The structure and elements of a Dutch oven

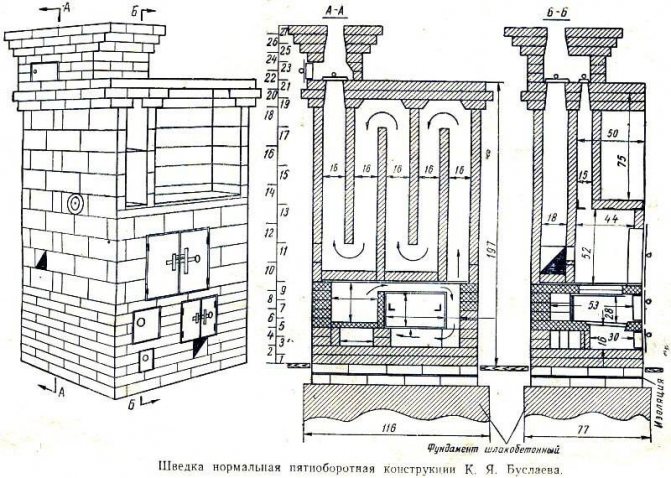

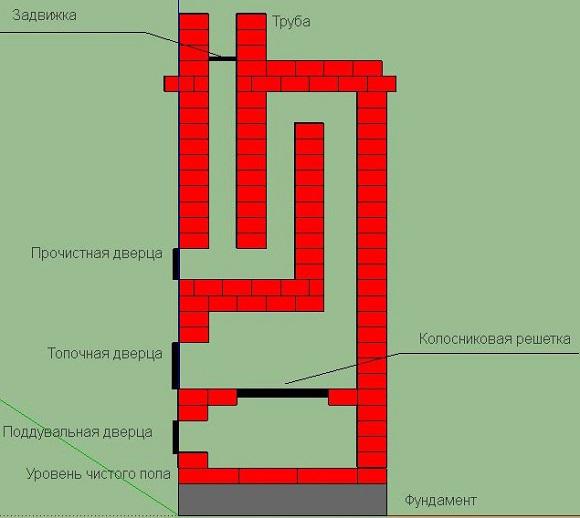

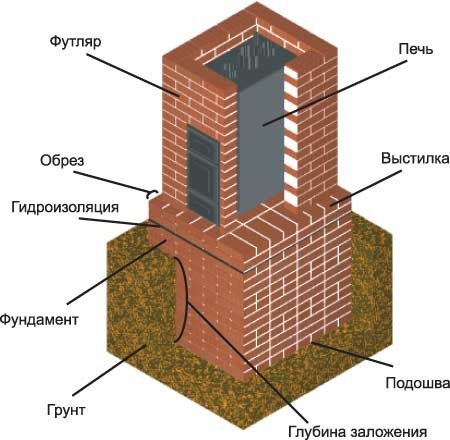

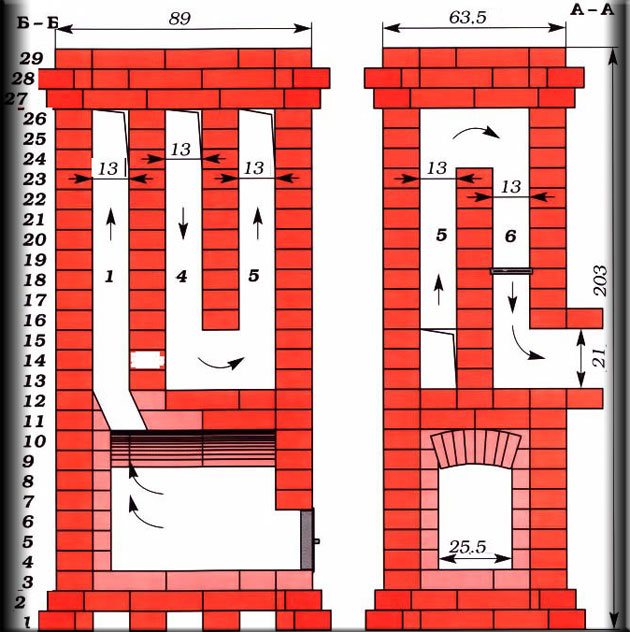

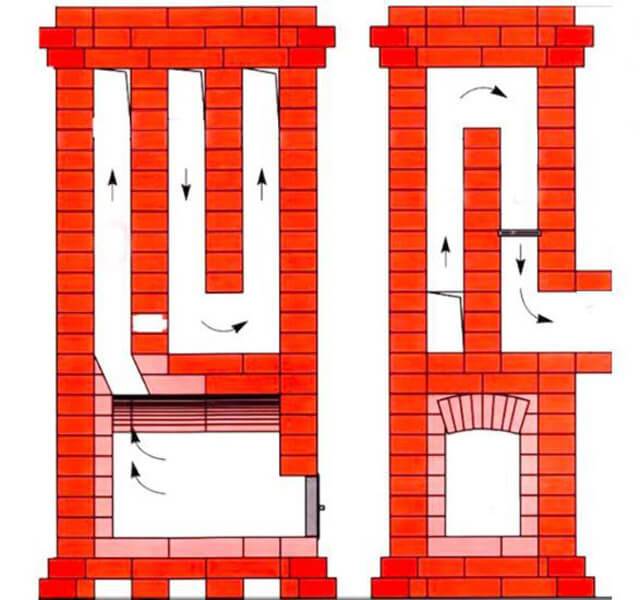

The main elements of a Dutch oven are the firebox, the duct chimney system and the chimney. Let's look at each part of the oven in more detail. Figure 4 shows the main elements of the furnace.

Whatever the size of the stove being laid out, the fuel chamber should always be spacious and rectangular in shape. This simple design increases the heat transfer of the furnace. A water heating system can also be installed in the firebox.

Duct chimney

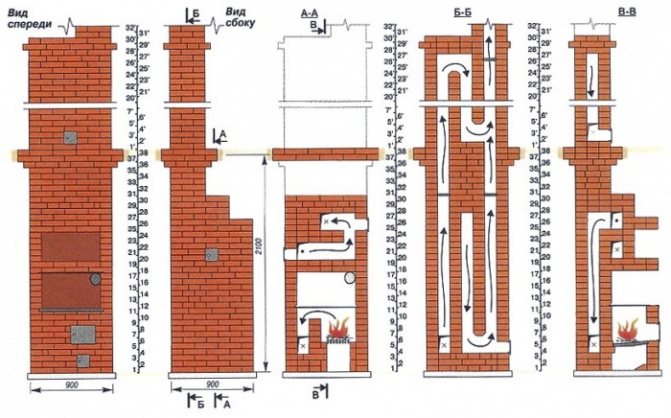

Typically, a Dutch oven has a six-channel chimney system, that is, 3 ascending and 3 descending ducts. Hot smoke generated as a result of fuel combustion moves along the ascending channel, heating the walls of the furnace. Cooling down, it falls down to the firebox, heats up again and rises. Through the last channel, the smoke goes into the chimney (Figure 5).

This chimney system allows the stove to heat up evenly and protects it from sudden temperature changes. The appearance of cracks resulting from temperature fluctuations can allow carbon dioxide to enter the living space.

Smoke circulation systems for Dutch ovens

Chimney

An essential element of a Dutch oven is the chimney. Usually has a side connection to the chimney. The connecting link is often a metal tube. The chimney is designed to discharge exhaust gases to the street. When the damper is open, it helps to quickly cool the stove if the stove is heated irregularly.

The standard layout of a Dutch oven is shown in Figure 6.

Standard Dutch oven design

Features of the masonry of a Dutch oven

Galanka: main characteristics and materials The galanka oven (gulanka, Dutch oven) can be used for any purpose, with the exception of baking bread. You can lay out the ovens yourself, following certain instructions.

Dutch oven diagram.

Galankas are quite effective, as they evenly and quickly warm up a medium-sized room.

Thanks to the vertically located winding passages #8212; smoke circulation, the stove is capable of maintaining heat for 12 to 24 hours, depending on the external temperature.

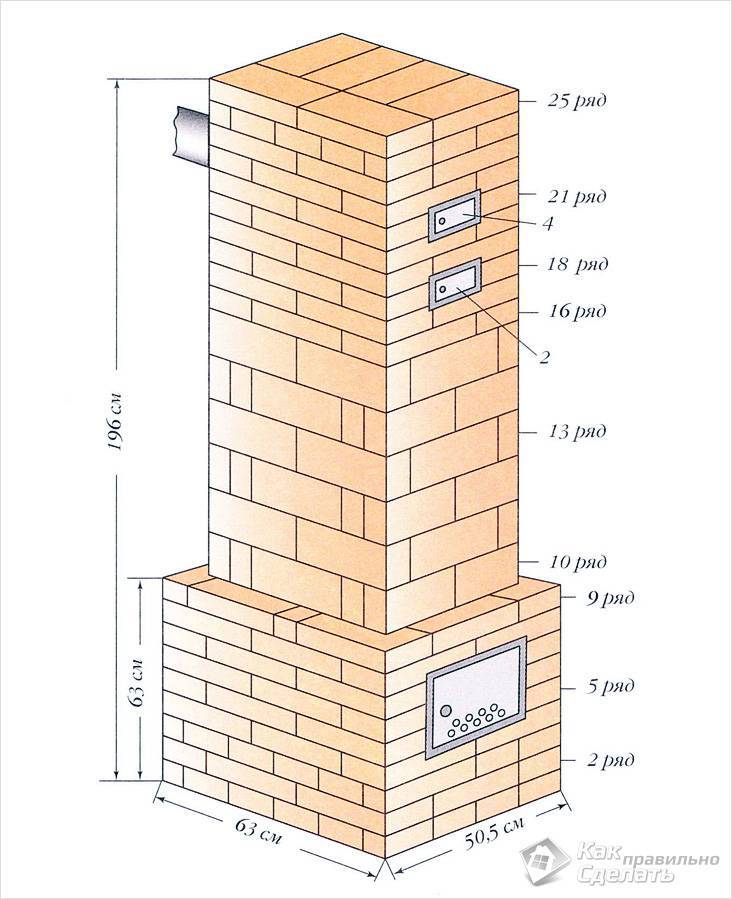

Width can be from 70 cm to 1 m, depth #8212; 1-2 m, and height #8212; 2-2.5 m.

The Dutch oven is not large in size, so it is possible to build it yourself. To do this you need to purchase materials:

- red brick #8212; 382 pcs.;

- fire brick #8212; 43 pieces;

- cast iron tiles (additional) #8212; 2 pcs.;

- pre-ceiling sheet #8212; 1 PC.;

- steel corners #8212; 3 pcs.;

- steel strips.

Some of the metal and cast iron items are sold in sets. They include a stove, grate, valves, doors, oven, water heating box.

The procedure for laying a gallanka stove

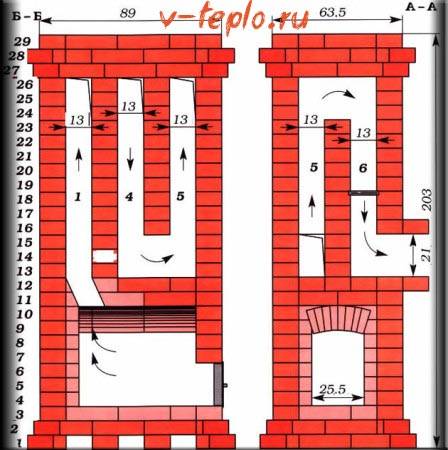

Furnace diagram #171;Galanka#187;.

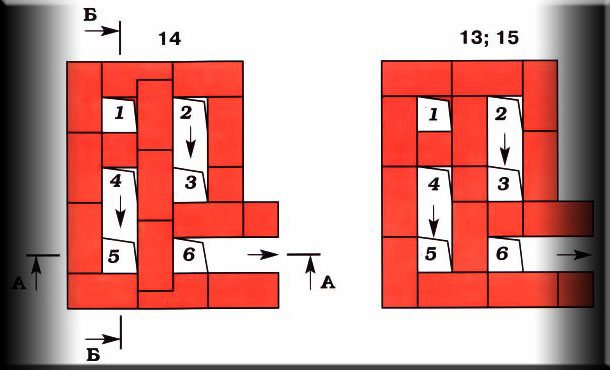

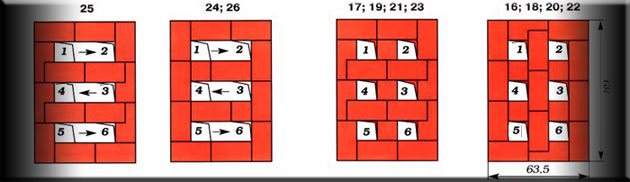

To mark the rows of masonry, order #8212 is used; strip with serifs corresponding to the height of the masonry row. When laying with your own hands, you should proceed according to the step-by-step instructions and drawings (drawing 1).

The first 2 rows are laid, observing the dressing. A blower door is installed on top of the 2nd row, which is lined with bricks in the 3rd row. Leave a gap for a cleaning window (under the oven).

The oven, inserted on the 4th row, is reinforced with roofing iron on 3 sides. The sides of the oven are lined with refractory bricks placed on edge. The combustion door is installed at the same level.

The 5th line laid secures the blower door and the cleaning window located under the oven.

A cast iron grate is installed and lined with refractory bricks under the firebox. The 6th row of masonry secures the oven and fire door.

For the oven walls in the 7th row, refractory bricks are used, laid on edge. When laying the 8th row, the fire door is strengthened, and a steel strip is attached to the top of it. The 9th line is laid on top, a slab is installed using 10 mm steel plates using bricks laid on edge.

Smoke circulation system for stove-galanka

The operation diagram of the furnace is clearly presented in sections A-A and B-B.

In the 10th tier of the gallanka there is a window for cleaning, which is covered by the 11th row. 2 more windows are left in it (to clean the lower channels and remove soot). 3 strips of #8212 steel are placed on top. the hanging internal walls will rest on them.

The canal cleaning windows overlap the 12th row.

The cooking chamber is installed. A wire is passed under it, and the chamber door frame is secured with it.

Bricks placed on the edge in the 13th row form the walls of the steam reservoir on both sides.

A steel strip and a corner are laid on top. In the 14th tier, a box is laid out from the side walls and the shield. The ceiling of the cooking chamber is covered with bricks in 2 rows. A hole is left in it to allow steam to escape from the oven.

a07ff0f2bc47417ca4e38dc4d992141a.jpe 1e4d6cd87019e985f14ece023e868111.jpe

6bcc323d3a88dfb5e1dfebdd9122d511.jpe

In the 15th and 16th rows the foundation of 2 ovens is laid. The ceiling of the lower, small one is formed by a sheet of roofing steel laid in the 16th row. When covering a steam hood, its cross-section should be reduced to the 21st row.

The 17th and 19th tiers are placed in accordance with the order. In this case, in the 18th row a window for cleaning is formed in the walls of both channels.

In the 20th row the chimney is blocked. The large stove is covered in the middle with a strip of steel and at the edge #8212; steel corner. Its ceiling is formed when laying the 21st row when blocking the smoke circulation. Steam and smoke valves are installed at the same time.

From the next row, the neck of the furnace is laid out, turning into horizontal cutting in the last 2-3 rows. The cross-section of the chimney to the masonry of the stove chimney (a second valve is installed in front of it) should be halved for draft.

Design features of the Dutch

The Dutch oven is extremely simple. Armed with the tools and necessary materials, even a novice stove maker can assemble it. A traditional Dutch oven does not have a vent, which ensures a slow, long burning. That is, we put firewood in a large firebox, light it, then close the door and enjoy the warmth for many hours.

A modern Dutch oven is made with a blower and a grate. These two elements were not present in the original; they appeared later. The presence of a blower provides convenient adjustment of the combustion intensity. For example, at the very beginning of ignition, it is desirable to get a powerful flame to warm up the stove and the room. After this, we close the ash door - the combustion intensity decreases, saving firewood. As for the grate, it is necessary for more convenient cleaning.

A large firebox is a key feature of a brick Dutch oven for the home. Some stoves, like many modern heating boilers, have small combustion chambers. A lot of firewood will not fit here, and there are also restrictions on the maximum length of logs. By installing a full-size Dutch oven in their home, consumers have heating units with large fireboxes at their disposal.

The Dutch oven has a vertical design. It takes up a minimum of free space, and greater heat transfer is ensured due to its area formed by the vertical walls.

Advantages of a large firebox:

- Long-lasting combustion - solves the main problem of wood heating associated with frequent addition of fuel.

- Convenient fuel storage – including convenient work with large-sized firewood.

- Ease of cleaning up ash and unburned firebrands - the extra space will make it easier to clean the Dutch oven.

If we talk about heat transfer, the Dutch oven is amazingly efficient. It gives off maximum heat. There are no strange tricks here that contradict the laws of physics. It's all about the multi-channel removal of combustion products. They are actually discharged through many vertical smoke channels. Passing through them, hot gases give off the vast majority of the heat to the brick. This ensures maximum efficiency of Dutch ovens.

Advantages and disadvantages

The Dutch woman has many advantages:

- takes up little space, which is important for small houses;

- created from inexpensive materials, including used ones;

- does not need a strong foundation;

- heats up quite quickly and retains heat for a long time;

- can be of almost any height, which does not have any effect on its performance;

- looks great in any interior;

- if necessary, equipped with additional elements;

- does not require preliminary heating.

The main disadvantage is the rather low efficiency - about 50 percent. In addition, if the view remains open after lighting, the device will cool down quite quickly. These flaws were leveled out by the Soviet engineer Grum-Grzhimailo. He equipped the stove with a grate and a hood. The Dutch hood turned out to be very economical and provided good efficiency - over 80%.

Required materials and tools

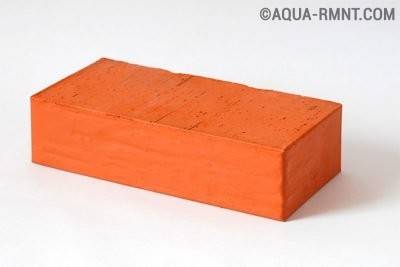

The oven is lined with two types of bricks.

Firebox walls - fireclay bricks

It is yellow in color and can withstand temperatures up to 1600 degrees.

Fireclay brick

The dimensions of fireclay bricks may vary depending on the brand. Thus, ShB-8 brand brick has the same dimensions as ordinary building bricks - 250x124x65 mm. Fireclay brick grade Sh-5 is slightly reduced: 230x114x40 (65) mm.

Signs of high-quality fireclay bricks are:

- fine-grained structure;

- absence of visible pores and inclusions;

- clear ringing sound when tapped with a hammer;

- when dropped, it breaks into large pieces (low-quality ones crumble into small crumbs).

When it comes to the appearance of the brick, darker color does not always mean higher quality. It all depends on the clay deposit: it also happens that lighter fireclay bricks have better characteristics.

It should be noted that since the thermal regime of a Dutch oven is not stressful, its combustion chamber can be lined with M150 ceramic oven bricks, capable of withstanding temperatures up to 800 degrees (not to be confused with ordinary building bricks).

The walls of the firebox can be laid out of clinker bricks, which have high strength and heat resistance. It is much more affordable in cost than fireclay.

Furnace body

The remaining parts of the stove, except the firebox, can be lined with ceramic stove bricks, or with medium-quality bricks with slight cracking.

Ceramic stove brick

Use of used material is allowed.

Materials for clay mortar

Sand

You can use river sand with grains 1 mm in size, preferably angular. But if you want to get a durable stove that can last more than 10 years, you should use sand without organic impurities. Previously, only very expensive mountain sand had this quality, but today, more affordable brick sand can be used instead. It is ground fireclay or ceramic brick.

87e4199ded4b8661b2dd1e0235b55992.jpe

The first option is used in mortars for fireclay masonry, the second - for ceramic masonry.

Clay

Mortars for laying fireclay bricks are best prepared using white kaolin or fireclay marl. Ceramic bricks can be laid on a mortar of any ground clay with fire-resistant properties; Cambrian clay (blue or gray) and gray kaolin are considered the most suitable.

Clay varieties with medium fat content are preferred.

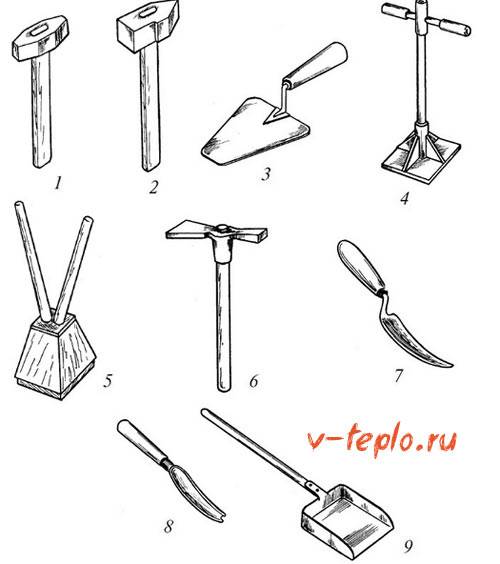

Tools

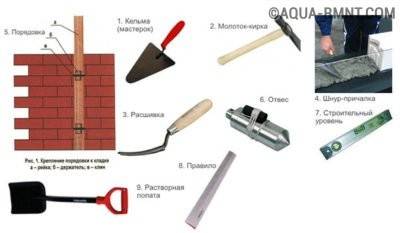

Among the tools, it is worth noting the order - a flat strip with a cross-section of 50x50 mm, on which marks are applied corresponding to the rows of bricks. Four rows are fixed in the corners in a strictly vertical position (nails are driven into them, which need to be inserted into the seams), after which it will be very easy to make the masonry even.

Tools

Other tools are the usual builder's kit: a hammer-pick, a trowel, a level and a plumb line.

Preparatory work

Furnaces with a volume of up to 500 bricks can be laid without a foundation, as long as the floors in the room are strong enough (capable of bearing a load of up to 250 kg/m2). A small country Dutch oven with a hob, the construction of which we will further consider in detail, satisfies this condition.

But if the floor in the room clearly does not have the required strength, then it must be installed on a reinforced concrete foundation.

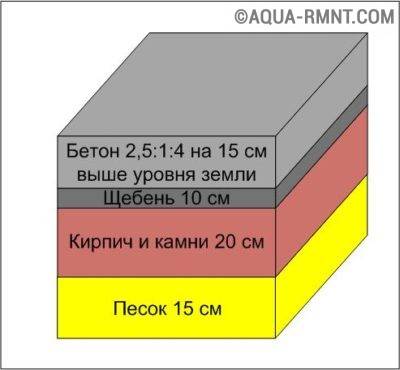

Scheme of the foundation for a heavy furnace

Its depth is usually 400–600 mm, and the edges should extend beyond the outline of the stove by at least 100 mm on each side. It is impossible to connect the structure to the foundation of the building - due to different shrinkage, distortion may occur.

After pouring the foundation, it must be ironed - sprinkled with cement.

Concrete foundation

When the concrete has matured - this takes about 1 month - it needs to be covered with two layers of waterproofing (roofing felt or roofing felt), after which it will be possible to begin building the furnace.

Foundation waterproofing

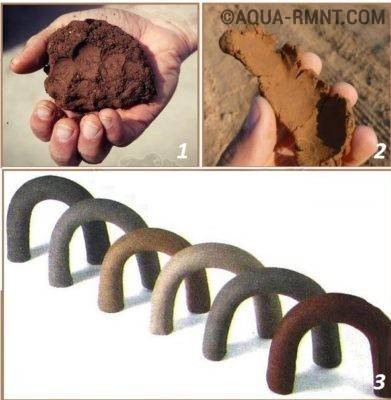

Before proceeding directly to installing the bricks in place, you need to prepare a clay-sand mortar. The correct ratio of sand and clay depends on the fat content of the latter. To determine it, proceed as follows:

- After soaking the clay for a day, stir it until it forms a dough, after which 5 portions of a solution are prepared with different sand contents: 10, 25, 50, 75 and 100% of the clay volume.

- After twisting each portion into a 30-centimeter sausage with a diameter of 10–15 mm, it is wrapped around a blank with a diameter of 40–50 mm and left to dry at room temperature for 2 weeks.

One way to determine the quality of clay

In the presence of:

- a fine network of cracks or their complete absence, the solution is considered suitable for any part of the furnace;

- large cracks, but not exceeding 2 mm in depth: the solution is suitable for furnace elements with a temperature not exceeding 300 degrees;

- For deeper cracks and breaks, the solution is considered unsuitable.

Having determined the optimal ratio of sand and clay, prepare a solution in the required volume. The clay is also soaked for a day, only after that it is further ground through a sieve. The sand is sifted and washed. The finished solution should have the consistency of sour cream.

Preparatory stage of masonry

The dimensions of a standard Dutch oven are compact, which allows it to be installed even in small spaces. The average height is 1.2 meters, and the dimensions of the square base vary from 1.2 to 1.3 m (each side). The following materials are used in Dutch construction:

- Ceramic bricks – 200 pieces

- Fire bricks – 50 pieces

- Base plate

- Dry cement

- Construction clay

- Sand

- Water

- Sieve for sifting sand and cement

- Armature

- Doors for firebox, blower

- Metal wire for fastening the door

- Roofing material required to create a foundation waterproofing system

- Chimney pipe

- Gate valve

A Dutch oven built with your own hands also requires the preparation of special tools for proper installation. These include:

- Brick pick

- Combination trowel

- Level

- Tape measure and plumb line

- Square to mark and control masonry

- Asbestos cord

- Containers in which the solution is mixed and water is contained

- The ladder necessary for laying out the upper rows of the stove and arranging the chimney.

Furnace diagram

Stage 2. Construction of the foundation

First, it is worth noting that from a structural point of view, the foundation being built should not be connected to the main foundation of the house. The further sequence of actions should be as follows.

Foundation for a brick oven

First you need to outline the outline of the future foundation

It is important that the width and depth of the base be 8-10 cm larger than the planned dimensions of the stove. At the same time, you need to check whether the foundation coincides with the location of the chimney pipe

A hole of appropriate dimensions is dug; its depth should be approximately 60 cm.

The bottom of the pit is covered with a 15-centimeter “cushion” of crushed stone. The crushed stone is carefully compacted, its surface is leveled using a mounting level.

8d842bcd869c90ef558187c4ba7d36bb.jpe

Then you need to build the formwork for the furnace foundation. For this you can use wood, chipboard and even thick cardboard.

Attention! If the material chosen for the construction of formwork absorbs moisture, then the inside must be lined with roofing felt (although any other waterproofing material is suitable for this). Concrete solution is mixed

To do this, dry cement is mixed with sand in a ratio of 1:3 and filled with the required amount of water. The solution is thoroughly mixed

The concrete solution is mixed. To do this, dry cement is mixed with sand in a ratio of 1:3 and filled with the required amount of water. The solution is thoroughly mixed.

The formwork must be filled with mortar and wait until it dries completely. This often takes a maximum of a week.

Characteristic properties

Before starting work, it is useful to familiarize yourself with the advantages and disadvantages of a design equipped with a cooking stove. Among the advantages of the stove, experts note the following features:

- Compactness. The minimum dimensions are 0.5x0.5 m; with such dimensions, a Dutch oven can heat an area of 20 m2. If the structure is enlarged, a room of 60 m2 can be heated; there are known cases of operation for a two- and three-story building.

- Compared to a traditional Russian oven, a Dutch oven with a stove will use almost half as much material.

- Due to the reduced material consumption, a lightweight stove with a stove is less demanding on the strength of the foundation.

- A special feature of the design equipped with a slab is the ability to adjust it without losing the effectiveness of the indicators; the main thing is to maintain the proportions.

- The Dutch is not demanding on the quality of bricks, with the exception of the masonry of the combustion chamber, which requires fire-resistant building materials.

- After a long period of inactivity, the stove and stove do not need to warm up slowly, and there is no need to worry about the appearance of cracks.

- A Dutch oven with a stove is ideal for installation in a country house, where vacationers will appreciate its ability to quickly warm up followed by slow cooling.

The numerous positive aspects of the Dutch oven accompany certain negative characteristics:

- Restrictions on the fuel used. Quickly burning material in the form of reeds, straw or sawdust is not appropriate here. A stove with a stove requires the use of wood or coal, since the efficiency of operation is based on the smoldering process. The smoke from instantly burning brushwood will evaporate at the same speed, without having time to transfer thermal energy to the walls of the oven with the stove.

- An additional requirement for the fuel used for the Dutch oven is the level of humidity. If a stove and stove are loaded with wet material, the channels quickly become overgrown with soot and require frequent cleaning.

- This stove design is characterized by low efficiency, not exceeding the 40% threshold.

- The low heat capacity of a Dutch oven with a stove due to the small amount of brick necessitates frequent heating. To maintain optimal temperature conditions, fuel must be added at least twice a day. Warning! It is prohibited to overheat the stove due to the risk of carbon monoxide release.

- Care must be taken when adding fuel. If you do not close the view after burning, the heat will quickly leave the smoke channels.

The nuances with fuel and the heating process are insignificant and are more than offset by the significant advantages of the design with a stove.

Varieties and modifications

There are several common modifications of Dutch ovens:

- Heating (classic). Optimal for heating small residential premises.

- Bell bells. They are distinguished by the most compact dimensions; existing laying schemes allow the construction of miniature Dutch ovens with a triangular cross-section for corner placement.

- Caloriferous. The action is based on the principle of forced air circulation. Optimal for buildings with high ceilings.

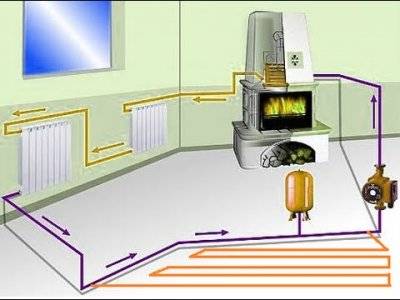

- Heating rooms with water heating boilers. They are used when it is impossible to place the stove in the central part of the house. The installation of a Dutch oven with a built-in heating boiler is carried out in the kitchen or in the hallway, after which the heating circuit is installed.

Important! The operation of Dutch ovens with built-in boilers for heating large areas requires the use of coal as fuel. In addition to using the Dutch oven as a purely heating structure, there are possibilities for additionally equipping the stove with a hob, fireplace or stove bench

To do this, at the preparatory stage, it is important to make the required amendments to the selected installation scheme. It is possible to use ready-made schemes available in the public domain

In addition to using the Dutch oven as a purely heating structure, there are possibilities for additionally equipping the stove with a hob, fireplace or stove bench

To do this, at the preparatory stage, it is important to make the required amendments to the selected installation scheme. It is possible to use ready-made schemes available in the public domain

Heating Dutch oven

The principle of operation of the classic Dutch oven is to increase the circulation time of smoke inside the housing due to the construction of winding smoke circulation channels. Before exiting into the chimney, the smoke from the burned fuel transfers its own thermal energy to the body. The stove acts as a heat accumulator: heat accumulates in the housing and is systematically used to heat the premises.

Reference.

Classic Dutch ovens do not require constant heating and warm up quickly after long periods of inactivity.

In addition to the general design features, the differences between Dutch stoves and other types of stoves vary depending on the installation pattern and the presence of additional equipment. The difference lies both in efficiency and in the set of functions.

With water heating boiler

The operating principle of Dutch ovens with a built-in water heating boiler is similar to the classic version.

The presence of a heating circuit increases the efficiency of the furnace by ensuring uniform distribution of thermal energy within the heated premises.

The stove turns from a heat source that implements the principle of air heating into the central element of a liquid heating system.

Advantages of round Dutch ovens (Utemarka) in a metal case

- Fast heating and slow cooling of solid brickwork

- Sufficient heat capacity

- Small dimensions

- Installation without foundation

- High service life and reliability

- Quick assembly of a round oven frame

- Light weight of building materials upon delivery

- Low cost

- Maintainability

If your old round stove in a frame does not work, then it is not necessary to completely disassemble it. Sometimes it is enough to clean it and rearrange the bricks in the firebox. Replace the door with a modern one. Install an additional cleaning door. For questions about the repair of round stoves in a case in St. Petersburg and Leningrad Region, write to the post office or call immediately.

How much materials are needed for an utemark stove with a diameter of 650 mm and a height of 2300 mm:

- Case for the stove.

- Solid brick 100 pcs.

- Fireclay bricks 120 pcs.

- Stove mix 7 bags.

- Fireproof mixture 8 bags.

- Grate 1 pc.

- Cleaning door 1 pc.

- Fire door.

- Valve.

This is what one of the stainless steel casing kit options looks like. Approximate cost 25,000 rubles from the manufacturer. This casing does not require painting - it is already beautiful.

Orders (drawings) of a round stove in a casing designed by V.E. Grum-Grzhimailo.

Drawings of a small heat-intensive brick oven for self-laying PTO-2500

If you need to repair such a stove or install a new round stove in a casing, call a specialist. Phone in the section Works are carried out in Vyborg, Priozersk, Tikhvin, Vsevolozhsk, Sosnovo, Sestroretsk, Lisiy Nos, Zelenogorsk.

Foundation arrangement

Despite the relatively light weight for a brick oven, the Dutch oven still needs a high-quality and reliable foundation. An excellent option is a monolithic slab. An important nuance: the foundation must be reinforced both in area and in volume, i.e. deep down. The dimensions of such a foundation must be at least 1.2 x 1.2 m. The Dutch foundation cannot be connected to the base of the main building.

How to make a foundationFoundation for a brick oven

The procedure for arranging the foundation is as follows.

First step. We outline the boundaries of the foundation being developed.

Second step. We dig a pit about 60 cm deep.

Pit for casting the foundation

Third step. We fill the bottom of the pit with a 15-centimeter layer of crushed stone. Carefully level and compact the backfill.

Crushed stone

Fourth step. We lay a mesh of reinforcing bars. The recommended cell size of such a mesh is 100-120 mm.

Foundation pit with formwork and reinforcement

Fifth step. We install vertical reinforcement at the intersection of the rods. We tie all the joints of the elements of the support system with wire.

Sixth step. We install the formwork for pouring the foundation. We cover each wall of the formwork with roofing felt or treat it with resin for waterproofing.

Seventh step. We pour concrete.

Poured concrete

Eighth step. We “iron” the surface of the base. To do this, sprinkle the fill with a small amount of dry cement.

Let the foundation gain strength. It is better to leave it for a month, but many craftsmen begin laying it within a week. At this point the decision is yours.

Order

Before the floor is finished, 2 rows of bricks are made with the seams bandaged, and only then the laying of the first row begins.

The first row is counted from the finished floor mark. The two middle bricks are beveled towards the ash pit. The space between the wall of the ash pan and the rear wall of the furnace is filled with dry sand from the first to the third row inclusive.

In the second row, a blower door is inserted with a gap of 3–5 mm, filled with asbestos cord. The steel legs or wire of the door are embedded in the masonry.

The third row repeats the laying of the second, taking into account the dressing of the seams in 1/2 brick. Bandaging of shortened bricks is allowed less.

The fourth row involves partial covering of the ash pan. A 35x4 mm steel strip is laid under the brick to cover the ash pit. At the back of the oven, the sand is covered with a brick.

Fifth row. A grate is placed on the open part of the ash pan with gaps along the firebox and a gap of 5 mm, which is compacted with sand or ash. The bricks here are beveled according to the order.

In the sixth row, a furnace door is installed with a gap sealed with asbestos cord. The bricks of the back wall are chamfered.

From the seventh to the twelfth row, the firebox is laid with the seams bandaged according to the order.

From the thirteenth to the fifteenth row, the firebox is blocked and the rear smoke channel is laid out.

The sixteenth row involves the installation of cleaning.

From the seventeenth to the twentieth row, the laying of channels is underway.

The twenty-first and twenty-second rows combine two channels: lifting and lowering.

The twenty-third and twenty-fourth rows involve overlap of the middle and posterior canals.

A cleaning system is installed in the twenty-fifth and twenty-sixth rows.

From the twenty-seventh to the thirtieth row, the laying of channels is underway. A valve is installed in the twenty-eighth row.

On the thirty-first row, bricks are laid with releases for future reroofing.

In the thirty-second row, a ceiling is made and a valve is installed.

The thirty-third and thirty-fourth rows continue the laying of the roof and smoke duct.

Step-by-step instructions for laying

Arranging a Dutch oven

The finished Dutch oven looks like a narrow brick pipe up to the ceiling, on which the only external elements are the firebox doors, the vent and the valve. Before starting the installation itself, the craftsmen recommend that beginners first build the stove without mortar, apply the necessary marks and cuts on the bricks. For reliability, you can assign the required number to each brick. To prevent the structure from coming out askew, you need to pull plumb lines vertically and constantly use a building level.

Craftsmen also advise immersing the bricks in water for 2 minutes before laying, and rubbing the inner surfaces of the oven every 4-5 rows using a wet washbrush or a regular piece of cloth.

The size of the seam for laying the stove is no more than 5 mm. Steel legs or steel wire are attached to the oven doors, which are then laid into the seam. Installation of all metal elements is carried out together with the masonry.

Ordering a simple Dutch jacket 52x52 cm:

- On roofing felt, sprinkled with a thin layer of sand, lay the first row of 12 bricks on a dry surface. Check the evenness of the installation using a level, fill the surface with a binding solution, and smooth it out.

- Install the ash door by wrapping it with asbestos cord. To fix the door, take a steel wire. Insert it into the box and double twist it. Make a cut in the top edge of the brick. Insert the wire into it, bend it and intertwine it with the masonry.

- Lay the second row of ordinary bricks on the mortar, and make the subsequent ones from fire-resistant material. Place a 200x300 mm grate between the 3rd and 4th rows.

- In the fourth row and beyond, place the brick on its edge. Install the firebox door in the same way as with the ash pan. From the fourth to the seventh row, lay the bricks on the back wall of the stove in a dry manner to make it easier to clean the combustion chamber in the future.

- Place the seventh row flat with 3/4 bricks to increase the reliability of the suture bandaging, but lay the back wall on the edge.

- For the eighth row, take a beveled brick or a simple one, laying it flat at an angle. Here you will complete the creation of the combustion chamber.

- Lay the next rows flat, moving the brick back a little in the ninth to widen the chimney. In the tenth, install the base of the metal pipe.

- In the 16th and 17th rows, lay out a cleaning hole and mount the door in the same way as the blower.

- From the 18th to the 24th row, form the return channels. Make sure that the bricks do not protrude.

- Lay out the channel overlap for the 25th–28th rows. Move the bricks slightly to the side. In the 28th row, leave an exit for the chimney channel.

- In the 29th row, install a damper, close the chimney with the thirtieth row and remove the pipe.

Drying will take 14 days. During this period, the firebox door cannot be closed. To check the draft in the oven, it is recommended to first burn the paper. If there are no obstructions to the smoke exit, the oven is ready for use.

A little history

There are several versions of the appearance of the Dutch woman in Russia. But they all agree on one thing - the laying of such stoves began in the 18th century, when Peter I issued a decree on the construction of stoves like the Dutch ones. The decree did not prescribe specific instructions for construction, so ordinary Russian stoves were often only lined with tiles or tiles imported from Holland. This is where its other name arose - gallanca. Some scientists are of the opinion that a stove was called a gallanka if it had a chimney structure typical of a Dutch stove.

Interesting: The tall chimney is a Dutch heritage. In order to save space, buildings in Holland were built tall. In order to avoid paying high taxes on chimneys and to heat more rooms, the Dutch began to build stoves with a chimney of several floors.

In encyclopedias, the concept of a “Dutch stove” is defined as a rectangular-shaped heating device that has a channel system of vertical smoke circulation and a side exit to a chimney lined with tiles.

Heating and cooking Dutch ovens

The operating principle of all Dutch stoves is elementary - heated air travels along an artificially elongated path to the chimney, but the design schemes differ:

- Shapes: rectangle, circle.

- Dimensions.

- The presence of additional equipment (stove, oven, stove bench).

- Gas distribution systems: multi-channel and bell-type. The latter is more efficient, as it has high efficiency - when fuel burns, heat remains in the chambers. Cold air entering the heated oven passes through, bypassing the chambers. A multi-channel system, in turn, is easier to construct; the number of channels can reach six.

With stove

This design differs from the standard one in that it is equipped with a hob on the 3rd-5th row from the firebox. The best material for such a part is a cast iron plate 5-8 mm thick.

The stove can be solid, only for heating food, or with burners installed in it for cooking. There may be several burners.

With hob and oven

This Dutch design is also equipped with an oven. The oven can be installed above the stove or on the side of the firebox.

The first position is preferable, since the hot air in this case evenly flows around the entire area of the oven. Being located on the side of the firebox, the structure heats up mainly on one side.

Operating principle

In order for the gases heated by the combustion of fuel to transfer their heat to the bricks as much as possible, their path is deliberately lengthened. Hot gases from the firebox rise through the upward channel, warming up the walls, and cool down. Then they descend to the firebox, warm up and rise up again. The smoke goes into the chimney from the last channel. The Dutch can be “stretched” upward by 2–3 floors, which the Dutch successfully did, saving space, materials, fuel and, minimizing the number of pipes.

Design features of the Dutch

The main elements of a DIY Dutch oven are:

- The chimney is a mandatory element

- Three outlet and three inlet channels (their number may vary) - thanks to them, the room is quickly heated

- Spacious firebox - niche for stowing fires

The stove is built in a variety of shapes: from round to rectangular. The smoke, passing through the first smoke channel, gives off its heat to the walls of the furnace. Then it cools down and, through passes through the second channel, descends to the combustion chamber. Near it, it is heated again and already flows upward through the next channel. Having reached the last one, the smoke goes into the chimney.

Let's get started

To start building a Dutch oven with your own hands, like any other similar structure, you need to prepare everything you need. You will need a standard oven set of tools (trowel, hammers, mallets, bucket, etc.), as well as a grinder with a special diamond-coated concrete circle, a tape measure, levels and a plumb line.

You will also need construction and consumable materials for the work:

- Clay and sand, cement

- Fireproof bricks

- Set of doors (blowing, combustion, for cleaning channels)

- Grate

Scheme of a classic Dutch woman

A classic Dutch oven is a design consisting of a large solid firebox, without a vent. The design of the Dutch oven is rectangular, with 6 smoke circulation channels. Three channels of which are lifting and three are lowering, respectively. From the firebox in the vault, smoke enters the channels of the Dutch oven, located as if one after the other. As gases flow, they enter the first channel. Having reached the pass, they enter the next channel through a revolution, descend to the (vault) of the firebox and through the revolution enter the 3rd channel. Under the arch, from this channel the gases are directed to passage 4, from the fourth to passage 5, from passage 5 to passage 6, and from there, respectively, to the brick pipe.

The firebox of a Dutch oven can accommodate a large amount of firewood, but combustion is slow due to the lack of grates (grids) and ash. The air required for combustion enters through the cast iron combustion door.

The arrangement of the chimneys in this order leads to the fact that the hottest gases enter 1 channel. Cooling down a little, they descend into channel 2, then towards the last passage the gases arrive very cool. In this way, the furnace structure is heated in parts. And therefore, the Dutch oven must be warmed up gradually, since when the stove immediately warms up, cracks appear in the masonry, through which smoke and carbon monoxide enter the room, cold air is sucked in and the stove quickly cools.

Household stoves can be divided into two groups: outdated designs and modern ones that meet human household requirements.

In place of old designs, improved models of fireplaces, Russian, bathhouses, cooking stoves and other stoves are being introduced into everyday life. This replacement does not occur immediately, but over several centuries. An experienced stove maker who is implementing new modern stove designs must clearly understand the shortcomings of the old models that still survive, and be able to repair and remodel them. To do this, he must be familiar with the main examples of not only new, but also outdated designs.

The classic Dutch oven (like the Russian oven) is an example of the design of household ovens of yesteryear.

A large firebox , which occupies the entire internal area of the stove, holds a lot of firewood, but its combustion occurs in poor conditions, with a lot of smoke. Due to the absence of a vent, air enters the firebox only through the open fire door, supporting the combustion of wood only near the door. In addition, when the firebox is open, cold air enters the firebox, cooling the already weak combustion of the fuel.

Through the chimney in the furnace roof, gases enter vertical chimneys arranged in a sequential order. From the furnace, gases rise through channel “1”, roll over under the furnace ceiling into channel “2” and, going down it, enter channel “3”, having risen along it, under the Dutch ceiling they enter channel “4” and fall into channel “5”, rise again under the ceiling, where they roll over into channel “6” and, having dropped to the branch pipe, enter the main chimney, built in the main wall or on a separate foundation near the stove in the main pipe.

Thus, the heated gases, successively rising and falling, pass through all 6 revolutions of the furnace.

Gases enter channel 1 at a high temperature, but, moving further through the chimneys, they gradually cool down and approach the last channel much cooler. And therefore, the heating of the entire furnace is also uneven. Uneven heating of the array leads to uneven heat transfer from the furnace and to the appearance of cracks in the furnace. Smoke can enter the room through cracks.

Primitive Dutch on six consecutive channels

The path of heated gases through the smoke circulation is excessively large, therefore, for smokeless operation of the stove, a strong draft generated by the chimney is necessary. If the height of the chimney is small and the atmospheric conditions are unfavorable, then the stove begins to smoke into the room

- Another version of the Dutch jacket Modern simple Dutch jacket

- Do-it-yourself five-channel heating hodka Five-channel holander

Brickwork

To prevent the heating structure from absorbing large amounts of moisture, each brick must be moistened before laying. To do this, you need to lower it into water for a couple of seconds. If you keep it in liquid for a long time, there will be poor adhesion. and the seams will be too thick. In addition, stains will appear on the stove and it will have a dirty color.

da91dcda8337a49af6f734ab62d7d122.jpe

- It is assumed that the foundation has already been prepared. To prevent moisture from entering, you need to fold the roofing felt in two layers and lay it on the foundation.

- A layer of sand is poured on top, the thickness of which should be no more than 50 millimeters. To do this, it is recommended to use a building level.

- After this, you can lay out the first row of bricks without using the prepared mixture. The total number of rows should be eleven. The order will allow you to make the layout correctly. The solution must be applied in a small layer to the first row.

- For laying the next two rows, prepared mortar and red brick are used.

- Then the brick must be laid edgewise. The seam should not exceed 5 millimeters. In the remaining rows, the thickness should not be more than 8 millimeters; ordering will help to check. Excess mixture can be removed with a regular trowel.

- To make a Dutch oven easy, the back wall must be collapsible. Therefore there is no need to use a solution. Another way is to install a small door, but in this case, heat loss will increase.

- The door is secured with steel wire. It also needs to be finished with fire-resistant material. Asbestos may be suitable for this purpose.

- Until the door is completely lined, you need to continue laying bricks edgewise. From about the eighth row, the brick is laid flat again; the order and building level will help you avoid mistakes in size.

- Subsequent rows are laid out flat, only the brick is also laid edgewise at the back.

- The eighth row completely covers the firebox. This level needs to be laid out askew, order will help with this.

- The ninth row needs to be moved back a little, and asbestos for the hob should be laid on top.

- At the next level, the base for the chimney is prepared.

- On the last row you need to make a flap and exit.

- The Dutch oven is finished with tiles. it can also be whitewashed or painted.

- The gap between the floor surface and the structure is closed with skirting boards.

Before using the oven, it must be completely dry. This will take two weeks. In this case, you need to open the doors of the structure. At home, you need to open all the windows to speed up drying. You can use a stove for heating a room only if there are no damp places on it. If the brick structure was built in the winter season, then it can be dried by lighting a small fire.

A self-built stove will heat a country house or country cottage for a long time

It is important to note that a Dutch oven can be combined with any interior style and can become the highlight of the room’s design. If these instructions are not enough, then you can watch a video on building a structure for a private house

Malyutka stove How to cover a metal stove with bricks in a house Garden stove: selection and installation Swedish stove: features and manufacture

Preparatory work

The weight of the stove is considerable, so they make a full-fledged concrete foundation using formwork:

- Mark the location of the furnace. It is necessary to ensure that the door and window are not on the same line and provide a chimney outlet. The size of the foundation will be 15-20 cm larger than the dimensions of the stove. Using a grinder, dismantle the wooden floor covering.

- Formwork is arranged and the foundation is poured with concrete (the upper level should not reach the floor surface by 2 bricks). Concrete is reinforced not only around the perimeter, but also in depth. To save on materials when constructing a foundation, it is sometimes made of rubble (broken stone, brick or any large construction waste is used).

- Next, they take a break from work for 20 to 25 days to allow the concrete to set.

- Lay a layer of roofing felt folded several times for waterproofing. The layers of roofing felt are connected with a stapler. This is a very important stage, since the Dutch oven is capable of transferring some of the heat to the floor. On a note. If climatic conditions are such that the soil freezes up to one and a half meters, it is recommended to use a layer of basalt cardboard for thermal insulation.

- Plumb lines are arranged to ensure that the oven is strictly vertical. To do this, strings or ropes are pulled, which will act as beacons. If this is not done, each row will need to be monitored not only horizontally, but also with a protractor with a vertical plumb line. If the design “goes to the side,” the performance characteristics of the stove will deteriorate.

- Bricks are selected for masonry and dry masonry is carried out. Mix the clay-based solution in an amount sufficient to use it at a time. On the second day, this solution will lose its quality. Clay is placed in a trough, filled with water and allowed to soak for about 2 days. The solution is stirred, breaking up lumps. The required plasticity is achieved using sand. To improve the quality, the mixture is kneaded with a construction mixer.

How to lay out a high-quality Dutch oven if you have no experience as a mason? There is one trick: before laying out the stove on the mortar, you should practice “dry”.