Wood briquettes: varieties

Fuel briquettes, familiar to consumers as “Eurowood”, are a solid fuel product that is produced using a press, sawdust and other natural materials under high pressure. Connects its constituent parts with lignin, which is found in plant crops. Thus, when creating briquettes, neither adhesive nor any other chemicals are used that could harm the environment.

There are 2 types of Euro firewood, but they do not differ significantly:

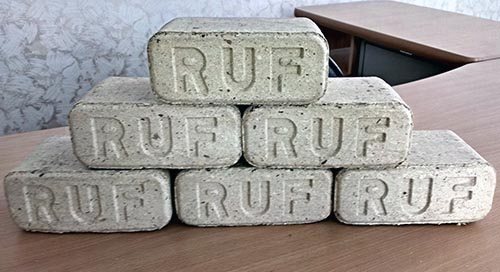

- Fuel briquettes RUF. They are created using a technology that has already been described: pressed wood chips and sawdust, held together with a natural adhesive. Euro firewood RUF has a rectangular shape. This is an excellent solution, because such fuel is cheap, but the cost does not affect the quality at all.

- Fuel briquettes Pini-kei long burning. They are created using the same technology, but at the last stage the briquettes are necessarily fired. Thanks to firing, briquettes of this variety become moisture resistant, which ensures their long-term storage. Because of this property, the cost of such fuel is higher. The price for 1 ton is approximately 2000 rubles. Outwardly, Pini-Kay is not similar to RUF: these Euro-firewood have a shape similar to a standard log, which has a through hole.

An alternative to the above briquettes is Euro firewood Nestro from the best German company. You can purchase fuel in retail hypermarkets, for example, OBI.

Advantages and disadvantages

Not everyone is familiar with the advantages and disadvantages of peat briquettes and the rules for their use. Positive characteristics of peat fuel:

- It is environmentally friendly.

- Suitable for any type of stoves operating on solid fuel.

- It flares up quickly, there is no strong smoke.

- During combustion, less soot and soot are formed. Chimneys do not need frequent cleaning.

- No sparks are formed and no toxic substances are released.

- Maintain a comfortable temperature for ten hours.

- They have good heat dissipation. It is slightly worse than that of firewood, but higher than that of coal.

- Economical. During combustion, some ash remains (approximately 1% of the volume of each block).

- Ash can be used as phosphorus and lime fertilizer.

- Production is located directly at the site where raw materials are extracted. This allows you to save money on transportation and other stages.

- Briquettes are light in weight and have the correct shape. They are easy to transport, store and use. There is no need to saw, chop and dry firewood.

- Less space is required for storage. There is no need to create special conditions; it is enough to protect the fuel from moisture by building a canopy. Humidity should be no more than 80%.

- Pressed peat does not absorb much moisture and remains flammable during long-term storage.

- The material has an acceptable cost.

- Fuel is sold in kilograms, not cubic meters. You can buy only the quantity you need at any time.

- Natural peat reserves are replenished independently.

Good to know: soot cleaner for chimneys.

Peat fuel has a significant drawback. The raw material is highly flammable, you need to be careful when storing it.

Fuel briquettes made from peat can be used for heating in a country house, country house, veranda, summer kitchen, bathhouse, sauna, greenhouse, winter garden, utility buildings, lodges, trailers, warehouses. They can light a fireplace and use it in fuel boilers, or light a barbecue.

Which is better: fuel briquettes or firewood?

Wood briquettes, like any other product, have both their pros and cons. What is the best and most profitable way to heat, what kind of firewood should I buy?

Compared to firewood, briquettes have the following advantages:

- They do not burn out quickly, 4 times slower than regular logs, which makes it possible to consume them in small quantities.

- They burn almost to ash, leaving behind no more than a percent of the original mass of fuel. But after burning the logs, coal remains, which is approximately 20% of the initial amount of fuel. By the way, ash from briquettes that have burned out can be used as fertilizer in the country: plant crops on such soil will grow better due to the increased amount of K.

- The heat transfer of briquettes is several times greater than that of firewood: the difference is 2 times. Euro firewood can keep warm throughout the entire burning time. That is, if for traditional logs the heating power decreases as they burn, and the coals go out in a quarter of an hour, then for fuel briquettes the heat transfer does not change even when only coals remain from the Euro-firewood, which will burn for another 60 minutes. This quality is extremely useful for those who love outdoor recreation, with barbecue and shish kebab.

- The fire from burning Eurowood does not spark and produces almost no smoke or smell. Thus, briquettes are harmful to the environment and do not create discomfort for people who are near the fireplace.

- When Euro fuel burns, it does not emit substances hazardous to human health. The fact is that standard logs contain fungi/mold, which die during combustion, but create smoke harmful to humans.

- If you ignite long-burning fuel, soot will not form on the walls of the chimney.

- The compactness of Euro firewood makes it possible to save on space: they are supplied in the form of neatly stacked stacks. They are long burning. Firewood almost always comes in different shapes and sizes, which creates a storage problem. In addition, the firewood is usually “dumped” out of the car onto any unoccupied space on the site, after which the person must independently carry it into the barn and carefully place it there.

In general, all the advantages of Euro-firewood fit into one word: efficiency. Yes, such wood fuel is cheaper and more practical. It makes sense for them to replace regular firewood. And the efficiency of Euro-firewood is higher. Also, one cannot help but mention several more advantages that distinguish Euro-firewood from ordinary ones. For example, one of the advantages is that there is little waste. Regular logs produce a large amount of wood chips and other debris. Briquettes do not stain the room. But does this mean that European firewood is definitely better than firewood?

Types of briquettes

Three types can be distinguished depending on the components of the briquettes:

- woody;

- peat;

- coal.

They all have their own features and characteristics. Let's look at each of them in more detail.

Wood briquettes

They are waste from the wood processing industry. Initially, the raw material is heated and then pressed. The materials can be: sawdust, straw, husks, as well as tree bark and dust. When pressing, high pressure is applied to the chips, causing the wood to release a sticky substance - lignin. Once this composition has completely hardened, the briquette for the stove or fireplace will no longer lose its shape. They are made exclusively from natural materials, so they do not cause any harm to humans.

Wood briquettes in the form of RUF bricks. They are easy to use and environmentally friendly. They don't require much storage space

Advice! Briquettes are more economical to use than firewood, since their humidity is only 10%, while for wood this figure is higher. When burning briquettes, 4400 kcal/kg is released, and wood, in turn, releases a maximum of 3900.

Properties of briquettes made from wood materials:

- efficiency;

- environmental friendliness;

- safety (there are no sparks or crackles from them);

- minimal smoke formation;

- heat transfer to the room for several hours;

- can be used for cooking;

- the carbon monoxide level is several times lower than when using firewood;

- convenient shape allows them to be stacked compactly;

- universal. Suitable not only for stoves, fireplaces and boilers, but also for making a fire outdoors;

- easy to control spending.

Read the article about the calorific value of firewood in addition to this material.

Cylindrical wood briquettes are the cheapest option. The downside is that they are fragile

Briquettes are also called eco-firewood. They deserve it for the following:

- the problem of waste disposal during their production is solved. Every woodworking enterprise around its machines and buildings is replete with sawdust, shavings and other waste. The production of briquettes is carried out precisely from them, therefore, by removing them and putting them in the right direction, the issue of environmental pollution is resolved;

- allow to reduce the volume of harmful emissions. This is due to minimizing the emission of carbon monoxide into the atmosphere;

- serve as fertilizer for the earth. After they burn completely, ash is formed, which is a good fertilizer for the vegetation on the site.

Manufacturers offer the following types of wood briquettes, varying in shape and method of their production:

- Made in the form of a rectangle or brick. They were first released by a German company. Their manufacture requires a hydraulic press that creates a pressure of three hundred to four hundred bar.

- The briquette is cylindrical. It can be made with or without a hole in the center. To create it, either a mechanical shock or, as in the first case, a hydraulic press is used. The briquette must be subjected to a pressure of four hundred to six hundred bar.

Brown tetrahedral wood briquettes with a hole in the center. The color changed after heat treatment - firing. They are practical and last a long time

- Four- and hexagonal briquettes with a hole. Initially, they are pressed under a pressure of one thousand to one thousand one hundred bar using a mechanical press, and then subjected to heat treatment. After it they become black or dark brown.

We also recommend studying this topic:

What to choose for kindling and heating – firewood or briquettes?

Many heating appliances operate as long as the correct fuel is available. However, before making a choice between briquettes and firewood, it is important to understand the significant differences between them.

5369 1 0

The first two production methods are the simplest, and accordingly the price of these briquettes is lower. However, they do not tolerate transportation and humidity well.

Advice! If briquettes will need to be stored for a long time, then you should opt for the third option, despite the fact that they are more expensive. They retain their properties for a long time.

Fired hexagonal wood briquettes with a hole in the center. They are compact for storage and are great for heating a stove or fireplace, or even a boiler.

Peat briquettes

The production of peat briquettes is similar to wood briquettes. First, the peat is dried well and only then is it pressed. After exposing peat to high temperatures, it becomes compacted and can be easily formed into blocks, which makes it easy to transport and store fuel.

Peat briquettes, which are widely used as an alternative to firewood and eco-firewood. They do not harm the human body and have good heat dissipation

Properties of peat briquettes or pellets:

- high thermal efficiency over a long period of time;

- burning time can be up to eight hours;

- ash is a fertilizer;

- completely natural materials, no chemicals.

Advice! Peat briquettes are more economical to use than firewood and wood. They emit 5000 kcal/kg, wood briquettes 4400, firewood - 3910, so it is more profitable to purchase them, despite their high cost.

Unlike firewood, there is no need to chop, dry and prepare large areas for storage. Peat briquettes are compact.

The photo shows one of the methods for producing briquettes from peat: a tractor with a special installation compresses the mass and pushes it out to dry.

Coal briquettes

The material for their creation is coal dust. It is first sifted, then crushed, after which it is pressed. A viscous substance is used to form a briquette. In fact, this is not a natural fuel and is based on coal.

Coal briquettes are used for heating, cooking, and also as fertilizer. They are a good alternative to firewood

Properties:

- no smoke is produced during combustion;

- safely;

- used for cooking indoors on a barbecue or grill;

- The burning time is seven hours.

All briquettes are successfully used for heating rooms and cooking. They are becoming more and more popular due to their clear advantages over firewood.

The advantages of firewood, or what is better to heat the stove: wood or briquettes

Despite all the advantages of Euro-firewood, in some ways firewood is still superior to this type of fuel.

Namely:

- Undoubtedly, the fact that European firewood burns more slowly and produces stable heat is a plus, but it produces less heat than conventional firewood. To warm up the house for the winter you will need to wait.

- If a person has planned a romantic evening with a cup of aromatic tea and a crackling flame in the fireplace, it is better to use ordinary firewood. The fact is that briquettes do not emit the characteristic crackling sound that creates that same home comfort. Firewood provides this effect due to the water it contains and is absent in Euro-firewood.

- The ashes of ordinary firewood, if compared, do not emit a tart smell.

- Euro firewood of ordinary quality or the RUF variety can be quite fragile, sometimes even crumbling in your hands. But there is high quality material, which is accordingly strong.

So, these are the main differences between Eurofuel for a bathhouse, fireplace or stove and ordinary firewood. But there is one more nuance that worries those consumers who are concerned about the question of how much firewood costs and what is more profitable to purchase. The cost of European firewood can vary, it depends on the quality. Briquettes come in premium and regular quality. The highest quality fuel is characterized by good density: 1400 kg per 1 m3. They are convenient to light, they burn longer, heat transfer is higher and leave a minimal amount of ash. They are dense and not cracked. Regular quality fuels have a density of approximately 1000 kg per 1 m3, are layered and more fragile.

In addition, they have less heat transfer, burn out faster, and leave behind more ash.

If they seem very expensive, even taking into account the fact of savings compared to ordinary logs, it is possible to make them yourself. To do this, you need to collect all the branches and twigs from the site, combine them with clay and fill them with water. There should be a small amount of liquid component so that the result can be made into a bar shape. The resulting composition must be poured into molds, compressed and left to dry in the sun. Drying for several days. Naturally, such fuel will be several times inferior to real European firewood, but will provide an opportunity to save money. In addition, the area will be cleared.

Total information

Fuel briquettes, or Eurowood as they are also called, appeared on the construction market relatively recently. However, due to their quality characteristics they quickly became popular. Now we can say with confidence that this advanced fuel for fireplaces and stoves has appealed to many people.

And how could it be otherwise, when the heat transfer from wood briquettes is almost twice as much as from firewood from a similar type of wood. Eurobriquettes burn longer and evenly release heat throughout their smoldering period.

How did specialists achieve such quality from wood? It turns out that everything is very simple. There are two main reasons for these increased characteristics:

- High density of wood, achieved through the process of thermal pressing of sawdust, shavings and wood dust.

- Minimum humidity, again obtained due to pressing and heat treatment. The moisture content of fuel briquettes is 7-9%, while the driest firewood, for example birch, has a moisture content of about 20%. The lack of moisture allows more heat to escape from the briquettes, since there is no need to heat and evaporate water.

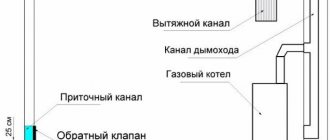

Due to this density and humidity, fuel briquettes are capable of releasing heat in the range from 4000 to 4500 kcal/kg. This heat transfer is enough to heat a house well and heat a bathhouse. In addition, there are no restrictions on the use of Eurobriquettes; they can be placed in any stove, even the simplest heater, which has restrictions on the amount of heat, approximately 4900-5000 kcal/kg. The stove is heated with fuel briquettes like regular firewood, except that you need to add them less often.

Laying fuel briquettes into the furnace firebox

The environmental friendliness of fuel briquettes is undeniable, since they are made exclusively from natural wood sawdust, which is pressed together. There is no need to add an adhesive composition, since the wood contains a suitable component, lignin, which holds the sawdust together.

Good to know: How to prepare firewood for the winter, how to chop and dry wood with your own hands

A distinctive feature of fuel briquettes is the small amount of ash remaining after their combustion. Approximately ash is obtained up to 1% of the total volume of the briquette. This burnout is again due to the high density of the material.

At the same time, the sawdust from which fuel briquettes are produced is practically devoid of resins, which means there is no smoke and soot during combustion. You can use such fuel even in black baths, not to mention the fact that there is practically no need to clean the chimney after using such firewood.

Modern packaging of compressed firewood

The long burning time and high heat transfer of Eurobriquettes indicate that the reserves of this fuel can be several times less than the volume of conventional firewood. In addition, packed in moisture-proof bags that are convenient for storage and have the same shape and size, fuel briquettes can be conveniently stored almost anywhere. Good packaging will reduce the amount of waste both during storage and during further use.

Pressed firewood or natural: which is better?

So, Euro firewood: it burns out more slowly, is neatly stacked and takes up little space, does not leave debris, is not harmful to health, and is cheaper than traditional logs. But nothing compares to the unique crackling of a dry log in a fireplace. And you won’t be able to quickly heat a house using briquettes.

The price depends on the manufacturer’s costs for the equipment: the more the material is pressed, the higher quality it will be and the faster the equipment on which the fuel is created wears out. This factor of rapid wear and tear is included in the price of the product sold.

It is clear that high quality European firewood will cost more. But at the same time, even eurobriquettes of the highest quality will cost less than ordinary birch logs, and there is nothing to say about ordinary quality.

Therefore, when choosing between Eurofuel and logs, you need to be guided not only by their characteristics and advantages, but also by personal plans for their use.

Eco-firewood or fuel briquettes

Eurobriquettes are the same firewood. They are made from wood. But the structure distinguishes them from ordinary firewood. The crushed wood chips are dried and pressed into a form convenient for use. This allows them to have an efficiency five times greater than that of firewood.

Fuel briquettes were invented by practical Germans. Or rather, the German specialist H. Ruff. He developed special equipment that gave sawdust the shape of a brick. The briquette standard that was obtained in this way was named after the inventor - Ruf. After this discovery, the production of ruf briquettes spread throughout the world. Including to Russia. Where, thanks to large forest reserves, the woodworking industry is well developed.

The technology for producing fuel briquettes is simple. Dry wood chips and sawdust are loaded into a special compartment, where excess moisture is removed from them. After which the mass is subjected to briquetting at high temperature. A press with a pressure of 250 atmospheres creates briquettes that are characterized by ultra-low humidity. It is 5-6 times less than the humidity of ordinary firewood.

Eurobriquettes are very common in Europe today. They are used not only for fireplaces or saunas, but also for heating ordinary houses. Special ovens are used for this purpose. Their design allows you to warm up a large room using a minimum amount of “eurowood”.

Recommendations: what is the best way to heat a solid fuel boiler?

Heating boilers without an automatic feed function operate on a variety of fuels.

You can burn brown coal and also use:

- Firewood;

- Peat briquette;

- Granules;

- Anthracite;

- Coke.

Moreover, their calorie content is different, and how the boiler will work depends on it. Therefore, those who buy such a boiler should take into account that when burning the least calorific fuel, the power can drop by 30% or more, depending on the humidity level. There is one more point. Usually the manufacturer indicates the best way to heat a solid fuel boiler and what fuel should be used as a basis.

That’s right, take into account the opinion of the expert and comply with all the requirements in order to achieve maximum heat transfer and make heating the cottage with a boiler as comfortable as possible.

For example, if the manufacturer advises heating with brown coal, you need to use it as the main one, and add another type of fuel only to the hot layer and little by little. Briquettes - can be made of peat, straw or sawdust.

Tips: how to heat the stove other than wood

What kind of fuel do people use to keep warm: chipboard scraps, sleepers, eurowood and others. They also throw a large amount of seed husks into the oven. However, the most popular material for heating a stove is wood.

There are Eurowood:

- Coal;

- Peat;

- Oak;

- Hornbeams.

Euro-firewood should be used when the stove has already lit up after using firewood, since they retain heat for a long period, thereby maintaining a high temperature in the room. Attention! Sometimes a summer resident, wanting to save money, heats the stove with old sleepers, without thinking at all that they are saturated with toxins that do not burn and are harmful to health.

Briquettes for heating stoves: reviews

It is correct to use oak or birch logs and avoid spruce and pine. If you put spruce material in the firebox, then during combustion various resins will begin to be released, which negatively affect the stove draft, efficiency, combustion of the material and pollute the chimney. It is ideal to use only those that are compressed. Euro firewood that disintegrates into sawdust can only be taken with traditional logs or brown coal, so as not to damage the heating equipment. Pellets can also be made from straw or wood waste. They are compressed, like European firewood, and are often used in special solid fuel boilers.

The consumer leaves exclusively positive reviews about this type of fuel.

Just go to the forum and see that people are happy:

- At a price;

- Quality;

- Practicality.

In addition, Euro firewood is environmentally friendly.

Types of fuel briquettes and pellets

Eurowood is divided into RUF, Pinii-kei, Nestro and Nielsen. These names are based on companies that produce presses for fuel briquettes. That is, hydraulic (RUF, Nestro), extruder (Pini-kay) and mechanical shock (CF Nielsen). But there is also a “folk” classification:

- “Round” – Nielsen or Nestro. Briquettes are cylindrical in shape, with a diameter of 6-9 cm and a length of 5-35 cm. They are made on hydraulic or mechanical presses. The thicker and longer the “log”, the higher the quality and the greater its density, which has a bad effect on the price.

- "Bricks" - RUF. Rectangular shape and parameters (LxWxH) 15x9.5x6.5 cm. Made on hydraulic presses of the manufacturer RUF, also made from crushed wood. The cost-quality ratio is optimal. But you should avoid briquettes made from birch dust (white color), they contain harmful compounds.

- “Square with a hole” – Pinii-kei. Polyhedron shape with a dark crust and a through hole. Parameters (LxW) 5-8x20-30 cm. During manufacturing, they are not only pressed, but also fired, so strength and moisture resistance are higher than other types, but also cost more.

Pellets are granules, their price depends on the raw materials from which they are made.

They are classified as follows:

- White - the variety is called “premium”. Made from wood waste without bark. The calorific value is high, in fact 95% of pallets on the market are of this type.

- Industrial - in addition to wood waste, it may contain non-combustible particles and bark.

- Agropellets are made from agricultural waste; the main advantage of the variety is the price, which is lower than that of other subspecies.

White pellets have a low ash content, so you can clean the boiler once a month, they are of the highest quality. In the case of the industrial grade, the color of the granules is darker, the ash content is slightly higher - by 0.7%, and the calorific value is virtually the same as white ones. Agropellets have normal quality, and the ash content is higher than other varieties. The boiler will need to be cleaned frequently, so it is better to choose self-cleaning models.

Eurodrova (video)

One way or another, the choice is up to the consumer. Some people are used to firewood, while others prefer innovative heating materials – it’s up to you to choose!

Comments

0 Daniil 02/01/2018 06:25 My parents once bought peat briquettes, of course they are a good thing, they burn for a long time and therefore are used very sparingly and burn out almost completely, after them there is no buzz, but for the price they are very expensive, although if you calculate everything, then they are even more profitable than cheap, but very often low-quality coal.

Quote

Update list of comments RSS feed of comments for this entry