- home

- Services

- Residential insulation

- What is the best way to insulate a floor under a screed? We understand the choice of optimal material

—

—

—

Since about 30% of all heat loss occurs through the floor, it needs insulation in the same way as other structural elements of the room - walls and ceiling. The main method of thermal insulation is insulating the floor under the screed.

When insulating under a screed, it is very important to choose the right thermal insulator. Insulation materials such as expanded clay, polystyrene foam, mineral wool, penoplex and polyurethane foam are most often used as insulation for installing a heat-insulating layer under screed. You can also install a floor heating system, which can be infrared, electric or water.

Insulation with expanded clay

Expanded clay is a highly environmentally friendly, fire-resistant material.

Expanded clay is a highly environmentally friendly, fire-resistant material. Polystyrene foam granules are highly porous, which increases the water absorption of the material; in addition, expanded clay is a fragile insulation material, so backfilling of the expanded clay thermal insulation layer should be done carefully.

In order for the floor to withstand significant loads, the thickness of the expanded clay layer must be at least 15 centimeters. This thickness entails an increase in the floor level, so expanded clay is not used for insulating rooms with low ceiling heights.

The expanded clay thermal insulation layer should be carefully insulated from moisture penetration, and before applying the concrete screed, the structure must be additionally reinforced.

Read more about floor insulation with expanded clay here: /uteplenie-pola-keramzitom-nedostatki-materialov-chto-podojdet-luchshe/

Foam insulation

Insulation with foam plastic sheets is carried out by analogy with floor insulation with penoplex.

You can insulate the floor either with foam plastic slabs or apply a screed with the addition of insulation granules.

When insulating with polystyrene foam granules, they are mixed in a 1:1 ratio with cement and the resulting mixture is poured onto the floor. It should be taken into account that the thermal insulation properties of such a coating leave much to be desired, and the strength characteristics of the floor also decrease.

Insulation with foam plastic sheets is carried out by analogy with floor insulation with penoplex. Sheets of material can be fastened either with adhesives or with dowels.

Insulation with mineral wool

Mineral wool has high sound insulation properties. Due to the high hygroscopicity of the insulation, the mineral wool thermal insulation layer must be completely isolated from contact with moisture.

Technology of floor insulation with mineral wool mats

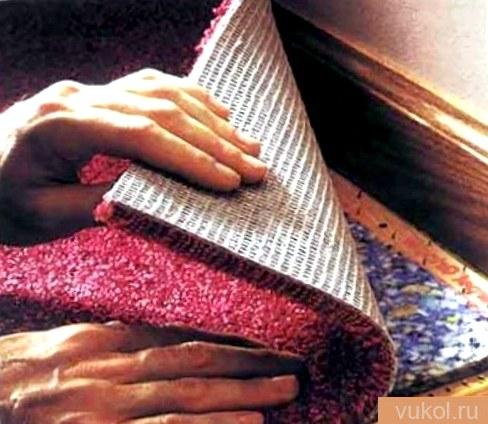

Before installing mineral wool mats, it is necessary to remove the old floor covering

Before installing mineral wool mats, it is necessary to remove the old floor covering, clean the floor from existing contaminants, cover cracks and crevices, then lay a waterproofing film, mineral wool mats and a vapor barrier membrane. Clamps are installed on top of the structure in order to provide the necessary ventilation gap, and a reinforcing mesh of 3 mm wire is mounted on top of the clamps.

A leveling concrete screed is applied on top of the reinforcing mesh. If significant static and dynamic loads will not act on the floor, then the concrete screed can be lightened by adding expanded clay to it.

Floor insulation with polystyrene foam

To make the house warm and cozy, care should be taken not only to insulate the walls, but also the floors. Do-it-yourself floor insulation with polystyrene foam is a relatively simple technology for thermal insulation of floors. The material itself is environmentally friendly and safe, and it is for these qualities that it has become very popular today. Insulating floors with foam plastic, you can also watch the video below, which describes in detail the nuances of the work.

Features of the material

Today, expanded polystyrene is an inexpensive and accessible material. It is often used for thermal insulation in city apartments and private houses. Expanded polystyrene is available in various grades, which differ in performance characteristics and material thickness. The floor on the first floor is insulated with polystyrene foam using PSB-S-35 grade slabs. Their thermal conductivity is approximately 0.038 W/sq.m, water absorption is no more than 2%. The edges of the slabs can be milled or flat, which makes it possible to overlap them using the tongue-and-groove principle, thereby reducing the risk of the formation of cold bridges.

If it is necessary to use a material that can withstand heavy loads, it is recommended to choose expanded polystyrene grade PSB-S-50. This is an excellent insulation option for garages and other utility rooms. The only drawback of this material is that upon contact with organic resins it begins to dissolve.

Advantages and disadvantages of floor insulation with extruded polystyrene foam

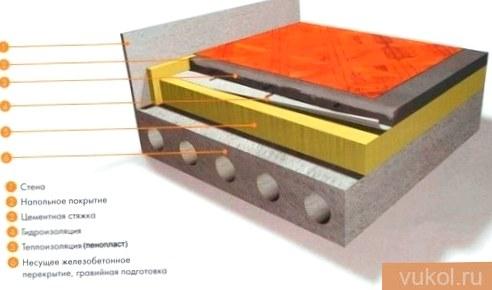

As a rule, experts recommend carrying out thermal insulation work for the floor using extruded polystyrene foam. The fact is that, in comparison with conventional slabs, it is characterized by greater hardness due to its dense cellular structure. On the ground floor it can be laid on a layer of gravel.

This is an excellent option for heat-insulating material where a very large load on the floor is expected. Therefore it is suitable even for industrial buildings. The advantages of this method include low coefficients of water absorption and thermal conductivity, due to which a gravel base is suitable for expanded polystyrene, and it can also be laid on the first floors of houses where groundwater is close to the surface.

However, floor insulation with extruded polystyrene foam also has its drawbacks. In particular, it is worth noting that this material is capable of dissolving upon contact with resins and mastics of organic origin.

Technology of floor insulation on the ground with polystyrene foam

The peculiarity of this technology is that the thermal insulation layer and the floor are in direct contact with the ground. Sometimes even with groundwater. Therefore, this method of floor insulation with polystyrene foam is aimed at improving waterproofing. Here you need to take into account the presence/absence of a basement. If there is one, then the thickness of the polystyrene foam when insulating the floor can be made smaller, but it should only be laid on top of the waterproofing barrier.

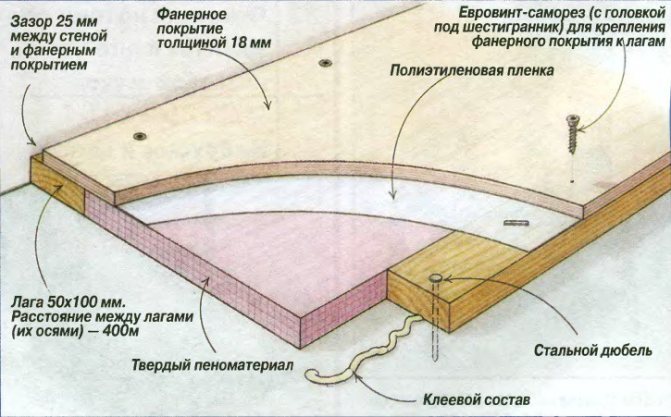

There are two possible options here. The first involves: a flat floor and decking, which are covered with gravel or slag and then compacted. Wooden logs are fixed on top, and sheets of extruded polystyrene foam are laid in the spaces between them. In the second option, the floor is insulated with polystyrene foam under the screed. So, first of all, sheets of polyurethane foam are laid, then they are covered with roofing felt, and then filled with concrete or cement-sand screed.

Stages of floor insulation with polystyrene foam with your own hands

Regardless of the material for the finishing coating, the process of thermal insulation of the floor proceeds as follows:

- Leveling the subfloor;

- Arrangement of a “pillow” of crushed stone approximately 10 cm thick;

- To fill voids, use expanded clay sand;

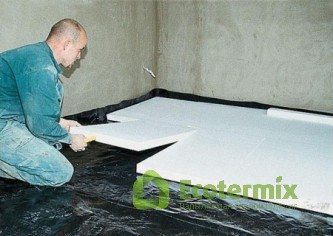

- Lay polystyrene foam slabs on the prepared floor;

- The insulation layer is covered with a waterproofing film, and at the joints there should be an allowance of 5 cm;

- To strengthen the floor, a reinforcing mesh is placed on top, which allows you to evenly distribute the load across the floor.

If you are planning to install a screed, then pouring it will be the next step. The final touch will be the finishing of the floor, which involves installing laminate, parquet or linoleum.

The video below shows how insulation work is carried out.

Insulation of a concrete floor with polystyrene foam

In most cases, the technology of work is similar to floor insulation with polystyrene foam under a screed. But this option is more labor-intensive. It should also be remembered that when a concrete floor is insulated with polystyrene foam, the height of the room decreases. True, there are cases when the thickness of the concrete screed is made no more than 5 cm; another amount is given for the thickness of the insulation. If the surface of the ceiling is leveled, it is permissible to use only polystyrene foam boards, which will allow you to gain a couple of extra centimeters.

polgid.ru

Penoplex insulation

Penoplex is a polymer insulation, the structure of the material is closed cells. It is thanks to the penoplex structure that the insulation has high moisture-repellent properties and has high compressive strength. In addition, the material is fireproof, which allows the use of a heat insulator for insulating wooden floors.

Penoplex floor insulation technology

Linoleum, tiles, laminate and other finishing materials can be used as flooring.

Before laying the insulation, it is necessary to thoroughly compact the soil, pour a layer of crushed stone and make a sand cushion. Penoplex sheets are laid on the base prepared in this way. The insulation must be laid in a checkerboard pattern, and all joints between the insulating boards must be taped. A waterproofing film is mounted on top of the heat-insulating layer and a reinforcing mesh is installed, which ensures the resistance of the floor to dynamic and static loads. A layer of leveling screed is applied on top of the structure, the thickness of which should be 4 centimeters. After the screed has dried, the floor covering is laid. Linoleum, tiles, laminate and other finishing materials can be used as flooring.

Before pouring the screed, a temperature gap should be created. It is necessary to lay a buffer tape along the entire perimeter of the room, and the gap between the screed and the wall should be about 1 centimeter.

More information about floor insulation with penoplex: /osobennosti-utepleniya-pola-penopleksom-pochemu-penopoliuretan-gorazdo-luchshij-vy-bor/

Instructions for insulating a concrete floor

Next, you are invited to familiarize yourself with step-by-step guides for working with each of the materials discussed above.

We use fibrous materials

When choosing the thickness of the thermal insulation layer, you should focus primarily on the manufacturer’s recommendations given in the accompanying instructions. In practice, a 50-100 mm layer of insulation is usually sufficient. In regions with cold climates, this figure can be increased.

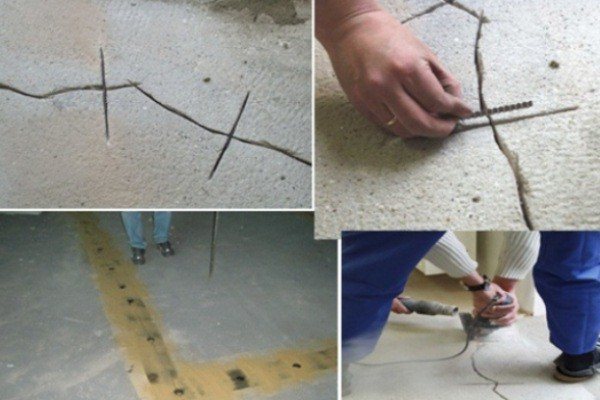

First step. Preliminary preparation of the base is carried out. It is necessary to seal all detected cracks (cement mortar or other suitable composition will help), traces of grease and other substances (removed with solvents or special detergents). The surface is thoroughly cleaned of debris and dust.

The concrete floor must be carefully prepared

Second step. The base is covered with a layer of waterproofing film, or even better - with a modern material that combines the properties of vapor and waterproofing, for example, isospan. When laying film sheets, a traditional 10-15 cm overlap is maintained. Subsequently, the joints are taped with metallized tape.

Laying isospan

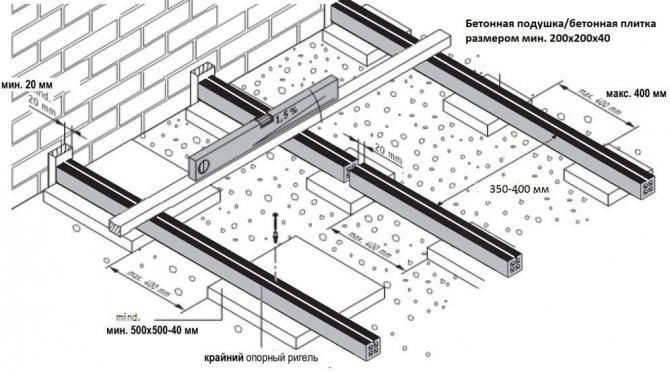

Third step. Logs are installed. The height of these elements must correspond to the thickness of the thermal insulation layer being installed. Also choose the installation step in accordance with the size of the insulation - it should fit tightly into the openings and without gaps. To fix the lags, dowels, screws or other suitable fasteners are used.

Scheme of laying support beams concrete base

The photo shows how to install the logs

Fourth step. The insulation is placed in the space between the joists and covered with a special waterproofing membrane film with vapor-permeable properties. This material has a rough and smooth side. The rough side of the film should be laid towards the thermal insulation, the smooth side away from it. Thanks to this material, steam will be removed from the thermal insulation layer, which will eliminate the risk of the mineral wool becoming damp and will additionally ensure its protection from water.

The principle of laying insulation between joists

Multilayer laying of insulation

Vapor barrier film

Fifth step. On top of the resulting structure, perpendicular to the joists, sheet plywood or tongue and groove boards are laid. The flooring elements are attached to the joists using self-tapping screws. After this, you can arrange the selected finishing on top, completing the necessary previous measures, if required by the installation technology of a particular material.

Floor plan with plywood covering

We use foam materials

Most often, polystyrene foam/polystyrene is laid followed by pouring a concrete screed. The mentioned materials are characterized by good waterproof properties, which allows them to be used in kitchens, bathrooms and other rooms with high humidity levels.

Extruded polystyrene foam

| Index | Polyspen | Polyspen Standard | Polyspen 45 | Control method |

| Density, kg/m3 | 30-38 | 30-38 | 38,1-45 | 5.6 each |

| Bending strength, MPa, not less | 0,4 | 0,4 | 0,4 | 5.8 each |

| Water absorption in 24 hours, % by volume, no more | 0,4 | 0,4 | 0,4 | 5.9 each |

| Thermal conductivity at 25+-5 degrees Celsius, W/m * °C, no more | 0,028 | 0,028 | 0,030 | at 5.10 |

| Toxicity, Hcl 50, g/m3 | T2 moderately hazardous | T2 moderately hazardous | T2 moderately hazardous | at 5.11 |

| Flammability group | G-3 normal-flammable | G-4 highly flammable | G-4 highly flammable | at 5.12 |

| Flammability group | B-2 moderately flammable | B-3 flammable | B-3 flammable | at 5.13 |

| Smoke coefficient | High smoke generating ability | High smoke generating ability | High smoke generating ability | at 5.14 |

| Compressive strength at 10% linear deformation, MPa, not less | 0,2 | 0,2 | 0,3 | 5.7 each |

The preparatory stage is similar to the previous instructions. After completing the necessary preceding activities, the main stage of work begins, carried out in the following sequence:

- Plates of heat-insulating material are laid on the surface. If you bought polystyrene foam/polystyrene designed specifically for thermal insulation work, the elements will most likely be equipped with special grooves. Thanks to these devices, the work will be done easier and better, without the appearance of gaps;

Laying slabs on the floor - the lower part of the walls along the entire perimeter of the room is covered with a damper tape made of foam material. Thanks to this tape, thermal deformations of the screed will be compensated, which will preserve the integrity and performance properties of the structure. If there is a layer of adhesive at the bottom of the tape, fixation is performed with its help. If this is not available, the material is secured using dowel-nails;

- the insulation is covered with thick polyethylene film. The strips are traditionally laid with a 10-15 cm overlap, followed by gluing the joints with tape. The film will prevent the screed being poured from falling through between the slabs, which will prevent the formation of voids and cracks;

- a reinforcing frame made of steel or PVC is laid, the screed solution is poured, leveled over the base and left to gain strength. Traditional concrete screeds take about a month to dry. It is recommended to cover the concrete with a layer of polyethylene while it hardens, and regularly moisten the screed with water to prevent the formation of cracks. Finally, all that remains is to lay the selected finish on top of the dried screed.

The photo shows a layer of expanded polystyrene with reinforcement and pouring the solution

The considered thermal insulation system can be used in combination with a water floor heating system. In this case, the heating circuit will be laid on top of the reinforcing mesh.

We use sprayed materials

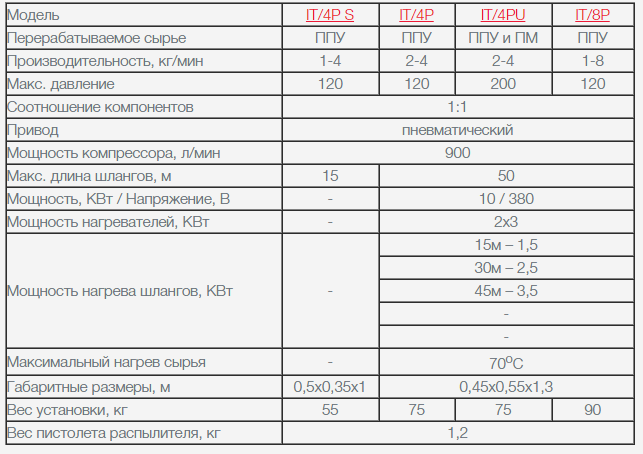

As noted, the application of sprayed thermal insulation materials requires appropriate skills, and, in the case of most insulation materials used in this category, special equipment.

The process of spraying insulation

The surface is covered with heat-insulating material, in most cases in the form of foam. As the material dries, it expands, resulting in a seamless insulating layer. To apply foam, a special apparatus is used, designed to mix carbon dioxide and polymer liquid under high pressure conditions.

Characteristics of pneumatic equipment for applying insulation

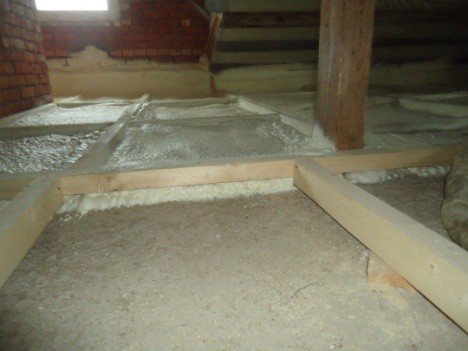

The actual work on arranging sprayed thermal insulation for a concrete floor is carried out in the following sequence.

First step. Dust and debris are removed from the surface. The floor is cleaned of all kinds of stains, traces of bitumen and other similar things - because of them, the structure of the foam will be disrupted. There is no need to pre-level the base if there are no large bulges or depressions.

Second step. Wooden logs are attached to the base. To make them, you can use a 4-centimeter board or timber. The elements are fixed in a standard way, using self-tapping screws, dowels and corners. The logs are set according to level. They will allow you to control the level of arrangement of the thermal insulation layer and facilitate the process of further installation of the finishing floor covering.

In the photo there are logs and sprayed insulation

Third step. The concrete base is moistened. This will improve the adhesion of the foam to the base.

Fourth step. Using a special installation, polyurethane foam is sprayed over the surface. The performer’s task comes down to uniformly filling the space between the previously installed logs. It is important to remember that as the foam hardens, it increases in size.

Insulation of concrete screed under the floor in an apartment

Standard sprayed thermal insulation materials take about a day to dry. After the polyurethane foam has dried, sheets of plasterboard, a wooden board or sheet plywood are laid on top of the joists, and then the selected finish is installed.

Due to good adhesion to all building materials, the foam forms a continuous layer

Important! Polyurethane foam does not tolerate direct contact with sunlight. It is strictly not recommended to leave the material uncoated for a long time.

You have become familiar with the procedure for insulating a concrete floor in accordance with the most popular and preferred methods. Of course, there are other technologies, for example, dry filling with expanded clay, but the effectiveness of such methods is in many ways inferior to those studied above. Otherwise, the choice of a specific thermal insulation option is up to you. Focus on the features of the location and operation of the building, the available budget and your personal preferences. You have already familiarized yourself with all the necessary information for the successful implementation of thermal insulation measures.

Good luck!

Insulation with polyurethane foam

Liquid thermal insulator polyurethane foam is an ideal insulation material for floor insulation

Liquid heat insulator polyurethane foam is an ideal insulation material for floor thermal insulation, since it is sprayed directly onto the surface to be insulated and does not require the creation of additional vapor and waterproofing layers.

Among all thermal insulation materials, polyurethane foam has the lowest thermal conductivity coefficient, which allows the insulation to be sprayed in a thin layer, significantly saving the usable area of the room.

Polyurethane foam has all the properties necessary to ensure high-quality thermal insulation of the floor. It is fireproof, environmentally friendly, chemically and biologically inert, and has high sound and moisture repellent properties. The high strength of the polyurethane foam layer allows you to apply a leveling screed on it without laying a reinforcing mesh.

The technology of spraying insulation makes it possible to easily and quickly insulate surfaces of even very complex configurations. The polyurethane foam thermal insulation layer hardens within 3-4 hours. Immediately after the thermal insulator has hardened, you can begin applying the leveling screed.

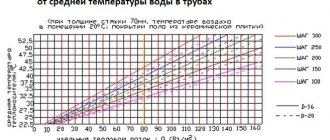

Organization of floor heating by installing a “warm floor” system

When installing a heated floor system, it is necessary to install a waterproofing layer, then lay insulation (penoplex, polyurethane foam, polystyrene foam, mineral wool mats), cover the structure with aluminum foil, which will act as a heat shield that reflects thermal energy, install the “warm floor” system (lay pipes or electric mats), complete the finishing fill and lay the selected floor covering.

We recommend that you first watch the video below to clearly understand how this happens:

Features of cement floor insulation

Before you begin directly to work on insulating a cement floor, you need to understand the insulation technology and choose a more suitable insulation option from the available ones.

The development of insulation of a cement floor is contained in the development of multilayer thermal insulation and has several steps to complete the work. The first step of insulating a cement floor is carried out before pouring the preliminary screed. The second step of insulation occurs during the creation and pouring of the cement mixture. At the 3rd step, the insulation of the cement floor is carried out during the creation of the floor covering. It is necessary to emphasize at the meeting that it is optimal to insulate a cement floor when it is developed from scratch. This is the only way to ensure a high-quality level of insulation.

There are only a couple of methods for insulating a cement floor. Any of them is produced in due time as sex is created. Some of these methods are discussed in more detail below.

- Laying a heat insulator under a cement screed . Such insulation is carried out during the creation of a cement floor from scratch. Based on this, if you want to insulate the floor in an already built house, you will first have to completely destroy the dilapidated cement screed to the base. With this method of insulation, materials with high strength, resistance to mechanical loads, moisture-resistant and long-lasting are used.

- At the moment, the “warm floor” system , which allows proactive heating of the cement floor over its entire area. Such a system is placed on top of a layer of heat insulation and filled with cement screed. Warm floors can be water or electronic. In any case, heating the floor using such a system will require the use of an external source of energy. Cement insulated water floors or electronic insulated floors mainly refer to the active heating system. But in general, they are great for insulation.

- Another option for insulating a cement field is to add aggregates such as expanded clay or perlite to the mixture instead of the usual crushed stone. Thanks to their thermal insulation properties, these materials can reduce the thermal conductivity coefficient of concrete several times. Concrete with expanded clay or perlite can be used both as a base on the ground and as a screed.

- One of the widespread options for insulating cement floors on upper floors is the creation of a “raised floor” . This method of insulation involves refining the wood logs and filling the space between them with a heat insulator. This approach is needed because it reduces the non-specialized load on the foundation of the house, and is useful for those who do not want to bother with pouring a cement screed.

- A ready-made cement floor can also be insulated using a floor covering. To do this, it is enough to use insulated floor materials . For example, warm linoleum or carpet. In addition, when developing the final floor covering, a layer of cork, foam cellophane or other thin-layer thermal insulator can be laid underneath it.

All of the above insulation methods, depending on the situation, can be used both in combination and separately. So, for example, if it is not possible to lay a heat insulator under the screed, it may be limited to the use of expanded clay and the creation of a multi-layer final coating. Or, when developing a “warm floor” system, do not equip a multi-layer warm final coating.