How to choose the right insulation thickness?

Since the thickness of mineral wool affects the thermal characteristics of the thermal insulation system, it should be selected taking into account the climatic conditions of the region of residence, air humidity, and technical characteristics of the insulated surface. The averages are approximately as follows:

- For an external wall, where it is necessary to achieve the standard indicator of the material’s resistance to heat transfer, the recommended thickness of mineral wool should be from 8 to 10 cm.

- For basements (walls, ceilings), surfaces in contact with the ground - the layer of insulating material should be from 6 to 15 cm.

- The thickness of mineral wool for the floor in a heated room is at least 6 centimeters, with a maximum thickness of 15 cm.

- The thickness of mineral wool for the ceiling of a house in contact with an unheated attic should range from 10 to 16 cm.

- Pitched roofs should be insulated with thermal insulation material with a thickness of 15 to 30 cm.

Average data may vary depending on the climate in the region of residence.

Features of building insulation with mineral wool

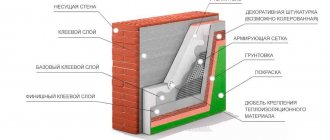

The process of installing a thermal insulation system made from mineral insulation materials is not particularly difficult. Existing methods suggest laying them in a frame, followed by covering them with finishing material. And when working on vertical surfaces, it is recommended to use dense slabs made of mineral raw materials (at least 75 kg per cubic meter). The thickness of mineral wool slabs should also be selected taking into account the climatic conditions of residence.

It is quite natural that the thickness of mineral wool affects its cost, so choosing insulation of a “universal” thickness cannot be considered the optimal solution. Since this will either lead to a large overexpenditure of funds, or the created thermal protection system will not provide the necessary resistance to thermal conductivity. When performing any installation work with mineral insulation, it is imperative to use personal protective equipment (respirators, long sleeves).

We recommend reading on the topic

Technology of ceiling insulation with mineral wool.

Modern technologies for ceiling insulation with mineral wool are used in almost all options for retaining heat in a room, providing a comfortable microclimate throughout the house.

The ceiling can be insulated both from the inside and outside. These operations are almost the same in cost. The quality of work depends on the material and the craftsman who insulates the ceiling.

The insulation process itself is not difficult. The owner can insulate the ceiling with his own hands, using the experience of craftsmen who post informational videos and text tips online.

Let's sum it up

All ceiling insulation in a wooden house has individual characteristics. Some retain heat well, but emit harmful substances. Others are environmentally friendly, but you need a lot of them.

Therefore, professional builders recommend universal options: basalt wool and glass wool. Such insulation is called in one word - “mineral wool”. They can be installed both from the attic and from the lower floors. They do not harbor mice and cockroaches, they do not burn and are able to contain a fire without emitting harmful substances. But the most important thing is that they will perfectly retain heat in your home and provide a comfortable microclimate.

The categories mentioned in the article are:

Thermal insulation

Thermal insulation

Insulating the ceiling with mineral wool.

Many people choose mineral wool for home insulation, because this material has a minimum of disadvantages and a lot of advantages, unlike other types of insulation materials.

- Availability. The cost of mineral wool allows each owner to purchase the necessary material;

- Convenient to use;

- It does not harbor various types of insects and pests;

- Fire resistance and moisture resistance;

- Mineral wool is completely protected from the occurrence of mold and fungi;

- Soundproofing properties;

- Environmentally friendly products. In the production of mineral wool, natural substances and fibers are used that are not harmful to the health of people living in the house;

- Vapor-permeable properties allow the ceiling to breathe (this property keeps the house cool in summer and does not let heat out of the room in winter);

- Mineral wool is resistant to mechanical stress.

Mineral wool has some disadvantages, but they are not significant and do not affect the overall result of insulation.

One of the main disadvantages is the loss of thermal insulation properties when compacting it at the installation site. Also, mineral wool can lose its properties when wet, so it must be protected from direct contact with moisture.

Thickness of mineral wool for ceiling insulation.

Among people who have insulated the ceiling with mineral wool, there are complaints about its quality. Some complaints are aimed at the appearance of drafts, excess moisture, and heat loss from the room.

The reasons for such opinions may be hidden not in the quality of the material, but in a violation of the installation technology or an insufficient layer of insulation.

If the roof and ceiling outside of the house are not insulated at all, only one insulating layer inside the room may not be enough to maintain a normal, comfortable microclimate indoors.

The fact is that the thickness of mineral wool should vary depending on the specific conditions of a particular home. Many nuances should be taken into account in order to properly insulate the ceiling with mineral wool.

The regulated thickness of mineral wool for a house with an unheated attic space is from 10 to 16 cm. If the roof of the house is also not insulated, the layer of mineral wool must be doubled, or, at the same time, insulation of the ceiling outside the room (in this case, from the attic) must be carried out. .

If the owner decides to insulate the pitched roof, the thickness of the insulation layer should be exactly 15-30 cm.

The main indicator of thermal insulation is not only the mineral wool, but also the quality of installation.

Insulation of the ceiling from the inside of a room in a private house

You can learn how to properly insulate a ceiling with mineral wool in a private house by watching the video on our website. The first step will be to pack profile bars in the room perpendicular to the light flux from the window. The distance between the two bars should be slightly less than the width of the mat. After this, a vapor barrier film is laid out in each individual segment and secured to the beam with a stapler.

Mineral wool is placed effortlessly into the resulting bed and secured to the ceiling with nails, screws, and self-tapping screws with a wide plate-head. From above, the entire structure is covered with a waterproofing film. New polyethylene film can be used as it. The overlapped joints are sealed with adhesive tape.

To finally impart strength to the structure, thin transverse slats are laid, strengthening them on longitudinal, more powerful slats. The installation of thermal insulation is completed, and the front finishing of the ceiling can be completed.

How much does it cost to insulate a ceiling with mineral wool?

The relevance of insulation generally depends on the region and climate conditions where the house is located. These indicators should be taken into account when planning insulation methods and the use of the necessary material.

Modern construction includes a clause on insulation work in the project itself, since this is a mandatory measure of energy-saving trends of our time.

Due to its low cost and quality, mineral wool is more often used for insulation at home. Such work can be carried out with your own hands, then insulating the ceiling will be much cheaper than using hired workers.

The average price of a standard roll of mineral wool (10 m long, 1.2 m wide and 5-20 cm thick) is about 1,200 rubles. This means that 1 m 2 of mineral wool costs 100 rubles.

The cost of insulating 1 m2 of area is about 70 rubles (at the beginning of 2020). Based on this, the insulation of the ceiling of a house of 20 m2 will be: (1200 rubles * 2) + 120 rubles * 20 m2 = 2400 + 2400 = 4800 rubles.

Also watch an interesting video about insulating the ceiling with mineral wool

3 comments: Technology of insulating the ceiling with mineral wool.

Reasons for ceiling insulation

Many owners of private property do not understand why they need insulation for the ceiling in their house, if during the construction process the attic space was equipped in accordance with the rules and requirements of modern heat conservation.

Among the most common are two significant reasons:

- combating condensation;

- reduction of energy costs.

Even with well-organized air exchange in the space between the floor ceiling and the roof in winter, moist and warm flows come into contact with the cooler ceiling surface, resulting in the inevitable formation of condensation.

It spoils the decorative design of the room, promotes the appearance of mold, and makes the surrounding air more damp and musty.

To carry out insulation work, it is not necessary to invite hired craftsmen. Having carefully studied the features of heat-saving materials and the technology of their installation process, the owner of the home can easily cope with the task.

As for reducing energy costs, for this purpose, when creating an autonomous heating system in a private house, it is imperative to calculate the potential heat losses. In the process, it is possible to reveal that about 15% of all valuable heat generated by heating equipment escapes through the ceiling into the street.

Losses can be covered by increasing the capacity of the existing boiler room or installing additional heating devices, which always costs serious money. Only insulation installed on the ceiling in a private house will help solve the problem of condensation and heat loss immediately without huge financial costs.

You can use both traditional natural and more advanced artificial insulators, which are widely represented on the modern construction market.

Insulating the ceiling with mineral wool (mineral wool) - step-by-step instructions

The conditions of the Russian climate with short summers and long frosty winters create the need to take additional measures to insulate residential buildings. One of them is covering the ceiling with mineral wool. This procedure will ultimately help not only to increase the period of heat retention in the premises, but also to avoid the appearance of mold and mildew on the ceiling due to condensation, which is formed as a result of direct collision of cold and warm air.

Ceiling insulation with mineral wool

It is recommended to insulate the ceiling in residential buildings using mineral wool, because... It is a non-toxic and environmentally friendly material, does not rot, is fireproof, and insects and rodents cannot grow in it.

The most important thing is that it has excellent heat and sound insulation qualities. Mineral wool is produced in the form of rolls and slabs. Also, when choosing, you should pay attention to the foil-coated nature of the mineral wool - it’s good if one side of the roll or slab is covered with a layer of waterproofing foil. If there is no such layer, then, ideally, you need to additionally purchase several rolls of foil polyethylene foam. Instead, you can use thick plastic film. Glassine is suitable as a vapor barrier. These materials are necessary to keep mineral wool dry, because wet insulation loses up to 40% of its thermal insulation properties. In addition, you will need self-tapping screws, fasteners with a wide plastic head, a counter-batten, glue for mineral wool, a profile and hangers for the profile, a stationery knife, a construction stapler, nails, a screwdriver, a hammer and a tape measure.

The most common thickness of the produced layers of mineral wool is 10 and 5 cm. When insulating the ceiling, a layer of insulation 10 cm thick is sufficient, in particularly difficult cases - 15-20 cm. Based on the method of performing the work, insulation is divided into internal, external and combined.

Types of mineral wool

Disadvantages of mineral wool

There are no perfect materials; each has its own pros and cons. Mineral wool is no exception; it also has several significant disadvantages. Firstly, this material cannot be crushed, much less compacted, since when the fibers are compacted, the thermal insulation properties decrease. Secondly, mineral wool must be carefully protected from moisture, since when wet it can completely lose its properties. Therefore, when insulating ceilings, it is used together with other materials that prevent moisture from entering. Most often, foam boards and polyethylene film are used together with mineral wool, in which case the thermal insulation is the most reliable.

Internal insulation

The need for internal ceiling insulation is most typical for houses with several floors or with an attic, as well as for city apartments. The entire scope of work consists of the following stages:

- Ceiling lathing - can be made of boards with a section of 30-40 x 100-200 mm (the width of the board directly depends on the thickness of the insulation layer) or a metal profile. The lathing is attached to the ceiling using nails or self-tapping screws, and the distance between adjacent parts should be about 50-60 cm, depending on the width of the mineral wool used.

Ceiling lathing

- A layer of waterproofing is attached to the finished sheathing - strips 50-60 cm wide are cut out plus a tolerance of 5 cm on each side, i.e. the final width will be 60-70 cm. These strips are attached with counterbattens to the wooden sheathing or with self-tapping screws to the profile.

- Next, mineral wool is laid and fixed with glue or a construction stapler to the ceiling, or, if the layer is thick, to the sheathing.

Fastening mineral wool to the ceiling - The next layer is a vapor barrier using glassine. It is mounted on mineral wool using a stapler.

- The finished structure is secured by transverse fixation of counter rails or profiles.

We attach mineral wool to the ceiling - The internal insulation procedure is completed, the next step is installation of plasterboard, panels or stretch ceilings on the sheathing.

How to insulate a ceiling in a private house with mineral wool

The technology consists of the following points:

- Preparation of surface and materials.

- Backfilling work, securing layers.

- Completion – finishing, construction of the floor.

The task is surprisingly simple.

Preparation for installation of mineral wool on the ceiling

Before any work, surfaces are cleaned. The attic is thoroughly washed using detergents and damp rags. Wet work requires drying afterwards.

Interesting! After washing, a wooden attic takes longer to dry than a concrete one. This is due to the fact that wood absorbs moisture.

Afterwards, the cotton wool is cut and the film sheet is cut out to the required size.

Thickness of mineral wool for insulation

The layer is calculated relative to:

- Necessary insulation effect.

- Beam heights.

- Thickness of the purchased material in its original form (rolls, slabs).

It is advised not to organize more than four layers.

Insulation layers

Related materials

The material component for installing cotton slabs is simple and does not require additional large costs.

A polymer film with hydro-repellent and vapor-repellent properties is required. Membrane is excellent, but other varieties are also used.

In addition to film, they stock up on tape. It is necessary for gluing the edges and provides additional strength. Use high-quality construction or stationery materials.

Regarding tools, you will need a “standard set”. It includes a knife - it is suitable for cutting film material. It is realistic to use ordinary scissors, but the knife is considered more maneuverable and easier to use. To carry out fastening, a construction stapler is used; special staples are required for it.

Laying

Interesting! Nail or screw fastening is also used. However, there is a high risk of wear and tear - there are still small “holes” that expand under certain circumstances.

No adhesive fasteners are used. The possibility of condensation does not allow the membrane film to be bonded to the cotton wool - there is no gap between them with such a device, the wool becomes wet and does not perform its main function.

Material calculation

The calculation is carried out taking into account:

- Surface area between beams.

- Height of beams.

- Required layer thickness.

Under any circumstances, the error is taken into account; to prevent incidents, they take more, not less.

External insulation

This method is used in private houses with an attic. Compared to internal insulation, this type of insulation is simpler to implement and takes much less time and effort. So:

- The entire area of the attic is covered with an overlapping layer of vapor barrier material (glassine) 5-10 cm wide, the joints are taped with adhesive tape or tape.

- The sheathing is made from boards with a section of 30-40 x 100-200 mm (the width, as with internal insulation, depends on the thickness of the mineral wool layer). The distance between adjacent beams is calculated according to the width of the roll or insulation boards.

We make lathing (grooves) for laying mineral wool

Lay a layer of foam plastic

The process of laying mineral wool in grooves on the roof

Combined insulation

Combined insulation is the installation of mineral wool on the ceiling both from the inside and from the attic. This method of insulation is typical for rooms in which it is necessary to maintain elevated temperatures for a long time - baths, saunas, steam rooms, etc.

In conclusion, a few words should be said about small tricks that will help avoid numerous problems after insulating the ceiling with mineral wool:

Video - Ceiling insulation with mineral wool

What layer of mineral wool is needed to insulate the ceiling?

The quality of mineral wool is determined by the condition of the material fibers, density, and thermal conductivity coefficient, which for slag wool is in the range of 0.046-0.48 W/ (m °C). When you buy mineral wool, there may be an R-value, which is defined as the ratio of the thickness of the material layer to the thermal conductivity coefficient: R = d/k.

For example, for slag wool with a thickness of 0.25 m we obtain R = 0.25/0.046 = 5.4 m2 °C/W , and the R-value of sand-lime brick with a thickness of 0.25 mm is 0.3 m2 °C/W , which in 18 times lower than that of mineral wool.

Thickness of mineral wool for ceiling insulation

It is not surprising that this material began to be used for insulating structures. This led to savings in building materials and cheaper construction.

Usually they produce standard sizes for material thickness: 50 mm , 100 mm . As can be seen from the example above, a thickness of 200 mm is enough to insulate a room for the harsh climatic conditions of the Russian winter . You need to focus on the material of the walls of the house. If these are wooden walls made of timber 150 x 150 or 200 x 200 mm, then one 50 mm layer of mineral wool is enough.

House-building factories produce ready-made panels, where the thickness of the mineral wool insulation is 200 mm in two layers of 100 mm, which corresponds to SNiP 2.11.02-87 , in which the R-value for walls is 2.1 - 5.6 , for ceilings and floors 2, 8 – 7.3 . They also take into account the installation technology and all the structural elements of the walls or ceiling: add the external cladding, the internal and vapor barrier layer, and even air gaps, then you get R above 7.3.

Which mineral wool to choose for ceiling insulation

Standard mineral wool insulation sheets have a width of 565, 600, 619 mm, and rolls - 1200, 1220 mm. These dimensions are suitable for installation between joists; The roll insulation is cut in half. A margin of 2-3 cm in width is needed for tight installation between the joists. The best mineral wool is the one with a higher R value and greater density.

According to this indicator, the best mineral wool from ISOVER , thermal conductivity, according to GOST 7076-99 λ > 0.038 W/(mK), where λ is the thermal conductivity coefficient (can be denoted by k). This should not be confused with the R value - a measure of thermal resistance.

The smaller λ or k, the better the insulation, and for the value of R, on the contrary, the larger, the better. Pay attention to this when purchasing. Select the density depending on where the insulation is located: for walls and roofs 80 kg/m3 is suitable, for light ceilings a lower density is suitable - up to 60 kg/m3.

Based on ease of installation, glass wool causes itching on the skin, while slag wool has prickly fibers. Stone wool is free from these inconveniences; moreover, unlike slag wool, it is used indoors. Mineral wool for external ceiling insulation is selected based on a density of 80 kg/m3 or more, as well as ease of installation, roll or sheet material

Ceiling insulation with mineral wool is best done from the attic . Correct laying of mineral wool - 2-3 layers to cover the joints of the sheets in order to eliminate cold bridges during laying. Select the required thickness of the material and lay the sheets between the floor joists, leaving a gap between the insulation and the membrane vapor barrier film.

This is a visual diagram of how to properly insulate a ceiling with mineral wool.

Look at the diagram to see how the membrane-type vapor barrier film . Shown here is the insulation of the ceiling from the outside. Using this scheme, it is not difficult to imagine insulating the ceiling with mineral wool from the inside when there is no access to the attic. This is possible if the roof is pitched or flat.

A sheet of mineral wool is placed between the floor joists. To fix it in this position, make a frame of thin twine . Simply staple it to the joists. This is necessary so that when stretching the vapor barrier and attaching it to the joists, the mineral wool does not slide down. Then a 20 x 30 mm lath and sheets of plasterboard, lining, and other material are stuffed.

Do-it-yourself ceiling insulation with mineral wool

If it is necessary to insulate a ceiling that has a ceiling in the form of concrete slabs or a solid ceiling, then a sheathing made of either wooden blocks or metal profiles is attached to the ceiling.

First, a horizontal wall beam . The beam is attached to the ceiling surface with anchors or corners in increments of 57-59 cm. The height of the beam is at least 70 mm for one layer of mineral wool sheet. If 2 layers are required, then instead of timber, a 40 x 150 board is attached with an edge to the ceiling with the same pitch. Then the vapor barrier is sewn on with staples. A lath for the air gap is nailed onto the beam, and then drywall.

Insulation of a suspended ceiling with mineral wool

First, they make a metal profile lathing for the suspended ceiling. Buy materials from one seller so that all profiles and accessories come in one set. There is a gap between the ceiling profile and the ceiling where mineral wool sheets and vapor barrier are placed.

First, mineral wool was laid on the sheathing, and then a vapor barrier film . Then the sheets of drywall are sewn on. Here, the distance to the ceiling allows you to lay the insulation in only one layer of 50 mm. If there is ventilation between the ceilings, then a vapor barrier is not needed.

How to insulate a ceiling with mineral wool without installing a frame

In cases where it is necessary to insulate the ceiling from the inside without a significant loss of height, mineral wool sheets are attached directly to the ceiling using glue, adhesive putty, dowels with long rods and plastic caps in the form of umbrellas. For insulation with a thickness of 50 mm, dowel-nails 10 x 120 mm will do.

The fact is that plastic rods are either fragile or too soft. The first ones break, and the second ones are difficult to hammer in and do not expand the dowel tip well; metal ones are better, but choose stainless steel nails.

Operating procedure:

- Preparatory work, cleaning the ceiling surface from the old coating, sealing irregularities and cracks with cement mortar.

- Apply primer with a brush or spray and let dry. Make two layers. Using a notched trowel, apply adhesive putty to one side of the slab with a layer of 5-8 mm.

- Place the slab against the ceiling and press down. It’s good if you have an assistant who will fix the slab in the center and then along the edges. After installing the slabs, wall profiles for the suspended ceiling are attached; a vapor barrier can be omitted if there is ventilation between the ceilings.

Dowel-nail, 2. Mineral wool, 3. Concrete ceiling.

The work can be made easier if you apply liquid nails-type glue to the surface of the slab.

and not worth highlighting anyone in particular High-quality material is visible to the touch: if it is dense, then more material was spent on its production. Also pay attention to the composition: fiberglass, slag (the cheapest), or basalt mineral wool, the most popular today. It is recommended for insulation both inside and outside; glass wool is best used outside; mineral wool made from slag is used for insulation of communications: pipelines, sewers.

Thermal qualities are determined by the value of thermal conductivity or thermal resistance R. Basalt wool is a non-flammable material, it can be placed in the passage box of a chimney, and sandwich chimneys for sauna stoves are made from it.

Materials for ceiling insulation

Building materials stores offer an assortment of insulation materials. Main types:

- mineral wool, produced in glass wool, slag wool and stone wool varieties;

- rolled foil polyethylene foam;

- foam boards of various thicknesses;

- polyplex or polystyrene, also available in the form of slabs;

- loose expanded clay.

Among the methods that are used less and less, but have the right to exist, sawdust can be noted.

The refusal of professionals to use this method, which was recently popular, is understandable. To protect against rodents and moisture, the material must first be thoroughly prepared, mixed with clay and lime, moistened, dried, and loosened. Against the background of these hassles, the advantage of cheapness fades, inclining the master to choose less demanding foam or polyplex.

Combining materials is allowed: the toxicity of mineral wool makes us think about an additional barrier against the gases it emits. This can be served by a dense but thin layer of foamed polyethylene on a foil base.

Popular materials for ceiling insulation: mineral wool, expanded clay, sawdust and polystyrene foam