Let's start with a definition. The Penoplex Foundation material is an elastic polystyrene insulation with small granules filled with carbon dioxide. Thermal insulation can withstand heavy and long-term loads. The areas of application are:

- Foundations of all types.

- Garden paths.

- Network engineering.

In a temperate continental climate , loam deforms when thawing and freezing, damaging the foundation waterproofing layer.

The polymer has proven itself well in the segment of low-rise construction in the middle zone: it prevents the negative consequences that soil swelling .

Specifications

The main difference between the characteristics of Penoplex Foundation thermal insulation and the parameters of other product lines made from extruded polystyrene is increased compressive strength . The material is able to withstand pressure up to 27 tons per 1 square meter of area without loss of performance.

Detailed information is presented in the table:

| Name | Test method | Dimension | Index |

| Density | — | kg/m³ | 29—33 |

| Compressive strength at 10 % linear deformation, not less | GOST EN 826-2011 | MPa (kgf/cm2; t/m2) | 0,27 (2,7; 27) |

| Water absorption in 24 hours, no more | GOST 15588-86 | % by volume | 0,4 |

| Fire resistance category | F3-123 | Group | G4 |

| Thermal conductivity coefficient at ( 25 ± 5 ) °C | GOST 7076-99 | W/(m×°K) | 0,030 |

| Operating temperature range | THAT | °C | —100 … +75 |

The insulation does not contain fire retardants , so it cannot be used in places with elevated temperatures .

Read here about the characteristics of other types of Penoplex.

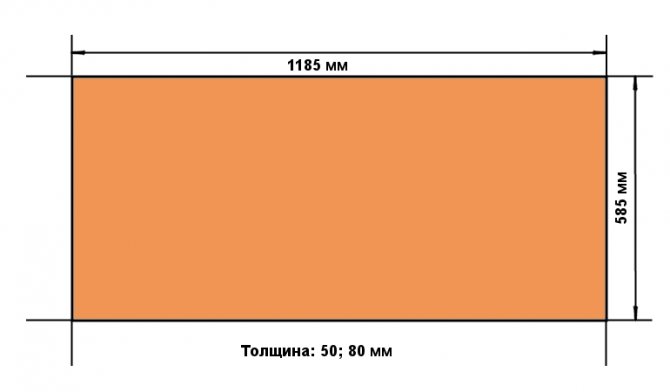

Standard sizes of insulation boards

The manufacturer produces Penoplex Foundation thermal insulation with the same length and width, only the sheet thickness is a variable indicator. The most popular product format is 1200 × 600 × 50 mm, but the dimensions are not entirely accurate, in fact there is a difference of 5 mm:

| Length | Width | Thickness |

| 1185 mm | 585 mm | 50;80 mm |

| Number of sheets per package | ||

| 50 mm | 80 mm | |

| 7 PC. | 5 PC. | |

The factory conveyor equipment assembles insulation boards into packages with a standardized thickness - from 350 to 400 mm. The thinner the sheets, the more of them there are in the briquette.

cares about its reputation, therefore it offers consumers only high-quality products from the “Foundation” line. On the official website you can see the quality certificate -

.

Application of penoplex "Comfort"

The use of this type of insulation is possible in almost any climate zone. It can be used not only for thermal insulation of floors, but also for insulation of swimming pools, saunas, baths and other rooms with high humidity levels. Installation work on laying sheet material does not present any difficulty; it has clear geometric shapes; for ease of joining, the edges are made in the form of the letter G. Penoplex “Comfort” is successfully used for insulation:

- balconies and floors;

- ground floor;

- building roofs;

- wall structures;

- foundation bases.

Options for using penoplex "Comfort" for roof insulation

The thickness of this type of expanded polystyrene can reach 15 centimeters, this determines the mechanical strength of the coating and significantly increases the service life of the building structure. In direct contact with moisture or soil, Comfort penoplex, due to its antifungal properties, is not subject to rotting and decomposition.

Floor insulation on joists

Insulating the floor on joists begins with inspecting and replacing damaged areas and treating the boards with a special compound that prevents them from rotting. Then all cavities are leveled with putty, the surface is dried and covered with primer. Sheets of insulation, pre-cut to the required sizes, are laid on dry boards with a minimum gap. The joints are taped with tape.

Sheets of material intended for arranging a vapor barrier layer are laid on top with an overlap. Chipboards, plywood or other similar material are attached to the most leveled surface, and parquet, laminate or linoleum is laid on top. This results in several layers:

- beam floors;

- wooden lumber;

- foam sheets;

- vapor barrier layer;

- panel covering;

- material used as flooring.

Floor insulation with laying on the ground

Penoplex "Comfort" is laid on the ground to insulate the floor in building structures, which are supported by a strip or pile type foundation. A layer of crushed stone or gravel is poured onto the leveled soil, and sifted sand is placed on top of it, which is compacted tightly.

Sheets of insulation are laid on the resulting surface with minimal gaps, the joints of which are made using tenons and grooves cut into them. A film is placed on top of the insulation to form a waterproofing layer, a reinforcing mesh is laid, and the surface is covered with cement mortar. After it dries, the floor covering is laid. The following layers are obtained:

- soil surface;

- crushed stone backfill;

- sand cushion;

- insulation;

- film waterproofing;

- mesh reinforcement;

- layer of cement mortar;

- material used as flooring.

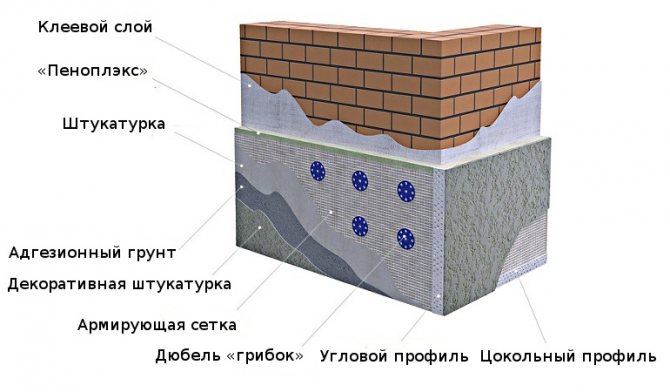

Insulation of walls from the inside

Insulating walls from the inside begins with thoroughly cleaning them and applying a layer of soil to their surface. The insulation sheets are strengthened with glue and plastic fasteners. The gaps between the joints are filled with construction foam. If their width exceeds 100 mm, scraps of insulation boards must be inserted into the cavities.

Insulation of the walls, floor and ceiling of the loggia with penoplex

A reinforcing mesh is strengthened on the resulting surface, on top of which a layer of mounting plaster is applied. After it has dried, finishing plaster is applied to the surface and the final covering of the walls with wallpaper or painting is carried out. Thus, the following layers are formed:

- primed surface;

- adhesive layer;

- insulation sheets;

- fiberglass mesh;

- plaster layer;

- putty;

- wall finishing material.

Advantages

The Penoplex Foundation material has the following advantages:

- Good thermal protection . Thermal conductivity is only 0.032 W/(m×°K), which is 63 times lower than that of reinforced concrete.

- Minimum water absorption . The insulation absorbs only 0.5 % of moisture from its own volume in 28 days .

- High compressive strength . The insulator can withstand a load of 27 t/m² - 3 times more than foam plastic.

- Long service life . The polymer does not lose its properties for 50 years after installation.

- Environmental friendliness . There are no harmful components in the composition, so penoplex is not dangerous to the health of people and animals.

Areas of application

Thermal insulation has a wide range of uses, although there are limitations. The Penoplex Foundation product is intended for installation in places with high pressure and low temperatures .

The structure of polystyrene is destroyed by contact with sunlight , so insulation boards must be covered with finishing materials .

Foundations

Basements and underground floors suffer the most from the effects of harsh climates. The main bottlenecks of the foundation:

- Waterproofing membrane . The material preserves the thin film from tearing when backfilling.

- Freezing . The insulator has low thermal conductivity, so negative temperatures are not dangerous for basements and floors.

- Groundwater . The insulation does not absorb moisture, which ensures unhindered drainage.

- Soil heaving . The dense structure of the polymer protects the foundation structure from the pressure of deformed soil.

Penoplex has high biostability . It does not decompose in the ground under the influence of microorganisms and is able to flawlessly solve its problems for 50 years after installation.

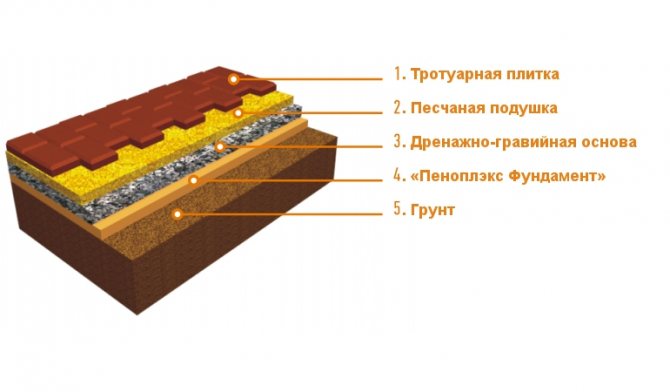

Garden paths

If the surface of garden paths is laid on loam, in the spring cracks may appear in the asphalt, and the bricks of the paving slabs will move out of their places. The insulation copes with the following problems:

- Frost deformation . Durable material will “absorb” soil pressure, like a shock absorber, and prevent the coating from “creeping”.

- Ice . "Penoplex Foundation" will protect the paths from continuous icing, and the owners of the site will not slip.

- Cooling down . Polystyrene will retain heat on paths with a heating system, thereby reducing utility bills.

Insulation should not be laid on bare ground. First you need to cover the soil with a layer of geotextile and pour a sand-gravel mixture on top.

Septic tanks

The material reliably insulates septic tanks, preventing them from freezing even in extreme cold. As a result, the number of accidents is reduced and the risk of sewerage blockage disappears.

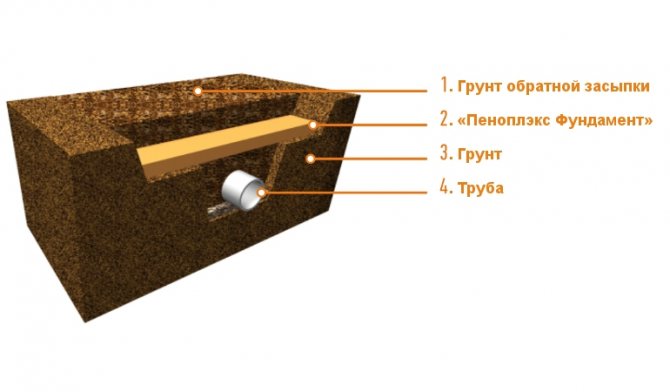

Pipelines and drains

The insulator keeps drains from icing, clogging and failure in severe weather. Water and sewer pipes are especially vulnerable in winter. Polystyrene will protect their contents from frost.

“ Penoplex Foundation ” is one of the few Russian-made materials that can be safely used when arranging protection for a private home from winter cold.

Absolute inertness to the effects of bacteria and mold , high strength and low thermal conductivity - thanks to these qualities, builders and owners of country real estate choose domestic insulation.

Insulation of the foundation with penoplex. Technology of work execution

Subsequence:

- Excavation;

- Preparatory work;

- Waterproofing the base of the building;

- Installation of Penoplex slabs;

- Plastering the surface.

The design of a thermally insulated strip foundation consists of:

- vertical foundation wall;

- waterproofing;

- thermal insulation Penoplex;

- cement-sand leveling layer;

- backfilling with soil;

- horizontally laid Penoplex;

- concrete blind area.

The design of a thermally insulated slab foundation consists of:

- sand cushion;

- Penoplex insulation;

- waterproofing layer;

- screeds;

- waterproofing of end faces;

- insulation of end faces with Penoplex;

- horizontal thermal insulation;

- concrete blind area.

Excavation

The soil is excavated in the form of a trench to the freezing depth in a given region. A drainage pipe is installed to drain groundwater. A sand cushion is laid at the bottom of the trench and crushed stone or gravel is added. Then, geotextile is laid on the bottom of the trench, and its edges are wrapped on the walls of the trench. A drainage pipe is laid on the geotextile at a slope of 2 cm per meter and covered with crushed stone.

Preparatory work

If an existing building is being insulated, then the foundation walls could lose their integrity. Protruding sharp protrusions or fittings can damage waterproofing or thermal insulation. The damaged structure is cleaned with a brush and the surface is plastered.

Sequence of preparatory work:

- installation of lighthouse guides. They are attached to the foundation, in increments of about a meter, to the entire height of the base with a protrusion above the ground of 50 cm;

- if the leveling layer is more than 2.5 cm thick, then it is necessary to reinforce this section of the foundation with a chain-link mesh;

- a cement-sand mortar is mixed in a ratio of 1:4 to the required consistency;

- the mortar is poured onto the foundation from the bottom up;

- using the rule, excess solution is removed. The rule is carried out from top to bottom along the guide beacons;

- The leveling layer is applied immediately after the first layer has dried.

Subsequent work is carried out only after the leveling layer has dried.

Waterproofing works

There are several ways to waterproof a foundation. The most common are:

- Bitumen waterproofing. The bitumen is heated to a liquid consistency and applied to the foundation using a brush. It is necessary to coat with bitumen in 2 or 3 layers. The resin penetrates into all pores and prevents moisture from entering. The operating time of bitumen insulation is very short, so bitumen is used with polymer additives that extend the service life of the material;

- Roll waterproofing. For this type of waterproofing, roofing felt, TechnoNIKOL, hydrostekloizol, technoelast, etc. are used. Rolled material is not able to penetrate the pores, so it is necessary to use mastic. The resin is applied to the surface of the foundation. After which, the roofing felt is heated with a burner and glued to the foundation structure with an overlap of 15 cm. Mastic is applied on top of the roofing felt and the next layer of roofing felt is arranged;

- Waterproofing with liquid rubber. This material has good adhesion to the surface, long service life and no seams. Liquid rubber is applied to the surface of the foundation. After the first layer has dried (this takes about a day), a second layer of rubber is applied.

Installation of Penoplex thermal insulation boards

Penoplex is attached in a vertical position from bottom to top. The slabs are attached using special glue or bitumen mastic. It is unacceptable to use dowels, as they can damage the waterproofing.

Additional fastening with plastic umbrellas is possible on the base. This is done after the glue has dried. Fixation occurs in the corners and in the center of each slab.

The glue is applied to the slab (about 40% of the surface), which is pressed against the surface of the foundation and held for about a minute. Then the next plate is mounted, which is installed in the groove next to the first one. The gaps between the plates are covered with glue. The second layer is applied in the same way, but offset so that the joints of the first layer overlap.

Leveling the surface

A reinforcing mesh with an overlap is mounted on Penoplex to avoid the formation of cracks. After which plastering is carried out with cement-sand mortar or special plasters for external use.

After completing the main work, the foundation is backfilled. But not completely. At a depth of about 30 cm, sand is added and the soil is compacted. Then waterproofing is laid on the sand and a horizontal thermal insulation layer of penoplex is laid on top of it.

After installing the horizontal layer, you can make a blind area around the perimeter of the structure. With this insulation technology, the foundation of the building will be protected from excess heat loss. Horizontal insulation under the blind area will be the key to protecting the base of the building from seasonal movement of soil masses.