The main reason for drafts and unpleasant odors in the area of the front door is a worn or poor-quality seal. Even if the door is insulated, heat loss inevitably increases over time. One fine day you will notice that extraneous noises have begun to penetrate into the apartment, and closing the metal door makes a lot of noise. The reason is the same.

The problem can be resolved by installing an additional seal. But you need a special one - for metal doors. Installation is quite easy to do yourself - instructions are included with certified products. With its help, you can solve another problem - insulating an iron door. But first of all, you need to decide what material is needed in this or that case.

Purpose of the seal

The very name of this element of door fittings contains the meaning of its use. The main functions of the seal include:

- Protection from outside air (humid, hot or cold), foreign odors, dirt and dust.

- Sound insulation – reducing the level of extraneous noise and audibility of what is happening in the apartment.

- Thermal insulation – minimizing heat loss.

- Sealing the door frame by ensuring the tightness of the mating of its components.

In accordance with the above objectives, the seal must meet the following requirements:

- Ensuring complete tightness of the room, preventing the entry of extraneous noise, odors, moisture, etc.

- Ensuring reliable, smooth and silent closing of the front door.

- Eliminates the occurrence of gaps under conditions of sudden temperature changes.

- Providing additional fire safety – preventing the spread of smoke and fire.

Window insulation tape - how to avoid drafts and increase energy savings

Surely, you remember that window insulation tape was used several decades ago. Now that new types of windows made of metal-plastic have appeared, it would seem that the need for such material has disappeared. However, it is not.

Photo of tape for window insulation

The tape is still in demand because it:

- avoids heat loss;

- helps avoid drafts.

By the way, in past years, materials for window insulation were still not as accessible as they are now.

Not everyone was able to purchase the tape, and therefore had to use more accessible means:

- cotton wool;

- rolled newspapers;

- gauze, etc.

Types of seals for metal doors

The seal for iron doors, depending on the material of manufacture, is classified as follows:

- Rubber. It is characterized by low cost, long service life and resistance to adverse influences. Especially products made of acid-resistant rubber.

- Silicone. It is highly environmentally friendly.

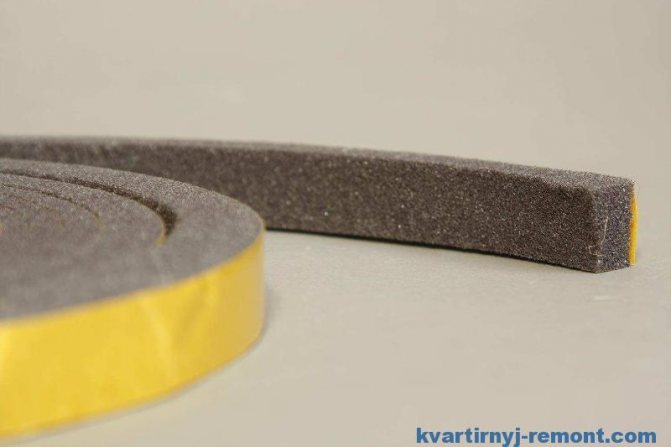

There are also polyurethane, plastic and foam rubber, which do not have high abrasion resistance, so they are used to seal interior doors. Despite the ease of installation (they have a self-adhesive film) and low cost, they are not practical to use on metal doors.

The main type of seal used for metal structures is rubber.

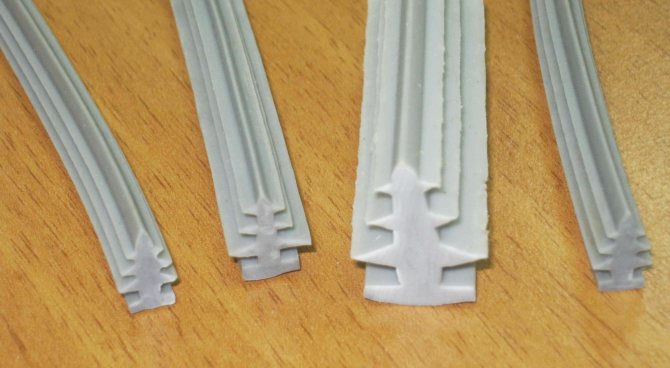

According to the method of fastening, the seal for iron doors is divided into the following types:

- Magnetic.

- With additional clamping mechanism.

- Self-adhesive.

Magnetic seals for metal doors have recently appeared on the market and are used mainly by manufacturers of door structures. This is an analogue of the seals used in refrigerators. It has a magnetic insert in a thermoplastic elastomer tube that is resistant to aging and temperature fluctuations (from -65 to +90 degrees).

Mounted on the door itself and the frame to ensure normal attraction. The difficulty of use is that the optimal force of attraction is difficult to select. If it is too large, the door will be difficult for a child to use, and if it is small, the required seal will not be provided.

With an additional clamping mechanism, it is distinguished by the need to attach a strip that holds the insulation in a given position and place. In addition, the bar allows you to maintain its shape for a long time.

The most common options

All seals are produced in the form of tapes with different profiles and widths. The following materials are used to make these products:

- rubber;

- ethylene propylene rubber;

- polyvinide chloride (PVC);

- foam;

- silicone

All elastic seals for wooden entrance doors are called contour seals, which indicates the peculiarities of their installation: along the contour of the door leaf or frame. The most common options are foam-based and PVC tapes. The first ones have a self-adhesive base, are fragile and short-lived. Their main advantage is their low price.

Self-adhesive foam tapes are suitable for filling small gaps formed between the wooden door leaf and the frame. In order to prevent cold air from entering the living room, it is important to choose the correct thickness of the tape.

Rubber bands have a D-shape and are designed to fill wider gaps: 8-12 mm. Manufacturers of these sealing tapes offer these materials in two colors: black and white. Any type is suitable for insulating the entrance area of a living space, garage and workshop.

Tapes made of ethylene propylene rubber are the most durable of all of these, as they are reinforced with fiberglass threads. The profile of these self-adhesive materials can be different: D-, E-, P-, V-shaped, as well as rectangular. Any of these types of tapes are designed to eliminate gaps 1-7 mm wide. Among the advantages are high frost resistance and a wide operating temperature range: from -50°C to +50°C.

Fireproof

Fire-resistant thermal insulation materials are used in the construction and glazing of wooden entrance doors and expansion joints. These tapes have a self-adhesive base and are capable of expanding under the influence of high temperatures in a plane direction (only in height) or in three directions at once: in both directions and in height. The purpose of such materials is to localize the fire in the room in which it occurred.

The most popular are two types of fireproof seals: Palusol and ROKU-strip. The processes of foaming and expansion of these tapes begin at temperatures from 100°C. There are three ways to seal a wooden door:

- along the perimeter of the door frame in places of contact with the door leaf;

- in the grooves of the front door or frame;

- along the contour of a wooden or metal entrance door.

Threshold

door seal can reliably close the gaps through which cold air enters. A distinctive feature of these products is that they are made from more durable materials:

- rubber;

- thermoplastic elastomer;

- ethylpropylene rubber.

All these materials do not lose their properties for a long time. Threshold seals are installed in a gap specially made for this purpose in the end part of the wooden door leaf. First, a plastic or metal profile is inserted inside this gap, then a strip of thermoplastic elastomer or rubber.

There is a button on the side of the profile, when it comes into contact with the door frame, the heat-insulating material falls out of the gap cavity and reliably covers the space between the floor and the bottom of the door leaf. There should be no gaps between the floor and the rubber gasket. When opened, the seal rises and fits into the groove intended for it.

Rules for choosing a seal for a metal door

First, the shape, type and quantity of sealant required is determined. It is sold in the form of rolls (the average length of the tape is 6 m), so one is enough for a standard door.

The shape and thickness of the tape is determined by the gaps in the metal door. To measure them correctly, plasticine is used. It is wrapped in polyethylene and inserted into the gap between the canvas and the frame with the door closed. Then the plasticine is removed, and its compressed part is measured with a ruler.

If the gap is between 1 and 3 mm, a foam rubber, polyethylene foam or polyvinyl chloride seal with a rectangular shape is used. Rubber sealant is used for gaps of 3 mm or more. At the same time, its shape varies depending on the thickness of the gap:

- C-shaped, K-shaped or E-shaped profiles are used with minimal gaps (3 mm).

- P-shaped or V-shaped is used for gaps up to 5 mm.

- O-shaped and D-shaped - with the largest gaps (from 5 to 7 mm).

When purchasing a seal, follow the following rules:

- When choosing a self-adhesive tape, be sure to check the shelf life of the glue. The adhesive part should be covered with small particles of fiberglass.

- All information about the material, technical features and shelf life is studied.

- Hermetic properties are checked. Lightly press on it. If it quickly returns to shape, then the material is of good quality. The material should be of medium hardness. This one lasts a long time and does not interfere with closing.

The color is selected to match the color of the door, but it is worth remembering that the best color is black.

How to seal a wooden door

The material sealing the wooden entrance door must be resilient and elastic. If it does not have a self-adhesive backing, installation will require silicone sealant, a glue gun or liquid nails. In addition to them, you will need the following materials and tools:

- scissors or stationery knife;

- White Spirit;

- clean dry rags.

Operating procedure

- Cutting ribbons.

- Degreasing the base.

- Sticker tapes.

Installation and sealing

To install the seal correctly, it is necessary to accurately measure the length of the tapes that will cover the ends of the wooden door leaf. This can be done in two ways:

- attaching the tape to the end and cutting it in the right place;

- using a tape measure, having previously measured the length of the end and measured a similar distance on the tape.

If the gaps are wide, more than 5 mm, the sealing materials do not need to be cut into pieces, but immediately glued to the base. It must be free of dust, dirt, fats and oils. For this purpose, use white spirit and clean, dry rags. Self-adhesive seals are attached by pressing them against a wooden sheet and gradually removing the protective layer as you go. Before installing materials without an adhesive base, a fixing compound is applied in the right places: silicone sealant or glue. Insulation of the interior door leaf is carried out in a similar way.

Door frame installation

If the wooden door leaf has a textured surface, it is more convenient to insulate it from the side of the frame. In this case, the door can be removed from its hinges, having previously marked with a pencil the places where the heat-insulating tapes will be applied. Before starting installation work, all sides of the wooden door frame are cleaned and degreased with white spirit. After that, sealing materials are glued in a convenient way.

The most important thing when insulating a wooden door is to choose the right thickness of the tape. In this case, you can count on high-quality sound and heat insulation.

Entrance doors of apartments and private houses must not only be insulated, but also, if necessary, sealed, achieving the maximum possible tightness between the leaf and the frame allowed by their design features. The effect of a correctly performed seal will make itself felt immediately - your apartment or home will become warmer and even cleaner; there will be fewer drafts, if they do not disappear completely; Annoying extraneous sounds and odors will no longer penetrate from the entrance or from the street. You can do the sealing of any doorway yourself - for this there are several ways to do this work and types of seals for both metal and wooden doors, as they say, to suit any ability and budget of the home owner.

First, we inspect the door and frame. If they already have some kind of seal that has ceased to perform its functions, then it must be dismantled. After this, if necessary, we pre-clean the surfaces in those places where the old material was, removing its remains. We use fine sandpaper for this.

It is then recommended to adjust the door if necessary. Distortions will cause uneven fit and wear of the seal. Different sizes of gaps between the frame and the door, top and bottom, left and right, will also lead to this if the material of the same thickness is chosen for the entire opening. Or you will have to select a seal for each side of the opening. The critical value of the skew and the difference in gap sizes is 1–1.5 mm. If they are larger, then it is better to eliminate them by adjusting the door. It happens that performing this operation eliminates the reason why it was decided to seal the opening, and the need for such work disappears.

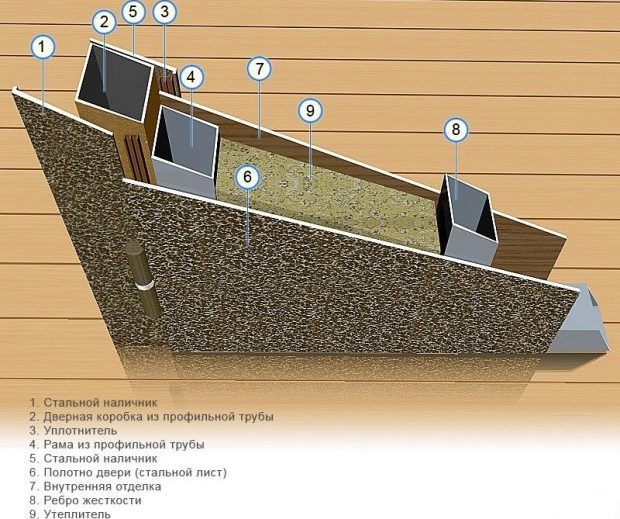

Door design diagram

Now we decide on the installation location and type of seal. This determines which part of the door or frame needs to be measured in order to find out the required amount of material.

Installation on a metal door

As a rule, a factory iron door is equipped with a seal. If it is not there, installation is done by hand. Installation is carried out in compliance with the following rules:

- The tape is applied to a thoroughly cleaned and degreased surface. Cleaning is done with sandpaper, after which the surface is wiped with acetone or alcohol.

- To ensure more reliable sealing, several layers are used (usually two or three). The first (and second) are placed on the canvas from the inside, the second - on the box, and the third - on the outside of the canvas. The external one should be more resistant to ultraviolet radiation, temperature changes and moisture.

- Rubber is placed on silicone glue. The tape is spread in a thick layer and pressed to the surface. Before installation on a painted surface, at least twenty days must pass from the moment of painting.

In the video you can see the door sealing process:

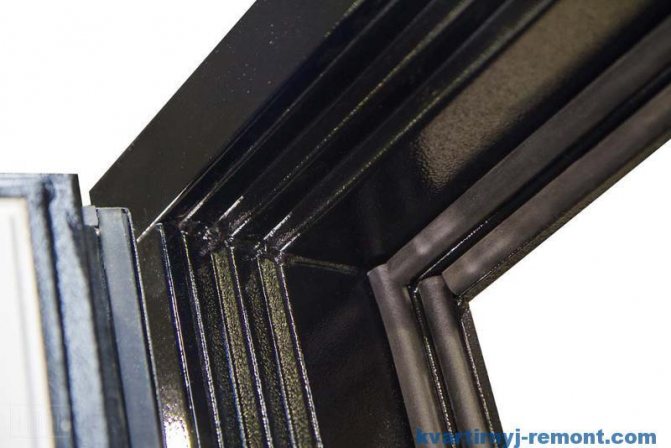

High-quality metal doors have special grooves into which a rubber seal is inserted.

Installation of self-adhesive seal

The procedure couldn't be easier. The surface is cleaned and degreased. The protective film is gradually removed, and the tape is pressed against the surface. This is done along the entire perimeter of the canvas. In the process, tension on the end adjusts the evenness of the tape. Then everything is smoothed out with the palm of your hand.

If the tape comes off, installation adhesive or sealant is used.

Particular attention is paid to laying in corners - these are where it is most difficult to achieve even distribution of the tape. She winces and moves away. After the seal is completely glued, its remains are cut off with scissors or a painting knife.

Source: GoldDveri.ru

Why do you need a seal?

The seal is essentially a tape that is glued along the entire perimeter of the box. Everyone noticed her when entering the house. As a rule, the seal in private houses is installed on street entrance systems or on structures leading from the cold corridor further into the room. In high-rise buildings it is installed on the doors separating the apartment from the landing.

This fittings performs several functions at once:

- The seal for the metal entrance door protects the apartment from the penetration of air from the entrance into it, including providing isolation from extraneous, unpleasant odors (garbage chute, cigarette smoke), dust, and excess moisture.

- Guarantees sound insulation. Moreover, it protects both the apartment from the penetration of sounds into it and reduces the audibility of what is happening in the room itself.

- Retains heat and prevents cold air from entering the house. In the summer, on the contrary, it prevents hot air from getting inside. This fitting also prevents drafts.

- The seal is responsible for the smooth and silent operation of a metal door. There will be no loud clapping with him.

In addition to these tasks, the seal for iron doors partly serves as protection in case of fire: it prevents smoke from leaking into the room. But the fittings will do this only if the tape fits tightly to the metal door without gaps, and its material and workmanship are of high quality.

Your protection from the cold: why do you need thermal tape?

Types of seals

This fittings are made from various materials. The simplest options are made from foam rubber, plastic or polyurethane. They are not expensive at all and are equipped with self-adhesive tape, which makes installation much easier. But they have a very big drawback: they quickly wear out and wear out. Therefore, such seals are not worth buying for metal doors.

The advantage of the former is that they are odorless, do not emit any substances into the indoor air, and have high environmental friendliness. There are no allergies to silicone, so such seals are installed in medical institutions, rooms where there are children or people with allergies.

But most often rubber seals are purchased for metal doors. Such fittings have an affordable price and a long service life. Modern types of rubber are resistant to adverse conditions (moisture, temperature), aggressive substances, ultraviolet rays, they do not crack or crumble. Some people are not afraid even of acid.

They come in three types:

- Self-adhesive. You can replace the seal for iron entrance doors of this type yourself, without any additional devices or tools.

- Magnetic. Quite a new type of tape. They are more often used by manufacturers of metal doors, who immediately equip their products with all the necessary fittings. These seals are not much different from those located on the refrigerator door. Their operation is ensured by a special magnetic insert located inside the thermoplastic elastomer. This product is resistant to aging and can withstand a wide temperature range: -65...+90 degrees. It is installed on the door frame, but you need to clearly adjust the degree of pressure so that the door does not open too hard.

- With additional elements for pressing. In this case, a strip is installed to hold the seal. Due to this, the material retains its shape and characteristics for a long time and does not deform.

Review: Window seal Strimat Service Thermal tape - will help insulate windows and forget about drafts

Advantages:

Excellent thermal insulation, easy to glue

Flaws:

not detected;

We have been living in an apartment for three years now, where the windows have old wooden frames. The house is over fifty years old, you can imagine what these frames look like. Since there is a small child in the house, naturally we cannot allow any drafts in the winter and we insulate the windows for the winter.

All previous seasons we used ordinary round insulation, like this:

But this is not very convenient: Firstly, the distance between the two doors and us is large, even folded in half, such insulation is not wide enough. Secondly, in addition to this insulation, you also need to buy masking tape to secure it.

And this year we decided to try this tape:

Despite its apparent thinness, this thermal tape reliably insulates breathability and sound permeability.

Our eternal drafts disappeared immediately, and the floors in the house became noticeably warmer. During the evening the temperature in the room rose by 2 degrees.

In addition, Thermal tape is very convenient to glue, it sticks like regular tape, but at the same time it holds very well (last year in some places the masking tape came off, especially in the kitchen, since the humidity there is high due to regular cooking), but this one holds on five!

Now about the expense: we insulated 3 windows and 1 balcony door, it took us 3 Heat Tapes (one Heat Tape costs 40 rubles, the total is 40x3=120)

Time of use: 1 season

General impression

.

will help insulate windows and forget about drafts

How to choose a seal for a metal door?

Tips for choosing a seal:

- The required thickness and shape of the tape is selected for the door itself and the resulting gaps. The easiest way to do this is with a piece of plasticine. It needs to be wrapped in film (bag) and inserted into the gap between the box and the canvas when the doors are closed. After this, you can measure the required thickness of the seal.

- If the thickness of the gap is insignificant (from 1 to 3 mm), then you can choose a seal for rectangular metal doors made of polyvinyl chloride or polyethylene foam.

- If the size of the cracks is more than 3 mm, then you need to buy rubber material. Its shape can be different, which is determined by its thickness. The thinnest ones up to 3 mm have the appearance of an E or K profile (reminiscent of these letters in cross-section). If the gap is up to 5 mm, then you should opt for P or V-shaped products. D or O shaped profiles are used for the largest gaps from 5 to 7 mm.

- It is better not to purchase a foam rubber seal for a metal door. Iron entrance structures are installed at the entrance of the room, they are often opened and closed, and foam fittings are short-lived.

- If the seal is not self-adhesive, then you need to immediately buy good quality silicone glue for it.

In addition to these characteristics, the color of the material is also important; it is selected depending on the design of the door. But the most successful product is considered to be black: no dyes are added to it, and they usually reduce the quality of the product. It is the black seals that are installed on the outer door, where the insulation requirements are maximum.

Door seals: main types, their design and performance characteristics

Manufacturers offer products of different sizes and configurations. This determines the possible area of use of a particular type and its operational characteristics. In order not to make a mistake when purchasing, it is worth getting acquainted with the main varieties and choosing the best option.

Depending on where the door is installed

The installation location of the door places certain requirements on the seal used. In order for the product to efficiently cope with the assigned tasks, it is worth knowing in advance what types are recommended to be used for entrance and interior structures.

Installation location is an important criterion PHOTO: static-eu.insales.ru

Input

For entrance doors, a tube-shaped seal made of rubber is preferred. Thanks to this design and sufficient wall thickness, it is possible to ensure a tight fit of the leaf to the door frame. For production, rubber with a porous structure is used, which allows achieving sufficient thermal insulation characteristics and tightness of the structure. The seal most often has a self-adhesive base, which greatly simplifies installation work. The disadvantage of this option is the short service life, which leads to the fact that over time the sealing tape begins to peel off.

Interior

Such a seal should not protect a house or apartment from external cold. Therefore, for the manufacture of this type, less rigid materials are used, for example, silicone.

The choice depends on the design of the interior door PHOTO: stormguard.co.uk

Depending on the material of manufacture

Various types of material can be used to make the seal. This determines its performance characteristics, possible area of use and service life.

Rubber and silicone

Rubber seals are used primarily to seal entrance structures made of metal. This material is highly wear-resistant. Not afraid of exposure to external natural factors. Thanks to its special structure, it is able to quickly take on its lost shape. Withstands significant temperature changes. Prevents metal elements from sticking together.

Rubber ones are very popular PHOTO: img1123.weyesns.com

Silicone elements are comparable in their characteristics. However, they are significantly inferior in terms of wear resistance. It is not possible to achieve higher performance characteristics through additional additives. Silicone seals are widely used when installing interior systems, being the second best option after rubber elements.

Silicone ones are quite in demand PHOTO: sanpol.ua

Foam and felt

Foam seal is the most affordable option. Available in the form of self-adhesive tapes. It has low noise and heat insulation properties. Easy to install, but has a limited service life: only 1 - 3 months. Over time it decreases in size.

Foam rubber will not last long PHOTO: master-remontus.ru

Felt seals are relevant for wooden buildings. They are environmentally friendly materials. They have good noise and heat insulation properties. Not prone to rotting or fungus.

The thickness of the felt seal may vary PHOTO: i.ebayimg.com

What to look for when purchasing?

In particular, you should perform the following actions:

- Read the label on the product, which indicates the expiration date, all the necessary information about the seal and the material used for its manufacture.

- By pressing it is worth checking the elasticity and tightness characteristics. The material should be medium hard, then it will not interfere with the door closing well. When pressed, it should quickly restore its original shape. This is a sign of high quality material.

- If the seal is on self-adhesive tape, then you need to find out the expiration date of the glue. Otherwise it could just dry out. Also, small particles of fiberglass should be applied to the adhesive part.

Most often you can find such products on sale from Germany, Sweden, Poland or Turkey. A good product should not harden when the temperature drops, or peel off when it fluctuates; release toxic compounds into the air.

How to attach the seal?

They do this taking into account the following recommendations:

- If the door is of good quality, then it already has special gutters for installing the seal.

- Before installation, the surface must be prepared: cleaned of dust, remnants of old tape (preferably treated with sandpaper) and be sure to degrease. To do this, simply wipe the surface with acetone, alcohol or another solvent.

- For good sealing, it is better to use 2 or 3 layers of sealant. Two are preferable for the door that opens into the entrance, three for the one that opens to the street. The first is mounted on the canvas from its inside, the second layer is installed on the box, and the third is glued to the outside of the canvas. The external one should be the most resistant to any factors: temperature, light, humidity.

- If the surface has been painted, then the sealing of the metal entrance door can be carried out no earlier than after 20 days.

- If the product is made of rubber, it is glued using silicone glue. The substance is applied to the tape in a fairly dense layer and pressed against the surface.

- If you use a self-adhesive seal for metal doors, then the film must be removed gradually, fixing the tape around the entire perimeter of the door leaf. As the tape is glued, it smoothes out.

The most difficult thing when installing a seal with your own hands is the corners. In them, the tape often wrinkles, comes off, and it is impossible to lay it flat. Therefore, you need to be especially careful in these places. For a more even fit, the rubber seal for iron doors pulls back slightly when gluing. When the product is completely glued, all excess is cut off with a knife.

Even an insulated metal door needs a seal installed to ensure there are no gaps at all. High-quality fittings will protect the room from noise and dust and provide thermal insulation. You should not save when choosing insulation, then it will last a long time.

Source: dveri365.house

Sealing strips by door type

For each individual variety, its own seal was developed.

Input

Most often, entrance doors are finished with a dense material in the shape of a tube, inside of which there is a void. The significant thickness and bubble nature of the material create a reliable fit of the door to the frame. Read this article on how to choose reliable and warm doors for your home.

Of particular interest is the internal structure of these rubber bands for insulating doors. Thanks to the presence of internal pores, a multiple increase in the insulating effect is achieved. Most often, the entrance door seal has a self-adhesive base, which makes its installation very quick.

On the other hand, over time, the glue loses its characteristics, and the strips begin to lag around the perimeter. You can read about comprehensive door insulation.

Interior

The seal for interior doors is not assigned the function of protecting the room from outside cold, as in the previous case.

This allows you to make it more aesthetically pleasing by using more elastic and soft silicone instead of dense rubber. The installation method for these products may differ, which will be discussed below.

If you decide to change the doors during the renovation process, be sure to read this article.

Plastic

This group of materials is characterized by high speed of installation and dismantling. Grooves are usually applied to plastic doors along the line of contact with the frame, so the seals are given a special shape that follows the configuration of these grooves. Thanks to the presence of walls on the sides of the fixation point, the sealing strip receives additional protection from external aggressive influences. The seal for plastic doors is not afraid of moisture and temperature changes, so it can be used both outdoors and on interior doors without much difference. It is important to keep in mind that this rubber seal was designed specifically for plastic doors with grooves, so it is not recommended to seal other types of doors with it. In addition, different manufacturers complete their plastic doors with an individual seal: this should also be clarified when selecting a suitable material.

Find out about the pros and cons of plastic doors in the room.

Glass

In the manufacture of seals for glass doors, silicone is used, equipped with a special profiled notch. When installing the strip, you must first wet the area where it will be placed: this will make the connection as strong as possible. Since the design of glass doors can be very different, therefore, a different seal is developed for each of them.

What is door insulation made of?

In order to choose the most suitable door seals for your home, you should also be aware of the materials used to make them.

Rubber

Most often, entrance doors are equipped with a rubber seal. Moreover, the manufacturing material is not simple rubber, but its modified varieties that can withstand the most extreme operating conditions, including severe frost and heat. In addition to the draft, the doors may also creak, but this can all be fixed.

Silicone

The performance characteristics of silicone products are slightly lower than those of rubber ones. This is explained by the fact that it is not possible to provide silicone with additional resistance to aggressive external influences even by introducing appropriate additives into its composition. For this reason, silicone liners are mainly produced for wooden interior doors that are used in comfortable conditions.

Foam rubber

It is the material used to manufacture the cheapest door insulation, which fails within one year. The reason for this may be temperature fluctuations, dirt and moisture, which provoke crumbling and disintegration of the foam rubber. The material gradually loses its original volume, which affects the functionality of products made from it.

Magnet

An innovative development, which is mainly used to complete expensive metal doors. The average person is familiar with a magnetic seal from household refrigerators and freezers, in which permanent magnets around the perimeter of the doors are attracted by poles of attraction. Most often, metal doors are equipped with three-circuit magnetic seals. The location of the two circuits is the door leaf itself, while the third is mounted on the door frame. The main disadvantage of such products is the rather high pressing density, which a child or an elderly person will not always be able to cope with. If the action of the magnets is weakened, then proper tightness and sound insulation will not be ensured.

It is recommended to install magnetic seals even on simple metal doors made of steel sheets, without decorative decorations. This seal includes soft filling and a magnetic insert.

Advantages of a magnetic door seal

The soft filler is made of thermoplastic elastomer, which has the following advantages:

- Significant service life.

- Stable tolerance of sudden temperature fluctuations (from -65 to +95 degrees).

- Possibility of recycling after loss of performance.

Felt

Typically, sliding doors are decorated with a felt seal, which helps save room space. Such tapes cannot provide special protection from noise and cold. They are used exclusively to prevent dust from entering the cabinet or room.

Basic methods for installing door seals

When starting to install a door seal, the first step is to find out what type of product you are dealing with. This will allow you to choose the most optimal way to glue the seal. The most common types of rubber seals are grooved and self-adhesive.

Groove seals

The installation of this material is very simple, which is why it is most often used when repairing doors yourself. The most difficult part of installing the door seal into the groove is finishing the corner areas. Beginners are advised to use careful trimming of the material. More experienced users achieve continuous installation, without joining areas. The latter option is more advantageous, since the level of door sealing in this case is much higher. However, to implement it you will need to show some skill. Door seals at the bottom are equipped with a special edge on which there is a brush: this structure of the material facilitates fairly quick installation into the groove cavity.

While laying both rubber and silicone seals, it is important to avoid even minimal tension on the tape. Otherwise, unacceptable stress will form inside the sealing layer, which will affect its performance. No matter how high-quality the silicone or rubber is, they will gradually stretch, losing their original volume and elasticity. Experienced craftsmen, when laying the seal in the groove, try to slightly compress it, which significantly extends the service life of the door insulation. Trimming of excess parts is carried out upon completion of installation. It is more convenient if only one edge of the rubber or silicone tape is left for trimming: in this case, the remaining segment is longer and can be used to insulate another door.

Self-adhesive seal

Laying such material is also not particularly difficult, although a few useful tips should be taken into account. In order for the self-adhesive rubber seal to stick to the seat efficiently and for a long time, it should be pre-prepared. This procedure includes several steps. Firstly, all dirt must be removed from the surface of the door: this is done not only along a narrow installation area, but by some expansion to the sides. For these purposes, soapy water or detergent is usually used.

The preparation of the wooden surface will require special care. You should not moisten it too much - just wipe thoroughly with a damp cloth. If the seat has roughness, protrusions and irregularities, they must be eliminated. In this case, the operating technology also depends on the surface material. For example, wood can be lightly sanded and puttied; For metal or plastic surfaces, gentle sanding will be sufficient. Individual protrusions can be carefully removed with a chisel or sandpaper. After the sealing area has been cleaned and washed, it should be completely dry. Sometimes, if the work is carried out in a confined space, or when it is necessary to speed up the process, a regular hairdryer is used for drying.

Before gluing the seal to the door, it must be degreased. When choosing a degreasing agent, it is important to consider the surface material. Most often, this procedure is carried out with white spirit, acetone or regular alcohol. However, it should be understood that all of these products are toxic and explosive, and you should work with them very carefully. It is better if it is possible to ventilate the premises well after application.

Helpful advice: in cases where the seal is installed where people are present at the time, it is better to use a special low-toxic emulsion or an aqueous alkaline solution for degreasing.

As for the actual installation of the self-adhesive seal, this procedure is not particularly difficult. All you need to do is remove the bottom part of the material from the protective film and carefully lay it along the edge of the door. It is more convenient to remove the entire film not at once, but in 10-15 cm segments, immediately installing the freed area on the seat. At the same time, it must be pressed tightly against the surface of the door, achieving high-quality adhesion. A similar algorithm of actions is maintained throughout the entire procedure. It is more convenient to start work from the top, and when you reach the bottom edge of the door leaf, cut the rubber tape using a sharp knife or scissors.

When sealing the front door with protective material, the door frame is also sealed. In this case, the material is glued along the outer and inner line of contact of the two surfaces, which makes it possible to create double protection against street cold and moisture.

As can be seen from the description, any person can seal the door. The main thing is to choose the right material and work carefully.

Source: kvartirnyj-remont.com

Insulation with sealing tape

Plastic windows

Typically, plastic windows lose heat for two reasons:

- breakdown of fittings;

- seal wear.

Correct installation of the tape increases the insulating ability of the window. The following sequence of work is recommended:

- before installation, the tape is kept at a positive temperature, since this affects its expansion inside the groove;

- The tape is cut to fit the window. The joints are cut at right angles. For thermal expansion, a reserve is created: for every meter 1 centimeter of material;

- The tape is pressed into the groove with a spatula, and the adhesive strips are removed in small sections.

Important!

1. In the corners of the frame, the tape is connected only end-to-end.

2. To prevent impregnation from leaking out, the tape is not compressed more than the permissible value.

After installing the sealing tape, the locking mechanism is adjusted: the pressure is changed by trunnions, which are located at the end of the sash.

Adjustment is made with a hex wrench. The pressure increases when the trunnion head is installed in a horizontal position.

Wooden windows

The Swedish method of insulating such windows using EuroStrip technology is in great demand. It has the following advantages:

- there is no need for annual window insulation;

- after ventilation, the tightness of the windows is not compromised;

- frame service life increases;

- high degree of protection from dust and street noise.

For insulation, two types of tapes are used: rubber and silicone.

By the way, branded Swedish silicone seals are easily inserted into the groove and last up to 20 years.

Installation is performed in the following sequence:

- the sashes are removed from their hinges and inspected. Rotten areas are identified and then restored;

- a groove is cut along the entire sash for the tape;

- using a roller, the tape is pressed into the groove;

- A rubber cord is placed inside the frame, and then the sashes are pulled together;

- The window is hung on hinges and adjustable. If necessary, the hinges are rearranged and the fittings are changed.

So, both types of window insulation tapes deserve attention. Which one is better depends on the condition of the window.

If you choose the right one, the insulation will quickly pay for itself, and the apartment will always be warm and cozy.

Varieties by purpose

Each individual type of door structure can be equipped with a specially designed seal. Products for entrance doors are hollow and internally dense tubular seals. It is due to the thick material and the internal cavity that the door leaf fits securely to the frame.

The rubber used to produce such products is porous, which allows the thermal insulation effect to be enhanced several times. This type has a self-adhesive base. This is both a minus - they come off quickly, and a plus - you can install a new door seal without effort or problems.

There is another option, which is designed for doors between rooms. This is the case in which there is no need to withstand drafts, so soft rubber or silicone is most often used for its manufacture.

A separate group is represented by gaskets for plastic doors. The main feature is that they can be quickly replaced. Thanks to the special configuration, installation consists of installing them in a groove. Thus, the influence of the environment on it itself is reduced, and it copes with its work at any temperature. This universal type can be installed for internal and external plastic doors. It must be taken into account that it is not suitable for any other purposes.

A separate type is represented by seals for glass doors, which are most often made of silicone and have a special profile section. To install the seal on the door, you need to wet it and then install it on the end. Once dry, it adheres tightly to the glass. Depending on the material used, products are divided into several types.

Functions of door seals

The main function of the seal is to protect the internal space from external sounds and external temperature. It also allows you to:

- prevent foreign odors from getting inside;

- achieve a sufficient level of thermal protection, prevent drafts;

- ensure an optimal level of system tightness due to the tight fit of the leaf to the door block.

Rubber gaskets

Rubber door seals, thanks to various adaptations, can be adapted to any, including harsh, operating conditions. For their production, acid-resistant, oil-resistant rubber of high technical or food quality is used. Most often, a rubber seal is used for metal doors facing the street. They have a number of positive properties, namely:

- increased degree of moisture and air tightness;

- resistance to various temperatures, ultraviolet rays, precipitation;

- long service life.

The rubber seals on the door are not in danger of cracking, and they are inexpensive.

Silicone and fleece seals

Silicone is one of those materials that, in terms of its performance indicators, is slightly inferior to rubber. It is not possible to extend the service life and improve quality by adding special substances. Therefore, it is used to make gaskets for interior doors, where it can last for a very long time. The advantages of silicone products include the fact that it:

- environmentally friendly for residential premises;

- does not emit hazardous substances;

- does not cause allergic reactions.

These qualities make it possible to install such a product in children's and medical institutions.

Another type of sealant includes fleecy or brush tape, which is used to seal compartment doors. The tape is not capable of providing heat and sound insulation. Basically, it is intended to protect the room or closet from dust.

Leading manufacturers

When choosing a door seal, you should pay attention to products from companies that have no complaints from consumers. They usually offer different types of material, which allows you to choose the best option for your home. These include:

- Gasket LLC. The Russian company offers expensive, high-quality products made from thermoplastics. The company produces ready-made sealing contours, and also provides the opportunity to order tape for any non-standard door structure;

- Volzhsky RTI plant. Manufactures door insulation from silicon-based rubber of various profiles and standard sizes. At a fairly reasonable price, the products are of high quality;

- LLC PKF "Kazpolymer" The domestic manufacturer offers plastic and PVC products for interior and entrance doors;

- Bars profile. The company from St. Petersburg offers high-quality products made from wear-resistant PVC materials. Offers seals of different configurations and different colors, meeting the requirements of GOST;

- Deventer. The German manufacturer uses environmentally friendly materials. The products meet the requirements of international quality standards;

- Stomil Sanok. The Polish sealing element can be used in a wide temperature range. Made from special microporous rubber. It is characterized by high wear resistance and long service life;

- Chord. Turkish sealant is able to maintain its performance characteristics for at least 5 years. Harmless. Available;

- Welless. The German company offers sealants of different types and colors, allowing operation in a wide temperature range and not afraid of exposure to chemicals. Relevant for residential premises and medical institutions;

- Varnamo. A company from Sweden uses porous rubber to make the seal. Offers K-, P-, D-shaped contours;

- Cyclone. The Swiss manufacturer produces a self-adhesive seal with reliable fixation and the ability to operate in a wide temperature range.

Products from leading manufacturers are of high quality PHOTO: stroy-podskazka.ru

Foam rubber and polyurethane types

Foam tape is the most affordable, simplest option. The presence of a self-adhesive base allows you to insulate the doorway in a short time, without the need to make any effort or have additional material. It can also be secured with small nails if the surface is made of wood. Foam rubber is a good protection, but its fragile structure does not allow it to withstand difficult operating conditions; it is negatively affected by: humidity, dirt, temperature changes.

Gradually it becomes unusable, shrinks, crushes, crumbles. Most often, foam rubber tape is used as a seal for interior doors.

A type of door seal is a polyurethane product, which, thanks to the self-adhesive film on one side, is easily fixed to the door. Its area of application includes wooden doors. Metal structures quickly damage the product, as a result of which the heat-protective qualities decrease.

Primary requirements

When choosing a seal for the front door, you need to start from the size of the gap that needs to be closed. For example, if the size of the gap when the door is in the closed position is 1-4 mm, then you can install a rectangular rubber band from:

- foam rubber;

- PVC;

- polyethylene foam.

Only rubber products can be a good seal for a metal entrance door. Today on the construction market there are such materials of various colors, which means you always have the opportunity to choose specifically for your door. The most common are black, white and brown. There is an opinion that when adding dye, the quality of the rubber decreases somewhat, and therefore it is worth purchasing a black seal that does not sparkle with originality.

Such materials must meet their basic requirements. First of all, this concerns ensuring complete tightness and protecting the room from penetration:

- cold air;

- extraneous noise;

- moisture;

- pungent odor;

- fine dust.

The door will close smoothly without leaving any gaps. After installing a seal for a metal entrance door, if the product is of good quality, it will not make sharp sounds. It must withstand temperature changes; such stability will not allow it to peel off or harden. The sealant, regardless of operating conditions, should never lose its main properties. It is also important that such products will help protect the door from damage that occurs due to drafts, which often lead to their sudden slamming.

As you can see, it is this seemingly insignificant detail that can ensure smooth closing of the door, tightness, improve sound insulation and retain heat in the room.

Source: BestDoor.guru