher the likelihood of getting this incurable disease.

We asked Dmitry Vinogradov, pulmonologist, associate professor at Moscow State Medical University, to comment on these results. Sechenov - in his opinion, there is an established connection between cancer and large doses of phenol absorbed into the human body.

“Microparticles released during the aging and destruction of mineral wool settle in the lungs and are allergens leading to the formation of dermatoses, obstructive and chronic bronchitis, bronchial asthma and other diseases. Recent studies confirm that the development of cancer is also possible,” says Vinogradov.

And does not sink in water, and does not burn in fire?

Doctors believe that mineral wool poses a particular threat to the human respiratory system: fiber dust, entering the lungs and lingering there, can cause various diseases. It all depends on the size and shape of the fibers. In their opinion, particles less than 3 microns thick and more than 5 microns long are the most dangerous. By the way, this applies not only to mineral wool, but also to asbestos fiber, and to a lesser extent, fiberglass - sources of tiny particles that enter the respiratory tract and are not pushed back out by the flow of exhaled air.

The situation is aggravated by the fact that mineral wool has increased moisture absorption compared to most alternative insulation materials. If you use this material in areas of high humidity and significant temperature changes, the thermal insulation efficiency of mineral wool is reduced. After two or three seasons - severe wetting, freezing, drying - the fibers break and turn into dust, blown by the winds both inside and outside the room. For example, according to some estimates, from a nine-story building of series 90 with an insulation area of up to 1500 m², over 25 conventional years of operation, air flows will remove approximately 1875 kg of fibrous dust from under the cladding.

If this statement is true, then this not only increases the thermal conductivity of mineral wool, but can also contribute to increased carcinogenic effects on the environment. According to recent studies, the results of which are publicly available on the Internet, with long-term use of slabs, mats, sandwich panels made of mineral wool with a density of 74 kg/m³, thermal conductivity increases by 2.8 times, with a density of 156 kg/m³ - by 1.9 times. And blowing wind at a speed of up to 0.7 m/sec increases the thermal conductivity of mineral wool by 60%. Accordingly, the weight of mineral wool decreases. Thus, the thermal conductivity coefficient of mineral wool depends on its service life.

Opinions are often heard that the listed properties and characteristics of mineral wool also lead to the formation of a favorable environment for rodents, mold, fungi, and putrefactive bacteria inside the walls. People living in rooms near such outbreaks may experience suffocation, coughing, and allergies.

Mineral wool manufacturers claim that their products are non-flammable (the mineral fibers that make up the insulating material do not burn) and are therefore safe. Opponents of mineral wool are sure that this is, to put it mildly, cunning (after all, the slabs use binders - highly flammable formaldehyde resins). Also, we should not forget that when producing slabs, mats and sandwich panels, various organic additives are used to reduce the moisture absorption of the material, which can increase the fire hazard of the material. Moreover, the fire is ignited by oxygen flows penetrating between the fibers to the source of ignition. Witnesses of such fires claim that glass wool and mineral wool burn like straw, creating such a high temperature that the jets of water from the fire brigade evaporate into the air without reaching the fire. We plan to conduct experiments on the flammability of some materials in the near future and present the results to the reader.

Should we sound the alarm about mineral wool?

On the one hand, in our country there are very few adults and completely healthy people who have never lived in rooms insulated with insulating materials based on mineral fibers. However, people familiar with the situation say the dangers of mineral wool used as insulation in residential and office buildings are a major concern in Western countries. Workers dealing with this insulation are required by safety regulations to use sealed protective clothing, including respirators, goggles and gloves. Many foreign environmentalists are strongly in favor of banning the production and use of hazardous building materials altogether.

In Russia, this problem is discussed little, and some time ago they were completely silent about it. Even today, any openly published material questioning the absolute benefits of any widely used product causes severe opposition from manufacturers. Government authorities consider demands to ban the widespread use of mineral wool as a heat insulator to be too exaggerated and unfounded. Officials only recommend not to use mineral wool in its free form - in order to avoid environmental pollution with chemical fibers. Mineral wool manufacturers claim that their products are absolutely harmless. Some doctors, ecologists, and leaders of public organizations are sounding the alarm, considering mineral wool a potentially carcinogenic material. But, for example, despite the proven harm to health from tobacco products - cigarettes are still officially permitted for sale and use, so any other product that has someone’s financial benefit behind it is very unlikely to be fair and unbiased in the near future studied or its use is limited by law.

It is difficult to say who is right in this dispute until large-scale, independent, competent research is carried out and the results of which are made public. Such research is needed. They could either reassure those who have already insulated their homes with mineral wool. Or bring a lot of problems to those who produce this material.

Basalt wool without phenol and formaldehyde

The buyer wants to receive basalt insulation completely free of phenol and formaldehyde. The production of mineral wool, unfortunately, cannot yet abandon synthetic resins, which are an integral binder. But science does not stand still, and today the introduction of new technologies helps to completely neutralize harmful phenol.

Increasingly, manufacturers are using mineral and biopolymer binders, which, although leading to higher prices for products, are in high demand among the literate population. Producing cotton wool without any violations does not cause harm to health or the environment. Such binders do not pose any danger. A certificate or sanitary-epidemiological report will help you find out the composition of the binder.

Never buy homemade stone wool. The savings will be insignificant, and your physical condition may deteriorate irreparably. When purchasing cotton wool, choose factory companies with a good reputation. Choose trusted stores; a good solution would be to buy basalt wool in Leroy Merlin.

Study the product certificate. In Rus' there is a saying: “You can’t buy health,” but you must admit, you can buy a product that is not harmful to health! Once you are convinced of the quality, make a purchase, insulate the house, in this case basalt wool will last a long time and will maintain comfort and coziness in your home. Watch the video about which insulation is better:

Myth No. 1. Toxic substances in the environment

Excellent thermal insulation, excellent sound insulation properties, effective fire protection. Such attractive properties make mineral wool popular. But today it is customary to care not only about the comfort of household members, but also about the environment in general. Every conscious person thinks about the impact that the materials used when building a house or renovating an apartment will have on the environment.

The binders in mineral wool are phenolic resins, which can release toxic substances. Phenol when ingested:

111

- affects the brain, provoking short-term excitement and subsequent loss of strength;

- provokes headaches;

- causes coughing and other problems in the respiratory system, including respiratory arrest;

- promotes attacks of nausea and vomiting;

- leads to convulsions, fainting, damage to the cornea of the eyes, surges in blood pressure;

- causes the growth of malignant tumors;

- may cause the birth of children with mental or physical retardation.

But their mass fraction of phenol in the material is so small (1-2%) that in order to cause damage to health, you need to try hard. However, manufacturers take into account the opinions of their customers who fear that the material is harmful. Poisonous binders are not only contained in cotton wool in negligible quantities, but also remain in a polymerized state, which does not pose a danger to human health. Today they have begun to produce mineral wool, which instead of phenol contains completely safe and environmentally friendly bitumen.

The second thing that opponents of using mineral wool for insulation are afraid of is formaldehyde, the permissible concentration of which per 1 cubic meter should not exceed 0.05 mg. Low-quality basalt insulation or glass wool can produce up to 0.02 mg of formaldehyde per square meter of insulated surface per hour. In addition, this poison is released by many finishing materials and furniture. This can lead to oversaturation of the air with poison, which can lead to irreversible damage in the human body, for example, cause infertility.

“Phenol-free” mineral wool from Knauf