Izolon (cross-linked polyethylene foam) is a universal soft porous material made of polyethylene foam with closed cells, designed for heat, steam, hydro, vibration and noise insulation. Resistant to any adverse influences, durable provided the technology is followed. The only drawback is the relatively high price. They are sold in rolls 1 or 1.5 m wide, less often in sheets. Rolled Isolon longer than 50 m may have joints. Their number, depending on the size, reaches 6.

Characteristics

Description of the main technical parameters:

- thermal conductivity coefficient - from 0.031 to 0.037 W/m*C;

- vapor permeability coefficient - 0.001 mg/m*h*Pa;

- compressive strength - from 0.031 to 0.033 MPa;

- noise insulation - up to 68%;

- density - from 25 to 200 kg/m3;

- water absorption - up to 1%;

- operating temperature range - from -60 to + 75°C;

- degree of reflection - from 95 to 97%.

| Fire hazard class | without flame retardants | with fire retardants |

| by flammability | G2 (moderately flammable) | G1 (non-flammable) |

| according to smoke-forming ability | D3 (high) | D3 (high) |

| by flammability | B2 (moderately flammable) | B1(hard to ignite) |

Technical characteristics of isolon

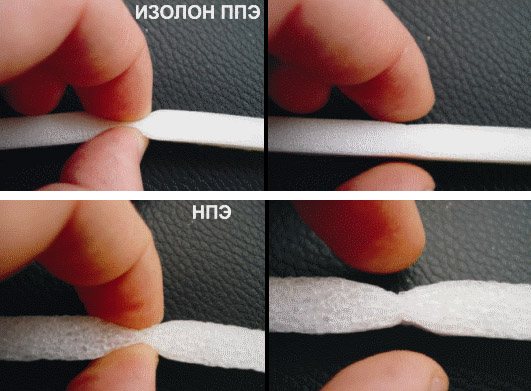

At this stage of technical progress, two types of isolon are distinguished: foil PPE and foil NPE. The first type is polyethylene foam, the second is non-crosslinked polyethylene foam. PPE is produced by vertical foaming, for which air is used. The structure of such an isolon is cross-linked.

Foil-coated NPE is made by melting a polymer into which carbon dioxide is introduced under pressure.

The structure of NPE is characterized by the presence of gas bubbles with evenly spaced closed pores. Izolon can have different features and characteristics, which depend on the substance used for their manufacture. The material can have different thickness and density.

Characteristics of isolon:

- Thermal conductivity. It has excellent thermal insulation characteristics. It has a low thermal conductivity coefficient.

- Hydroscopicity. It has a low moisture absorption coefficient. It is waterproof and vapor proof.

- Elasticity. Does not change its flexibility when temperature changes. The material will also not break if bent.

- Durability. The material does not lose its properties after 80-90 years.

This type of insulation is resistant to various types of weather conditions. This is an environmentally friendly material, completely safe for use in residential areas. Isolon does not release toxic substances when ignited, but simply breaks down into its constituent components (water and carbon dioxide).

PPE - what is it: description

Modern production of insulation materials does not stand still. Today, manufacturers can offer consumers a wide selection of materials for insulation and sound insulation. One such material is isolon PPE. Decoding PPE sounds like polyethylene foam.

Izolon PPE is multifunctional: it is light, resilient, elastic, resistant to moisture, and is not afraid of chemical and biological influences.

Izolon is used not only in the construction industry. It is also used in mechanical engineering, the food industry, and in furniture production. The thickness, density and structure of the material varies.

Description of isolon PPE:

- It is a cross-linked sheet of polymers through physical or chemical action. The material is pre-processed by extrusion.

- During the foaming process, isolon increases its volume, becomes multilayered and acquires a structure consisting of cells.

- In order for the material to be durable, it is reinforced using reinforced mesh and covered on one or both sides with foil with reflective properties.

Polyethylene foam is resistant to shock and sound vibrations, does not absorb moisture and does not allow heat loss. The material is safe for use, since even if ignited, it does not emit toxic substances harmful to human health. PPE is resistant to ultraviolet rays, so it can be used to insulate open structures.

Polyethylene foam (PPE): types and properties

Foamed polyethylene is a popular material in various fields, from construction to repair and production. To obtain this unique product, specialists carried out numerous tests on HDPE - melted it, saturated it with gases, added additives to it, etc.

As a result, a material with excellent characteristics has appeared on the market, excellent heat retention (70%), reliably insulating from moisture and noise, and withstanding mechanical stress.

Other benefits of PPE

- resistance to temperature changes (retains properties at the lowest temperatures);

- low thermal conductivity (which makes polyethylene foam a good insulator);

- environmental safety (does not emit toxic components even during combustion);

- light weight (this greatly simplifies the transportation and installation of PPE products).

There are also disadvantages, the most important one being high flammability (at temperatures above 100 degrees, PPE begins to melt and burn, this must be taken into account when using products made of polyethylene foam). But the advantages outweigh the weaknesses of a unique product.

Products made from PPE are ready to last up to 80 years (not subject to rotting). This is a universal raw material used in construction, household, repair and other areas. Foamed polyethylene is used for insulation of interfloor ceilings, floors and ceilings. The material has proven itself in the construction of residential buildings, bathhouses, garages and outbuildings. Using PPE, loggias and balconies are insulated.

Other Applications

- packaging production;

- production of containers (from canisters to tanks);

- production of medical devices;

- mechanical engineering and automotive industry.

And this is not a complete list of areas in which foamed polyethylene foam is used. PPE is used to make rolls, strands, pipe casings, mats, substrates and other popular products.

Polyethylene foam - what is it: characteristics

There are many types of PPE on the construction market. Brands of isolon vary depending on the method of its manufacture and execution. It can be square or rectangular sheets, the thickness of which varies from 15 to 100 mm. Such plates are characterized by elasticity and softness.

Izolon can be in rolls and have a standard panel width (80 cm - 1.5 m) and length (10 - 200 m), thickness (5 mm - 8 mm).

One or two layers of foil coating can be added to the isolon composition. It can be thin aluminum or reinforced metallized film. During the lamination process, an outer reflective layer is attached to the PPE. The adhesion of the materials is very reliable and durable, which indicates the high quality of the material.

Technical characteristics of isolon:

- Diverse range of operation;

- Thermal conductivity;

- Vapor tightness;

- Water resistance;

- Strength;

- Soundproof.

Izolon PPE has unique properties, for example, foaming ratio. Thanks to the first two numbers on the marking, you can determine the foaming ratio, then the thickness of the material. When purchasing, it is important to pay attention to what the material will be used for. For the substrate under the laminate, choose a thinner isolon, for heat and vapor barrier - a denser one.

NPE - what is it: material features

The building materials market is equipped with three types of polyethylene foam. Two types are cross-linked isolon (PPE), the latter is non-cross-linked (NPE). All types are called foamed. To make the right purchase, you need to understand the characteristics of insulation materials.

Non-crosslinked polyethylene foam has an unstable molecular environment because the molecules do not have a strong bond with each other.

The composition of NPE includes large bubble cells, and the foaming of the material occurs due to gases: freon and propane-butane. The material does not have a cross-linked molecular “network”, so large loads can lead to rupture of the material. NPE usually does not meet the requirements for insulation materials, so it is more often used for packaging.

NPE features:

- The use of the material is not as widespread as the use of PPE.

- In most cases, the properties of NPE do not allow it to be used as insulation.

- NPE is used for packaging furniture, household appliances and shoes.

- Izolon NPE does not withstand heavy loads, so it often breaks.

- The air gradually leaves the cells, so the material is prone to deformation.

Over time, NPE becomes an ordinary film, unsuitable for use. Therefore, you should not use this type of isolon as a material for insulation. Also, it cannot be used for vibration-damping floor screed.

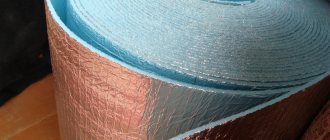

Izolon foil: characteristics

Today, a new type of insulation materials is presented on the market - foil-coated isolon. It has reflective properties that can stop heat flow. Izolon meets all GOST standards: it is safe for use in residential premises.

Foil-coated isolon (lavsan film) is a multilayer material that consists of polyethylene foam and one or two layers of foil.

Reflective insulation works on the principle of transferring heat from a hot surface to a cold one. The process is based on the following physical characteristics: thermal conductivity, convection, thermal radiation. Thanks to the use of foil-coated isolon, it is possible to minimize heat loss.

Where is the material used:

- Food industry;

- Oil refining industry;

- Gas production industry;

- Heating systems;

- Water supply;

- Ventilation;

- Conditioning.

Adhesive PPE is of high quality. For thermal insulation, it is best to use metalized isolon, which is adhesive to the surface. Before gluing the material, you should carefully study the instructions. Izolontape 3010 has excellent characteristics. There are black, white and colored foil Isolon. If you are not satisfied with the color of the material, you can always paint it in the desired shade.

The use of foil isolon and its features

When insulating damp walls, they must first be dried and treated with an antiseptic. The lack of vapor barrier leads to the penetration of moist water vapor from the air into the components of the insulated wall and condensation.

It is necessary to ensure effective ventilation of the insulated wall structure to avoid moisture accumulation.

Often users have to face the problem of choosing insulation for a balcony. It takes quite a long time to search for materials for each of the options. It's nice and cool in the summer, but in the winter? There comes a time when there is a desire for the balcony to please even during the long winter months of our harsh winter. A modern balcony, if you apply a little imagination, desire, materials and material investments, is an additional room that can be used at any time of the year.

When thermally insulating floors using reflective insulation, heat flows reflected from the foil layer do not enter the supporting structures under the floor. When applying the solution directly to reflective insulation in a heated floor system, it is necessary to protect the foil with plastic film.

Contact between the cement screed and aluminum foil is not allowed, since cement mortars are an aggressive environment.

Do-it-yourself insulation of a frame house

It works as thermal insulation and vapor barrier, preventing cold air from the basement from penetrating into the load-bearing structures of the floor, and also as sound insulation, providing reliable protection against household and structural noise.

Sound absorption of at least 32 dB. In lightweight structures, it is recommended to install material with slight sagging, which will allow for natural ventilation of the roof.

After cleaning from dust, the material is mounted on concrete and metal structures using glue, or self-adhesive ISOLON is used. A tight fit of the material to the base will avoid the accumulation of condensation.

Characteristics of isolon PPE (video)

Izolon is a modern material that is used as insulation. It also has waterproof and soundproofing properties. The material is based on polyethylene, which is foamed during the manufacturing process. Izolon can be of different types: PPE and NPE. The latter is not very suitable for insulation work. The width and length of the material can be different; the dimensions of the isolon are chosen depending on the purpose. Isofoum PPE is a universal material that is characterized by elasticity, flexibility, elasticity, reliability and strength. Izolon is an environmentally friendly material, it is safe for human health and does not emit toxic substances.

Izolon

- Product Catalog

- Thermal insulation materials

- Izolon

- Izolon laminated NPE LP

Izolon

, depending on the production technology, it can be “stitched” or “unstitched”. Non-crosslinked isolon refers to polyethylene foams that have an unbound molecular structure (i.e., the polymer molecules are not linked to each other by chemical bonds). When producing uncrosslinked isolon, the structure of polyethylene does not change, but when producing crosslinked isolon, it is modified. As a result of cross-linking, a so-called cross-linked or network molecular model is formed. Cross-linked polyethylene foams are qualitatively different from non-cross-linked ones, having better characteristics. Due to the cross-linking of molecules, the most important parameters of isolon are increased, such as heat resistance (the operating temperature range of cross-linked isolon is usually 20 - 30 ° C higher than non-cross-linked isolon), resistance to organic solvents, oil, petroleum, gasoline resistance, greater resistance to ultraviolet radiation and weather resistance, which means a longer service life of the material itself.

Brands isolon

Depending on the production technology and the raw materials used, the following brands of Isolon are distinguished:

- Izolon brand PPE

is physically cross-linked polyethylene foam. Thanks to radiation cross-linking, the molecular structure of the material labeled PPE acquires a cross-linked or network model, which significantly increases the durability and resistance of the material to mechanical and temperature influences. Density range - 25...200 kg/m3. Operating temperature range: 60°С…+100°С.

- Izolon brand PPE NR

is physically cross-linked polyethylene foam, foamed in a horizontal oven, up to 2 m wide. Density range - 25...200 kg/m3. Operating temperature range: 60°С…+100°С.

- Izolon brand PPE NX

is chemically cross-linked polyethylene foam, foamed in a horizontal oven, up to 2 m wide. Density range - 25...200 kg/m3. Operating temperature range: 60°С…+100°С. - Izolon brand PSEV

is a physically cross-linked penosevilene. In comparison with Izolon PPE penosevilene has improved physical and mechanical properties, in particular low residual deformation, incl. and during cyclic compression. Density range - 33...200 kg/m3. Operating temperature range: 80°С…+80°С. - Izolon brand NPE

is foamed (gas-filled) polyethylene with a non-crosslinked molecular structure. This material has the best price/quality ratio. Density range - 19...35 kg/m3. Operating temperature range: 80°С…+80°С.”

Recommendations for the use of isolon and installation*

In accordance with the certification test protocols of the Research Institute of Building Physics, Izolon of the PPE and NPE brands is recommended for thermal insulation of enclosing structures, refrigeration equipment and pipelines, taking into account the requirements of regulatory technical documentation for structures and equipment, as well as as elastic soundproofing cushioning materials in structures interfloor ceilings and foundations for engineering equipment.

| Description | Mark Isolona |

| An effective heat-insulating layer of isolon between the load-bearing part of the wall and the internal decorative finishing, between the front sides of wall partitions | PPE 3004 - 3050 NPE 04 - 20 |

| Elastic shock and sound insulating layer between the base of the floor and the screed in a floating floor structure | PPE 3004 - 3008 |

| Elastic shock and sound insulating substrate between the screed and the floor covering (parquet, laminate board) | PPE 3002, NPE 02 |

| Thermal and vapor barrier layer of the base floor, installed above the basement/underground premises | PPE-L 3008-3010, NPE 10 |

| Thermal insulating (and at the same time heat reflecting in the case of using isolon with foil or metallized PET film) layer under the heating elements in the design of an active heated floor | PPE 3004 with metallized PET film |

| Shock-absorbing mat for artificial turf. | PPE-L 3008-3010 |

| An isolon profile used as a seal when laying roofs with tiles or other corrugated surfaces for thermal insulation, protection against dust penetration, prevention of moisture condensation and noise reduction. | PPE-L 3030 |

| Izolon mats used to compensate for linear elongations of pipes during underground laying of hot and cold water supply pipelines using the ductless method | PPE-L 3015-3045 |

| Thermal insulation of tunnels, isolation from the penetration of groundwater with the subsequent formation of ice layers. | PPE-L 3010 - 3020 |

| Sheets that prevent heat loss due to hydration during concrete laying at low temperatures. | PPE-L 3008 - 3010 |

| Izolon strips for thermal insulation (reflective insulation) of hot (up to 100°C) and cold water supply pipes. | PPE 3004 - 3010, NPE 05 - 10, incl. with metallized PET film |

| Thermal and sound insulation of air conditioning units (adhesive or mechanical fixation). | PPE-L 3004 - 3010, NPE 05 - 10, incl. with metallized PET film |

| Sealing joints of prefabricated building elements and structures. | NPE 03 - 08, PPE 3003 - 3005 |

| A sliding membrane is a strip of isolon used as a partition between lightweight concrete structures. | PPE 3005, NPE 08 |

* This list is far from complete and serves only as a basis for new ideas.

Recommended adhesives for isolon

Thanks to its uniform cellular structure and elasticity, Izolon is very easy to install. In general, installation is carried out by gluing to the surface, the joints are formed overlapping, welding with a construction hair dryer is possible.

Recommended adhesives: AKROL CONTACT (TU OP 2241-001-32998388-97), aqua spray "NEOPREN 2136", glue 88-NP. It should be remembered that before gluing it is recommended to clean the surfaces from dust, grease, oil, etc.

Using double-sided mounting tapes, Izolon can be easily attached even to a curved surface. For fastening to a flat, smooth surface, you can use staplers, screws, slats, etc.

When laying parquet or laminate boards, care must be taken to keep Izolon sheets without tears or cuts. Avoid sound bridges between seamless floors and concrete floors, walls and pipelines passing through them.

When laying Izolon as a heat-insulating layer, the required sheet thickness is calculated according to SNiP 11-3-79 “Construction Heat Engineering”.

Physical and technical indicators of isolon

Characteristics of isolon

| Indicator names | Unit change | Izolon PPE | Izolon NPE |

| Apparent density | kg/m³ | 25-38 (for construction grades) | 19-35 |

| Specific heat | kJ/kg°C | 1,8 | 1,95-2,0 |

| Calculated mass ratio of moisture in the material: under operating conditions A under operating conditions B | % | 2,0 10,0 | 2,0 5,0 |

| Calculated thermal conductivity coefficient: under operating conditions A under operating conditions B | W/m °C | 0,036 0,037 | 0,048 0,049 |

| Calculated heat absorption coefficient (with a period of 24 hours) under operating conditions A under operating conditions B | W/(m² °C) | 0,39 0,43 | 0.44 0.49 |

| Vapor permeability: under operating conditions A and B | mg/(m.h.Pa) | 0,001 | 0.001 |

| Breaking tensile stress, not less: - longitudinal direction - transverse direction | MPa | 0,33 0,21 | 0.30 0.30 |

| Compression resistance at 10% strain | MPa | 0,02 | — |

| Compression resistance at 25% strain | MPa | 0,025 | 0.015 |

| Water absorption (96 hours) | % volume | less than 1 | less than 1 |

| Heat shrinkage - longitudinal direction - transverse direction | % | (70°С, 22 h) 1.45 0.75 | (80°C, 24 hours) 1.7 0.8 |

| Dynamic modulus of elasticity under loads: 2000 N/m² 5000 N/m² | MPa | no more than 0.23 0.70 | 0,22 0,60 |

| Relative compression at loads: 2000 N/m² 5000 N/m² | % | 0,05 0,1 | 0,05 0,08 |

| Sound absorption coefficient with a thickness of 10 mm: frequency 250 Hz frequency 500 Hz frequency 1000 Hz frequency 4000 Hz frequency 6000 Hz | % | 7 15 24 50 60 | — |

| Reduced impact noise reduction index, not less | db | 18 | 18 |

Fire resistance categories of Izolona PPE

| Options | without added flame retardant | with added flame retardant | |||

| thickness, mm | 2-5 | 6-10 | 12-20 | 2-5 | 10-20 |

| flammability group according to GOST 30244 | G2 | G2 | G4 | G1 | G2 |

| flammability group according to GOST 30402 | AT 2 | AT 3 | AT 3 | IN 1 | AT 2 |

| smoke generation group according to GOST 12.1.044 | D3 | D3 | D3 | D3 | D3 |

Fire resistance categories of Isolon NPE

| Options | without added flame retardant | with added flame retardant | ||

| thickness, mm | 1-15 | 20-50 | 1-15 | 20-50 |

| flammability group GOST 30244 | G2 | G4 | G2 | G2 |

| flammability group GOST 30402 | AT 2 | AT 2 | AT 2 | AT 2 |

| smoke generating ability group GOST 12.1.044 | D3 | D3 | D3 | D3 |

Isolon is one of the most effective heat insulators and can significantly reduce the weight of structures and save usable space. For comparison, 1 cm isolone replaces:

- 1.2 cm polystyrene foam;

- 1.5 cm mineral wool;

- 15 cm of brickwork;

- 4.5 cm of wood (spruce, pine).

In accordance with the certification test protocols of the Research Institute of Building Physics, Izolon of the PPE and NPE brands is recommended for thermal insulation of enclosing structures, refrigeration equipment and pipelines, taking into account the requirements of regulatory technical documentation for structures and equipment, as well as as elastic soundproofing cushioning materials in structures interfloor ceilings and foundations for engineering equipment.

Some ideas for using Izolon*

| Application area | Description/function |

| Concrete Curing Sheets | Sheets preventing heat loss due to hydration during concrete laying at low temperatures |

| Sound and heat insulation of floors (floating/floating floors) | Isolon sheets (sometimes with an embossed surface) are used as acoustic barriers between concrete blocks and the floor. |

| Underlay for parquet, laminate boards and various floor coverings | Sheets of isolon (sometimes complex, with an embossed surface) for heat and sound insulation and as a barrier to the rise of water vapor. |

| Subfloor insulation | Izolon sheets for impact and sound insulation of floors, soft and elastic underlays for parquet, linoleum, carpeting or other types of flooring. |

| Artificial turf bedding | Isolon sheets as bedding for artificial turf. |

| Building foundations (separating partitions) | Izolon sheets and flooring are used to separate adjacent walls subject to vibration and movement. |

| Pipe insulation | Izolon strips for thermal insulation of hot and cold water supply pipes. |

| Insulation of ventilation pipes | Sheets or flooring made of isolon for thermal and sound insulation of air conditioning units (adhesive or mechanical fixation / fastening). |

| Joints of concrete sidewalks | Sheets or decking between concrete blocks to reduce stress and prevent cracking. |

| "Floating" stair steps | Sheets for shock and sound insulation from the floor and side walls. |

| Sealing tapes | Sealing joints of prefabricated building elements and structures. Primary seal for expansion joints or non-bonding backing for cold air seals. |

| Sliding membrane | A strip of isolon as a partition between light weight concrete structures. |

| Membrane protection | Isolon sheets as mechanical protection for sealing membranes. |

| Threshold seals, partition walls | Tapes as a seal against water and air between the foundation, wall partitions and threshold slab. |

| Ribbed Roof Insulation | An isolon sheet glued or layered onto a ribbed metal roof for thermal insulation, preventing moisture condensation and reducing noise. |

| Window insulation tape | Izolon tape with an adhesive layer as a sealing connection between the glass and the frame. |

| Thermal insulation of walls | Izolon sheets for thermal insulation and covering the walls of cottages, country houses, garages, caissons, etc. |

| Heat reflective screens | To reduce heat losses, sheets of isolon with a metallized polymer film are attached to the surface of the area behind the radiator of the outer wall. |