388

The room heating technology created by I.V. Kuznetsov back in 1962 is still relevant and is regularly improved. Maximum benefit is achieved due to the fact that cold and hot air do not escape anywhere, but change places as they heat up or cool down. Cold currents spread along the bottom, and heated ones rise.

Kuznetsov water heating furnace

Disadvantages of brick kilns

No matter how paradoxical it may sound, any brick oven has two disadvantages: combustion and high temperature of the flue gases. Naturally, without these components, the operation of furnaces would be impossible, however, it is these two indicators that reduce the efficiency of an ordinary brick unit built by our ancestors. More details:

- The products arising during the combustion process are CO and H2O. As a result of the formation of even a small amount, these substances largely interfere with the normal complete combustion of firewood or coal. At the same time, the net temperature used to heat the room and water is significantly reduced, and more fuel is required.

- It follows from the first point that the required amount of heat requires an increase in fuel, which, in turn, entails greater heating of the flue gases. They leave the oven and therefore take the calories they produce with them. You have to “feed” the unit again to maintain comfort inside.

Adjusting the flaps and the ash pan door will do little, since it only reduces the combustion intensity - the draft remains the same. In addition, such actions are unsafe and lead to the accumulation of carbon monoxide.

At a minimum, the need for cleaning gas ducts is increasing. And as a result: high fuel consumption and at the same time low efficiency. What does Kuznetsov’s bell-type brick stove offer? The design is improved with special brickwork, in the form of a container, with a gas outlet at the bottom. Wherein:

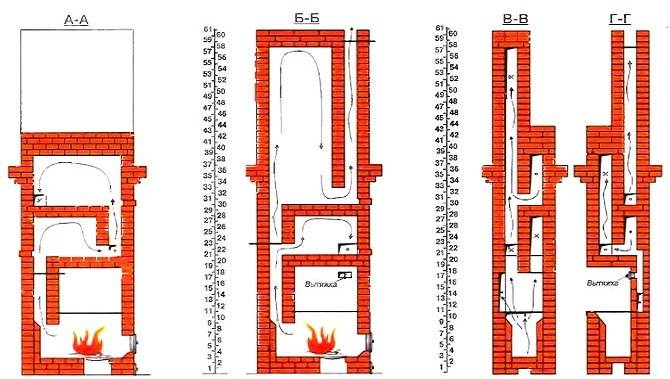

- During combustion, gases are separated into hot and less heated ones. According to the law of physics, the highest temperature rushes upward, lingering in the hood, and cold products exit through the channel at the bottom of the oven.

- Since the hood is located in close proximity to the firebox, the remaining flue gases burn out directly in it, giving up their temperature to the walls and the built-in heating element with the carrier.

Volumetric stoves using this method have several combustion hoods, which allows the unit to be used in houses of more than one floor. Hot flue gases will linger in them until they give up all the heat. The benefit is natural - saving fuel and increasing efficiency.

Features of the Kuznetsov furnace

The furnaces of engineer Kuznetsov have been known not only in their homeland, but throughout the world since the 60s of the last century.

Moreover, the relevance of developments made half a century ago has not diminished at all, but on the contrary, Kuznetsov’s furnaces are becoming more and more popular.

Bell furnaces are one of the most common and their characteristics are in no way inferior to channel furnaces.

This stove is the latest development in the conservative field: installation and design of stoves. This stove is distinguished by a fundamentally new method of using hot gas.

In a standard type design, the movement of cold and hot gas occurs due to the draft of air, which enters through the ash pan.

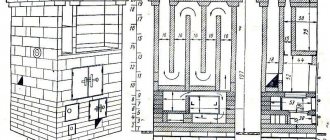

Construction of the original Kuznetsov furnace with a water boiler

The schematic diagram of the Kuznetsov stove for a wooden house is simple:

- Firebox.

- Dry masonry that covers the heat exchanger from direct interaction with the flame.

- Cap with water boiler.

- Top cap.

- Chimney.

Outside, above the lower hood, a hob is installed. It should be made whole, without burners. Otherwise, a large number of seams may become an outlet for combustion products. Above the second hood, another useful area or even a bed is arranged - in the old days, the sick and infirm were raised with the heat of the stove.

Heating boiler assembly

In order not to look for any special materials to assemble a water tank, you should consider cast iron heating radiators as an alternative. They are the most reliable, as they can easily withstand high temperatures inside the oven. The unit must be disassembled into its component parts and washed with a solution of hydrochloric acid to remove scale and residual products of former water heating.

Then the sections are connected using asbestos cord, previously soaked in drying oil, as a seal. It is wound onto the joints and carefully knocked down the structure along with the cast iron nipples. Leave the holes free, on one side - the top and bottom. The supply and return pipes will be laid there. Thus, the heat exchanger for the furnace is ready.

About O.V. Kataev and his books

About O.V. Kataev and his books.

When I have time, I go to bookstores and quickly look through books related to stove making. The bulk of it is literature that is not worthy of attention, sometimes of poor quality; there is nothing new about stoves. It is rare to find books with original developments and high-quality books by qualified authors-compilers who weed out low-grade material that wanders through different books. I buy books like this with pleasure and recommend them to other people. While looking through the books, I look at the drawings of the included stoves and new materials about them. If I liked the book, then I look at who the author or author-compiler is. I didn’t come across any decent books with the name Kataev, and I didn’t know that such books existed. There were materials about stoves on computer disks, the contents of which I did not like, and I did not look at who their author was.

Therefore, during a fleeting meeting at an NP seminar in Moscow on March 10, 2009, I did not know who Kataev was and could not understand the reasons for his strange, sharply aggressive behavior towards me and our partnership. He immediately began to scold us and our system, ask many questions and, without trying to listen to the answer, asked new questions. E.V. Kolchin, the general director of our NP, had approximately the same opinion. I did not attach any importance to this meeting, since everyone can have their own opinion. Before this, I was not aware of any cases of negative statements by Kataev on forums addressed to us. Before the start of the seminar, E.V. Kolchin announced the NP’s plans to begin preparing materials for the creation and publication of a number of albums of furnaces of our system.

After this, in March 2009, Kataev appeared on the “stroiteli.info” forum in the section Podgorodnikov’s Furnaces, and not just Kuznetsov’s. At the same time, on the forum “forumhouse.ru” Kataev (Experienced) opened the section “Real Grum-Grzhimailo stoves”. Deliberate lies and slander are contained in all his speeches. At both forums, an unprecedented, sophisticated, rude, boorish, unfounded campaign of defamation of Podgorodnikov, Kuznetsov and their furnaces began, unleashed by Kataev. Kolchin, the general director of our NP, also got it, because he dared to present numerous positive test results of our furnaces. Many objections from forum participants were not taken into account, questions were not answered, and the results of testing the furnaces were ignored.

It should be noted that at the initial stage on the forum “forumhouse.ru” they tried to reason with Kataev to conduct a correct debate, warned him, and cited facts about the fallacy of his statements. However, talking and arguing with Kataev, apparently a sick person, and as it turned out later, defending his huge business, is useless and a waste of time. For this reason, many good stove makers left the forum and people who came here and received qualified help were deprived of the opportunity to receive it.

This made me pay attention to Kataev’s work, get acquainted with him, and look for the reasons for his such behavior. Which I don’t need at all, since it’s a waste of time, distracting me from work, but I had to defend the cause to which I devoted 47 years. Show the public that Kataev’s activities are harmful to people and the state.

The result of my acquaintance with Kataev’s work unpleasantly struck me, revealed the reason for his dirty, sophisticatedly disgusting behavior towards other people’s works, unworthy by human standards, and also allowed me to appreciate his work.

The answer was on the surface.

I don’t know any Kataev stoves, and I haven’t heard anything about them. They simply do not exist, and cannot exist, since he does not understand anything about the stove business. He is the author and compiler of numerous books about stoves, fireplaces, houses, baths, the material of which he illegally borrowed from many authors, including drawings and theoretical materials, since he does not refer to sources, but passes them off as his own and which wander in his books under different names. Lies and slander accompany all his activities. He operates with phrases taken from others’ texts, the meaning of which he does not understand. He asks questions to which he himself does not know the answers, and which no one needs, and especially him. In my understanding, he is a thief, because he plagiarizes, a falsifier, a fraudster and an unworthy person who uses unfair methods to discredit people who interfere with his business. All his books contain the stolen intellectual work of many authors. In most of his books, he appears as the author, and not the author-compiler, which is already illegal.

The reason for defaming us is simple.

His business is to sell books and CDs filled with stolen materials online and in stores, and at a high price. You can check this on the Internet and where to buy the book or CDs. In our store we have his stove “Secrets of Baking Craftsmanship”, Moscow 2009, well decorated, bright in appearance, empty inside, costs 844 rubles. Judging by the quality of design, prices and scale of sales, his business is highly profitable, despite the low quality of the contents of the book, which contains non-working fireplaces and stoves that are not included in the list of stoves of the State Construction Committee. Here is his original phrase, which speaks about the scale of theft and the cost of a business based on the stolen intellectual work of others: “Since 2001, the materials of my books have been posted on the Internet, disks with technical graphics have been released, at a price of 100-150 rubles there were and are almost in every bookstore in Moscow. No one has yet repeated the animation of the piece-by-piece layout of ovens on discs for 8 years. Over the course of 8 years, tens of thousands of books have been reprinted annually, and the growth of books and discs is only growing.” Judging by this information, his business amounts to hundreds of millions of rubles.

Behind him stands a large team of well-trained people of various specialties, including apparently strong lawyers who do not know the business of stove designers, who are in the process of processing other people’s drawings into Kataev’s “pride,” “an animated three-dimensional circular image of a stove and a piece-by-piece layout of bricks.” In fact, it turned out to be a low-quality image of the rows shown in the plan, with errors and not containing stove appliances.

Only in this case can you not be afraid to sell someone else’s intellectual work, regardless of the presence of the Russian Federation Law “On Copyright and Related Rights.” It should be noted that outstanding Russian stove makers who made a great contribution to the development of stove making did not allow themselves to cite materials from other authors without reference to them. In Russia and the USSR it was not allowed to do this in the same way.

Why is he afraid of us?

Unlike Kataev, we have developed sketch drawings and built hundreds of new designs of proprietary stoves of various functional purposes and power, with and without fireplaces, with stove benches, multi-storey boilers, which have no analogues in the world. It is possible to create countless new furnace designs that cannot be done with other systems. Practical operation of furnaces for decades and tests have shown their remarkable qualities. We have posted on the website free of charge drawings of dozens of stoves for various functional purposes, multifunctional stoves and other information on stoves. Therefore, our intention to enter the book publishing market scared Kataev, as his business might suffer.

This also explains Kataev’s unfounded attacks on people and their works, who publish original books on the subject of baths and stoves. This is: I.S. Podgorodnikov and his daughter Alla Iosifovna, who from 1959 to 2000 prepared 19 editions of her father’s works; V.M. Kolevatov, author of numerous books on stoves; József Koso, author of the books “Stoves and Fireplaces”, “Fireplaces” Hungary; Yu. M. Khoshev, author of several books about baths; Sh.K. Afanasiev “Fireplaces a modern look”; N.N. Matvienko “Fireplaces, barbecues” and other people. Here is the original: We had to start exposing it after that, even “our” doctors of science began, following the Hungarians and Germans, to prove in books in Russian that the culture of stove art is higher abroad.

In what way does he discredit.

Kataev’s sophisticated, disgusting and criminal behavior is evidenced by his creation on the Internet of a website bearing the name of the state symbol of Russia “National Project”. The main page of the website https://www.nazproject.ru (Kataev incognito) contains a chaotic set of official materials, some excerpts from the National Projects of Russia and their comments from various sources. The reader is presented with the idea that this is a state website and the materials posted on the site are the official position of the state on certain issues. In the invisible underground of the site, the key to which is in Kataev’s possession, anonymously compromising materials on unwanted people and competitors are provided. Anyone who uses a link to search the Internet for confirmation of Kataev’s absurd accusations ends up there. If necessary, Kataev provides a link there, where a comment from the state is provided that coincides with its opinion on this issue. Here Kataev acts as an experienced anonymous person, a falsifier. His website is a serious tool to discredit any objectionable person and his work, or to promote his work, passing off his opinion as the opinion of the state. On behalf of the state, “execute or pardon,” which he does anonymously. All the numerous justifications invented by Kataev for the inoperability of our furnaces are not confirmed in the literature and the Internet. Confirmation of Kataev’s absurd, false statements can only be found on this site, and here they are presented as state opinion.

The same can be said about the newly created Information Agency “National Project” , https://www.v-book.ru. This is a new stillborn child, existing only in the brains and materials of Kataev, where they use the State symbols of Russia in their own mercantile, criminal interests, created to discredit unwanted people. According to the link on the Internet, the National Project Information Agency cannot be found among the registered ones, but it can provide links there.

About Kataev as a person and his activities.

All of the above suggests that Kataev is a figurehead in this company, the director of the “Horns and Hooves” enterprise from Ilf and Petrov. Such sophisticated and cunning actions are beyond the power of a person with the intellect of Kataev, who is only capable of insulting, lying and declaring, appropriately and inappropriately, quotes he has memorized on forums. Such negative, deliberately false information can be spread about people he dislikes, who are interfering with his criminal business, by a half-educated, illiterate, disgusting person, or a person suffering from Paranoia. Here are the signs of this disease: A psychopath of a paranoid type, prone to overestimating his own personality, overly self-confident, intolerant of other people's opinions, treating people condescendingly, with a pronounced sensitivity to facts that infringe on increased pride. Prone to being carried away by some idea, reaching the point of fanaticism.

I am not afraid to give information that in 1970 I graduated from the full-time department of the construction faculty of the Ural Polytechnic Institute named after S.M. Kirov (now USTU-UPI), majoring in industrial and civil engineering (industrial and civil engineering). Mr. Kataev O.V. is afraid to give such detailed information about his education, although, according to him, he graduated from the same institute. He is afraid of being caught red-handed, as he has been caught many times in his boundless lies. Here is the original of the objectivity and literacy of this “specialist”: “Your stoves are an attempt to heat “leaky” German stoves (in order for the 2-tier hoods to become Russian, they must be skinned, as Kuznetsov’s teacher - Podgorodnik did) to heat in Russian, and you have to measure their effectiveness in German, otherwise the efficiency is 5-9 times worse than that of Podgorodnik, plus the danger of explosion, which the Germans reduce by prohibiting installing valves in the chimney and making an easily removable furnace ceiling in case of an explosion.” Or another original from Kataev’s literacy: “By the way, the Grum-Grzhimailo stoves - they tried to heat the hoods “in German” - without closing the views, because The CO went off scale and could not burn out in the hood - the efficiency dropped from 80% to 45%. This is a fact, not fabrication."

Who gave the right to Kataev, who was unhinged with impunity, to arrogate to himself the right to defame people he disliked, in the name of the state. If he is a patient who cannot be held accountable, then he must be treated. I am surprised by the position of third-party observers of the leaders of respected forums, which provide the opportunity for Kataev to discredit the work of respected people and advertise his worthless products, as a result of animated alterations, that have filled store shelves.

There is no point in discussing any issues with him, debating them, since he has memorized answers to everything from a quotation book, the meaning of which is always the same: you are “shit.”

Having a highly profitable business is not forbidden, but encouraged. And Kataev and his team have such opportunities. It is possible to cite in books genuine author’s materials of high quality and useful to people, indicating the source, which is not visible in his works, and not “improved” animated drawings of other people’s furnaces, remade with errors, which have nothing to do with the list of furnaces of the State Construction Committee. Why was there any need to do this work if there are drawings of beautifully designed furnaces of the State Construction Committee, which contain drawings of metal furnace devices and specifications. They could be used after obtaining permission. This was done by A.E. Schoolboy in the book “Stove heating of low-rise buildings.” Yu.P.Sosnin and E.N. Bukharkin in the book “Household stoves, fireplaces, baths, water heaters”, Moscow, 2001, New Wave. This book contains drawings of stoves from Gosstroy and other authors, but they are well designed. They did not take credit for themselves. They present, without distortion, drawings of standard stoves recommended by the State Construction Committee of Russia of the current series 1.193-1 and 1.193-2 and an album of heating household stoves, in two parts, GSI Publishing House, Moscow 1961, published under the direction of I.I. Kovalevsky and editors Yu.P. Pine, on the basis of which the above series were produced. Therefore, their books are in high demand.

You can publish original stoves of original Russian stove makers with their permission. As it was done in the book “House Heating”, project manager S.M. Kochergin. Phoenix Publishing House, Rostov-on-Don, 2006. Well-designed book. All materials are accompanied by links from where they are given. Many good original works with reference to the author.

Why is the quality of the materials selected by Kataev, as the author-compiler, so low, and the use of ovens that are sometimes inoperable and outdated. Why doesn’t he understand the materials of the authors whose works he quotes and about whom he writes?

The answer is simple, Kataev needs a “shaft” to earn money, and not to bring knowledge to people, so he takes someone else’s everywhere as his own, what is bad and can be appropriated with impunity. Without understanding the operation of stoves and fireplaces, he does not weed out the bad material. Therefore, his books contain drawings of non-working stoves and fireplaces. The same recycled drawings, including low-quality stoves, are passed from book to book with different names. It should also be noted that his books contain furnaces with various convective systems, including the hated “explosive” bell-type furnaces (according to Kataev’s definition, “bell-shaped”, from the word to fool). At the same time, “his caps”, apparently, unlike Kuznetsov’s ones, do not explode.

Kataev’s pride, “an animated three-dimensional circular image of a stove and a piece-by-piece arrangement of bricks, which no one has yet repeated in 8 years,” when tested, turned out to be a three-dimensional image of the rows shown in the plan. Three-dimensional images do not contain furnace equipment and in some cases do not correspond to the drawings. The masonry was made without bandaging from 2 to 5 rows, which is a gross violation of the rules for laying stoves installed in the albums of Gosstroy heating stoves, which entails cracking and destruction of the stove.

I do not have the opportunity to analyze all the material and drawings of the furnaces processed by Kataev, and I don’t need it. A quick glance is enough to appreciate the general low level of his work. This is what I found in Kataev’s materials available to me.

The main characteristic errors found in the furnace drawings given by Kataev:

Heating and cooking stoves.

Stove 3.5x4 https://www.nazproject.ru/PECH8/TABLV77.HTM There are no drawings of this stove in the Gosstroy albums recommended for construction. This is a stove with vertical channels, an outright hack borrowed somewhere by the author, does not have a direct (summer) valve, made in 3 D with errors. The drawings of the rows in plan do not correspond to the rows in 3D, and they do not show stove appliances and metal structures (furnace fittings). There are few sections explaining the operation of the furnaces. Meanwhile, in the current albums of Gosstroy there is a stove Sh-2, 102x89 cm, devoid of these drawbacks and with correctly drawn up drawings.

Heating and cooking stove (1020x640), these are drawings of a stove designed by Potapov, distorted during processing, in a mirror version. The 3-D animation shows the oven in a mirror design, and the section in a normal design. It is impossible to build a furnace using his revised drawings. You can check this if you compare his drawings with the beautifully designed drawings of the Sh-5 furnace, located in the Gosstroy album.

The Russian stove with heating and cooking furnace (1140x1140), a stove of an outdated design with uneven heating of the walls, has reduced crack resistance. Poorly executed drawings as a result of their processing into an “animated three-dimensional circular image of the furnace.” It is not on the list of furnaces of the State Construction Committee.

At the same time, Kataev does not provide information about Podgorodnikov’s heated vehicles, which have proven themselves in operation for more than 70 years. Teplushki T-4 is given in books by many recognized authors, I.I. Kovalevsky, A.M. Shepelev, Gosstroy albums. T-15 utes at P.I. Voropaya, A.E. Shkolnik and other authors. Kataev, despite the facts, manages to slander these stoves, like all bell-type stoves.

Designs of heater stoves.

This section contains drawings of outdated designs of low quality stoves, not for people, but for profit.

In the section on Heating Furnaces , drawings by various authors are given, including outdated designs (for example, a terrible, almost direct-flow furnace 630x505), while presenting them as their own furnaces. The website lists a heating stove 890x510 with “animated three-dimensional all-round inspection and piece-by-piece placement of bricks” just like his stove. In fact, this is a V.I. oven. Strezhnev, published in the magazine “Water Supply and Heating Equipment” No. 6 for 1957. Included in the album of household stoves part 1, GSI Moscow 1961 under the name OPT-2 with reference to the authorship. Available in the current series 1-193-1 with reference to the authorship under the name OPT-3. At A.E. Shkolnik in the book “Stove heating of low-rise buildings”, VSh, Moscow 1991 has the name PTOU-2500, without reference to the authorship, where the number 2500 indicates the average hourly heat transfer W with two fireboxes per day. In all editions, the stove has high-quality drawings. Kataev made mistakes when processing this stove that prevented him from folding the stove correctly.

Heating stove (1150x510). The drawings are not for people, but for sale, carelessly and with errors redrawn drawings of OPT-3, already like his oven. It was easier to copy a sheet of a standard album. Without dressing 2-3 rows.

Heating stove (1010x510) . The “people” call it a three-channel stove with poorly organized wood burning. There are no stoves recommended for construction on the Gosstroy list. Without dressing 2-3 rows.

Heating stove (1660x640) . Copied, as if it were our own, the Gosstroy oven OPT-11, with errors without bandaging rows 3-5.

Heating T-shaped stove (1280x1020). Bell-type 2-tier stove, borrowed from the “Encyclopedia” by Yu.P. Sosnina and E.N. Buharkina. In the back there is a cap with two exits (lifting channels) from it. The second tier is forced movement with two channels. It was reworked with errors, without bandaging the seams of rows 2-3, it became a Kataev stove and, unlike other bell-type stoves, it immediately became “explosion-proof”.

Heating triangular stove (1090x1080) . Reversible obsolete furnace with vertical channels. A furnace with reduced crack resistance due to uneven heating of the front wall. There is no dressing in rows 2-5. Meanwhile, in the Gosstroy album there are drawings of a high-quality corner furnace OUT-1

The drawings of the two slabs were borrowed from the album (series 1.193-2), where they are named KP-4 (by A.E. Shkolnik – OK-1200) and KP-3, respectively. Unlike the original, the drawings were made outrageously poorly, with errors (KP-4). There are no sections, drawings of furnace appliances, or specifications. The declared animated three-dimensional circular image of the furnace is actually a three-dimensional image of the rows shown in the plan. Volumetric images do not contain stove appliances. It was easier to copy beautifully designed drawings from albums.

ABOUT KATAEV'S WORK.

Kataev is not a consistent and contradictory person; the variability of opinions amazes him. Today he can accuse, dirty insult and criticize, citing many fictitious arguments, and tomorrow, when he is caught in a lie, he can, without blinking an eye, retract his words. He writes and declares one thing, but does another, here is the original: “I have always emphasized that the best stoves are made by Gosstroy. that the most reliable are those built in the thousands,” and in his books he himself includes low-quality stoves, everything that “lays poorly,” and which is not included in the list of stoves of the State Construction Committee. Or he writes that “bell-type furnaces explode,” but he himself includes some of them in his books, since he cannot distinguish bell-type furnaces from non-bell-type furnaces. Or he writes: “No one can make real bell-type stoves anymore? Grum-Grzhimailo stoves are a masterpiece of heating engineering! And he himself does not include them in his books. This shows a complete misunderstanding of the materials of the authors whose works he writes about and uses. Publishes and promotes canceled GOSTs and does not publish current ones. Here is what one of the users writes about this: As the director of operation of a cottage village, I use only the current SNiP 41-01-2003, GOST 9817 and NPB252 for heating systems, but they are not even mentioned in your book.

All his work can be divided into the following parts:

- Textual presentation of materials on the topic, collected from various sources. Including from official materials, in general, correctly borrowed materials from others, without reference to authorship;

- Blueprints. The low quality of the stoves selected by Kataev, as the author-compiler, and the revised drawings, sometimes inoperable and outdated. Most of the materials given in his books are plagiarized;

- Sections in which he adds comments to the text, his vision and understanding of the issue under consideration. These sections are full of lies and misunderstanding by Kataev of the material he writes about.

For example: “Y. Koso writes: For the normal functioning of the smoke duct and the fireplace (stove), in general, it is necessary to provide for the organization of an additional air flow into the room, compensating for the air consumption during fuel combustion in the firebox of a closed fireplace at the rate of 4 cubic meters. meters/kW/hour.”

This is a clear and precise recommendation. He writes about the need for supply ventilation and provides the quantitative data necessary for calculating supply ventilation.

And here is how Kataev understands and interprets this point:

“This clause excludes the possibility of making claims to the company if you do not have a meter for the amount of incoming air, while from the total amount of incoming air it is necessary to separate an additional air supply. Moreover, the use of artificial ventilation (in which it is at least theoretically possible to measure the amount of incoming air) can cause reverse draft in chimneys, which will lead to smoke in the premises. When the fan operates, a vacuum is created in the room, and a reverse draft is formed in the smoke ducts. Russian building standards provided for 3-fold air exchange in residential premises through vents, leaks in windows and walls. But there are no recommendations, much less requirements for installing meters, in either Russian or foreign building codes.”

This is complete nonsense and verbiage of Kataev’s “Heat Engineering”, where one can see a complete misunderstanding of what J. Koso writes about.

And here is what Mirkis S. M., the author of the Index of designs of stoves and fireplaces published in Russia over the last 100 years, writes about bell-type stoves to Kataev:

Apart from the well-known fact that they are not recommended for conversion or construction for gas, I have not seen anywhere in the literature in the range: Semenov - Kovalevsky - Shkolnik that they are as dangerous as Oleg Viktorovich represents.

The convective system called “channelless bell-type” is generally accepted in Russian furnace construction and is used along with other schemes. Oleg Viktorovich is a supporter of Gosstroy stoves (furnaces recommended by the USSR Gosstroy for mass construction). I also think they are good, and Igor Viktorovich also spoke about this several times. In general, I would advise many novice stove makers to do them, so as not to get themselves into trouble. I wonder to myself. How can you oppose bell-type systems if almost all Gosstroy stoves have a combined smoke circulation scheme: bottom - duct, top tier - bell? For those in doubt, see fig. 53c, p.38 from Shkolnik A.E. “Stove heating...”, M, 1991. I quote: “...the furnace hood can be designed in the form of...or one chamber with partitions (cuts) that increase the heat-storing capacity of convective surfaces...”. This is exactly how the firebox part (upper tier) is made, for example, in the Gosstroy furnace PTO-3100, the design of which is posted in the book by O.V. Kataev. “The Big Book about Furnaces”, M., 2009 on page 110. There is also a “gas view”, a necessary attribute of any hood. We look at the description of this stove by Shkolnik A.E. on page 54. I quote: “The stove uses the principle of a “gas view”, which allows you to save heat in cases where the smoke valves are not tightly closed. The essence of this design feature is that the cold air entering the furnace does not rise into the system of parallel flues filled with hot gases, but passes along the bottom of the above-furnace volume, without cooling it, directly into the chimney.”

Therefore, I do not see the logic in Oleg Viktorovich, who is against hoods, but at the same time promotes Gosstroy stoves, which for the most part include a hood. To finally make sure that our predecessor colleagues, who did a colossal job of testing and selecting furnaces for their further recommendation for mass construction (list of furnaces of the USSR State Construction Committee), were not afraid of hoods - let's look at the Gosstroy furnace PTO-2300 (from Shkolnik A.E. Fig. 61 on page 48, you can find it in any other book). There is probably no need to explain to anyone that this is a bell-type stove in its purest form.

Therefore, I see no reason to scare people with bell-type stoves.

For me personally, the cap is a progressive phenomenon in our stove construction. The “Two-tier hood”, however, has 1) lower internal resistance and 2) an easier opportunity to create a wide variety of multifunctional furnaces, as can be seen in the example of furnaces designed by I.V. Kuznetsov.

Since I had to turn to Oleg Viktorovich Kataev’s book “The Big Book of Furnaces”, M., 2009 (I brought two of them from Moscow - 2007 and 2009), I will at the same time express my comments on it. Without even digging deep, but opening the book by chance on page 57, I immediately discovered unacceptable negligence. We are talking about the project “Kitchen stove with oven and hot water box (1150x640)”. By the way, it has the State Construction Committee OK-1200 marking. I look at p.57, rows 8,9,10 and 11 (lower left corner) - a through vertical seam for as many as 4 rows (no dressing), although in rare cases a through vertical seam is allowed in only two rows. I looked at the specification and it was full of typos: the number of parts of the composite cast iron deck and the size of the grate were incorrectly indicated. This worries me, as if other argumentation were not of such quality.

Regarding authorship. I am a supporter of indicating the authorship of projects, and probably the Copyright Law and scientific and engineering ethics do not teach otherwise. Is it really impossible to sign projects properly? On State Construction projects, indicate their markings, as well as indicate the authors of the projects given in the mentioned book (it contains the projects of A.I. Ryazankin, Ya.G. Porfiryev and Yu. Proskurin). And no matter how the bricks are rearranged in these projects (preferably without mistakes), these are still their projects. When I was studying, we were not allowed to defend our diploma for lack of references to borrowed texts and works.

Oleg Viktorovich, it’s so difficult to have a conversation. You saw that I cited sources and even indicated figure and page numbers. And it turns out that you seem to know something from closed sources that are in special storage and for which you signed a non-disclosure agreement. I would be grateful if you provide links to sources for all your statements. I would check everything as soon as possible. More than 70 years have passed since then and it would be possible, without particularly violating (since 70 years after the death of the author) the Copyright Law, to post these texts and documents on the Internet for public viewing and discussion. This is how a deaf man talks to a blind man.

As for “I didn’t want to bother,” I talked to V.M. Kolevatov. and he refused such an offer, because... he has no problems publishing his books and projects. And that's his right. And the right of Ryazankin A.I. give or not give permission to publish your projects. And if you do not have such permission, then you should not include their projects in your books and look for ways to circumvent the law.

Older people also remember that in the USSR everything was planned and regulated. How many acres of land were allocated for a garden plot, what area and height should the garden house be, etc. and so on. Strict standards were also established in housing construction. Naturally, to heat such buildings, corresponding stoves were needed. In addition, city-forming village enterprises, collective farms, state farms, and agricultural enterprises switched to centralized heat supply and gasification of villages. Therefore, furnace developers had no need or incentive to develop new furnace designs or create multifunctional, complex furnaces. There was no need for such ovens.

A lot has changed now. People are trying to leave the city. They build modern houses according to their needs and capabilities, in which they want to live comfortably. Houses of all kinds of space-planning and design solutions in accordance with the wishes of the customer, architect, material of enclosing structures, availability of various energy sources, etc. Servicing buildings and structures for other purposes are constructed on the site. There is a need to create many new designs of heat generators of various number of floors, power and functional purposes. All this encourages designers to design stoves with an individual solution for specific human needs. For example, when designing a stove for a bathhouse, a designer needs to take into account the space-planning and structural design of the building, while the safety rules must be followed, this is TABOO; It is necessary that the stove provides in every room, steam room, sink, rest room, etc. appropriate temperature and humidity conditions. At the same time, take into account the customer’s wishes about the thermal conditions in the steam room, the number of people using the bathhouse, the mode of use of the bathhouse, the need for hot water and the amount of hot water, the presence of a fireplace in the stove, a stove bench, technological and supply ventilation for the successful operation of the fireplace, etc. Similar tasks face the designer of furnaces for other buildings and structures.

The existing arsenal of Gosstroy furnaces cannot provide a solution to the problems posed by the trends of the present time. Humanity is moving forward in its development. What previously seemed like fantasy is now reality. Therefore, original stove makers have appeared in Russia, building original stoves and trying to solve the issues posed to them by customers. You can find many wonderful works of such masters on the Internet. Not all of them make their developments available to the public. It's their right.

The SDH system, patented by me, allows us to solve the above problems. At the same time, furnaces built taking into account the latest developments meet international standards in terms of efficiency and cleanliness of combustion. It's hard to argue with this. There is a theory, there is a practical result, there is a “school” in which professional stove makers are trained in various cities of Russia and other countries. There are many new furnace designs with new properties that cannot be implemented in another system. There is a consumer and high demand for our stoves. There are people who independently build our stoves according to the drawings on the website. There are numerous positive reviews about the operation of the stoves. There are positive results from testing our ovens in the USA, Canada, France, Sweden, and comparing them with ovens of other convective systems, including the world's leading oven manufacturers. Our Non-Profit Partnership also tested a furnace built in Moscow, and received encouraging results. There is interest in the “new Russian fuel combustion technology” in developed Western countries, where stoves of our system are being built. Seminars, including practical ones, were held on the construction of furnaces and boilers of our system in various cities of Russia and other countries. These are France, Germany, Sweden, Norway, Czech Republic, Hungary. Three workshops were held in the USA.

Furnace laying

The process starts from the foundation. It is installed on the platform of the house, and not on the floor boards - firstly, it is unsafe, and secondly, the weight of even a small stove can break the logs. Features of the foundation for a Kuznetsov furnace with water heating are:

- It should not be connected to the common foundation of the house. This is especially important if the object has not yet given final shrinkage. That is, it needs to be installed on the ground, in compliance with all the requirements for any platform - depreciation, reinforcement, formwork, pouring.

- If you decide to attach the stove to the wall, then the gap between the foundation of the unit and it should be the same. It is subsequently covered with sand.

- The depth of the pit should be commensurate with the level of freezing. The width of the future foundation should be 10-15 cm larger on each side.

- After the concrete base has hardened, it is waterproofed with bitumen or roofing felt - the accumulation of moisture in the concrete is quite possible, which will subsequently lead to the destruction of the entire furnace.

It is impossible to use concrete mixture for subsequent laying of the furnace - high temperatures will cause cracking of the joints. It will be impossible to eliminate the defects.

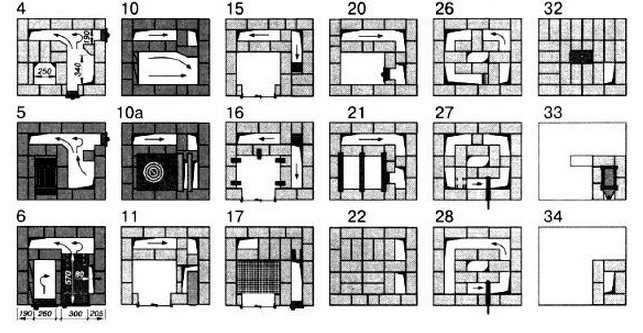

Next is the masonry. For novice stove makers, it is important to have an order - instructions indicating the number of rows and elements corresponding to this. The masonry features are as follows:

- The first row of bricks is laid dry, without using mortar. The bottom of the oven should be thick, so do not limit yourself to one row - 2-3 will be enough.

- Then it’s the ash pan’s turn. A door is immediately attached to it. You should purchase all cast iron components in advance. It is better to make several cleaning moves.

- The next row is the combustion chamber. It is impractical to make it large; it will require a large filling of fuel, which will affect the overheating of the stove and its premature failure.

- On the 10th row, laying is done under the hob, and after two more rows of bricks, the first cap is laid out. To ensure that the stability of all elements does not cause alarm, steel corners are used for “suspended” structures. Their thickness is small and will not affect the distortion in any way.

- A manufactured cast-iron boiler is placed under the first cap, covering it with a brick partition. It does not have to be airtight - two rows of bricks will create the necessary gap. Immediately make holes for connecting the heating wiring.

- After the 18th row from the foundation, a second cap is installed, making sure that they are connected by a common smoke channel. Be sure to use a level and a mooring cord in your work - this way the structure will be level inside and out.

When the stove body is ready, the chimney is removed. To do this, prepare a place in the roof by removing the covering in advance and strengthening the rafter system. The length of the common channel should be 0.5 m higher than the roof ridge, so good traction will be ensured.

We can say that the Kuznetsov stove with water heating is ready. However, the combustion process is still far away; you need to connect the radiators in series and bring them to the heating tank. The system is checked for leaks. It should be taken into account that during combustion the pressure will increase, which means that even small fistulas should be eliminated in advance.

Volkov oven: order

1st row - on the left, leave a recess of 140x370 mm for the ash pan. To make it easier to remove ash, part of the brick should be pushed towards the stove ash pit.

2nd row - placed with the installation of the blower door, resting on the first row. The longitudinal upper edges of the two bricks, directed towards the blower hole, are cut off - then the coals and ash easily roll down the slope.

The laying of our 3rd row brick oven begins with the installation of a 130x140 mm cleanout door.

In the 4th, lay out a cleaning channel along the back wall, in which another door is placed on the right side. When laying, cover the door of the blower, leaving a 25x25 cm hole above it, which is covered with a grate in the 5th row so that there is a gap of 5 mm on all sides between it and the masonry. On the right side of the oven, near the cleaning area, at a distance of 190 mm from the back wall, place half a brick, where the corner of the oven will be across the row. This brick is crushed along the path of the smoke.

5 - laid out from refractory bricks. Clamp two bricks near the grate so that it looks like a container for collecting coals. We place half a brick on the brick triangle in the chimney, which will serve as a support for the rear right corner of the oven.

In the 6th row, first place the fire door on the previous row, not forgetting to lay out the fastening wire screwed to the frame along it. Then install the oven so that there is a gap of about 80 mm wide between it and the brickwork. Installing the oven this way will create a downward chimney along the right wall. Having placed a whole brick on the end, use it to block off the back side of this channel for the entire height of the oven. To prevent the wall of the oven near the firebox from burning out quickly, surround it with spoon-shaped bricks.

In the 7th row behind the oven, cover the horizontal channel with two full bricks and two ¾ bricks so that behind the firebox there is one ascending channel and another falling from the oven to the right. The resulting gap will allow the movement of hot gases from the 5th side of the oven.

8 - do the same as 7th. Cover the channel behind the oven completely with two ¾-m.

In the 9th row, cut the top of the bricks located along the oven towards it. This rounding will help better movement of hot gases. Cover the top of the oven with a metal strip, which will later help you remove it if it burns. Then everything is in order.

In the 10th row, on the right corner behind the oven, place a brick, cut in the direction of the smoke. Then we place the cast iron plate on the mortar. Two metal strips to the right of it will support the water-heating box and the construction of the right wall of the cooking chamber.

11 start from the right corner, where you install the water-heating box, and then the frame with flaps that cover the cooking chamber. In the middle of the partition, lined with bricks, and the hot water box there should be a 50-70 mm channel for gas flow. The channels behind the volkov cooking furnace are the same as in the 10th.

On the left side in rows 12 and 13, block the horizontal channel to the floor. its length.

In the 14th, lengthen the horizontal channel again, and behind the water-heating box place a hewn brick facing the ascending channel with a cone.

In the 15th, cover the water-heating box with two full bricks and, with hewn bricks, complete the laying of the inclined lower part of the gas summer passage.

From the 16th to the 18th, with three bricks, hewn in the tray part, begin to lay out the inclined upper part of the summer flue.

In the 17th row, after finishing the masonry, install a 350x500 mm grid for drying. Place a brick with a hewn part opposite the cleaning door.

We begin to lay the 18th, like the previous one, from the door, opposite which there will be another hewn brick.

Place the 19th in such a way that the horizontal channel behind the stove is 75–77 cm. Close the channel above the cleaning with a summer valve, used when the entire Volkov heating stove does not heat up. Place two steel strips above the frame on the front side.

In the 20th place in the cooking chamber, install a 130x130 mm door, necessary for ventilating the firebox area during cooking, and cover the cooking chamber with 4 full bricks of the front row.

The 21st is the same as 20, only lay three steel strips 50x5x0.5cm above the top of the cooking chamber. They are necessary to hold the bricks that cover the chamber in the next row.

22 - in order.

23 nearby finish the first floor of the Volkov furnace. Place a cleaning door in the hole of the samovar going into the central heat channel.

24 - lay it out so that a closed air chamber is formed inside the masonry, which warms up perfectly, which is very important in the cold. In the same row, place two cleaning doors - on the front and left sides. During the laying process, a horizontal channel will be created.

25 - place as the previous one, only taking into account the dressing of the seams and the overlap of the samovar.

26 - installation of whole bricks in two zones of the horizontal channel - on the left and rear sides, which divide it into 4 parts.

In the 27th row, on the front side, with support on the 26th row, place the winter shutter vertically. To the left of it we divide the front smoke channel into two parts with a brick.

28 - in order.

29 - in order.

30 - cover the top of the stove, leaving an air channel in the center of the masonry, and a smoke outlet on the right.

31 - Cover the top of the Volkov heating stove with the second layer of masonry. Install a valve on it to close the stove after firing.

32 – last row, place a plug in the center above the air channel. The pipe starts from this row above.

Place the 33rd and subsequent ones in 5 bricks, making a chimney 260x130 mm. An additional protection against heat loss will be a valve in the pipe.

As you can see, Volkov stoves for the home are quite practical and very convenient! Moreover, building them is not so difficult. As they say “patience and work”….

Share on social media networks

0

Tweet

Drying, lining and kindling

Premature kindling can lead to defects in the stove that will be impossible to correct - the seams will come apart and the hoods will become deformed. All this will affect the combustion process - flue gases will definitely enter the room.

To prevent this from happening, the oven is dried naturally over several months or forcibly by burning wood chips in small portions. The second method lasts at least three weeks.

When the stove is prepared for lighting, but the appearance leaves much to be desired, it is brought into the desired state. In general, by entrusting the laying of the unit to a specialist, the owner immediately receives a beautiful model using rounded bricks.

This type does not require decoration. If you had to do everything yourself, then clinker tiles or tiles are presented to the consumer in numerous types.

The kindling is proceeding slowly. Small portions of fuel are increased gradually. When the Kuznetsov stove with a water heating boiler is heated to the desired state - this will be felt by the atmosphere gaining temperature, you can begin to adjust the draft. This is done with the ash pan door or valves in the chimney.

Brick kilns are still popular among owners of private houses. In addition to their traditional appearance, they are the most economical of all existing sources of thermal energy. Modernized units of the Kuznetsov type make them even more optimal. In addition, there are no problems with expensive installation - the process is available for do-it-yourselfers.

[youtube=https://www.youtube.com/watch?v=F0Xdso8MzWs]

Pavel Smirnov

Author of publications on 1Drevo.ru with topics: Roof windows | Material for a wooden house | Imitation timber | Double-circuit gas boiler| Geothermal heating | Log house | Log house | Decorating a wooden house | Solid or laminated timber | Log house made of laminated veneer lumber | Gazebo made of timber | Siding | Sealant and others.

Collections of publications on topics:

House on a stove Water heating stoves Furnace with boiler

Was this publication useful to you?

Bookmark it on social networks!

Total score: 10Votes: 2

Solar collectors for water heating and heating - how to use

Choosing a stove for heating a house with water heating

We recommend! — Encyclopedia Wooden Houses — NEW

You can find out detailed and expanded information on the topic of the article from the book “Wooden Houses,” which reflects all stages of building a house, from laying the foundation to installing the roof. Book price = 77 rubles.

You may also be interested in other BOOKS on building houses from wood with your own hands.

We recommend other posts on this topic:

How to choose the right electric heating boiler

Gas boiler for heating a room: floor-mounted or wall-mounted

Boiler heating of a country house - which boiler to choose

Differences between heating a one- and two-story private house

Individual heating system in a log house

Installation of a boiler and installation of electric heating in a private house

General information

Cast iron and steel models

If you do not plan to install the stove yourself, then instead of brick models, you can consider purchasing a structure made of sheet steel or cast iron. Such furnaces are characterized by rapid heating and more efficient heat transfer. However, they also cool quite quickly, so they need to be heated much more often than brick ones.

Cast iron construction

And yet, compact sizes, as well as a very affordable price, make steel and cast iron structures quite popular. The most popular brands of cast iron cooking and heating stoves include:

- Heating and cooking stove Alma Mons. It is a fireplace-type device that provides effective heating even in large rooms. One of the key features of this model is the lining of the metal firebox with refractory bricks.

Alma Mons – fireplace type model

- Line of stoves Bavaria. It is made from thick sheet hoists or cast iron and has a vertical layout. The durability of the structure is ensured by the fireclay lining of the firebox.

- Breneran is Canadian. A compact option that combines all the advantages of the “Canadian” models with the ability to cook food on the top stove.

- The Taiga model is another small device that provides effective heating of small areas. This model has a small hob located on the top of the horizontal firebox, and is, by and large, an addition to the main functionality.

Using "Taiga" for heating water

Brick kilns

In most cases, heating cooking stoves are made of brick. High-quality red brick is used for the main elements of the stove, while the structural parts in direct contact with an open flame are made of refractory brick.