Firing ceramic materials is a complex technological process. At one time, the book I want to introduce you to helped me understand a lot. It allows the reader to understand the processes that occur during the firing of ceramic bricks.

Synopsis of the book “Firing Ceramics” by O. Tikha

translation from Czech by V. P. Poddubny

Heat treatment refers to the processes of exposure to heat in order to remove impurities and obtain the required properties of the product.

As a result of heating the ceramic material, impurities that were introduced into the mass to give it molding properties are removed.

The ceramic brick production technology assumes that during drying, physically bound water is removed from the molded product, which evaporates under the influence of heat and is removed by the drying agent.

During further heat treatment in the firing oven, dehydration and decarbonization , i.e. under the influence of heat, water of crystallization and decomposition of carbonate compounds are removed.

The term “ firing ” refers to the process of thermal exposure - heat treatment, during which ceramic brick acquires the specified final properties and the final transformation of the material occurs.

A kiln for firing ceramic bricks is both technological equipment and a thermodynamic open system.

Complex technological processes take place here: dehydration, phase transitions, chemical reactions. In the firing furnace, processes of thermodynamic interaction between the heat source, coolant and the material subjected to heat treatment take place. And there is also a constant heat exchange with the environment.

How to fire ceramics?

To properly fire ceramics, it is important to maintain the temperature regime in the kiln. Firing takes place in three stages:

- Evaporation of moisture. The products are heated to 250 °C and kept at this temperature.

- Heating up to 900 °C in a closed oven. Clay sintering occurs.

- Gradual cooling.

Firing furnaces must not only develop the required temperature, but also allow it to be regulated. The design should be as simple as possible , loading and unloading products should be easy.

Clay and ceramic mixtures. Properties of clay

Clay is the basis for the production of tiles

It consists of oxygen, hydrogen, silicone and aluminum and when water is added it changes its structure, becoming more flexible and viscous. When water is removed, the clay hardens and becomes rigid. It is very important to know that clay that has only recently been dug out of the ground is not yet ready to be used as a raw material for ceramics. The working qualities of newly mined clay leave much to be desired

The main characteristics of clay that will be important to you are plasticity, firing temperature range and degree of shrinkage.

Plasticity of clay

Plasticity allows you to obtain complex shapes (such as the corners of steps, for example)

If the clay is too plastic, it will not have sufficient strength to make large-shaped products from it, and it will collapse at high temperatures. In this case, it is worth adding coarse-grained materials to it. Clay with a coarse-grained structure will not be sufficiently plastic, it will tear when twisted and molded, and it will be impossible to obtain the desired shape from it. To make it more convenient to work with, add stickier or more plastic clays to the composition.

The plasticity of clay can be easily determined by eye by squeezing and rolling out a lump. You can do a simple test - make a sausage out of clay and start bending it in an arc. The smaller the radius of the arc along which the clay bends and does not crack, the more plastic it is. Another simple way to determine plasticity is to tear a clay sausage into 2 parts. If the ends of the edges are thin and stretch like threads, the clay is plastic. If the ends are thick and dry, like stumps, and the clay itself crumbles in your hands, it has low plasticity. Potters call plastic clays fat clays, and low plasticity clays lean clays.

Let us repeat that none of these types of clays can be used in their pure form to prepare tiles; they will definitely need to be mixed to obtain the material of the desired consistency.

Clay firing temperature range

Each type of ceramic clay and each added ingredient has its own specific melting point, which determines the firing temperature required to sinter the clay when it turns into ceramic. The clay mass formula or formulation may include several different clays, as well as other non-clay materials that are added to obtain a material with certain properties, depending on the purpose of use of the product.

Potters distinguish low-melting clays (with a melting point below 1350 degrees), medium-melting clays (temperatures from 1350 to 1580) and refractory clays (temperatures, you guessed it, above 1580 degrees). The more plastic the clay, the lower the firing temperature it can withstand. To increase the temperature, add fireclay or pumice to the clay (with pumice the temperature will drop to 800 - 950 degrees).

Clay shrinkage rate

Your piece will change in mass and size during drying and firing as the water evaporates from it. When you are making tiles that are specifically designed for a limited space, you need to learn as much as possible about the shrinkage rate of the clay in question.

The greatest shrinkage occurs during firing, when chemically bound water leaves. Next, a continuous process of hardening and compression occurs with the formation of glass crystals in the fired clay, which transform the clay mass into ceramics. The higher the firing temperature, the more the clay shrinks. To reduce shrinkage, increase the amount of fireclay in the ceramic mass.

How to avoid cracking and deformation of clay

Whether you succeed or fail in your tile making venture depends on choosing the right type of clay. One of your biggest challenges will be to avoid cracking and warping during drying and firing. Fortunately, this task can be made easier by adding a significant amount of granules or particles of a coarse material such as fireclay to the clay. Ideally, the amount of fireclay should be from 15 to 40 percent, and it is desirable that the particles be of different sizes.

A good tile clay should contain 12/2? percent finely ground chamotte and 25% medium grinding. For those who already have experience working with ceramic masses, this amount may seem extremely large (and it is not suitable for making small ceramic figurines, where the fireclay content is unlikely to exceed 20%), but the open porous structure that is obtained thanks to the fireclay, allows the tiles to dry more evenly and avoid deformation.

Firing technique

Firing takes time. Attempts to save time, electricity or fuel may destroy the products. After loading the kiln, start firing at a low temperature and open all ventilation holes. The temperature should slowly rise to 400°C, after which you can speed up the process a little until the temperature reaches 600°C. The temperature can then be increased further until it reaches the desired temperature. In the case of primary firing at low temperatures, the highest temperature is 900-1000 °C. Primary firing at high temperatures varies from 1250 to 1300°C

When the required temperature is reached, the oven can be turned off , but you should wait until it has cooled to room temperature before opening it.

Types of furnaces

There are different types of thermal energy sources:

- The oldest is the wood stove. The masters kept the secrets of firing and passed them on only to their students. Today, wood burning is very rare. Technological types have replaced them.

- The most popular is natural gas. With forced air injection, products can easily be heated to temperatures above 1500 °C . Gas equipment is easy to make with your own hands, and gas can be purchased in liquefied form in cylinders.

- The most high-tech is electricity. Electric spirals are evenly laid inside the oven, quickly and accurately heating the chamber with the products. Such equipment is more difficult to manufacture; high voltage requires compliance with safety precautions and electrical installation rules.

Photo 1. Small electric kiln for firing ceramics with evenly laid out spirals inside.

Wood-burning: structure and principle of operation

This is a great option for a beginner potter. It does not require large material costs to manufacture, and dry firewood is available everywhere. Wood stoves come in several types :

Earthen

A descendant of the ancient technology of burning in a fire flame. Above the narrow pit - the firebox - a clay roof is built on which the products are laid. A vault of bricks or strips of clay is built around the products, and a smoke hole is left at the top. The design works like this: charcoal is burned in the firebox, which gives a high temperature and does not smoke.

How to make a ceramic kiln:

The process of creating a stove yourself begins with the presence of a gas stove that is no longer suitable for use. It will become the body of the future furnace. All plastic components (if any) must be removed from it. If you don’t have it at your disposal, you can weld the body yourself using sheet steel. Its minimum thickness is 2 mm.

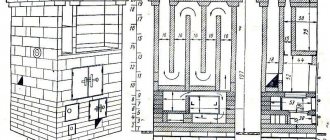

Scheme of a kiln for firing ceramics

It will be possible to burn bricks at home if you properly arrange the thermal insulation of the stove you are creating. This characteristic will have a powerful impact on the efficiency of the installation.

When organizing internal thermal insulation, work with fire-resistant bricks (fireclay). Perlite is suitable for external thermal insulation. It will significantly reduce heat loss to the external environment. Instead, there is a suitable option - basalt wool. And asbestos is absolutely not suitable here. Because when it heats up, carcinogenic elements are released.

There must be heating components inside the oven. Usually these are special spirals. They can be created from the following types of wire: nichrome or fechral. In any case, its permissible thickness is 1 mm. When using the first option, you guarantee an excellent plastic spiral that is resistant to corrosion.

Kiln for firing ceramics

If you use the second option, you will provide yourself with good savings. The low price parameter is due to the fact that such wire contains a small proportion of aluminum.

To build your intended furnace, create an arsenal of necessary materials and tools in advance. Most likely you will also need clay. The required tools are:

- Bulgarian; welding equipment; metal scissors; means to protect against potential injuries (burns).

Required supply of materials:

- steel (corners made of it); fireproof brick; heat-resistant silicone; fire-resistant mixture; basalt wool; wire (one of the two types indicated).

If you are creating such a stove not based on a gas stove, then you need sheet iron. It is cut in advance with a grinder. Whatever directional furnace (vertical or horizontal) you want to create, you need to follow one technology.

On the designated sheet, cut out a rectangular strip of the required parameters.

Then bend the workpiece into a pipe. Here you need to form a seam. This will require welding equipment. To protect against corrosion, coat it with fire-resistant paint. This requires several layers.

After forming a cylinder, weld a circle to it. She will become his bottom. Make it also from iron sheet. Its diameter must correspond to the diameter of this cylinder.

The walls of the hull and bottom need to be strengthened. What is steel reinforcement suitable for? When calculating the dimensions of the housing, take into account that some of its internal space will be occupied by a thermal protective layer and fireclay bricks. This brick rests on a composition that includes clay.

A refrigerator can also serve as a housing. Its bottom and walls are reinforced using the same method. Only here are steel corners used.

Protect the inner sides of the housing walls with basalt wool. It needs a very thick layer.

Method one. Making a chamber stove from a refrigerator or washing machine

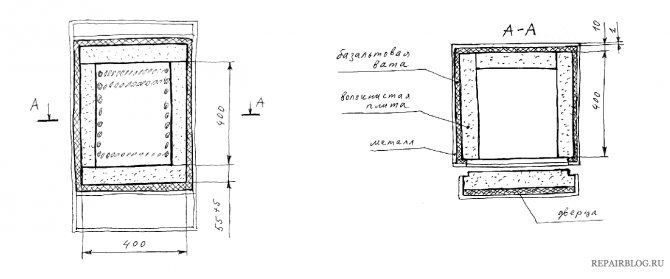

For such a design you will need only three main elements:

- metal body (suitable for a washing machine or refrigerator);

- heating coils;

- chamber made of fireclay material.

When everything necessary for work is ready, we proceed directly to the manufacturing process.

- First, it strengthens the bottom of the metal case. We use a steel corner for this purpose (as an option, it can be replaced with an ordinary pipe with a diameter of 1.5 centimeters). We weld pieces of corners/pipes into the corners of the bottom - they will serve as support legs for us.

- In addition, we need to similarly strengthen the top of the frame, the door, and at least one of the sides (the one to which the door hinges will subsequently be welded).

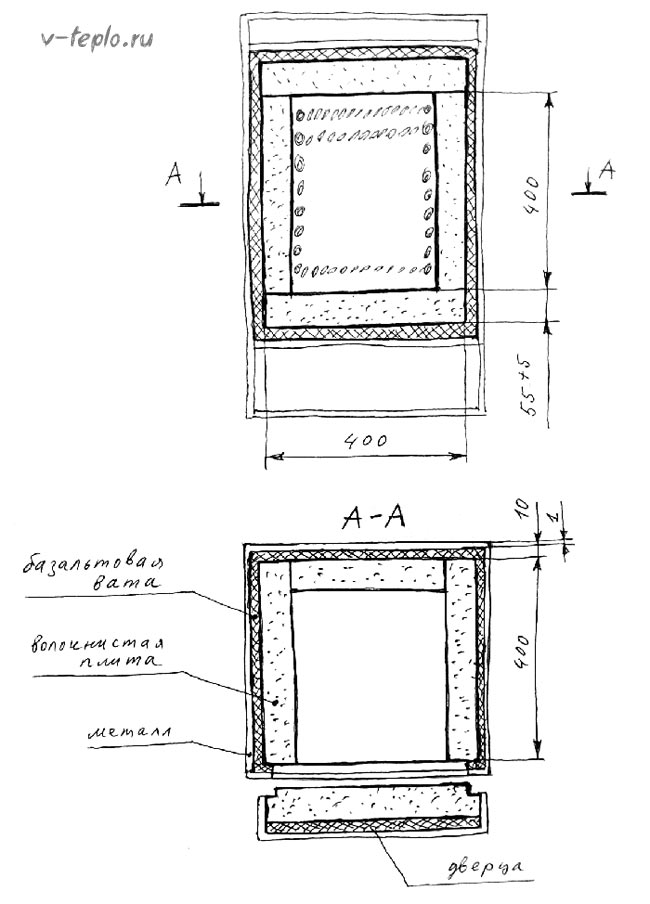

- We lay a 1-centimeter layer of basalt wool on the bottom of the body (a similar layer must be laid on the inner walls). To avoid deformation of the insulation under the weight of the chamber, we lay several pieces of metal corner or rectangular pipe. At the end of these procedures, we cover the insulation with a sheet of metal.

- After this, we decide on the fireproof material that we will use in the manufacture of the chamber. Ideally, these should be fibrous fireclay slabs, which can either be cut on site after purchase or ordered in the required sizes. Our DIY clay kiln requires six of these slabs.

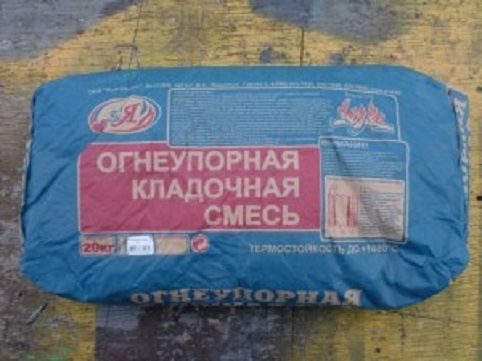

- We bind the bricks using mortar, which corresponds to the marking of the material. There is also a cheaper option - ordinary fireclay clay or fireclay masonry mixture.

- Now we begin the laying itself. We adjust the bricks as tightly as possible relative to each other, making the seams between them no larger than 0.5 centimeters. If necessary, we cut individual bricks to the required dimensions.

- We start laying from the bottom of the box. Dissolve the mixture with water and mix thoroughly. Before installing each brick, we moisten it with water, otherwise the mixture will dry too quickly.

- We begin to raise the walls. We place sheet metal and insulation in the gap between the body and the brick layer. If the brick is laid flat, then we can not use insulation.

- The upper part will take more time: the bricks along the edges need to be laid with a slight upward slope, and trapezoidal blocks must be laid between them.

- We weld the hinges and adjust the door. We must ensure that the gap between the brick layer of the body and the door is minimal.

- After the masonry has dried, we begin the next stage of work. On the surface of the bricks we must make grooves into which the heating coil will be laid. We use a spiral of nichrome wire 0.1 centimeters in diameter; the diameter of the coil will be about 0.5-0.7 centimeters. The grooves should be the same depth/thickness.

- When heated, the wire can expand, and the spirals, in turn, “climb out” of the grooves. Therefore they should be recorded. The image below shows the main ways to install spirals:

There is another way - to build a chamber from heat-resistant brick, since this material is sold everywhere and is used for laying stoves and fireplaces. For the chamber of such a furnace, it is recommended to use lightweight bricks marked “ShL” (for example, “ShL-0.5”).

This mixture is sold in the same place where bricks or fireplaces are sold. To fix the brick on a metal surface, add a little cement to the mixture (about 30 percent of the total volume).

Note! To create the outer layer, we prepare the solution separately - with the addition of cement.

The door is also lined with fireclay bricks. We make a quarter around the perimeter in such a way that a protrusion eventually appears (we will place it in the stove window).

- using small pieces of wire;

- through a groove located at an angle;

- by means of a groove having a protrusion;

- using an MKR tube.

Note! A very important point: the turns should not contact each other!

- We make 2 circuits from the spirals so that the temperature can be adjusted using a switch (the same as in an electric stove).

- We mount a ceramic plate on top (for example, from a burner) and fix the ends of the spiral with bolts.

- We will equip our kiln for firing clay with our own hands with the switch shown below, in which there will be three contacts on one side and two on the other.

- We mount the switch in such a way that its pin goes out, i.e., onto the front panel. We connect all the wires, on the side where there are only two contacts, we connect zero and phase.

- We connect the cables leading from the plate to the other three contacts. Typically, one of the cables should close a pair of contacts on the edge of the plate.

- As a result, we should get the following: at the first “speed”, the spiral circuits will be connected in a certain sequence, since in this case the temperature will be the lowest.

- This, in principle, ends the furnace manufacturing process. At the end, we need to thoroughly dry the structure, for which we place it in open sunlight or next to a heating radiator for at least 1-2 months. After this period, we need to perform final drying by running the device for 3-4 hours at the minimum “speed”. When steam is no longer billowing from the structure, the device can be turned off - it is completely dry. We can proceed directly to firing!

We bring the ends of the spirals upward.

If the “speed” is second, then only 1 circuit will be connected due to the fact that the temperature will be higher. It is characteristic that this should be the circuit that is drawn from below, so that the elements located in the lower part are also heated.

Finally, at the third “speed” the circuits are connected simultaneously - here the temperature will be maximum.

Chamber kiln for firing ceramics

The firing temperature for clay products is 1000°C. Therefore, only a special oven can cope with this task. There are two types of electric firing furnace: muffle, when the heating element is located around a refractory container (muffle), and chamber. In a chamber oven, the heating element is located inside the container. It was the chamber oven from an old washing machine that the author decided to make.

Tools and materials. Washing machine body; Welding machine; Fire brick; Heating element (spiral); Basalt wool; Fireproof masonry mixture; Electrical installation materials; Metal sheet; Pipe.

Having disassembled the washing machine, the author leaves only the body of it.

Since the load on the furnace body will be large, he strengthens the lower part by welding a 15mm pipe across it. It also strengthens the top, side and back walls. At the corners of the lower part, legs are welded from scraps of pipe of larger diameter.

From the inside, a square pipe is welded to the bottom of the furnace, as if dividing it into sections.

Lays basalt wool on the bottom.

Cutting it to size covers the lower part with a sheet of iron. Bricks begin to be laid on the iron.

To lay bricks on an iron sheet, cement is added to the fire-resistant masonry mixture in a proportion of up to 30%. If brick is laid on brick, there is no need to add cement.

After soaking the brick, place it as tightly as possible on the prepared mortar.

Lay out the walls so that they narrow at the top, forming a trapezoid. Basalt wool is placed between the brick and the body and covered with a sheet of iron.

The door is also lined with bricks from the inside and reinforced with corners around the perimeter. Hinges are welded to the door.

Next, a groove is hollowed out in the brick for the heating element. The oven will have two independent circuits.

The heating element is a spiral of nichrome wire with a diameter of 1.5 mm. The spiral coil is about 12 mm. By placing the spiral in the groove so that it does not touch each other, he secures it. The ends are brought to the top.

Secures the ends of the spiral to the distribution bar.

Next, install the switch. For the stove, the author installed a switch, when turned on, one or two circuits operate in series or in parallel.

To do this, install a switch with two connectors at the top, to which he connected phase and zero, and three at the bottom, to which he connected the outputs on the distribution strip. Moreover, the blue wire closes the two outermost contacts.

Now, when two circuits are turned on in series, the oven begins to warm up at an average temperature.

Having switched the switch, one lower circuit begins to heat up at full power. By turning the switch handle again, two circuits are connected in parallel and the oven warms up to the highest temperature.

Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Method two. We make a stove without having a metal casing at hand

The manufacturing process in this case is not much different from that described above, but there are definitely some nuances here. Let's start with the fact that the working volume of the design below will be about 13 liters. The spiral, as mentioned above, can warm up to a thousand degrees in just 1.5 hours, while the temperature of the outer walls of the device will not exceed 100 degrees. The algorithm of actions should be as follows.

Step 1. First, using a 4x2 centimeter profile pipe (with a square cross-section), we build a stand for the device. After this, we paint the finished stand with enamel.

Step 2. We attach a sheet of galvanized steel on top of the stand (its thickness should be approximately 0.1 centimeters), using “metal” self-tapping screws.

Step 3. We make the walls from fireclay bricks and a special fireplace composition (everything is the same as in the previous version). After the solution hardens, we make grooves for the spiral.

Step 4. We assemble the bottom from brick separately, and use the same mortar for fastening. Before continuing work, wait until the structure is completely dry. Do not forget to wet each brick immediately before laying.

Step 5. We lay a thermal insulation layer on top of the metal base (we can use the same basalt wool for this). In order to maximize compaction of this layer, it must be moistened before fixing the brick bottom.

Step 6. We continue the traditional laying of the stove, but we try to ensure that all voids and seams are carefully filled.

Step 7. We traditionally make the lid for the chamber from fireclay bricks, but at the same time we fasten them together with a metal tie.

Step 8. Place the spiral in the prepared grooves and insulate the structure from the outside with thermal insulation material. Next, we cover everything with sheets of galvanized steel, which are cut according to the dimensions of the resulting chamber.

As you can see, this requires knowledge not only in the furnace business, but also in the field of electricity. You can see another possible manufacturing method in the video below.

Method three. Making a vertical muffle furnace

Despite the fact that we do not recommend making this kiln for firing clay with your own hands, we will still briefly consider its design. The design diagram is shown in the image below. It consists of a ready-made muffle (1) and a burner (3) from a regular tile. The volume of the muffle will be 3 liters, it will warm up to eight hundred degrees. The ratio should be approximately the same as in the diagram, although minor deviations are still acceptable.

We purchase the burner separately and, installing it on a sheet of steel, we power it from a cylinder equipped with a reducer. Using a jet, we adjust the heating intensity (the same as in a regular stove). The body (2) may not be as strong as the muffle, for this reason we make it ourselves. To do this, you will need fluffed asbestos and fireproof clay.

Step 1. First of all, we ferment the clay to create a box: pour the clay powder into the prepared container, add water along the filling line, and then forget about it for about 24 hours. After a day, we begin mixing the solution to the consistency of plasticine, add 1/4 of the refractory sand.

Step 2. Next, add one or two parts of fluffed asbestos, mix the solution thoroughly. At the same time, we prepare a wax blank for the inner cone in the body. All external elements are made by hand or using a pottery wheel. We leave holes for the steel legs (although these legs can be made from the same composition).

Note! In this case, there is no need to check the clay for fat content. The natural fat content of this material is quite sufficient for this design.

Step 3. Then we dry the structure for two weeks at a temperature of 25-27 degrees. After this time, we melt the wax using a household hair dryer, since it is no longer suitable for further use.

Step 4. We continue to make a kiln for firing clay with our own hands. Now we need to burn the dried body. We lay it out of dry bricks and enclose it with a metal mesh about 75 centimeters high (this is necessary so that the coals do not crumble, but oxygen flows to them). We place the structure on the floor, cover it with a ceramic container and fill it with firewood to the level of the top of the fence.

Step 5. Light the fuel from below. We add firewood until the hot coals completely hide our workpiece. After this, continuing to gradually feed the flame, we maintain the combustion for another five to six hours. And then, when the ash has cooled, we remove the workpiece.

Note! The firing procedure must be carried out under some kind of canopy. Drops of moisture are not allowed!

Step 6. The final firing is carried out in a finished furnace (that is, in the shell), between the cheeks of which thermal insulating material is laid. We install an empty muffle in the appropriate place. We activate the burner (at minimum power), then gradually increase the flame to maximum (in about half an hour). We warm up the stove for another 1.5 hours, after which we can proceed directly to its operation.

As you can see, if desired, and also if you have certain knowledge, making a kiln is not difficult. But follow safety rules - both when working and when using the structure! That's all, good work and warm winters to you!

Clay firing technology

Clay kiln

The best option for firing clay is a muffle furnace

. The temperature in this oven can be adjusted. It should be remembered that such a stove is very expensive and not everyone can afford to buy it. But there is no need to be upset, because it can be replaced with other good devices, for example, firing clay in the oven. Start firing the clay at 200° for 2 hours. Then, over the course of 6 hours, gradually raise the temperature to 1000°. This temperature regime allows you to protect the clay product from stains and help maintain a uniform structure.

Clay firing can also be done in a barbecue or brick kiln.

. These species are a closed space characterized by a stable temperature. It is needed so that the clay product heats up evenly, and various defects do not form on it, such as spreading of the surface. The product that is being fired must be left until the fuel has completely burned out and the firebox has cooled down. The product should be in the oven for approximately 4 hours.

Firing a clay product over a fire is a very affordable option. It is used for firing small items. So, take a clay product and place it in a tin vessel, which you have previously heated and made holes in the sides. In most cases, the vessel is an ordinary tin can. Fire the product for about 8 hours, no less.

to fire clay in the microwave.

. Such an oven can only remove moisture. Clay products, after you have air dried them, place them in the microwave for 3 minutes. This is done to make their condition better.

Temperature

The main rule in firing clay products is that you need to gradually raise the firing temperature and then gradually lower it, giving the product time to cool. At first (first 2 hours) the temperature should be no more than 400°. The firing temperature can fluctuate in the range of 200-1000° during firing. If the temperature is lower, the firing will be insufficient and the figurine will not have the desired properties. If the temperature is very high, then the figurine may collapse.

Duration

This process can last from eight hours to several days. This depends on the size of the product and the firing technology. If the figure is small, then this can be done in the shortest possible time.

Operating rules

The electric oven may only be plugged into a reinforced socket. You can also run a large cross-section wire directly from the shield. In addition, it would be useful to install a circuit breaker.

Since this device model has exposed wires, you need to be extremely careful with it. Do not touch the coils while the oven is running. To avoid accidents, it is recommended to install a limit switch on the door, which will turn off the unit when the door is opened. If you are not very good at electrical work, seek the help of a specialist who can help make the device as safe as possible, including grounding it.

Making a muffle electric furnace with your own hands

Before starting work, select materials, instruments, and electrical equipment. The oven is connected to the household electrical network .

Selection of materials

The stove of this model is compact; its production does not require special materials and parts . To work you will need:

- mortar (ready mix) - 5 kg >;

- sheet steel thick (2.2 sq. m);

- fireclay bricks 16 pieces;

- rolled mineral wool (basalt);

- tube made of fiberglass , ceramics (diameter 10 mm , length - 15 cm >);

- rolled steel angle section - 3 m >;

- spiral (fechral, nichrome) for electric stove (1.6 m);

- thermocouple.

Important! Used materials and electrical components do not guarantee normal operation of the electric furnace.

Preparing tools and equipment

To lay the muffle you will need stove maker tools (trowel, spatula, tape measure). To work you need to buy or rent equipment and tools:

Step-by-step instruction

Before starting work, mix the masonry mortar. Construction of an electric furnace includes the following stages:

- Sheet steel is marked , outlined using a pencil, ruler and square, then the parts of the casing and door are cut out with a grinder.

- The casing is welded using a welding machine .

- Fastenings for the door are welded to the casing . A lock is welded onto the door.

- Grooves are made in the bricks using a Pobedit drill (for a spiral).

- A frame (for the muffle chamber) from an angle profile

- A muffle (chamber) in the frame

- The chamber is dried for 5-6 days.

- carefully placed into the grooves, the ends are brought out beyond the muffle through a pre-drilled hole.

- The spiral is fixed in 3-4 places with a solution.

- A thermocouple is inserted through the hole into the muffle chamber ; the contacts are protected with a fiberglass tube.

- The places where the wires come out are covered with masonry mortar.

- The chamber is dried for 2-4 days.

- is placed on the back wall of the housing .

- A lattice stand is placed in the body , and a muffle is placed on it.

Important! The grid plays an important role , thanks to it the heavy muffle will not compress the porous heat insulator.

- The gap between the body and the fireclay chamber is filled with a porous thermal insulator (mineral wool).

- A layer of porous thermal insulator and fireclay plates to the inner surface of the door

- The door is hung on hinges , and the seals are adjusted to the dimensions of the chamber.

Photo 2. Finished working chamber of the muffle furnace: metal casing, layer of insulating material, brick with a spiral.

The brick does not have to be attached to the door. When firing, it can be placed directly in the muffle, in front of the door. The next stage of installation is connecting the stove to the electrical network . For this you will need:

- thermostat;

- electromagnetic starter (relay);

- terminal blocks (made of heat-resistant plastic);

- steel casing for the shield;

- electrical two-core wires;

- fork.

Reference. The technical parameters of the circuit are calculated in advance . Based on the calculations, a thermostat and relay and heater parameters are selected.

In the electric furnace under consideration, a standard M-1-K thermostat . The device allows you to set the firing temperature to 1250–1350 °C. four buttons on the front panel of the device to switch modes . Connecting the thermostat is described step by step in the documentation for the device. The thermostat, electromagnetic starter, and terminal block are mounted in a shield box with brackets and bolts.

Possible problems and difficulties

A big problem during the construction and startup of a furnace is the incorrectly selected electrical equipment, heating elements, and spiral parameters.

This leads to destruction of the heating elements or coil. If the technician does not have experience in calculating electrical circuits, you should seek help from a professional electrician.

When laying a fireclay brick muffle, mortar or fireclay-sand mixture is not always used . Instead, amateur craftsmen take a regular clay-sand mixture. As a result, cracks appear . When the furnace is first started, the cracks increase. To solve the problem, the muffle is disassembled and the bricks are placed on fireclay mortar.

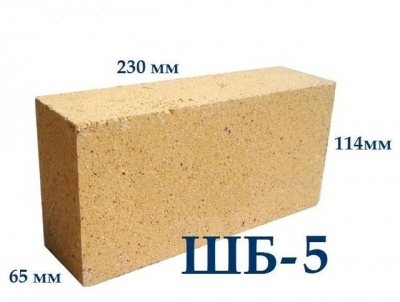

Advice. For a muffle furnace, fireclay bricks with the letter “Ш” are suitable . Brick with the letter “U” (recycling) is less durable.

When making an electric muffle furnace, not all home craftsmen install thermostats . This leads to overheating and damage to products already at the first start-up. To solve the problem, you should install a thermocouple and a thermostat.

If old, used brick cracks appear in it even during test runs . The camera will have to be dismantled and a new one built.