Heating system booster pump

Pump for pumping up the heating system, manual.

Manual pressure tester for heating systems up to 60 bar

Manual pressure tester for filling heating systems up to 60 bar.

Manual pressure tester for heating systems up to 50 bar

Manual pressure tester for filling heating systems up to 50 bar.

Pump for filling and testing heating systems 60 Bar

Pump for filling and testing the heating system 60 Bar. Capacity: 6 l/min

2013-2020 © "Dixis Coolant"

Dear visitors, by submitting any form on the site, you agree to the privacy policy of this site.

In the section “ Pumps for filling, crimping and pumping up heating systems ” the following are presented:

- 1) Pumps for filling the heating system of the Malysh type with upper and lower liquid intake. The price of a pump with an upper liquid intake is lower, but with such a pump it will not be possible to pump out the coolant from the filling tank to the bottom, so to pump the system it is more convenient to use a pump with a lower intake; they are available in two configurations: with an electric cable of 10 and 25 meters. When purchasing a pump, do not forget about a 2.5 meter connecting hose with clamps and an adapter for connecting to the heating system.

2) The NIR-25 is designed for pumping coolant into a pressurized heating system of a private home. Everyone knows that the pressure in a heating system filled with antifreeze periodically drops below 0.7 Atm, and the heating boiler stops. In order to start the boiler, it is necessary to pump 1-3 liters of coolant into the system, after which the pressure will rise above 1 Atm and the boiler will start working. The Saturn NIR-25 pump is best suited for such purposes; it is very compact and does not take up much space; pumping points are usually located in technical rooms, so it is not necessary to disconnect it from the system every time, but it is better to leave it connected to the service valve. The same pump can also be used for pressure testing of system elements to a pressure of 25 atm.

3) Pumps NIR-50 and NIR-60 serve the same purposes, only they have greater productivity, are assembled using premium materials and can be used by professionals in everyday work. They can pressurize systems up to 50 and 60 atm, respectively.

- 4) Electric pressure tester NIE-6-60 up to 60 Bar - pump for filling the heating system with a capacity of 6 liters per minute. Professional plumbers should pay attention to this model, which has an electric drive; such pumps are much more profitable to use than manual pressure pressers, because... significantly save time and physical effort. Electric pressure testing pumps are manufactured in Russia, are equipped with glycerin pressure gauges with vibration protection, are lightweight and have a 220V power supply. The working group NIE-6-60 is made of stainless steel and brass using graphite seals. All products have a 1 year factory warranty.

You are viewing the Pump , located in the large System Components section.

Technical parameters of water supply laid down in the standards

Modern household appliances are designed for water supply pressure of 4 bar. If there is less pressure in the tubes, the devices turn off. You can find out the pressure using a pressure gauge or using a homemade device - a transparent tube 2 m long connected to a tap.

The following are recognized as equivalent physical pressure values: 1 bar, 1 at, 10 m water. Art., 100 kPa. Such indicators can be found in the pump data sheets.

The normal pressure for which pipes, connections, and gaskets are designed is 4 bar. At 6-7 bars, leaks appear in the line, at 10 the pipes can burst. You need to know this when choosing a pump to increase water pressure.

Is it always possible to install booster pumps?

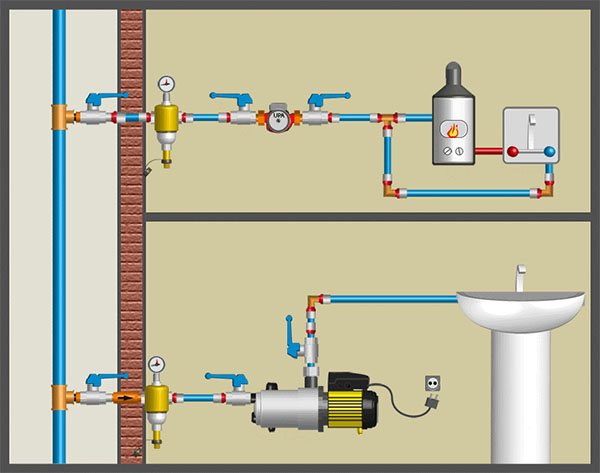

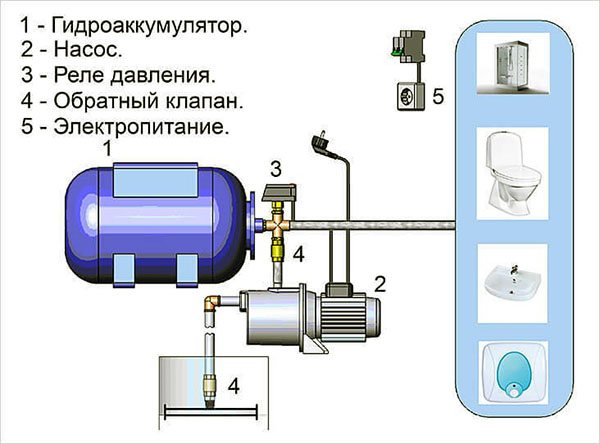

In a private house, the lack of pressure in the main line is relieved by installed pumps. At the same time, their power supply through the battery tank allows for stable input parameters. Install devices in areas where it is necessary to increase the pressure after the pump. A pump for increasing water pressure differs from a centrifugal one in that it turns on periodically, upon request. The centrifugal apparatus in the system operates constantly.

On this topic:

Excellent quality polishing machine from China

Jun 5, 2018

To help the master, a staple crimping tool from China

Feb 1, 2018

BACK FORWARD 1 of 48

There may be several problems in an apartment building:

- there is no required pressure in the manifold on the distribution comb for any reason;

- during periods of peak loads, water flows to the upper floors with interruptions in flow;

- In an apartment, the pressure is different at different points.

Examinations should show the cause of the lack of pressure. There are cases when the pressure in the main line is normal, but the neighbor below narrowed the nominal passage when replacing pipes. It happens that the pipes are completely clogged with rust. In such cases, it is useless to install a pump to increase water pressure in an apartment with a common wiring. It is necessary to restore the conditional passage in the system.

A legal solution could be to install an accumulator tank in the basement, common to the riser, then all residents can use a pump that increases the pressure in the water supply on the common line.

If there is a general lack of water in the system, it is prohibited to install an additional pump to increase the pressure; penalties are comparable to the cost of the equipment.

Pump selection criteria

First of all, a pump is selected based on the outlet pressure, about 4 bar. It is important to know the dimensions, wet or dry rotor, noise level. When choosing a high-pressure pump, the determining factor may be the presence of automation or manual control.

Different pump systems are used for hot and cold water supply. Cold water systems are equipped with pumps from well-known manufacturers:

On this topic:

How to choose a pumping station for your home

AQUAROBOT pumping stations - main characteristics

Electronic caliper from China for super-precise…

In the country kitchen, a tool for cutting vegetables from China

BACK FORWARD 1 of 25

- WILO - the booster pump is recognized as the most popular. They are distinguished by their simple design, reliability and long warranty period.

- Grundfos - works silently, in demand, warranty is issued for 1 year

- OASIS is a brand that strives to get into the TOP, and so far it has succeeded due to its simple device, reliability and low price.

- Gilex is a recognized domestic leader in the production of pumps.

Their models are compact and low noise. The pipes for installation are standardized for Russian water utility systems.

Pumps for increasing water pressure come in two types, with a “wet” and a “dry” rotor. Devices with a wet rotor are installed in a pipe. The power part is located outside the pipe, is air-cooled, and is attached to the wall in a cantilever manner - a pump with a dry rotor.

High pressure water pumps on the manifolds operate continuously. More often they are equipped with not one, but several wheels; the pressure increases in steps. Such devices can create a pressure of several tens of atmospheres on the discharge line. Industrial high pressure units are only available with a separate air-cooled motor.

Recommendations for selection

When choosing booster equipment, you must pay attention to the following rules:

- The power of the device is determined by the load of the heating network that it is intended to serve.

- The permissible noise level emitted by the pump depends on the installation location . Residential buildings require the installation of quiet models; in utility rooms this indicator is less important.

- ? The choice of device depends on the diameter of the pipes on which it is installed.

- The use of various adapter fittings of variable cross-section reduces the efficiency of the heating system.

- The maximum permissible operating temperature of the pump cannot be lower than the operating temperature of the heating system (up to 90–95 °C).

- ? The dimensions of the device determine the choice of location for its installation.

- The performance of the unit must correspond to the parameters of the heating system.

Read also Asteriscus primariscus herbaceous plants for open ground

Power selection

In a closed heating network of a private house, the normal pressure value is 1.5-2 atmospheres. This pressure is created using a standard circulation pump. In an open heating network operating with natural coolant circulation, the pressure does not exceed 1 atmosphere. Then for the proper functioning of some network elements it is necessary to increase this pressure.

The initial power value when choosing a device is the difference between the existing pressure in the network and the pressure required for the operation of the desired element. For example, for a heated floor to function, a pressure of 2 atmospheres , and the pressure in the network is 1 atmosphere. Then a booster pump is installed in front of the heated floor, increasing the pressure in it by 1 atmosphere .

If several different models meet the obtained parameters, then choose the device with maximum efficiency.

Attention! Excessive pump power leads to a heavy load on the elements of the heating network and their rapid wear.

Installation of a pump in an apartment

First, you should distribute water to devices that require stable pressure. Installing a pump before wiring will allow you to get by with one device, which is turned on manually or automatically.

Before starting work, make sure that the reinforcement does not allow the agent to pass through. To guarantee, the common cold water riser must be shut off from the collector.

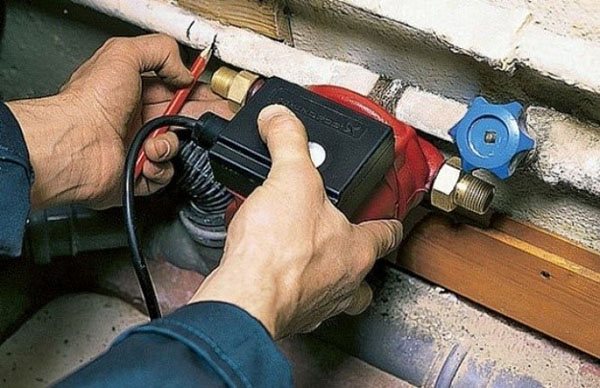

Steel pipes must be welded by a professional welder. Polypropylene water conduits are connected with special fittings; a soldering iron is required. Shut-off valves must be installed before and after the pump.

It is important to correctly install the high-pressure water pump impeller in the direction of fluid flow, as indicated on the arrow. A general booster pump can be installed immediately after the main valve, then pressure is maintained at all sampling points. After checking the system for tight connections, plug the pump into the outlet.

Using the accumulator tank and high pressure pump

Such a scheme will be required if a multi-storey building chronically lacks pressure on the upper floors. The activation of the high pressure pump is caused by an increase in the flow rate in the line to a certain value. Since pressure and flow rates are interdependent, an increase in flow rate is a signal to turn on the high-pressure pump.

When turned on, the pump will create the necessary pressure in the system on all floors. Thus, it is possible to solve the problem of water supply for residents in a cottage or multi-story building.

Video: circulation pump as a booster

As you know, heating systems can be divided into two groups: with natural and forced circulation of coolant. In modern houses, individual heating with forced circulation is more common, since it allows you to uniformly heat all rooms in the house, regardless of their distance from the hot water boiler. The key design difference of this system is the use of equipment to maintain constant circulation of the coolant - a circulation pump. This article is devoted to the characteristics of the circulation pump, which determine the optimal operating mode of the system and the service life of the equipment.

As you know, heating systems can be divided into two groups: with natural and forced circulation of coolant. In modern houses, individual heating with forced circulation is more common, since it allows you to uniformly heat all rooms in the house, regardless of their distance from the hot water boiler. The key design difference of this system is the use of equipment to maintain constant circulation of the coolant - a circulation pump. This article is devoted to the characteristics of the circulation pump, which determine the optimal operating mode of the system and the service life of the equipment.

The choice of pump is influenced by many factors, one of which is the pressure of the circulation pump . Its value must correspond to the calculated circulation pressure in the heat pipeline in order to maintain the specified hydraulic mode in the heating system. This parameter ensures the ability of the coolant to overcome linear and local resistance to the movement of water along the elements of the heat pipeline and the heating radiator.

When choosing a circulation pump based on the pressure it is capable of creating, you should take into account the interdependence of the flow rate and pressure of the water passing through it. For comparison and selection of equipment, a graphical characteristic of the pump is used. Suitable for use in specific conditions is considered to be equipment whose operating point is not lower than the graphical curve of the pump characteristic, which is closest to the point with the highest efficiency. The operating point is determined by the intersection of the design flow and pressure. In the case where not one pump, but several, meets these requirements, equipment of lower power should be selected. Circulation pumps with a flat operating characteristic are better suited than others for systems in which the coolant flow rate varies over a wide range.

When choosing the pressure value, you should take into account the hydraulic imbalance of the heating system, which manifests itself in unsatisfactory circulation of the coolant in circuits remote from the pump unit. To do this, you should select equipment with a reserve of pressure and coolant flow. This reserve should be about 20%. The inverse relationship between pressure and water flow should be taken into account. The pressure value decreases by an amount equal to the square of the increase in flow rate. In other words, if the coolant flow rate increases by 3 times, the pressure will decrease by 9 times. When choosing a circulation pump, one cannot neglect the magnitude of the natural circulation pressure in the heat pipeline, caused by the difference in the density of the coolant in the hot and cooled states. Natural circulation pressure in the heating system is a variable value, depending on the ambient temperature, which varies at different times of the heating season. Sometimes, the share of natural pressure and its influence on the characteristics of the heating system are large. To compensate for this effect, you can install automatic regulators for the differential flow and pressure of the coolant.

It should be noted right away that the exact choice of characteristics of the circulation pump should be made by a heating engineer, taking into account the formulas and design features of the heating system. This is especially true for modern houses with complex architecture and an extensive network of heating circuits. Otherwise, the heating operation may be ineffective, and the funds for its construction will be wasted. The recommendations below are simplified, valid for simple heating systems, and the values of the ratios of quantities were obtained experimentally.

Empirically, the following ratio was derived: for every 10 meters of pipe, 0.6 meters of circulation pump pressure is required. Thus, to ensure circulation in a pipeline 100 meters long, it is necessary to select a pump with a head of 6 meters. This calculation does not take into account local hydraulic resistance in individual sections of the heating circuit. To overcome them, we select a pump that provides a pressure value 15% greater than the calculated one. This reserve will allow for hydraulic losses in a simple heating system.

To ensure stable coolant circulation, two pumps can be installed in the system: the main one and the backup one. A bypass should also be provided to ensure natural circulation of liquid and energy independence of all heating.

Initially, the rule was established to install the circulation pump on the return branch of the heating circuit. This was due to the desire to extend the life of the equipment by reducing the effect of high temperatures on it. Modern equipment from well-known manufacturers is capable of withstanding the operating temperatures of the coolant, and therefore can be installed on both the supply and return parts of the heat pipeline, depending on the requirements of a specific heating system.

Read also New Year's decor made of plywood

The circulation pump divides the entire heating system into two zones:

- Suction area, in front of the pump

- Discharge zone, after the pump

The zero point, where discharge gives way to suction, is the expansion tank. In these areas of the system, hydrostatic pressure must be taken into account. In the suction zone, the pressure can drop below atmospheric pressure, which will lead to airing of the system, and in the discharge zone it can rise, which can lead to boiling of the coolant fluid. To avoid the negative consequences of these phenomena, the rule must be observed: at any point in the suction zone, the hydrostatic pressure in the pipeline must remain excessive. The ways to comply with this rule are varied: from changing the location of the expansion tank and circulation pump, to using special equipment.

Although sometimes it is possible to select and install a circulation pump yourself, it is still better to entrust such work to professionals. Our company employs heating engineers who will calculate the heating system and select the necessary equipment, and qualified craftsmen will carry out competent installation taking into account modern requirements and standards. We work to create warmth and comfort in your home!

You are viewing the Pump , located in the large System Components section.

Low temperatures in the heating system in winter can be associated not only with clogged pipes, air pollution, or low heating of the coolant.

Often the reason for slow water circulation in the network is low pressure in the system . This drawback can be eliminated using a booster pump.

Cost of booster pumps

The market offers models of pumps for increasing water pressure at a price corresponding to the prestige of the brand, degree of automation, and parameters. The minimum cost for a pump is 2,500 rubles. Brands that work on the “set it and forget it” principle can cost as much as 30,000 rubles.

Industrial installations for highways are purchased by agreement. In any case, installing a high-pressure pump will require a pipe inspection and an installation project approved by the housing office.

Video about the operation of a booster pump in a water supply system

What affects the operation of circulation equipment

Passport calculations and parameters do not take into account individual operating conditions. This is worth taking into account when choosing equipment and then during operation. Productivity largely depends on external conditions, including:

- ambient temperature. For example, starting a heating system after a long period of inactivity, especially in winter, increases the load on the device until the room warms up and the pump itself accelerates;

- pipe diameter - power directly depends on the cross-section of communications. The larger the Ø, the more powerful the equipment should be. Otherwise, the device will not cope with the increased load;

- It is not recommended to integrate a pump with a pipe diameter larger or smaller than the Ø of the heating network into the system. The discrepancy will affect performance.

Read also: Southern cereal on brooms

In order not to make a mistake in choosing a device of the required power, it is best to contact specialists. Professionals will perform calculations and advise on the optimal model. You can count on them when installing the pump, and practical tips and recommendations will contribute to the competent and rational operation of the device.