The basement of the house accounts for most of the environmental impact (temperature changes, precipitation, etc.). That is why it is recommended to properly and effectively insulate the base. This will allow, in addition to direct protection from the cold, to improve waterproofing, as well as reduce the risk of dew point and condensation in the underground part of the building. If the base is properly insulated, the service life of the structure will be increased by several decades. Insulation of the base from the outside is the main part of the work on thermal insulation of this structure.

Insulation work can be carried out during the construction of a house or after its completion.

Experts recommend that all thermal insulation and waterproofing work on a wooden house be carried out during construction. Insulating the basement upon completion of all construction work can result in some difficulties.

Insulation methods

The choice of one or another method of insulating the basement from the outside will depend on the main operating characteristics of the building and weather conditions, as well as on the financial capabilities of the owner of the house. In addition, it is additionally recommended to insulate the basement of the building from the inside.

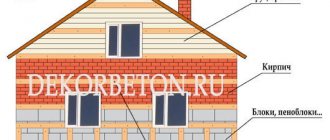

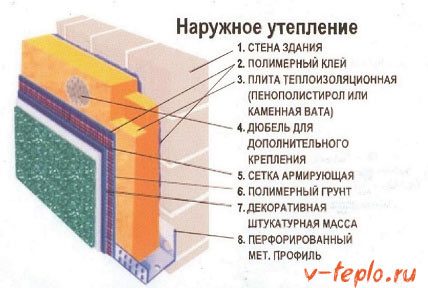

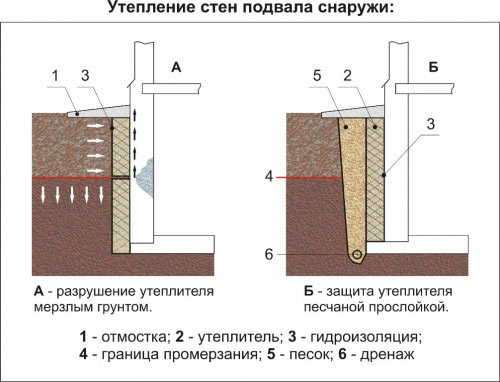

Insulation diagram for the basement floor.

Insulation of the basement and basement in recent years has increasingly been carried out using extruded polystyrene foam. Today this thermal insulation material is sold in the form of slabs. The material has excellent performance and performance characteristics. Heat insulators of this type can be used in conditions of high humidity and severe temperature changes.

In addition, expanded polystyrene simply perfectly resists biological effects (mold or fungal colonies will never form on the material). This is a certain guarantee of the integrity of the insulating layer. If polystyrene foam is installed correctly and in accordance with all requirements, outside and inside the house, then condensation will never form on the walls.

Insulation of the basement and basement floor using extruded polystyrene foam can be done with your own hands. The resulting “sandwich” will effectively redistribute the temperature, which will increase the service life of the walls and foundation.

The technology for installing a heat insulator outside the base involves installing thermal screens and several insulating layers in strict sequence. That is why it is necessary to carefully monitor the technology of work execution.

Why is basement insulation required?

The basement floor is special because its floor is located below ground level (approximately ½ of the height of the room). And this area should be protected from various types of damage caused by groundwater and weather phenomena. Any material can be used for insulation - tile, stone, etc. As for insulation, you will need one of the following materials:

- Styrofoam;

- reinforcing mesh;

- foam type fasteners;

- wall structures;

- plastic dowels.

And here the question arises: will the insulation be able to withstand all the relevant loads - both external and internal? The answer is yes, since the structure can handle all this, moreover, it will effectively retain heat in the building. However, there are a number of nuances that you should definitely be aware of during the assembly process.

So, the foam substance should be replaced with a stronger material. A foam solution having the characteristics of adhesive can act as polyurethane foam. This will be of better quality and more practical if you plan to insulate the base. In addition, it is also advisable to insulate the blind area. Finally, in view of the fact that this floor will be efficiently heated from the inside, it should be ensured that the soil around it freezes as little as possible. Only under such conditions will the insulating layer be effective, while utility bills will be significantly reduced.

External insulation of the base

First you need to decide on the material that can be used in the thermal insulation process. The option you choose must meet the following requirements:

- it must be durable and resistant to mechanical loads;

- it must not be harmful to the environment;

- Its frost resistance and minimal moisture absorption are also important.

In view of all this, the following is often used as insulation:

- liquid rubber;

- bulk soil;

- liquid polyurethane foam;

- expanded clay;

- extruded polystyrene foam boards.

Note! Thanks to the insulation, the temperature will not only be maintained, but also the contact of the foundation with the soil will be minimized. Moreover, the quality of the insulating material will be maintained, it will not deform when the soil freezes, and the walls of the base will be reliably protected from condensation (as a result, fungi and mold will not appear).

Now let’s look at how to insulate the basement using one or another insulating material.

Insulation using expanded clay

How to insulate a floor using expanded clay

Previously, we talked about the detailed technology for insulating the floor in a house using expanded clay; in addition to this article, we advise you to read this information and read about it here

The algorithm of actions is given below.

We say right away that you can rent formwork here arendaopalubki.spb.ru

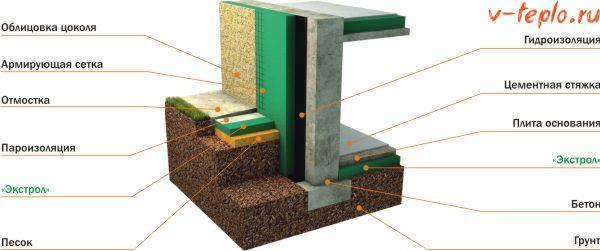

Step 1. As soon as the foundation is poured, additional formwork is built around it, the width of which should be 15 centimeters.

Step 2. The formwork is filled with a special solution consisting of expanded clay and concrete.

Step 3. As soon as this kind of heat-insulating layer hardens, waterproofing material is laid on top of it.

Step 4. Next, the soil is filled in, and the method of so-called soil filling should be used (sand and crushed stone layers are present here).

Step 5. After this, the horizontal base slab is also covered with expanded clay mixed with concrete mortar, mineral wool 300-400 millimeters thick (in two layers), as well as a film for waterproofing, is laid on top.

How to properly insulate windows in an apartment

Previously, we talked about the detailed technology for insulating windows in an apartment; in addition to this article, we advise you to read this information and read about it here

Thermal insulation using extruded polystyrene foam

Another effective method of insulation, which involves the following steps.

Step 1. First, the base is covered with a waterproofing membrane.

Step 2. Next, slabs of thermal insulation material are installed on top of it (their thickness can vary between 3-12 centimeters, it all depends on the specific conditions). Expanded polystyrene is attached using a special glue, and this is done point by point.

Step 3. Of course, you can use thinner slabs, but in this case they are laid in two layers. Thanks to this, the thermal insulation characteristics of the sandwich will noticeably increase, especially when compared with slabs of greater thickness. So, if thin polystyrene foam is used, then the slabs should be laid in a checkerboard pattern so that the seams of the previous layer overlap the next one.

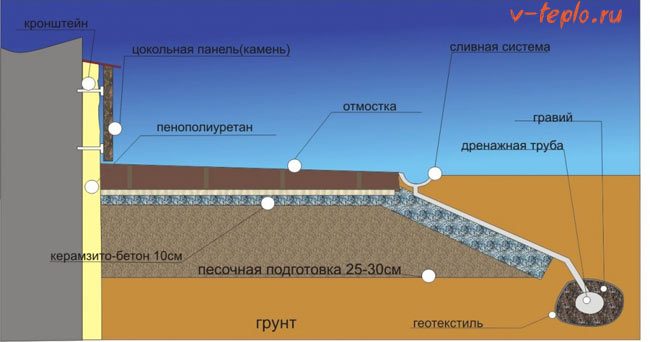

Step 4. Next, the slabs are covered with a profiled membrane - it will also serve as a kind of drainage that drains underground water.

Step 5. The profiled membrane is covered with a filtration layer of geotextile, which will protect it during operation. After this, the geotextile is covered with earth.

Step 6. At the end, the base, horizontal base slab and cement blind area around the entire perimeter of the structure are insulated.

Insulation with spray polyurethane foam

Step 1. This technique is different in that it does not require laying additional layers of waterproofing. Let's look at how the procedure is performed.

Step 2. When thermally insulating with spray polyurethane foam, the base is processed using a special mounting gun. Application is carried out directly on the concrete base, and the layer thickness should be approximately 60-70 millimeters.

Step 3. Polyurethane foam dries instantly, resulting in an even and smooth moisture-repellent coating.

Note! In order to increase the thermal insulation qualities of the coating, you can spray the material in two layers (typically, nothing can be laid between them).

Step 4. Coatings treated with polyurethane foam require additional surface treatment, since this insulation, as is known, does not withstand direct sunlight.

Step 5. A mounting mesh is attached on top of all this, then the surface is plastered and - as soon as it dries - the finishing is done.

Internal thermal insulation

To understand how to insulate a basement, you first need to understand all the intricacies of heat distribution. Let’s make a reservation right away that people who believe that cold can penetrate buildings are mistaken. In reality, the concept of “cold” simply means the absence of heat, therefore, it cannot penetrate into something. What happens in buildings is the following: thermal energy simply leaves it.

Note! If the basement is not heated, then there is nothing to come out of there. In this case, to improve the situation in the building, it is enough to insulate the floor between the basement and the first floor.

Although there is another problem: the surfaces of the walls in the basement can freeze. In such cases, care should be taken about external insulation. The fact is that internal insulation will only cool the masonry even more, since the tiny amount of thermal energy that the basement receives will stop flowing there altogether.

Note! Many people store food, fruits and vegetables, and other perishable items in basements. Insulation is not required here; on the contrary, it can even cause harm.

Let's consider another important point. If the basement room is heated, and the room above it is also heated, then the temperature difference between the objects will be small, therefore, there is no point in insulating the ceiling. It is also better not to insulate the floor on the ground floor, because it is often located no lower than the freezing level of the soil.

Selection of insulation material

Suppose the basement room is heated, but for some reason it is impossible to insulate it using one of the methods described at the beginning of the article (that is, from the outside). All that is required is internal insulation, which is reliable and of high quality. How to make it? There are several ways.

- Using polystyrene foam. It’s not for nothing that we talk about this material first - it is the most practical, it combines quality + price better than others, and it’s quite easy to install even for people far from the construction industry.

- Application of bulk heat insulators. The cheapest, and therefore the most popular method, which, however, is not suitable for internal use.

- Using mineral wool. An excellent non-flammable heat insulator that does not emit harmful substances even at critically high temperatures. Moreover, it is resistant to pests and does not deteriorate over time. Perhaps the only disadvantage is that mineral wool is hygroscopic, that is, it requires the installation of high-quality waterproofing.

- Application of polyurethane foam. At the moment, this is the most effective material, which, as noted above, is applied to the surface in liquid form and forms a durable and seamless layer. But polyurethane foam is still not very popular, since it is expensive, and installation work is not cheap.

It turns out that it is more advisable to use polystyrene foam or mineral wool. And to choose one of the options, you need to pay attention to the moisture level of the walls. And if the foundation is poorly waterproofed (or there is no insulation at all), then give preference to foam plastic, since it is more resistant to moisture.

Note! The use of mineral wool is advisable in cases where the humidity of the walls is normal and in the future they will be sheathed with clapboard, plywood, etc. (the fact is that this material is easier to install inside the frame).

You should not insulate the walls with mineral wool under a layer of plaster, because even the hardest types will sag under a certain pressure. As a result, the finishing is destroyed.

Instructions for insulating from the inside

So, you want to know how to insulate the basement from the inside. In reality, there is nothing complicated here, the main thing is good instructions (and they are given below).

Step 1. First, the walls are cleaned of debris and dirt. Next, all seams are carefully sealed, and all detected defects are eliminated.

Step 2. The surfaces of the walls are covered with a deep penetration primer mixture.

Step 3. Next, take the first sheet of foam plastic, and cut off the locks on its left side (this is the case if the installation will be performed from left to right). Then, using a dosing spatula, special glue is applied to one side.

Step 4. The sheet is pressed in the right place against the wall and secured with dowels. These dowels must be driven into the corners on the left side, as well as in the center of the slab.

Step 5. Next, take sheet No. 2, cover it in the same way with adhesive and press it to the wall surface. It is important that the locks on the edges match - each new slab must overlap the locks of the previous one (but under no circumstances should it be inserted!). Dowels are driven in in the same way.

Step 6. The first row ends. The next row begins with 1/2 of a whole sheet in order to achieve the notorious displacement of the seams. In this case, when fastening, only a couple of dowels are hammered in - in the center and at the bottom left. All remaining corners will be pressed in the future by other sheets covering the locks around them.

Step 7. In this spirit, the entire wall is covered. Now the finishing of the second wall, the third, the fourth begins - until the entire room is insulated. A special reinforcing mesh made of fiberglass is laid on top of the foam (a layer of glue is applied to secure it).

Step 8. The walls are covered with plaster on top of the mesh, on which the required finishing coating is applied (a layer of putty, plaster, and so on).

What if the basement is made of wood?

The question of how to insulate a basement floor with a wooden floor is becoming increasingly relevant for owners of country houses. Moreover, today you can still find old high-rise buildings in which the floors are also made of wood, and in the basement floors there is practically no thermal insulation. In such cases, experts advise using lightweight insulation materials characterized by low density. The algorithm of actions is as follows.

Step 1. The old wooden floor is dismantled.

Step 2. Between the support beams - the floor elements - the first layer of thermal insulation is laid, but before that it is necessary to lay polyethylene film (or a special waterproofing material) with an overlap and an exit to the walls of 50 millimeters.

Step 3. Even a layer of expanded clay (about 30-50 millimeters) or the above-mentioned sprayed polyurethane foam can be used as insulation here.

Step 4. A 3-centimeter “cushion” consisting of quartz sand is laid on top of the insulation and carefully compacted.

Step 5. Floor slabs are placed on the sand. Both moisture-resistant plywood and gypsum fiber board sheets can be used as such boards.

Step 6. The slabs are glued together, and the seams between them are carefully sealed with bitumen-based mastic.

Step 7: Finish is installed with traditional underlayment.

Video - Base insulation

Insulation installation technology

Any work on insulation or waterproofing of a wooden or brick house should begin with cleaning the surface that is supposed to be insulated.

Waterproofing layer.

Next, it is necessary to check the covering of the base with soil and identify the absence of counter-slopes, which could potentially bring moisture to the base of the house.

Installation of polystyrene foam boards.

Then, the order of work is as follows:

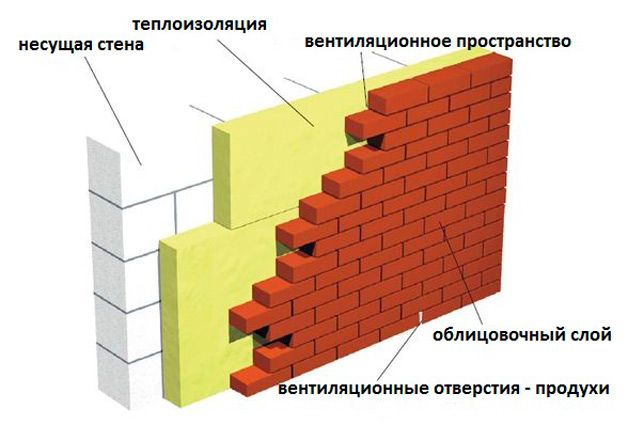

- Insulation of the basement floor of a wooden or brick house begins with the installation of a protective sealed layer. You can waterproof the base using special moisture-proof materials that have an adhesive base. They are easily glued to the surface and help protect structures from moisture.

- Then you need to apply a waterproofing layer. This is an important factor in ensuring the basement and basement are properly insulated. Waterproofing is designed to drain groundwater and any precipitation from the walls of the structure.

- Laying polystyrene foam boards is one of the most important stages in insulating the basement and basement of a wooden house. In most cases, one layer of slabs 5-8 cm thick will be enough. But much will depend on the climatic conditions of the area, according to which it is necessary to select the thickness of the thermal insulation layer of the base. If the weather conditions in the area are difficult, then it is recommended to lay two layers of polystyrene foam slabs, and the second layer should be installed so that the slabs overlap the joints of the first layer. In this case, so-called “cold bridges” will not appear, which significantly reduce the efficiency of insulation work on a wooden house.

In accordance with the specifics of insulation technology using polystyrene foam boards, installation of a decorative layer on the boards immediately after finishing the base is not allowed.

You can insulate the base, as already noted, yourself and without the use of special tools. But it is best to carry out thermal insulation and waterproofing work directly at the stage of building a house. In this case, the work efficiency will be higher.

Decorative stone finishing.

concrete-area.com

In order to begin work on the construction and insulation of the foundation, it is best to choose either spring-summer time or autumn, for the reason that the air is warm enough and the humidity is normal. Together with the portal, today we will talk about how to insulate the foundation of a house from the outside. In this article you will find interesting ideas for yourself and find out what materials are best used for these purposes. Below in this article we will try to tell you in more detail with the portal how it is necessary to properly insulate the foundation from the outside.

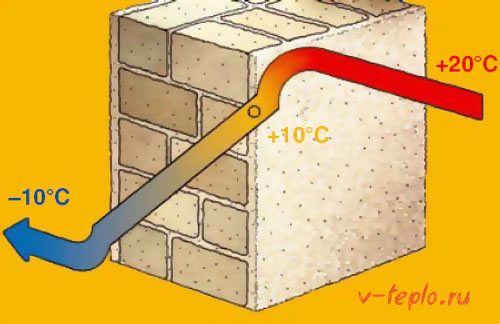

Why do you need to insulate the foundation?

The use of insulation for the foundation is the same important point in the work as the insulation of the walls in the house. Mainly where there is very cold weather and the soil freezes to a fairly large depth. The foundation of the building is capable of releasing 15-20% of heat loss into the environment. Freezing of heaving soils is very dangerous for the foundation. They can freeze in winter and increase in volume. As a result of this, the soil level rises, due to which the foundation of the building begins to deform, changing its linear dimensions. If the foundation is constructed above the freezing level, and its base is not insulated, then at the moment the soil freezes underneath it, frost heaving will occur. It will have a perpendicular direction to the top of this foundation base. Based on this, in the process of arranging the foundation, thermal insulation of its base is carried out. (or slabs).

It is worth saying that the subsequent operation of this building and the conditions for comfortable living will depend on the quality of the insulation work performed. And a plan for performing these works must be carried out during the construction of the building. Due to the fact that the main part of the cold air enters the building through the base of the foundation, during construction it is necessary to use special floor coverings, which are usually located above ground level. Basically, all the cold will be at the level of the foundation and floor, and the heat, in turn, will rise upward. And if the roof of the building was not properly insulated, warm air will be lost through it and go outside, thereby allowing the cold to penetrate inside the building. But if your basement is intended for functional purposes, then it should be insulated as well as possible. Perhaps a gym will be located in this room, or a laundry room; in any case, the room should be cozy and comfortable. But if you do not properly insulate the foundation, then you will be provided with increased humidity and dampness.

A basement that is not equipped with a heating system, as a rule, does not require thermal insulation. But here it will be necessary to start insulating the basement part of the foundation in order to reduce heat loss along the floor level on the 1st floor of the heated room. Carrying out work on thermal insulation of the foundation base will help you save maximum heat in the building and close the path of cold. You must always remember that with excellent insulation of the house, as well as its foundation, you can save approximately 35-45% of your money intended for heating. In addition to thermal insulation, the main insulating layer of the foundation will play an important role in waterproofing. Now let's try to find out what the main role of foundation insulation is.

- Reduces heat loss;

- Makes it possible to reduce heating costs;

- Almost completely reduces the impact of frost heaving forces on the foundation;

- Balances the temperature inside the building;

- Prevents condensation from forming on the inside of the walls;

- Performs the function of protecting waterproofing;

- Serves as a factor in the longevity of the entire foundation of the building and waterproofing.

What insulation should you choose for the foundation?

In this article we are talking about how to insulate the foundation of a house from the outside. Here we will provide our readers with useful tips and invite you to watch an interesting video. Carrying out thermal insulation work first of all includes the correct choice of insulation.

What material is needed to insulate the foundation of a building?

First of all, it must have the following characteristics:

- do not absorb moisture into its base;

- do not change their linear dimensions and do not deform under the influence of soil pressure.

Currently, in the construction markets you can see a huge number of different thermal insulation materials. It is clear that mineral wool in this case is not suitable for insulation due to its very soft and water-absorbing properties, since this reduces the thermal insulation qualities. In order to insulate the foundation, many experts advise remembering 2 main methods:

- Insulation using extruded polystyrene foam;

- Carrying out work on spraying polyurethane foam.

These materials differ from each other in terms of their thermal insulation parameters and price. To make a more competent choice of this product, you should first study in detail all its advantages and disadvantages. Polyurethane foam is one of the popular insulation materials, which carries several main functions at once - it provides maximum hydro-, heat and sound insulation. In order to use it in work, you will need certain equipment, with the help of which polyurethane foam will be sprayed layer-by-layer onto the insulated surface. The thickness of its layer should be 50 mm, with a material density of 36 kg/m3. The same effect can be achieved by using polystyrene foam with a thickness of at least 120 mm.

Polyurethane foam

In a coating such as polyurethane foam, all seams and gaps are usually absent. When carrying out foam insulation work, all existing joints should be hermetically sealed. This will also require special mounting fasteners, which, in turn, will increase the cost of the work performed and increase time. The main advantages of using polyurethane foam:

- High adhesion of this material;

- Seamless coating;

- Strength;

- Little steam and heat permeability;

- Longevity of the material.

- There is no need to carry out additional work on steam and waterproofing.

The main disadvantages of this material include the mandatory presence of certain equipment and the harmful effects of ultraviolet radiation on it.

Insulation of the foundation with polyurethane foam

The only advantage of extruded polystyrene foam is its low price. But this fact does not make it more significant, for the simple reason that installation work is quite difficult and this material, in addition, has very low thermal insulation functions. Plates consisting of extruded polystyrene foam do not absorb moisture, as they have a closed cellular structure. This suggests that this material is not subject to destruction over time and freezing will not occur. For this reason, extruded polystyrene foam has a maximum service life while maintaining its thermal insulation properties.

It should be noted! What is the answer to the question “What is needed to insulate the foundation? we offer this... The use of standard foam plastic for thermal insulation of the foundation, as a rule, can lead to the fact that after a large number of seasonal cycles of freezing and warming up the foundation base, the layers of this material undergo crumbling. This factor occurs due to the fact that polystyrene foam absorbs all moisture very well. And to carry out vertical insulation of the foundation of various industrial or civil facilities, it is done using extruded polystyrene foam slabs having a compressive strength of 250 kPa or more. When insulating private buildings, polystyrene foam with a compressive strength of 200 kPa is used. To insulate floors, slabs with a strength of 500 kPa should be used. These strength features of this material are very capable of maintaining the integrity of the waterproofing part of the foundation. Also, thanks to extruded polystyrene, a long life of the foundation itself is ensured. Among the wide variety of insulation materials, as well as extruded polystyrene foam, there are slabs with special milled grooves. Together with geotextile fabric, this type of insulation perfectly performs the role of drainage, protects the waterproofing layer of the foundation as much as possible and removes the moisture accumulated in it into the drainage system.

Pay attention to the publication of the portal: Tips on how to choose polyurethane foam

Thermal insulating polystyrene boards with milled grooves

The main advantages of extruded polystyrene foam:

- Long service life (more than 35 years).

- Increased compressive strength.

- During use, constant hydro- and thermal insulation characteristics are achieved.

- This material is not edible for rodents.

Insulation of the foundation using expanded clay

More recently, a material such as expanded clay was considered the most popular for the ability to insulate the foundation from its outer part. But it was supplanted by those methods of foundation insulation described in our article above, which, in turn, are cheaper and better in their properties.

How to insulate the foundation of a house with polystyrene foam from the outside

There is a basic rule for insulating the outer part of the foundation. It occurs, as a rule, in areas of soil freezing by installing special heat-insulating slabs at the required freezing depth. And the corner sections of the foundation, in turn, should be insulated as much as possible. To do this, the layer of polyurethane foam or slab in the corners of the foundation is increased by one and a half times. You should also insulate the soil itself around the entire perimeter of the house. A layer of insulation consisting of extruded polystyrene foam should be located under the blind area. It is used mainly to reduce the depth of soil freezing around the walls, as well as to maintain the freezing boundaries in a layer of non-heaving soil running along the walls of the building.

When laying slabs of extruded polystyrene foam, the angle must be at least 2%. The width of the blind area itself should be equal to the depth of soil freezing in a given climatic zone. The most ideal thickness of the slabs should correspond to the thickness of the vertical insulating layer of the foundation.

How to insulate a foundation with penoplex

In this article, we not only talk about those materials that are suitable for insulating a foundation, but also tell you how to insulate a foundation from the outside with various materials that are suitable for such a task.

Before you begin to insulate the outer part of the building’s foundation, you should prepare the surface of the walls by leveling them and waterproofing them.

Foundation waterproofing

When installed, extruded polystyrene foam slabs act as a durable and airtight shell for the outer part of the foundation. For this reason, the use of special fasteners to be able to fix this material cannot take place in this case, since depressurization of the insulating layer may occur. The work of fixing these slabs is carried out by applying glue to their outer part or by melting a layer of special bitumen waterproofing at 4 or 6 points. Next, polystyrene foam is pressed tightly against them.

How to insulate a strip foundation

The installation of thermal insulation boards should be done from below, and the rows, in turn, are connected to each other end-to-end. The thickness of these plates should be the same. Seams located next to each other should be combined with each other using the checkerboard method. All seams formed between the insulation boards are usually filled with polyurethane foam.

It is quite convenient to insulate with slabs that have a stepped edge. If it is completely glued, a dense and airtight layer will be created, as well as additional insulation of the foundation itself. Depending on the waterproofing material used, the adhesive is selected. When using bitumen-based mastic or roll materials for waterproofing, bitumen mastic is used as an adhesive solution, which, in turn, does not contain aggressive components for expanded polystyrene.

Before insulating the outer part of the foundation, you should wait until the bitumen mixture has completely hardened (about 6-7 days). Under no circumstances should expanded polystyrene slabs be installed on a wet bitumen mixture, as they will corrode and all waterproofing will be damaged. On the same slabs that will be mounted below ground level, glue is applied in the form of several small dots. This method will ensure that the accumulated moisture in the space between the wall and the insulation can drain down. The use of special fasteners together with an adhesive solution consisting of polymer-cement adhesives is necessary for installing slabs that are located above ground level in quantity - at least 4 pieces per 1 slab. Those slabs that are located in the ground itself are mounted using an adhesive composition and pressed against the soil layer.

How to insulate a foundation slab

From this article we learned how to insulate the foundation of a house from the outside with our own hands. When drawing up a plan for how to insulate the foundation from the facade in order to effectively insulate the basement and floor, you need to think about the possibility of insulating the base of the foundation (slab) itself. In this case, insulation boards are mounted on a waterproofing layer. If knitted steel reinforcement is used to fill the reinforced floor, then the top thermal insulation layer can simply be covered with PVC film with a slight overlap of 100 or 140 mm and taped. If welded reinforcement is used in this work, then a concrete screed will need to be made on top of the film, and only then welding work will begin.

Useful articles

- How to properly prepare a concrete solution

- How to decorate a sea container for a house

- Types and types of concrete mixtures

- We understand the characteristics of OSB sheet

- We buy gates for a summer house

- Storage water heater design

Final finishing

The insulation of the base is completed by decorative finishing of the surface. You need to understand that these works carry not only an aesthetic function. The decorative layer is also a certain protection for the insulating layer of the plinth and the basement floor.

Tiles for decorative finishing.

Work on the installation of a decorative layer is carried out using special adhesive-based materials and metal mesh. Reinforcement ensures high strength of the thermal insulation layer of the base and basement floor, and also reduces heat loss.

As soon as the polystyrene foam boards are laid, you can begin preparing the surface of the plinth for installing the decorative layer. To increase the level of adhesion of adhesive-based materials, it is recommended to use a deep penetration primer. In addition, as already noted, it is necessary to use a reinforced network. Reinforcement is especially important in cases where decorative stone or tiles are to be laid on insulating boards.

In most cases, special materials are used to decorate the base. For example, decorative tiles, artificial or natural stone are extremely popular. In addition, with the help of deep types of plaster you can significantly save money, while creating a fairly effective protective layer on the outside of the basement of a wooden house. Insulation of the outside of the house in this case will be sufficient.

Many builders and experts recommend using modern decorative bricks for decoration.

Additional drainage

It is noted that the base is the most important protective element that ensures the integrity of the foundation and walls of the house for many years. At the same time, the base is located on the line of contact with large volumes of moisture.

This is why it is very important not to expose the plinth to excessive water. To do this, it is necessary to additionally install a drainage system on your site, which will drain water from the house and all underground buildings (for example, a basement or cellar). If there is a drainage system, there will be no need to carry out excessive insulation of the basement and basement floor from the outside (although much will, again, depend on the weather conditions of the area).

You can insulate the base from the outside with any other modern or traditional materials that are offered on the market today. The choice of one material or another will depend on climatic conditions, soil type, groundwater level and financial capabilities.

Why insulate the foundation?

- Functionality . The first and most common reason: many owners of private houses want to make their basements (ground floors) functional. For example, use them to house a gym or laundry room. But doing fitness in a cold room is not very comfortable. Thermal insulation can be done both outside and inside.

- Avoid dampness . As a result of temperature differences (outside and inside), condensation occurs and dampness appears. This is especially true for houses with concrete floors. Thus, paying attention to insulating the foundation means extending its service life.

- Saving . The absence of heat loss leads to savings on heat payments, which is also important. With well-designed thermal insulation, savings can reach 35%.

- Foresight . In combination with other work, it will make the house more durable and safer.

Conclusion: if you want to build a comfortable, modern home and enjoy living in it for many years, thermal insulation is necessary. It is worth mentioning here the need for a drainage system that will remove excess moisture during the off-season.