What is vermiculite and what are its main characteristics

Although vermiculite, as an insulation material, is a mineral of natural origin, its beneficial properties, surprisingly, were recognized not so long ago. It was described as a rock only at the end of the 19th century, but it took almost another century for the characteristic features of this mineral to be put at the service of man.

In fact, natural vermiculite is a rock of the silicate class, a group of hydromicas. It differs from ordinary mica in the increased content of water bound in the crystal lattice and the low level of bonds between the layers of the material. Thus, the common molecule of the original, natural vermiculite includes four water molecules “attached” to it.

Fragment of hydromica - raw material for the production of expanded vermiculite

In its normal state, it is a fairly hard rock, with a high density, reaching 2400÷2700 kg/m³, resistant to abrasion, but easily stratified into plates. Its melting point is about 1350 °C. But an interesting feature of the mineral was noticed and used - if it is not brought to melting, but heated to temperatures of the order of 900÷1000 ° C, then the material completely changes its crystal structure. Thin plates swell - increase in size 15-25 times and turn into porous worm-shaped columns or even thin threads with a pronounced golden or silver tint. Apparently, this is where the accepted name of the mineral came from – vermiculite, from the Latin “vermiculus”, which literally means “worm”.

The result is expanded vermiculite - precisely the material that is subsequently widely used in a variety of sectors of construction, industry and agriculture. The air-filled structure has a very low density - it is much lighter than water, and its specific gravity becomes only from 60 to 130 kg/m³.

When fired at high temperatures, pieces of mica turn into layered “worms”

Currently, the production of expanded vermiculite is put on an industrial basis. Our country has rich deposits of the necessary mica rocks - in the Murmansk, Chelyabinsk, Irkutsk regions, in the Krasnodar and Primorsky Territories.

The production cycle consists of several stages. This is raw material sorting, enrichment (removal of ballast impurities), crushing into fine fractions and roasting. The firing process takes a matter of minutes - and then the expanded columns go through the stage of crushing to the desired fraction, followed by sorting, packaging and shipment to consumers.

Prepackaged expanded vermiculite

Vermiculite produced at enterprises must comply with certain standards introduced by GOST 12865-67. So, it is divided into:

- large - grains ranging in size from 5 to 10 mm;

- average - from 0.6 to 5 mm.

– fine – grains up to 0.5 mm.

Typically, consumers are supplied with three different grades of material - 200, 150 and 100, in which the numbers indicate the upper limit of the bulk density of the material (kg/m³). The density itself and, accordingly, the insulating qualities of vermiculite depend on the size of the fraction. For example, without going beyond GOST, manufacturing plants offer material with the following parameters:

Average fraction size, mmAverage bulk density of material, kg/m³Average thermal conductivity coefficient, W/m×°C

| at a temperature of +25 °C | at a temperature of +100 °C | ||

| 0,5 | up to 130 | 0,056 | 0,062 |

| 1,0 | up to 120 | 0,052 | 0,059 |

| 2,0 | up to 110 | 0,051 | 0,057 |

| 4,0 | up to 95 | 0,048 | 0,054 |

| 8,0 | up to 65 | 0,046 | 0,052 |

Vermiculite has now become widely used in construction, as it has a number of advantages:

- The low coefficient of thermal conductivity allows the use of vermiculite as an effective thermal insulator for building structures. In terms of these indicators, the material is quite comparable to other popular insulation materials, for example, mineral wool or expanded polystyrene, but significantly surpasses them in its other characteristics.

- The operating temperature range is extremely wide. Thus, vermiculite itself, and many construction materials based on it, can withstand freezing below -200 °C and heating up to 900 ÷ 1000 °C. The material itself is absolutely non-flammable and does not contain any additives that could contribute to combustion or the spread of fire. When heated, vermiculite does not emit any gases that are dangerous to the human respiratory system. These qualities are used to create effective fire barriers or protect metal structures of buildings and structures.

One of the tasks of vermiculite is fire protection of metal structures

- The pronounced granular and at the same time layered structure of vermiculite becomes an excellent soundproofing barrier. Both airborne and impact noises are attenuated in the thickness of the material, and a building structure (wall or ceiling) insulated with vermiculite or made on its basis will not be a transmission “membrane” that propagates sound waves further. The sound absorption coefficient at a frequency of 1 kHz reaches from 0.56 (for material with a minimum fraction of 0.5 mm) to 0.7÷0.8 (with a fraction of 4÷8 mm).

- Despite the layered and seemingly unstable structure, vermiculite grains are highly durable. So, if we compare it with another expanded material - perlite sand, then vermiculite is not afraid of transportation, vibration, it does not shrink, does not break into small fractions, and does not generate dust.

- The material is chemically resistant and completely inert - it can withstand the effects of all known acids, alkalis, organic solvents or other technical liquids used in construction without any loss of its qualities.

- A very special property of the material is its pronounced adsorbing ability and the highest moisture absorption. Thus, vermiculite is capable of absorbing a volume of water that is five times its own weight. This, of course, can also be attributed to the shortcomings of the material. However, vermiculite just as easily releases moisture into the atmosphere, without losing its qualities at all.

By the way, the adsorbing properties of vermiculite are actively used for filtration systems, for cleaning soil and water bodies from oil stains and for other similar purposes.

Where is vermiculite used?

If vermiculite and what it is is now clear, then its scope is quite wide. Taking into account that materials made from this mineral are characterized by biostability, nonflammability, neutrality with respect to acids and alkalis, as well as strength and high thermal properties, it is not surprising that it has been used in approximately 200 areas.

The shipbuilding and power engineering industries know how to use vermiculite. It is used for the manufacture of non-combustible structures and vermiculite slabs and shells. The remaining most popular areas in which vermiculite has been used are:

- metallurgy;

- chemical and paint industry (as a filler for thermal varnishes and acid-resistant liquid reagents);

- energy;

- automotive industry (for creating brake pads);

- wood and paper industry;

- animal husbandry (as an ingredient in animal feed: its usefulness is due to experiments that have shown an increase in the level of hemoglobin in animals, protein, phosphate, calcium, red blood cell count, etc.);

- poultry farming (here the presence of vermiculite in the feed guarantees an increase in the fat mass of birds, egg production of chickens, iron levels, viability and much more);

- agriculture (unique and rare sorption properties allow it to be a sorbent, fertilizer, ameliorant, radioprotector, mulch);

- production of soft roofing (plays the role of sprinkling the top layer in the process of producing roofing materials);

- production of electrodes;

- construction and much more.

Specifications

The parameters of vermiculite depend on the size of the fraction; in addition, its exact composition has an impact. Key characteristics of expanded vermiculite:

- thermal conductivity;

- hygroscopicity;

- sound absorption;

- heat resistance.

Fractions smaller than 4 mm are mainly used in construction. The coarse fraction is used as a filler for refractory concrete. The fine fraction of 0.5-1 mm is used as a bulk heat insulator, which is used to fill voids in walls or as a fill for insulating floors. The characteristics are presented in the table.

| Thermal conductivity, W/m*K | Density, kg/m3 | Moisture content, % | Sound absorption coefficient at a frequency of 1 kHz | |

| Vermiculite expanded 0.5 mm | 0,053 | 144 | 3 | 0,56-0,6 |

| -//- 1 mm | 0,050 | 125 | 4 | 0,6-0,65 |

| -//- 2 mm | 0,049 | 100 | 4 | 0,7-0,8 |

| -//- 4 mm | 0,048 | 94 | 5 | 0,7-0,8 |

| -//- 8 mm | 0,045 | 87 | 3 | 0,7-0,8 |

More details on properties.

Thermal conductivity. The layered structure of the material after swelling under the influence of temperature has a dominant role on this parameter. The individual plates remain firmly connected, but the direct contact between them is broken and filled with air. The material itself has a thermal conductivity of the order of 2-2.7 W/m*K; due to the breaking of bonds between the crystalline plates, this figure is reduced to 0.03-0.12 W/m*K, which puts it on a par with mineral cotton wool and extruded polystyrene foam. At the same time, it is used in bulk, from which the material is able to fill all the irregularities and niches.

Hygroscopicity. A property that explains the demand for vermiculite in agriculture and even hydroponics. The gaps between the crystallized plates are filled with equal ease by air and water. The material is highly hygroscopic. For example, 100 grams of vermiculite can hold up to 500 ml of water. More importantly, water and moisture enter and exit the material with equal ease. When using vermiculite as insulation for building envelopes, this must be taken into account and it is advisable to use it as an advantage, and not as a disadvantage.

Sound absorption. Vermiculite has proven to be an excellent material for creating soundproof barriers. High absorption, lack of settling in the material during compression and increased elasticity allow reverberation to be controlled over a wide range. Simply put, vermiculite is able to absorb sound waves without producing secondary waves or extraneous sounds under the influence of friction or deformation. When vermiculite is compressed and pressed by approximately 10-20%, maximum absorption of sound waves is achieved.

Heat resistance. The melting point of vermiculite exceeds 1300 degrees. After swelling, the material no longer undergoes modifications and is not subject to decomposition, changes in composition, etc. This makes it a heat-resistant material that can be used to insulate stoves, fireplaces, pipes and chimneys.

Vermiculite boards

In addition to these characteristics, vermiculite can be described by a number of useful properties:

- Environmentally friendly, without harmful emissions in the entire range of permissible operating conditions.

- Prevents condensation. It quickly absorbs moisture, and then just as easily releases it in the form of steam. It is important to create optimal conditions for removing excess moisture.

- High turnover. Easily fills voids, niches and surfaces of complex shapes.

- Does not attract rodents. It is not an attractive food for them and, due to its high hygroscopicity, quickly absorbs the odors of rodent marks, which makes them quickly lose interest in the space filled with vermiculite.

- Does not cause allergies.

- It is not radioactive and reflects part of the radiation spectrum, has a neutral pH.

Expanded vermiculite is sold as insulation in bags of 50 liters. This is enough so that with a layer thickness of 10 cm, two bags are enough to fill 1 m2.

Material with a fraction of 0.5-1 mm for insulating floors is supplied to the installation site via air ducts, just like, for example, ecowool. Otherwise, it is filled directly from the bags. There is no need for additional fluffing for filling.

Vermiculite: application in construction

The active use of vermiculite in this area is justified by the fact that it is the only material that can provide building structures not only with the highest fire protection, but also at the same time thermal insulation, decorativeness and sound insulation. In construction it is used as follows:

- as fire protection for load-bearing steel metal structures;

- to create a warm floor;

- as bulk insulation, lightweight concrete fillers;

- in the installation of self-leveling floors;

- in the production process of heat-resistant partitions;

- in plasters, various kinds of mixtures;

- Due to its fire-retardant properties, it is used in the creation of intumescent fire-retardant coatings, the most effective of which is a slab, which has many advantages.

Vermiculite in construction helps to solve several problems simultaneously, namely:

- protect structures and buildings from fire,

- keep warm,

- isolate the room (both inside and outside) from extraneous sounds, and this is not the end of the list.

The scope of its use in the construction industry is quite wide, and there is no doubt that with the development of technology, it will find more and more application.

Vermiculite as a building material

Vermiculite is a natural material with a multilayer structure based on plate-like crystals, containing a number of metals (iron, aluminum, silicon, magnesium) and their oxides in combination with water. In construction, expanded vermiculite is used, obtained during the heat treatment of raw materials, in the form of cubes of a porous layered structure of yellow-brown, golden or bronze color.

Expanded vermiculite

The main characteristics of vermiculite that determine its scope of use are:

- thermal conductivity;

- hygroscopicity;

- sound absorption;

- heat resistance.

These characteristics vary depending on the fraction of the material in the following ratios:

Due to its physical properties, vermiculite is widely used in construction, these are:

- for protection against fire damage (fire protection) of building structures for various purposes and made of various materials;

- for insulation of various elements (floor, walls, ceiling) of buildings and structures, as well as utility networks (water supply, sewerage, etc.);

- as a filler in the production of lightweight concrete;

- when installing self-leveling floors and heat-resistant partitions;

- when preparing plaster solutions;

- in the production of building boards with increased fire-retardant properties.

Advantages of loose-fill thermal insulation made from expanded vermiculite:

- Excellent thermal insulation ability. Thermal conductivity coefficient – depending on the fraction 0.04–0.06 W/(m×K) at a temperature of +25°C.

- No seams or voids. Vermiculite allows you to create a continuous layer of insulation, which is impossible with traditional methods of insulation with slabs and roll materials.

- Fire safety, fire resistance. Vermiculite does not support combustion and prevents its spread. Melting point +1350°C.

- Environmentally friendly. Natural material, no toxic gases are released in case of fire.

- Biostability and longevity. Does not rot and prevents the spread of mold. Protects walls from mold, mildew and dampness.

- Lightweight material. Volumetric weight depending on the brand is 90–200 kg/m³. Reduces the volumetric weight of insulation by 2-3 times, reduces the load on the foundation.

- High performance in terms of sound insulation and noise absorption.

- Ease of performing thermal insulation work. Bulk material can be poured into structures of complex shape during the construction and reconstruction of buildings. Reduces labor costs for construction and installation work by 30%.

Vermiculite technical characteristics

The properties of vermiculite largely depend on the size of the fraction. In addition, this moment also affects the specific composition.

The main parameters of expanded vermiculite include:

- thermal conductivity;

- resistance to high temperatures;

- noise absorption;

- hygroscopicity.

As a rule, in the construction industry, material is used whose fraction sizes do not exceed 4 millimeters. The material, which has larger fractions, is used, as noted above, as a filler in the preparation of refractory concrete. Vermiculite of a small fraction (no more than 1 millimeter) is an excellent bulk insulation material, which is used to fill ceilings or voids in walls.

Table. Key characteristics of vermiculite.

| Thermal conductivity, W/m*K | Density, kg/m3 | Moisture content, % | Sound absorption coefficient at a frequency of 1 kHz | |

| Loose vermiculite 0.5 mm | 0,053 | 144 | 3 | 0,56 — 0,6 |

| -//- 1 mm | 0,050 | 125 | 4 | 0,6 — 0,65 |

| -//- 2 mm | 0,049 | 100 | 4 | 0,7 — 0,8 |

| -//- 4 mm | 0,048 | 94 | 5 | 0,7 — 0,8 |

| -//- 8 mm | 0,045 | 87 | 3 | 0,7 — 0,8 |

Table. Volumetric and technical properties of vermiculite

| Standard of stamps | |||

| Index | 100 | 150 | 200 |

| Volumetric bulk weight in kg/cub.m no more | 100 | 150 | 200 |

| Thermal conductivity coefficient at 250C, kcalm.h.deg no more - According to GOST 12865-67 - According to thermal tests carried out by the Krasnoyarsk Institute "Promstroyniproekt" | 0,055 — 0,053 | 0,060 — 0,057 | 0,065 — |

| Sound absorption coefficient at frequency 1000 Hz | 0,7 | 0,75 | 0,8 |

| Humidity by weight in%, no more | 3 | 3 | 3 |

| Application temperature | -260 to +1100 | ||

| Melting point | +1350 | ||

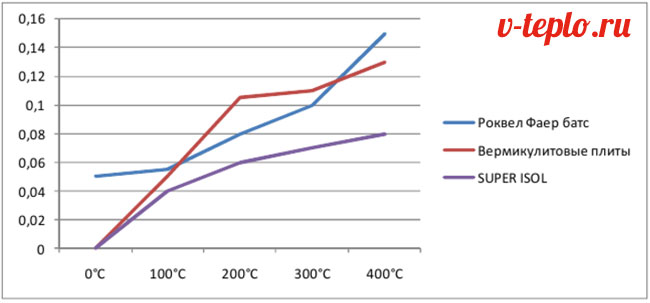

Thermal conductivity coefficient (W/(m xc))

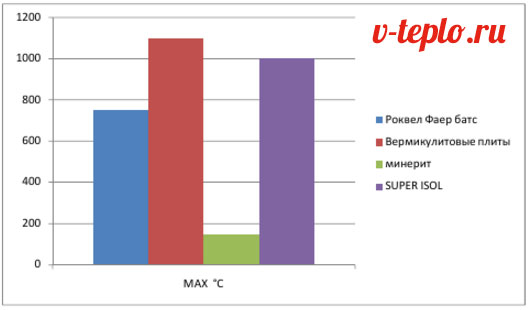

Comparison table of vermiculite with other materials

| Rockwool firebats | Vermiculite boards | Minerite | Magnesite | SUPER ISOL | |

| Density (kg/m3) | 110 | 375 | 1150 | 1,00 | 225 |

| Limit of compressive strength (MPa) | No data | 1,3 | Flexural elasticity coefficient: — In a dry state along, GPa 4 — In a dry state across, GPa 3 | No data | 2,6 |

| Bending strength limit (Mpa) | No data | 0,5 | — | No data | 1,9 |

| Total porosity(%) | No more than 1% by volume. | 86 | Moisture resistance Water absorption, % 32.0 Wet-dry-wet, mm/m 2.2 Swelling after 24 hours in water, % 0.7 | No data | 91 |

| Vapor permeability | 0.14(kg/GPa * m*s) | No data | 450-330 (ng/m2 s Pa) | 0.7(nPm) | |

| Specific heat capacity(kJ/kg*h) | 0,8 | 1,18 | 0,9 | 0,84 | |

| Fire resistance (°C) | 1000 (Fire Batts is a non-flammable material according to GOST 30244-94. Fiber melting point 1000) | 1300 | No data | 1345 | |

| Maximum operating temperature (°C) | Maximum permissible temperature: On the mineral wool side up to 750 °C. On the aluminum foil side: glue 80°C foil 500°C | 1100 | 150 | 1000 | |

| Thermal conductivity coefficient (at an operating temperature of 200 C W/(m*K) | 0,08 | 0,105 | Thermal conductivity, W/m C 0.25 (at what temperature is not known) | 0,14 | 0,06 |

| Flammability class (GOST 30244-94) | G1 | NG | NG | NG | NG |

| Flammability class (according to EN 13501) | A1 | A | A1 |

Maximum operating temperature (C)

Now let's take a closer look at each of the listed characteristics.

Thermal conductivity

This property is due to the fact that the structure of the material is layered, which is obtained through foaming under conditions of elevated temperature. The mineral plates are firmly connected to each other, but their direct contact is broken, as a result of which they are filled with air. The thermal conductivity of ordinary vermiculite is no more than 2.7 W/m*K, but after the bonds are broken, it decreases to approximately 0.12 W/m*K. Consequently, in terms of this indicator, the material is in no way inferior to extruded foam or mineral wool.

At the same time, vermiculite is applied in bulk, thanks to which it fills all the niches and irregularities.

High temperature resistance

The material melts at temperatures above 1300 degrees. When swelling is completed, it no longer changes or decomposes, and the composition becomes constant. In other words, vermiculite is rightfully considered a heat-resistant material, suitable for insulating stoves, fireplaces, chimneys and other things.

Noise absorption

The material is ideal for creating soundproofing barriers. Thanks to features such as increased absorption, elasticity and resistance to compression, reverb can be controlled over a fairly wide range. In simpler terms, vermiculite successfully absorbs sounds, but at the same time does not reproduce them during distortion or friction. When the material is compressed, reducing the volume by approximately 20 percent, the maximum sound absorption coefficient is obtained.

Hygroscopicity

This property, by the way, explains the popularity of the material in agriculture and hydroponics in particular. The voids between the plates, which, as we found out, can be filled with air, absorb water with similar success. The hygroscopicity of this material is quite high. For example, 200 grams of insulation can hold up to 1 liter of water. And what’s more interesting is that water not only gets into vermiculite well, but also leaves it just as well. This property must be taken into account when using the material as thermal insulation of enclosing structures, and even better - used as an advantage rather than a disadvantage.

The use of vermiculite for thermal insulation work

To ensure the necessary thermal insulation characteristics of a building, vermiculite can be used in several options:

- In bulk form - for filling the cavities of insulated structures.

- As part of special mortars.

- In the form of ready-made building elements (slabs) made of vermiculite-based composite materials.

The use of vermiculite in the form of backfills

One of the popular methods of using vermiculite is to fill the cavities of insulated structures.

A. Insulation of the roof structure

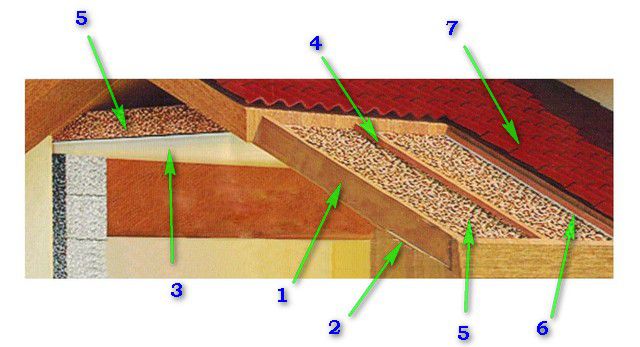

The figure shows an approximate scheme for insulating a pitched roof, for example, during the construction of a residential attic.

Scheme of insulation of a pitched roof and attic ceiling with vermiculite

1 – rafter legs.

2 – a layer of vapor barrier film that prevents moisture from the premises from penetrating into the insulation layer.

3 – internal lining of the slopes and ceiling of the attic.

4 – frame structure – sheathing for further roofing.

5 – dry vermiculite is poured into the formed cavities.

6 – a wind barrier is laid on top of the insulation - a diffuse membrane that prevents weathering of loose vermiculite and direct contact with water, but does not prevent the free evaporation of moisture.

7 – then, a counter-lattice is installed on top of the membrane, and the roofing material is laid.

b. Insulation of floors

The floor insulation scheme is, in principle, similar.

Insulation of attic floors with vermiculite

A reliable waterproofing material is laid on the hemmed “rough” ceiling between the floor beams, with obligatory overlap of the sheets and sealing of the joints. A sheathing system (joist) is installed for the subsequent laying of the attic floor.

Then, the cavities formed are filled with dry vermiculite. Usually a layer of 100 ÷ 150 mm is sufficient for this.

Vermiculite prices

insulation SVT Vermiculite VVF

A diffuse membrane is attached on top of the beams and joists, and then a plank or plywood floor covering is laid (if necessary).

If the attic (attic) is ventilated, moisture will not accumulate in such an insulating layer - it will have free access to evaporation into the atmosphere.

Since vermiculite is a fairly expensive material, some owners use a mixture of it with sawdust. Usually the proportions used are either 1:1 or 3:2. It is interesting that when mixed with vermiculite, sawdust “takes over” its resistance to biological decomposition - caking and rotting processes will not be observed in them. This dry mixture can be prepared using a regular construction mixer or a drill attachment.

V. Insulation of hollow walls

When building walls using the “well masonry” technology, it is fashionable to fill the space between the bricks with dry vermiculite. A similar approach can be used when insulating frame walls.

Vermiculite can be poured into the abandoned cavities of multi-layer brick or frame walls...

Backfilling is carried out in stages, as the load-bearing wall and facing layer (sheathing of the frame structure) are erected, with light compaction of the material.

Another option for creating “warm walls” is to fill the voids of building blocks. The thermal insulation effect of such a structure increases sharply, and the noise absorption performance of the wall increases.

...or it fills the voids of building blocks

At the same time, the wall remains “breathable” - the free exchange of vapor in it is not disturbed.

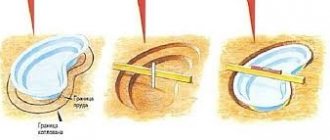

d. Thermal insulation of chimney pipes

An important point when installing a stove or boiler is always the thermal insulation of chimney pipe passages through walls and ceilings. And this problem can be solved very effectively using vermiculite.

Options for thermally insulated chimney pipe passage through ceilings using vermiculite

One option is to install a metal box at the passage point. The resulting cavity between the pipe and the ceiling is filled with dry vermiculite - and thermal insulation of the chimney will be ensured.

Another option is to use through sleeves, which are also filled with vermiculite inside.

The use of vermiculite as a component for construction and finishing mortars

Insulation of vermiculite in the form of dry backfill is highly effective, but still a very expensive solution. Therefore, in the practice of private construction, this material is more often used for the preparation of mortars - this way their thermal insulation characteristics can be significantly increased.

A. Preparation of solutions for screed

If the floor is supposed to be filled with screed, and at the same time it requires additional thermal insulation, it makes sense to use a concrete solution containing a significant proportion of vermiculite for this purpose.

Screed with vermiculite has increased thermal insulation and noise-absorbing properties

To prepare such compositions, standard Portland cement M400, sand and vermiculite with a bulk density of 80 to 150 kg/m³ and a fraction of 0.5 to 5 mm are used. As a result, such a fill will be characterized by a small overall massiveness and pronounced thermal insulation and sound insulation qualities.

There are several tested proportions for the preparation of such solutions. They are selected depending on the required strength and insulating qualities of the coatings being created. The proportions and basic solutions for screeds are presented in the table:

| Mortar proportions (cement sand vermiculite) | Proportion of components per 1 m³ of solution | Density of the solution, kg/m³ | Strength, kg/cm² | Coef. thermal conductivity, W/m×°С | |||

| Cement | Sand | Vermiculite | Compression | Bend | |||

| 1 / 0,5 / 2 | 495 kg | 247 kg | 865 l. | 1000÷1100 | 45 | 24,5 | 0,25 |

| 1 / 0,75 / 2,25 | 430 kg | 320 kg | 895 l. | 1120÷1180 | 35,5 | 30 | 0,28 |

| 1 / 0,75 / 1,75 | 410 kg | 307 kg | 800 l. | 1210÷1275 | 58,5 | 30 | 0,33 |

| 1 / 1 / 2 | 380 kg | 380 kg | 785 l. | 1300÷1350 | 47 | 30,5 | 0,35 |

| 1 / 1,25 / 1,75 | 365 kg | 455 kg | 740 l. | 1400÷1425 | 66 | 32 | 0,41 |

| 1 / 1,65 / 2,5 | 365 kg | 685 kg | 640 l. | 1450-1550 | 72 | 35 | 0,44 |

Due to the fact that vermiculite has increased hygroscopicity, the solution is prepared directly at the place of its use, and must be consumed within 30 minutes from the moment it is mixed with water.

Usually, for reliable insulation of the floor above an unheated room (basement, basement), 100 mm of screed is sufficient. For interfloor ceilings, a layer of 30 mm is sufficient.

When using such compositions, you must remember that in solutions with a cement mass fraction of less than 450 kg/m³, the poured coating will not be frost-resistant - it will withstand no more than 5–7 cycles. So such screeds are recommended exclusively for internal heated rooms.

b. Preparation of masonry mortars

When laying walls, it would be optimal to use materials with increased thermal insulation characteristics - gas silicate blocks, hollow bricks, etc. But the vulnerable area still remains the seams - if the thermal conductivity of the masonry mortar is higher than that of the wall material itself, powerful “cold bridges” are formed in these places, which sharply reduces the thermal performance of the entire structure as a whole.

Masonry joints can become powerful “cold bridges”

The solution is to select solutions in such a way that their thermal conductivity is comparable to that of blocks (bricks). And in this case, vermiculite can again come to the rescue.

The proportional composition of masonry mortars is, in principle, the same as shown in the table above. This means that when choosing a wall material, it is necessary to compare its thermal conductivity indicators with similar parameters of solutions, and choose the closest one in terms of this value. To make it easier, below is a table that shows the thermal conductivity coefficients of the materials most commonly used for laying walls.

| Material type | Density, kg/m³ | Thermal conductivity coefficient, W/m×°С |

| Expanded clay concrete | 1000 | 0.27 |

| Expanded clay concrete | 800 | 0.21 |

| Expanded clay concrete | 600 | 0.16 |

| Expanded clay concrete | 500 | 0.14 |

| Perlite concrete | 800 | 0.16 |

| Perlite concrete | 600 | 0.12 |

| Gas silicate blocks | 1000 | 0.29 |

| Gas silicate blocks | 800 | 0.21 |

| Gas silicate blocks | 600 | 0.14 |

| Foam-gas-ash concrete blocks | 1200 | 0.29 |

| Vermiculite concrete | 800 | 0.21 |

| Vermiculite concrete | 600 | 0.14 |

| Vermiculite concrete | 400 | 0.09 |

| Concrete with polystyrene chips | 600 | 0.145 |

| Concrete with polystyrene chips | 500 | 0.125 |

| Concrete with polystyrene chips | 400 | 0.105 |

| Ceramic brick | 1600 | 0.47 |

| Ceramic brick | 1400 | 0.41 |

| Ceramic brick | 1200 | 0.35 |

| Cement-sand masonry mortar | 1800 | 0.58 |

| Lime-sand masonry mortar | 1600 | 0.47 |

By comparing the data from the two tables, it will not be difficult to determine the optimal composition of the masonry mortar.

V. Production of “warm plasters”

A very effective method of significantly increasing the thermal insulation qualities of walls is the use of so-called “warm plasters” made on the basis of vermiculite.

The use of “warm plasters” with vermiculite is gaining popularity

Such wall coverings have many advantages. First of all, the specific gravity of the plaster layer itself is several times lower than that of traditional compositions. Thermal resistance indicators, on the contrary, are significantly superior. So, for comparison, a layer of only 25 mm will be similar in thermal characteristics to 100 - 150 mm of ordinary cement-sand plaster.

The use of “warm plasters” makes it possible to reduce the thickness of the brick wall being built by about a quarter, without any loss of thermal insulation qualities.

In addition, the soundproofing qualities of the wall structure immediately increase significantly. For ordinary plasters, the sound absorption coefficient is in the range from 0.015 to 0.02, that is, they practically do not resist the spread of noise. For “warm” people this figure is incomparably higher – from 0.2 to 0.65.

For plastering walls, the same compositions that were discussed in the first table can be used. However, there are also lighter solutions that do not use sand at all. The components are only M400 cement and vermiculite with a fraction of 0.5 to 2 mm.

| Plaster mortar parameters | Solution No. 1 | Solution No. 2 |

| Solution proportions: | ||

| — cement, kg | 760 | 600 |

| - vermiculite, l. | 1050 | 1300 |

| - water, l. | 530 | 455 |

| Dry density, kg/m³ | 1100 | 880 |

| Compressive strength, kg/cm² | 50 | 35 |

| Thermal conductivity coefficient, W/m×°С | ||

| - dry | 0.22 | 0.165 |

| — at humidity 5% | 0.27 | 0.22 |

All these plasters are quite suitable for exterior work on almost any wall surface - their adhesion indicators are very good. The frost resistance of such coatings is estimated at approximately 25 cycles.

If you plan to decorate walls or even ceilings with “warm plasters” from the inside of the premises, then you can use modified solutions. Under such operating conditions, high strength indicators are no longer so important, and direct exposure to water on plastered walls is not expected. But the evenness of the coating will certainly come first, for which purpose it is advisable to introduce plasticizing components into the composition of the plaster. In order not to disturb the natural mineral structure of the mixture, lime or purified fine clay can be used as additives that increase plasticity and improve the rubbing ability of the finished surface. “Recipes” for such plasters are given in the table below (“C” - cement, “I” - lime, “G” - clay, “V” - vermiculite):

| The ratio of components in the solution | Approximate consumption per 1m³ of finished solution | Density of the solution, kg/m³ | Compressive strength, kg/cm² | ||||

| C | AND | G | IN | Water, l. | Cement. kg | ||

| 1 | 2 | — | 6 | 400 | 185 | 586 | 8.1 |

| 1 | 3 | — | 8 | 400 | 125 | 581 | 6.7 |

| 1 | — | 2 | 6 | 400 | 185 | 650 | 10.3 |

| 1 | — | 3 | 8 | 400 | 135 | 624 | 8.1 |

Both external and internal plasters with vermiculite have high vapor permeability, which contributes to normal self-regulation of temperature and humidity conditions.

“Warm plasters”, subject to certain rules for their preparation, have another remarkable property - the natural golden or silver tint of vermiculite creates a very interesting decorative effect when finishing facades. It will be especially noticeable in the play of sunlight.

Vermiculite decorative plasters are quite capable of decorating the facade of a house in an original way.

To make plasters decorative, either colored cements are used, or mineral pigments are used with white cement, for example, red lead, ocher, umber and other compounds. The amount of pigment is chosen from 5 to 25% of the total mass of white cement. With minimal consumption, soft pastel colors of facades are obtained. By increasing the pigment content to 15–25%, the facade will receive a bright, rich color.

Approximate recipes for homemade decorative “warm plasters” are given in the table:

| Plaster mortar ingredients | Using white cement and pigments | Using colored cement |

| Cement | 200 kg | 380 kg |

| Lime | 250 kg | — |

| Vermiculite | 1000 l. | 1000 l. |

| Water | 700 l. | 400 l. |

| Plasticizer | — | 0.2 kg |

| Pigment dyes | 20 – 50 kg | — |

You can also purchase a ready-made dry construction mixture - plaster with vermiculite filling. It is prepared immediately before use according to the manufacturer's instructions and applied in accordance with the technological recommendations attached to it. As an example, we can cite two compositions - “TEPLOVER standard” “VERMIX”:

| Name of parameters | "HEATLOVER STANDARD" | "VERMIX" |

| Illustration |

| |

| Shelf life of the mortar mixture | up to 4 hours | Up to 2 hours |

| Dry thermal conductivity coefficient, W/m×°C | 0.08 | 0,12÷0,13 |

| Vapor permeability, mg/m×hour×Pa | 0.09 | 0.21 |

| Tensile strength, MPa | ||

| - detached from the base | 0,44 | 0.6 |

| - for compression | 2,19 | 2.3 |

| Time to reach standard values for strength | 28 days | 28 days |

| Frost resistance | F50 | for interior work |

| Brand of mixture by mobility | PC8 | PC3 |

| Permissible thickness of the plaster layer, mm | ||

| - minimum | 10 | — |

| — maximum | 100 | 50 |

| Factory packaging | Paper bag 25 l. (9 kg) | Paper bag 25 or 50 l. (9 or 17 kg) |

| Dry mixture consumption | 1 package per 1 m² with a plaster layer thickness of 25 mm | 9 kg per 1 m² with a plaster layer thickness of 25 mm |

And as a clear example, here is a video presentation of another type of “warm plaster” based on vermiculite:

Application of vermiculite

Vermiculite insulation can be used in a variety of forms:

- As a backfill insulation in frame structures and well masonry. In this case, waterproofing is not required.

- In insulating backfills for floors, roofs and attics.

- In warm masonry mortars during the construction of walls made of cellular concrete blocks.

- In plaster mortars - for additional insulation and sound insulation of external and internal walls and partitions.

- Vermiculite-based slabs and plasters for fire protection of load-bearing and enclosing metal structures.

- In floor screeds.

- As a filler for decorative plasters.

- In agriculture - to improve soil structure, mulch plantings and fertilize.

Application of vermiculite in construction

What is vermiculite used for? Due to its properties, vermiculite is a high-quality and promising bulk insulation material . Its use can significantly reduce the cost and material consumption of structures, while providing the house with reliable heat and sound insulation. In addition to low thermal conductivity, what makes vermiculite stone especially irreplaceable is its environmental friendliness and durability. Insulation of a house made from this material will last for many years, provide a pleasant appearance and even fire protection.

Sound insulation of walls and insulation with vermiculite

This is the most popular area of application of this material. In terms of its thermal conductivity properties, a 20 cm layer of vermiculite is equal to the thermal insulation of a 2 m wide concrete wall. Insulating mixtures consisting of concrete and vermiculite are used for internal and external plastering of premises using primary tools. The layers are easily laid and rubbed for an aesthetic appearance. Treating external walls with this solution will also preserve durability, protecting them from harmful insects, fungi and mold.

After construction work, there is often a need to clean equipment, tools, and the construction site from cement mortar residues. For this purpose, special concrete cleaners are used, which make it easy to clean the coating from dried mortar.

The use of such decoration of premises, especially the facade of the building, will look impressive even in the absence of additional finishing and decorative work. The golden-brown tint of such plaster plays favorably with colors in the sunlight, creating a natural, environmentally friendly and heat-resistant finish for the facade. For decorative mortars, colored cements or white ones with the addition of mineral pigments of various colors are used. For example, umber, ocher or red lead. When adding 5% pigment, the facade acquires light pastel colors; for a bright and rich coloring of the house, it is rational to use 15-25% pigment in the solution.

Backfill

When constructing walls using well masonry, dry vermiculite is used to fill the space between the bricks. Backfilling is carried out in stages with gradual compaction as the wall is erected. This technique is also applicable for creating heat-saving walls from building blocks. The parameters of heat and noise insulation with this use increase significantly.

Dry bulk vermiculite is also used for thermal insulation of roof coverings , filling the space of the roof frame structure with it, covering it with a diffuse membrane on top to protect it from wind and moisture. A counter-lattice is laid on top and the roofing material is directly laid. The installation of floors between beams is carried out using the same principle.

The problem of thermal insulation of chimney pipes is easily solved by using a backfill made of this material. This is done in two simple ways:

- Installation of a metal box around the perimeter of the chimney and filling the resulting area between the pipe and the box with loose vermiculite.

- Installation of feed-through sleeves on pipes, which, in turn, are also filled with backfill.

Finishing solutions

The production of a solution will help to significantly increase the thermal insulating properties of building materials . For example, adding a portion of vermiculite to a floor screed will ensure noise and thermal insulation of the floor covering. The solution should be prepared immediately before installation and used within half an hour. For interfloor ceilings, the optimal layer width is 30 mm; for basement or basement, mostly unheated rooms, a layer of approximately 100 mm is required.

To prevent heat loss through concrete joints during masonry, heat-saving material should also be used . This application will prevent the passage of cold, unlike conventional masonry mortar, which has less thermal protection.

Insulation of vertical structures

Insulation of vertical structures with backfill with vermiculite is possible both during the construction of walls and during the operation of finished housing.

To insulate the walls when making well masonry, lay out the outer and inner parts of the wall, tying it through 600-900 mm with jumpers or laying reinforcing mesh through 4-6 rows of masonry, then the space between the walls is covered with vermiculite, lightly compacting it.

Masonry made from hollow blocks can simply be insulated with vermiculite backfill.

To insulate already erected buildings, for example, a log house, made of double timber, OSB or chipboard, or fiberboard, an additional partition is built at a distance of 100-150 mm; the space between the partition and the outer wall is also filled with vermiculite with light compaction. When performing such insulation, unfortunately, the area of the premises decreases.

IMPORTANT: With high-quality sealing of the insulation cavity, the use of hydro- and vapor barrier layers is not required.

Insulation of horizontal structures

Horizontal structures - floors, attic floors, roof slopes with a slight slope - can also be insulated with vermiculite backfill. To keep the backfill in working condition, a vapor barrier is required from below and waterproofing on top of the insulation layer.

When performing flooring over wooden joists, after installing the subfloor, a vapor barrier material is laid over the entire surface, fastening it at the joints with special double-sided vapor barrier tape. The overlap of adjacent panels must be at least 15 cm.

The vapor barrier is covered with a layer of insulation that provides a standardized heat transfer resistance of 2.5 m2*K/W (for central Russia, at least 17.5 cm). Waterproofing material is laid on top of the backfill and running flooring is made on the attic floor or a clean floor in the interfloor ceiling.

ATTENTION! In order to save money, it is possible to insulate the structure with a mixture of vermiculite and sawdust in a ratio of 1:1, 3:2. The mixture will not lose its heat insulating qualities, and sawdust can be purchased at a bargain price.

Insulation of a pitched roof

When insulating the floor, waterproofing is placed under the vermiculite.

With such insulation, it is important to correctly select the thickness of the vermiculite poured. It depends on temperature conditions and ranges from 10 to 20 cm. The technology for insulating a pitched roof is as follows:

- a vapor barrier film is laid on the rafters;

- granular vermiculite is poured in;

- covered with a layer of waterproofing and a counter-lattice;

- the roof is spreading;

- Internal lining is carried out with any material.

Vermiculite insulation, the properties of which have been well studied, is a modern material that has a wide range of applications. The advisability of using vermiculite insulation is evidenced by reviews, which can be found in more detail in the following video:

The use of lightweight concrete created using vermiculite for insulation of roofs and walls

Vermiculite in construction is suitable for creating light, warm cement mixtures with a weight of 280-350 kg per m³, thermal conductivity up to 0.092 W/m°C. When preparing such solutions, sand is not added to them. Since such vermiculite compositions are self-supporting, they must be used in places that are not exposed to stress from external influences.

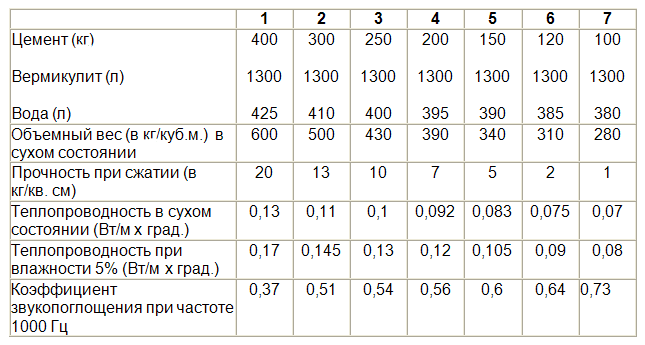

In tab. 2 shows the properties and composition of vermiculite concrete with cement.

table 2

The heat absorption rate of all of these compositions is up to 5 W/m°C. Mixtures No. 5-7 are self-supporting and cannot be subjected to external loads. Each such vermiculite fire retardant composition can be used for thermal insulation when creating three-layer walls.

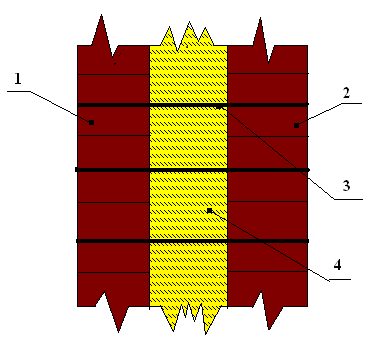

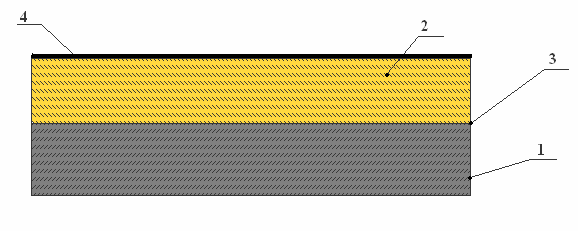

In Fig. Figure 2 shows the design of a three-layer wall made of brick, stones, or blocks.

Rice. 2 Insulation of a three-layer wall with vermiculite concrete (vertical section)

1- layer of cladding; 2-bearing layer; 3-flex connections; 4-vermiculite concrete

When creating brickwork, vermiculite concrete prepared according to one of the given recipes is poured into the space that is formed between the cladding layer - 1, the load-bearing base - 2, which are combined through flexible connections. The mixture is poured in layers. Each of the formed layers should have a thickness of 0.5-1 m.

Since all mixtures are characterized by sufficient fluidity, they can independently fill all voids in the structure, including defects that formed during the bricklaying process. If necessary, specialized equipment can be used to ensure maximum solution density.

The thickness of a layer of vermiculite concrete of 2 cm in terms of heat transfer is equal to the heat transfer of brickwork created from one brick. Due to this, if a three-layer structure is created from half-brick cladding, 1-brick brickwork, vemiculite concrete, its performance without the use of additional insulation will be equal to 1 m thick masonry made from 7.5 bricks.

Solutions No. 1-4 can be used when performing those construction works where concrete must withstand small operational and installation loads. The use of vermiculite in construction is especially important when creating and insulating roofs of flat structures - Fig. 3.

Rice. 3 Insulation of a flat roof with vermiculite concrete

1-overlap; 2-vermiculite concrete; 3-vapor barrier 4-roof carpet

On the ceiling - 1, on which the parapet is pre-arranged, a vapor barrier is laid - 3 created using polyethylene film. After this, vermiculite concrete is laid over it, created according to one of the recipes indicated in the table. The layer of the mixture can have any desired length. In the conditions of the far north, the layer of thermal insulating concrete on the roof of production facilities should be up to 20 cm.

A week after the concrete gains strength, a roofing carpet can be installed on it. It is not necessary to carry out work to create a leveling screed on vermiculite concrete, since it is characterized by sufficient plasticity and fluidity so that during the process of roofing work it can be immediately leveled, giving the entire surface an even appearance.

Also, the compositions indicated in Table 2 can be used when performing interior plastering work, since they are endowed with increased fire resistance, heat, and sound insulation.

More:

- non-combustible sheet material based on expanded vermiculite

- instructions for using vermiculite

- vermiculite slabs

Using vermiculite for mixtures and solutions

Mixtures for masonry and plaster are produced from fine-grained vermiculite. They are sold ready-made. Another option is to make the raw materials yourself. You will need cement, sand and insulation. The ratios are: 1:0.5:2 or 1:1.25:1.75. At the output, the plaster will have a thermal conductivity coefficient of 0.24–0.4 W/m*K.

Reinforced concrete floors can be insulated with a screed containing vermiculite. In addition to thermal insulation, the layer will protect the rooms from noise. The technology for forming the screed does not change.

However, since the insulation is hygroscopic, it is not recommended to use it for very damp rooms, basements, or foundations.

Otherwise, vermiculite is a universal, environmentally friendly and practical material, used both in the process of building a house and in the finished building. It is easy to work with, and its long service life will allow you not to think about changing the insulation for many years.

Vermiculite prices

Now let’s look at popular manufacturers of this material, as well as approximate prices for their products. Let’s immediately say that there are quite a lot of similar enterprises, so we will get acquainted only with those whose products are in greatest demand.

Vermiculite mixtureApplicationStrengthPackagingPrice

| VERMIX K50 | Masonry mixture with improved thermal insulation | 50 | 20 kg. | 390 rub. Buy |

| VERMIX K75 | Masonry mixture with improved thermal insulation | 75 | 20 kg. | 380 rub. Buy |

Vermiculite mixtureApplicationStrengthPackagingPrice

| VERMIX ШВ25 | Internal plaster for heat and sound insulation | 25 | 9 kg. | 370 rub. Buy |

| VERMIX ШН25 | External plaster for heat and sound insulation | 25 | 9 kg. | 430 rub. Buy |

| VERMIX ШВ50 | Internal plaster for heat and sound insulation | 50 | 17 kg. | 720 rub. Buy |

| VERMIX ШН50 | External plaster for heat and sound insulation | 50 | 17 kg. | 830 rub. Buy |

Vermiculite mixtureApplicationStrengthPackagingPrice

| VERMIX C50 | It is used for floor screeding, as well as insulation and sound insulation and ceilings. | 50 | 15 kg. | 820 rub. Buy |

| VERMIX C100 | It is used for floor screeding, as well as insulation and sound insulation and ceilings. | 100 | 20 kg. | 1000 rub. Buy |