Home / Gas boilers

Back

Published: 10/24/2019

Reading time: 3 min

0

1160

Gas is the most common type of fuel on which heating boilers operate. It becomes especially relevant for owners of apartments, private houses and cottages equipped with an individual heating system.

Installation of such equipment on premises is carried out exclusively by specialists from organizations that have SRO approval to provide such services. Self-installation is strictly prohibited.

Residents of Russia who are planning to acquire such a device often do not understand where exactly they can place or hang the heating boiler. Let's try to figure it out.

- 1 Installation of gas boilers in the house 1.1 Basic standards

- 2.1 Specifications

Is it possible to hide a gas boiler in a closet: decorating methods

Many owners of both private cottages and apartments in multi-storey buildings decide to disconnect from the heating plant and install autonomous heating. As a rule, a gas boiler is installed in the kitchen. An ordinary white unit can disturb the interior of the room, so they think about how to fit the boiler into the existing design.

A gas boiler can only be installed in non-residential premises, and the presence of a window and a door is mandatory!

The design of the part of the room where the boiler is installed needs to be thought out before installing the heating device.

How to hide a boiler:

- Homemade chipboard box for the boiler. Ideally, the front panel of the box should coincide as much as possible with the facade of the kitchen unit.

- Niche made of profile and plasterboard. The front part of the structure is also closed with a door to match the overall style of the kitchen.

- Finishing the boiler with film or special paint.

When installing new furniture, you need to discuss in advance the size and location of the cabinet for the boiler. The wiring of communications is also taken into account, which can be hidden if desired.

Floor-standing AGV can be installed in the corner of the kitchen according to the installation rules. It is also allowed to hide the floor-standing boiler in a cabinet-cabinet, while complying with the standards and safety rules.

Step-by-step installation of equipment

Before installation, you need to unpack the new boiler and check the completeness of the delivery. The availability of parts is checked according to the operating instructions, which must be included with the device.

If any item is missing, please contact the supplier immediately. One more nuance. The boiler must have an ideal appearance without dents, chips or signs of repairs. If this is not the case, you need to call the sellers.

It is important to make sure that the technical data specified in the technical data sheet of the heating device exactly matches those printed on the device itself. In addition, they must correspond to the numbers specified in the operating instructions for the device.

Immediately before starting installation, you need to flush the boiler pipes, which may contain various debris that got inside during the manufacture of the device and its transportation.

Installing a gas boiler involves connecting heating pipes, water supply and gas mains, as well as installing a chimney

It is also advisable to flush the heating system lines. After the preparation is completed, you can begin installation.

We invite you to familiarize yourself with ᐉ Norway maple description and features

The specifics and procedure for its implementation are determined by the characteristics of the equipment: the number of circuits involved and the type of combustion chamber.

Most often, double-circuit appliances with a closed firebox are installed in houses. Let's take a closer look at the installation of just such a modification.

To secure gas boilers, a special bracket is used, which should be included in the delivery of the device. Reliable fasteners are used for mounting it on the wall. They should be selected according to the material from which the wall is made.

It is quite possible that those that the manufacturer packaged with the heating device will not be suitable. Then you will need to choose and purchase others.

The purpose of the bracket is to support the weight of the boiler and additional equipment, as well as to provide it with an even, clearly aligned position without distortion.

To accurately mark the wall, you can use a paper stencil, which usually comes with the boiler. With its help, you can easily mark holes for fasteners.

Once this is done, the bracket is secured in place and the boiler is hung onto it.

Heating pipes are connected to the corresponding pipes of the gas equipment. You can determine their location from a photograph.

Depending on the type of heating system, and it can be single-pipe or two-pipe, the number of pipes connected to the boiler may vary. In any case, we start by removing the plugs from the device’s pipes.

To protect the boiler from the ingress of dirt particles from the heating line, it is recommended to install a mesh filter at the return inlet.

If the water in the system is hard or in other respects does not meet the requirements stated by the heating device manufacturer, you should take care of installing additional treatment equipment.

These could be, for example, polyphosphate dispensers. If this is not done, the device will quickly break down. All connections must be made in compliance with all rules and regulations.

Sealing is required. For this purpose, special sealants are used: traditional paint or tow, or modern thread sealants. In addition, experts recommend the mandatory installation of shut-off valves for supply and return.

This is necessary to facilitate repair of the boiler if it fails. In addition, the fittings will help prevent possible airing of the radiators.

A water filter is an element that must be installed when connecting a gas boiler to a water circuit

This work is almost the same as connecting heating pipes. The main difference is the taps used and the diameter of the pipes.

The cold water supply must be equipped with a filter, which will eliminate the possibility of contaminant particles entering the heating device. Otherwise the equipment will be damaged.

The taps used to isolate the boiler from the water supply must have detachable connections.

Such models are also called “American”. They significantly simplify installation, and in case of unforeseen situations, they make it possible to quickly replace a worn-out faucet.

It must be remembered that the pipes supplying cold water are located on the heating device on the left side relative to the center, and those supplying hot water are located on the right.

This part of the work should only be carried out by a qualified specialist, since the cost of an error can be very high. In any case, upon completion of the connection, its correctness must be checked by a representative of the gas service. He will also conduct the first start-up of the equipment.

All operations when carrying out work independently must be performed with the utmost care. They start by connecting the branch of the gas main with the corresponding pipe on the boiler.

When connecting the boiler to the gas main, you can only use tow to seal the threaded connection, otherwise it will not be possible to achieve the required tightness

A special filter must be installed on the tap that cuts off the gas supply from the main line. Experts strongly recommend not to skimp on this detail.

A cheap, low-quality filter will not work for long, which can cause the gas boiler to fail. When arranging a connection, special attention should be paid to its sealing.

You must understand that the weight of gas is much less than air, and if the connection is not tight enough, it will leak out of the pipeline. The consequences can be the most dire. Therefore, careful sealing is mandatory.

The main materials for sealing a threaded connection are paint and tow; the use of sealants such as fum tape is unacceptable.

A special flexible connection is installed after the filtration element. You need to know that using rubber hoses for its installation is strictly prohibited.

This is due to the fact that over time, the material from which the part is made dries out and becomes covered with cracks through which gas begins to leak. Therefore, the best choice for arranging such a connection is a corrugated hose.

A corrugated hose is a good choice for connecting the device to the gas main. It is quite strong, durable and does not collapse under the influence of gas

For its manufacture, high-quality durable stainless steel is used. This is a very strong and durable material, particularly resistant to high humidity and the adverse effects of gas.

The hose is secured to the heating device pipe using a union nut. In this case, a paranitic gasket must be used, which provides the necessary sealing of the connection.

This operation is only necessary for appliances with a closed firebox that require electricity. It powers the fan that removes combustion products and the automation that controls the system.

Typically a standard three-wire connection diagram is used. Experts recommend connecting the boiler to the network only through a stabilizer, which will make it possible to avoid power surges and thereby extend the life of the boiler.

If you live in an area where there are frequent power outages, then it is additionally advisable to purchase an uninterruptible power supply - this will protect your equipment from sudden power surges

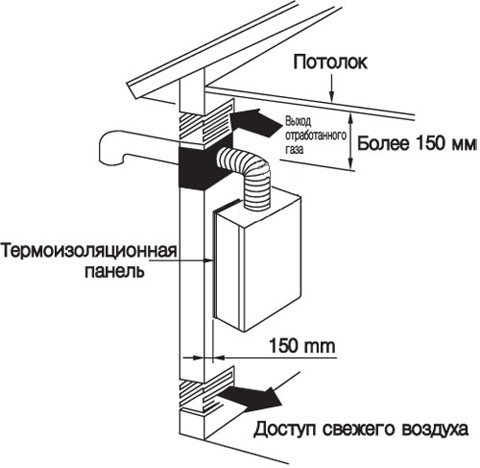

The easiest way is to connect a heating device with a closed firebox to the chimney. For them, special coaxial pipes are used. In apartment buildings, the boiler must be connected to the collective chimney.

In individual buildings, a coaxial type chimney is led out to the street through a wall. The height of the pipe suspension in this case is not particularly important, since the necessary draft is created by the built-in fan.

Appliances with an open firebox must be connected to an individual chimney. The boiler is connected to it by a pipe of the required cross-section.

The material for its manufacture is selected so that the part is resistant to combustion products, high temperature and mechanical wear.

You can check the tightness of the gas pipe connections using a soap solution. A gas leak will manifest itself as bubbles

Before starting work, you need to make sure that there are no soot residues, installation debris, etc. in the chimney. When installing a chimney pipe, it should be positioned with a slight slope towards the gas boiler.

A vertical section of pipe is installed at the outlet of the device; its length before turning must be equal to at least two pipe diameters. The total length of the connection section to the chimney should be minimal.

Before the test run, the heating system is filled with water. The liquid is pumped until a pressure of 2 atmospheres is reached. Pumping water is carried out as slowly as possible in order to remove the maximum amount of air collected inside.

In addition, the system is checked for leaks. All leaking connections must be sealed immediately.

To identify insufficiently tight connections on the gas main, you need to dilute a soap solution and lubricate all connections with it. Then watch.

Air bubbles will appear in poor quality areas. Any faults found should be corrected and re-checked. The first start-up of the equipment should be carried out only in the presence of a gas service representative.

Kitchens with a gas boiler: design and installation of a chipboard cabinet

If the gas boiler was installed after purchasing the kitchen set, and there is no way to hide it in one of the existing cabinets, you can decorate it with a homemade door. To make a boiler cabinet with your own hands, you will need chipboards and wooden slats.

In addition to the tools - tape measure, bolts, jigsaw and awnings, you will need a ready-made door that is closest in color to the kitchen facade.

Before starting work, you need to accurately calculate the dimensions of the gas boiler. The minimum distance from any side of the boiler to the cabinet is 3 cm, respectively, add 6 cm to the height and width of the boiler and select a door of this size.

Kitchen in a private house with a gas boiler: installation rules and regulations

Placing a gas boiler in the kitchen requires certain rules and regulations. Failure to comply with them can lead to serious consequences. The room in which the gas boiler is installed must be at least 4 square meters, more than 2.5 m high, have a window and a door to the corridor. There must be a device in the kitchen that will notify you of a gas leak.

The power of gas boilers installed in the kitchen should be no more than 60 kW. The heating boiler can be installed on the floor or attached to the wall.

The gas boiler is attached to the wall, which is made of non-combustible materials. The boiler must not be installed close to cabinets; there must be space for air circulation between the appliance and the walls of the furniture.

In houses with wooden floors, it is recommended to cover the wall with a metal sheet.

The layout of gas and water pipes must be carried out in accordance with the rules. The gap between the boiler and refrigerator and gas stove must be at least 30 cm. The heating boiler is installed at a distance of at least 0.8 m from the gas meter at a height of 1.6 m. The electrical socket for the boiler is mounted at a distance of 1 m.

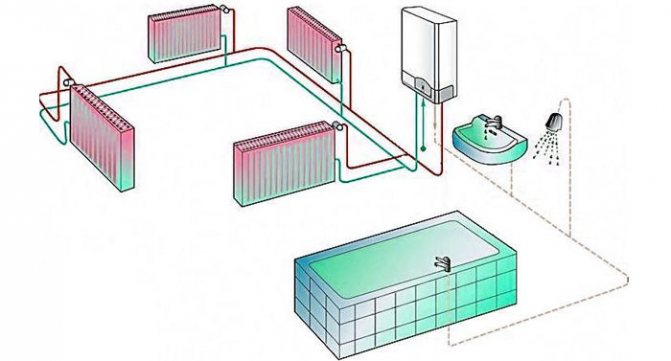

Installation of autonomous gas heating in an apartment

If you decide to turn off the central heating, then you should know how to install individual heating in the apartment, and what elements are needed for this. It would be better to entrust this procedure to professionals.

Autonomous heating installation diagram

The installation of a gas boiler is carried out in compliance with certain requirements for its placement.

So, it should not be closer than 20 cm from other household appliances or flammable materials (this distance can be greater (30-50 cm), which depends on the boiler model). Also, you should not place the heating device between walls or near a window, although the power source, on the contrary, should be as close as possible. Important! As soon as you select a suitable location, be sure to check the purchased gas boiler for the presence of all fastening and additional elements: mounting templates, fixtures and brackets, because if they are absent, it will be problematic to make autonomous heating in the apartment using the same gas boiler.

In addition, be sure to compare the technical characteristics declared by the manufacturer (indicated on the packaging) with the values indicated on the identification plate located on the inside of the front cover of the boiler.

Before you proceed to installing the equipment, be sure to flush all the boiler pipes and the system as a whole, which will help remove foreign particles that often get inside the system during factory assembly.

The strips for mounting the boiler (included in the kit and fixed to the wall with anchors) are placed at a distance of 1.0-1.6 m from the floor. The wall must be level and strong enough, otherwise it will not be able to support the weight of the boiler and all related devices.

To prevent clogging of the heat exchanger, it is better to install an angle-type mesh filter at the water outlet. Ball valves are located on both sides of it, which will facilitate the maintenance and repair of the boiler in the future. After this, you also need to check the evenness of the equipment, because skew in any direction can cause extremely undesirable consequences.

At the next stage, as soon as the boiler takes its place on the wall, it is necessary to connect the heating and water supply system pipelines to it (before connecting the boiler to the water pipes, be sure to remove all plugs installed on the pipes). The connection between the boiler and the pipeline is made using polypropylene couplings, at one end of which there is a thread with union nuts, and the second part is soldered to the pipe.

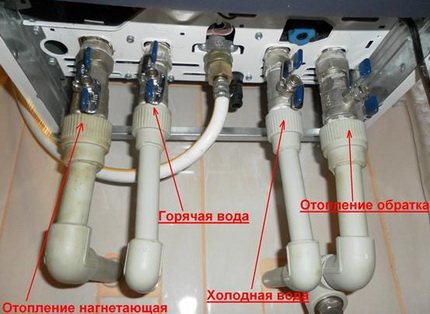

Wall-mounted double-circuit gas boilers have 5 outputs:

- 1 – treatment, used to return cooled coolant from the heating system back to the boiler;

- 2 – supplies cold water from the water supply;

- 3 – gas tube;

- 4 – is responsible for the output of hot water for the water supply system;

- 5 – supply tube through which the hot coolant is directed into the heating system.

Important! For different boiler models, these tubes may have different locations, so to avoid mistakes, always study the technical documentation that comes with the boiler.

Single-circuit boilers have only 3 outputs: gas, supply and treatment.

Ball valves are installed on all boiler pipes, and they are present even where at first glance it seems that there are none.

The process of installing a wall-mounted boiler is described in great detail in its passport, so you can find answers to almost all the questions that you will have during the installation process in this manual.

But do not forget that only a specialist from the gas service can connect the boiler to the gas pipe. A gas tap or ball valve (certified only), a gas meter, a thermal shut-off valve and a gas alarm are installed in front of the boiler. It is necessary to ensure constant open access to the gas tap.

Remember! Connecting on your own is a very dangerous activity.

Boiler installation tips

A gas heating project in an apartment is the first step towards installing a boiler. In this matter, it is worth considering a number of recommendations from experts. For example, it is very important to fix the mounting bracket clearly parallel to the floor so that the boiler is positioned without distortions (you can use a level or plumb line to check the evenness). Although there are no serious requirements for wall-mounted boilers, when placing them it is worth maintaining a minimum distance from the boiler to the nearest walls or cabinets: on the side - 25 mm, on top - 20 cm, on the bottom - 25 cm, on the front side - 100 mm (if you plan to hide the equipment behind the door).

If the gas boiler is attached to a partition made of flammable materials, then a protective sheet of metal (at least 3 mm thick) should act as a kind of gasket, and the boiler itself will be fixed at a distance of 5 cm from the wall. We also must not forget about the load-bearing capacity of the partition itself - it must support the weight of the unit and additional equipment.

Kitchen interior with a gas boiler on the wall: how to hide communications

Having solved the problem of masking a gas boiler in the kitchen, the question often arises of how to hide the gas and water pipes leading to the appliance. The bulky, ugly chimney and hoses connecting the unit to the individual heating system are also not pleasing to the eye.

Under no circumstances should all elements be covered in the wall; they must be accessible if necessary!

Today, the most popular option for hiding communications is a box made of profiles and plasterboard, which can be covered with tiles or wallpaper. When installing the box, you should use moisture-resistant drywall.

The gas pipe can be hidden behind the kitchen unit. In this case, cabinets and bedside tables should not put pressure on the pipe; you need to leave about 1 cm of free space between them. If the pipe runs at a height of more than 1 m from the floor, you can use it as a stand for towels. To do this, the pipe is cleaned of rust and covered with several layers of chrome paint - after drying, you can hang towels and napkins on it.

Corner water or gas pipes that cannot be covered with a cabinet can be decorated with artificial flowers or fruits, decorated with glass mosaics, or painted with colored paint to match the interior of the room.

Types of wall devices

According to their functional purpose, gas heating units are divided into two groups:

- Single-circuit. Intended for heating only. They are connected to the heating circuit and heat the coolant. The organization of hot water supply in this case is carried out by installing an electric or gas water heater of any type.

- Dual-circuit. They heat the room and provide hot water. An additional circuit for heating water is built into the boiler. The technological feature of the device is that it is impossible to simultaneously heat water and heat the room.

The priority action of dual-circuit units is to heat the water; heating operation stops at this time. Considering that water can be heated quickly, the boiler heats the building quite effectively.

They come with one or two heat exchangers. When equipped with two, they can simultaneously serve two circuits. Based on the method of fuel combustion, all devices are divided into the following two groups.

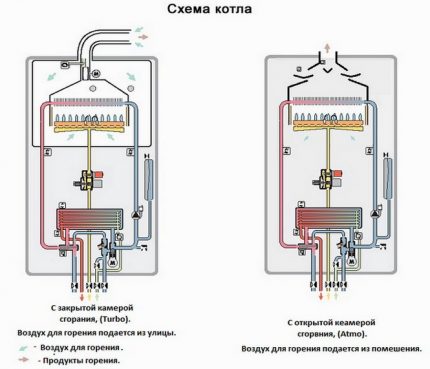

Such devices are also called natural draft heating devices. They take the oxygen necessary for combustion from the room in which the device is located.

To remove combustion products, they need a traditional type chimney. Thus, a mandatory requirement for installing such a boiler is the provision of good ventilation.

If the heating device is installed in a residential area, it must be equipped with high-performance supply ventilation.

The best option for installing a heating device with an open firebox is the presence of a separate room, the so-called firebox, where it is placed.

Systems with natural ventilation are quite popular due to their low cost and energy independence.

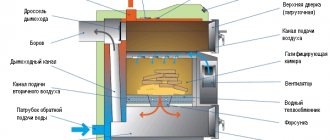

The figure schematically shows boilers with open and closed type burners

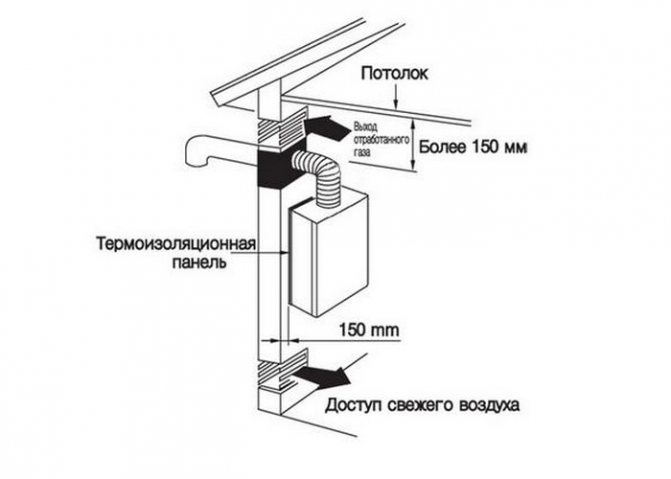

Turbocharged devices are equipped with a closed combustion chamber. They take the air, without which the combustion process is impossible, from the street. For this purpose, the devices are equipped with coaxial type chimneys.

Such a chimney is made in the form of a structure of two pipes, one of which is nested inside the other. The combustion products are discharged outside through the inner pipe.

At the same time, street air flows in the opposite direction through the gap between the two pipes. It is clear that boilers with a closed firebox do not in any way affect the composition of the indoor air, which makes it possible to install them even in living rooms.

We invite you to familiarize yourself with the Kurnik for chickens

In this case, it is necessary to equip a coaxial chimney system, which is higher cost and more complex installation compared to a separate traditional chimney.

Solution 1: Safely placing the boiler inside furniture

If you are planning to improve the kitchen space and hide the gas boiler, you need to study the norms, installation and use rules. This is an important point on which your health and life depend.

I will focus on the main points:

- Placement is carried out on the wall or floor.

- The gap from the floor is 80–160 cm, from the ceiling - 80 cm.

- The cabinet used for “camouflage” cannot be adjacent to the walls of the unit. Gaps are made on the sides - from 5 cm, in front - from 10 cm.

- The room must have windows for ventilation.

- The power of a household boiler is selected to be no more than 60 kW.

- Installation and configuration is carried out only by specialists.

- The distance to electrical appliances and stoves is at least 30 cm.

- It is advisable to install gas leak alarm sensors.

The chimney must have good exhaust. Its performance is checked twice a year.

This is what a geyser looks like without decoration

Solution 2. We hide the boiler in a closet: decorating techniques

The best option for disguising a white unit is a wall-mounted kitchen cabinet. In this case, the proportions are maintained and the interior style is maintained.

How to choose a cabinet

When purchasing furniture, you need to correlate the height and depth of the cabinet with the parameters of the boiler. In this case, the cabinet should be larger and not restrict air circulation. When planning to camouflage a gas boiler, consider the main points:

- installation height;

- communications wiring;

- hose length;

- method of their installation;

- possibility of installing a mounting box/channel.

Wiring, valves and connections cannot be bricked up, they must be accessible