Plastic materials have long begun to occupy a leading place among plumbing systems. They are quite practical, have a lot of positive qualities and sometimes even cost a little less than metal structures. However, it is worth saying that there is simply a huge number of similar products and therefore the question of how PVC pipes are installed is of great interest to novice craftsmen.

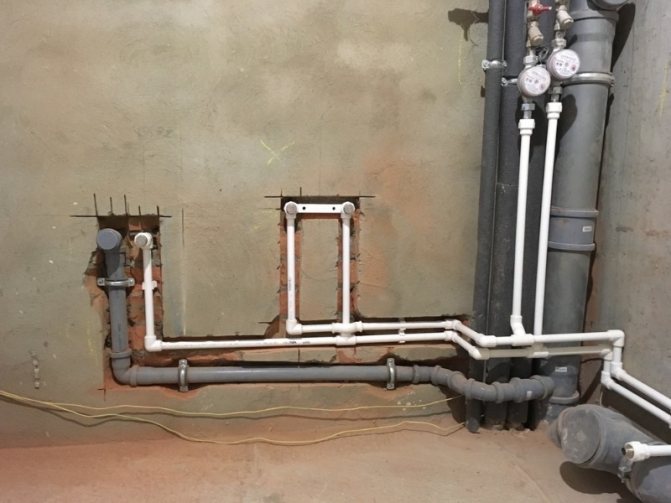

Amateur photo of the sewer pipe system located under the bathroom

Which pipes to choose for installing water supply in an apartment

The water supply in the apartment comes from a central riser and includes taps, filters that protect against mechanical and chemical impurities, meters, outlets to plumbing and other connections.

For the installation of water supply pipes made of metal-plastic and plastic are suitable.

The use of steel pipes is a thing of the past; copper pipes are still found, but their popularity is also falling.

Copper

The advantages of copper pipes include versatility - they can be used for hot and cold water. They do not clog and resist corrosion well, and their service life can be about 70 years.

But the disadvantages of copper pipes compared to the advantages of plastic products make their use undesirable. Copper parts are expensive, installation of joints requires special skills - without a specially trained worker it is unlikely to be able to do this, which will lead to additional costs.

Joints in copper pipelines are soldered with tin. Therefore, in hard-to-reach places, assembling the water supply system will be difficult.

Now developers and residents renovating apartments use polymer pipes, which are divided into metal-plastic and plastic.

Metal-plastic

Metal-plastic is durable, has a smooth inner surface, and is highly resistant to corrosion. Metal-plastic pipes are easy to install yourself. This is due to the high elasticity of the material, the ease of making joints and the available tools for the job. The ability to bend at any angle leads to lower costs as the number of fittings is reduced.

The pipes are connected by crimping or threaded connectors. The use of a compression fitting eliminates the possibility of bricking up metal-plastic connections - as a result of temperature fluctuations, the tightness is weakened. This leads to the need for preventive crimp tightening approximately once a year.

To join plastic products yourself, all you need to do is purchase or rent a pipe cutter.

If you use a compression fitting, you will need pliers for crimping it, and if you choose threaded connectors, you will need adjustable wrenches. In both cases, you should not neglect the calibrator and anchor to remove burrs on the cuts.

Another advantage is the many connectors that allow you to join metal-plastic pipes with products made from other materials.

Plastic

Plastic pipes for transporting water are divided into several types based on their chemical composition and properties. The most common are:

- polybutylene;

- polyethylene;

- PVC;

- polypropylene.

Polybutylene can withstand temperatures of +90°C, so pipes made from it are most often used for installing heated floors. The ease of installation of such networks is facilitated by their high elasticity - the pipes can be bent rather than using connectors. Joints soldered without violating technology do not leak. The disadvantage of polybutylene is its high price.

Polyethylene pipes are considered a budget option, so their capabilities are limited. They cannot withstand the pressure of the city water supply and temperatures above +60°C.

This leads to a limitation of the area of their use to watering household plots and water supply to unheated premises. This application is possible due to the important advantage of polyethylene - products made from this material are not destroyed due to liquid frozen in them.

PVC, or polyvinyl chloride, also belongs to budget materials. Pipelines made from it are resistant to aggressive environments and can withstand temperatures up to +80°C. Pipes are connected using soldering or glue, but the joints are less durable than the product itself. To prevent accidents, it is recommended to use Aquastop.

Replacing a damaged section is a complex and time-consuming task, so you can choose PVC pipes when the length of the branch does not exceed 10 m and the number of water points is less than seven.

Polypropylene is used for water supply installations more often than pipes made from other materials. Despite the budget price, it is durable, can withstand water temperatures up to +130°C and can operate under a pressure of 12 atmospheres.

Polypropylene products are joined by welding. As a result, the connector material is fused with the pipe material, which allows for leak-free joints. The internal surfaces are smooth and do not form clogs.

Disadvantages include deformation from thermal expansion. Therefore, polypropylene pipes are not laid in grooves. Parts heated by hot water begin to deform, which leads to the destruction of the finish in the places of installation.

Varieties

To begin with, it should be noted that there are several types of such products, which differ in the way they are connected. Therefore, if you are installing PVC pipes yourself, then you should find out in advance about the system for combining them and the tools necessary for this. It is worth noting that this material can have completely different connection methods, according to which it is worth separating it.

Various types of tees, crosses and couplings designed for connecting routes from sewer pipes

Sewage systems

- First of all, it must be said that this type of pipe is usually connected using a rubber seal . Moreover, all components for PVC pipes have special extensions at one end, where this system is installed.

All such products are equipped with special rubber seals, which are installed in a special place created during the manufacture of the part.

- It is worth noting that the connection is quite tight and even in order to make the connection you have to use Vaseline or other fats . However, it is worth remembering that such systems cannot operate under high pressure.

- It must be said that all corners for PVC pipes are made for use with other products from this manufacturer . Therefore, experts recommend purchasing products from one brand.

- It is important to mention that each separately developed system is practically unique or adapted to a specific apartment plan . Taking this into account, any work should begin with the creation of a project or installation plan.

Advice! When connecting such elements, distortions must not be allowed. Otherwise, leaks may occur in these places. That is why it is also recommended to thoroughly wipe the rubber bands before installation.

Such lines are fixed to the wall using special fasteners in the form of a clamp.

Crimp couplings

Recently, special clips for PVC pipes have begun to gain some popularity, allowing for fixation when connecting two sections. It must be said that such systems showed excellent performance when working under pressure.

Along with conventional connecting elements, crimp fittings are also very often used.

The fact is that a crimp coupling for pipes consists of a brush on which the pipe is mounted, a cut ring and a nut. In this case, the fixation principle works in such a way that when pressure is applied, the ring begins to hold the material on the brush even more strongly.

The principle of operation and appearance of compression fittings

It is necessary to mention that there is a special cutter for PVC pipes. It allows you to obtain material of the required length, without distortions, burrs or great physical effort. However, it must be said that such products are designed to work with pipes of a certain diameter.

Advice! Typically, such systems are used for laying open routes or in basements. Similar materials also exist in the form of watering systems for garden use.

Assembly of adhesive materials is quite simple, but it is not suitable for all technical conditions

Glue or soldering iron

First of all, it must be said that the standard installation instructions do not require the use of glue when working with PVC materials. However, some craftsmen use it to strengthen joints, using it together with a special additional sealant.

A special knife designed for cutting such materials

A regular soldering iron, which is used for polypropylene products, is not suitable for working with this material. In fact, such pipes are not used for domestic purposes, although they are simply irreplaceable for outdoor installation.

Soldering irons of this type are only used with polypropylene systems for which they were designed

It is worth noting that such systems use butt soldering of pipes. This requires special equipment, the price of which is quite high, and it is simply impossible to rent it. However, these types of connections can be considered the most durable and reliable.

Advice! Sometimes it is much easier to use the services of special teams than to carry out the installation yourself. This will significantly help reduce time and eliminate errors that can be made when making calculations.

Butt welding of polyethylene pipes using special equipment

Why is it important to make a plan?

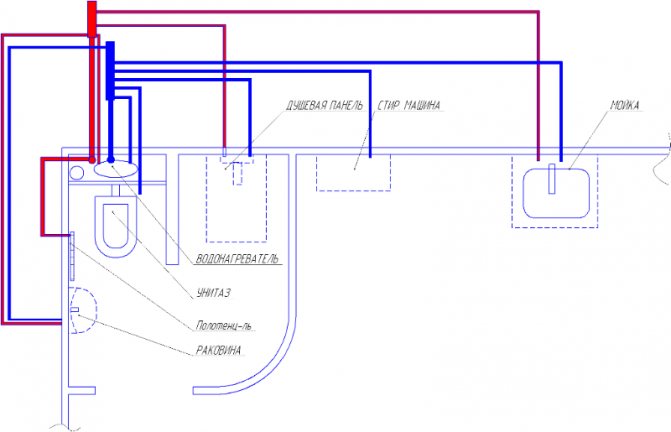

Pipe routing begins with a drawing. Water supply design cannot be neglected. The task of delivering water to all water distribution points in a residential area is not an easy one.

The home owner will want to install a shower cabin, a dishwasher and an automatic washing machine. The bathroom is located in a separate room, where a bidet is placed next to the toilet. The floors in the apartment are heated.

An increase in the number of water distribution devices complicates the water supply scheme and requires greater productivity of the water supply system.

In order to correctly determine the size of the pipes and the number of plumbing fixtures, fittings and other parts necessary for the water supply system, you need to carefully consider the wiring around the apartment.

The result of competent design will be efficient operation of the system and reduced costs for materials, installation and operation of the water supply system.

The pipeline diagram is drawn on the apartment plan and the names and locations of plumbing fixtures and auxiliary parts are indicated. Here the directions of pipes for hot and cold water, cross-sectional size, and material of manufacture are determined.

Such a plan is not difficult to draw even for a homeowner inexperienced in plumbing matters. To do this, it is enough to know the types of wiring and the list of devices that ensure stable operation of the water supply network.

Specifications

The abbreviation PVC is a shortened version of the spelling of the word “polyvinyl chloride,” identifying an environmentally friendly polymer with a low melting point and low frost resistance. It is worth noting that the last two not very attractive properties are compensated by the high stability and the same mechanical strength of this material. Actually, its physical characteristics give the PVC pipe the following qualities:

exceptional ring rigidity.

The product is not afraid of water hammer and can withstand pressure up to 120 atmospheres; excellent resistance to temperature deformation. When the temperature reaches the maximum permissible level, the pipe dimensions will increase by only 5%; poor heat resistance. The loss of rigidity of an adhesive polyvinyl chloride pipe is recorded at a temperature of +78˚C.

Therefore, it is not allowed to use this product when creating pipelines with a working environment temperature exceeding +40˚С; fear of low temperatures. Polyvinyl chloride can withstand cooling without irreversible changes in its structure only to -15˚C. Accordingly, if a PVC pipeline is intended to be used in regions where such temperatures are not uncommon, the plastic pipeline must be insulated.

The following points are worth highlighting from the operational characteristics:

long period of operation without the need for cleaning.

The high smoothness of the internal surface prevents siltation and clogging of utility lines; they are ideal for arranging sewage systems. This is due, again, to the smooth inner surface and small wall thickness; durability. One of the main reasons for this property of adhesive PVC pipes is the excellent resistance of the polymer to UV radiation.

Adhesive PVC pipes are available in different sizes and are used for water supply and sewerage systems

Types of plumbing wiring diagrams

In practice, wiring is done in three ways:

- using distributor tees - sequential;

- through the collector;

- with pass-through elements - sockets.

The choice of water supply layout in an apartment depends on the individual needs of the homeowner and the design features of the premises. In some cases it is appropriate to use series and collector wiring simultaneously.

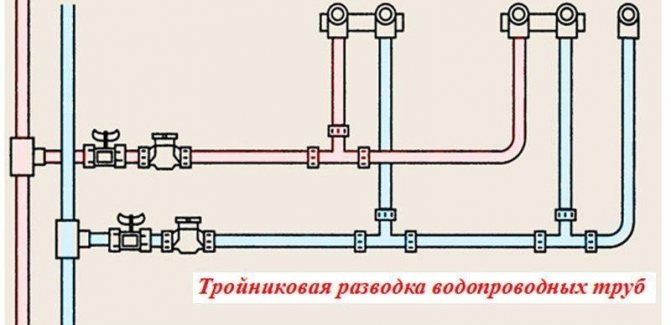

Tee

This scheme for distributing water supply in an apartment is based on the transportation of cold and hot water through two central pipelines. At the locations of water collection points, outlets are installed using tees, through which water reaches the consumer.

Since after the start of water flow through any tap, the liquid pressure in the main decreases, the central pipe is selected with a larger diameter than the internal dimensions of the bends.

In addition, it is necessary to correctly position the pipe joints. It is best to arrange them in places hidden from view. For example, in closed parts of sinks, bathtubs, wall niches. There the connections will be accessible for maintenance, but will not spoil the appearance of the room.

The main advantage of tee wiring is the minimum number of pipes, which significantly reduces water supply costs. This advantage is especially evident in small apartments, where the bathroom is combined with a bathtub.

The disadvantage of a serial connection is that the branch is completely cut off from the input in case of repair. To solve this problem, additional emergency valves can be installed, but increasing their number leads to a decrease in pressure. In addition, the tee scheme is characterized by sealing the joints into the walls. If the pipe leaks, you will have to dismantle the trim and break the wall.

Sequential wiring will be ineffective in rooms with a large number of water points on one branch. In such a section, a pressure drop will inevitably occur at the points furthest from the input, especially when several devices operate simultaneously. The consequence of such differences may be equipment malfunctions.

Collector

It is more profitable to use a collector water supply scheme in the case of a large number of water supply units in the apartment.

The main difference from the tee version is the use of a manifold. From the central riser, water is supplied to the collector, and from it to each individual plumbing fixture. Thanks to this, it is distributed evenly. Therefore, the pressure in the pipeline does not decrease at the points furthest from the input.

If repairs are necessary, only the damaged branch is cut off, and not the entire water supply. For the same reason, each branch can be mounted uniquely to suit the needs of an individual consumer. The area that supplies water to the washing machine may need to install additional filters. And they won’t be needed to operate the toilet cistern.

Due to the design differences between the water supply sections, the collector connection diagram becomes more complicated. Costs also increase because more pipes are required to lay it.

Separate collectors are purchased for distributing hot and cold water. Taps are installed between them and the risers to stop the water supply in an emergency or during repairs. Consumers receive water from collectors, and hot water and hot water supply are supplied to the bathtub and sinks. To the toilet and washing machine - only cold water, and to the heated towel rail - only hot water.

If there are a lot of water collection points, then several consumers can be connected to one branch of the collector using a tee circuit.

With pass-through sockets

A pass-through socket is a connector in the form of an elbow with a 90° bend, which is used to connect the water supply in the apartment. The design of the sockets includes brackets for fastening to the wall, threads on the consumer connection side and inlet holes for soldering to the pipe through which water is supplied.

Sockets are suitable for hidden and open installation of pipes.

To connect mixers, double sockets are produced on the strip. Such connectors are used for faucets in the bathroom or shower stall. A significant drawback is the complexity of installation - you have to solder two pipes at the same time.

Features of installation of PVC pressure pipelines

Features of installation of PVC pressure pipelines

Installation of PVC pipelines involves fitting pipes and fittings with tension. Although adhesive for PVC products has excellent sealing properties,…

Installation of PVC pipelines involves fitting pipes and fittings with tension. Although glue for PVC products has excellent sealing properties, it is still not recommended to leave a gap between pipes and fittings.

Installing pipes using glue is an easy and quick way to create durable, reliable and leak-tight connections.

Adhesive for PVC products has a chemical effect on pipes and fittings. Softening the surfaces, it penetrates into the product at the molecular level and thereby ensures a reliable, tight connection. The strength of the joints may be reduced if the adhesive is applied to poorly cleaned and unprepared surfaces.

When installing PVC pipes, the use of glue for PVC materials is mandatory! The main thing when working is to strictly follow the instructions given below.

Installation of PVC pipes - instructions

- Using a special roller pipe cutter, cut the pipe to the required length. Instead of a pipe cutter, you can also use a plastic hacksaw, but when using it, chips and dust may get inside the pipe, which will require additional cleaning of the surfaces.

- Bevel 3-5 mm long depending on the size of the pipe and at an angle of 45 degrees. This is best done using a chamfering machine.

- Measure the depth of the fitting. Mark the appropriate length on the pipe. The mark is necessary to control the correct installation and will help ensure that the pipe is completely (all the way) inserted into the fitting.

- Make sure the surface of the pipe and fitting is clean and dry and free of moisture, condensation and contaminants. Clean the surfaces thoroughly using a special cleaner, applying it to a paper or cloth napkin.

- Using a clean brush or the applicator that came with the adhesive, apply the adhesive to the surface of the pipe and fitting you want to join. The adhesive layer must be uniform and completely cover the area to be joined. It is very important to apply the glue quickly so that it does not harden, and during installation you do not have to exert unnecessary physical effort to insert the pipe into the fitting.

To apply the glue, use the correct size brush. The diameter of the brush should correspond to half the diameter of the pipe being mounted.

- After applying the glue, insert the pipe completely into the fitting. Hold them in your hands in this position for some time: a few seconds for pipes with a diameter of up to 16 mm, 1 minute for a diameter of up to 225 m, for a larger diameter - several minutes. If the adhesive is applied correctly, the connection will create a neat edge of adhesive around the connected fitting and pipe. When installing, do not skimp on glue; the more glue there is, the easier it will be to insert the pipe into the fitting. When working with pipes at subzero temperatures, make sure that the joint is dry and free of moisture, condensation or ice.

- Carefully remove excess adhesive from the external surfaces that were glued.

- Check that the pipe is inserted into the fitting up to the previously marked mark.

- Leave the joint for 10 minutes until the glue has completely hardened. Then continue assembling according to the instructions.

- Allow the glue to dry thoroughly before testing the pipeline under water pressure.

SAFETY

- Do not use glue near an open flame.

- is prohibited during installation work.

- It is forbidden to use glue in unventilated or poorly ventilated areas, because fumes may cause poisoning.

- Do not carry out installation work in conditions of high humidity or rain.

- Do not use dirty glue brushes or dirty, oily napkins.

- Do not dilute the glue.

- Do not use the same brush for different types of glue.

- Follow all the rules listed above, as well as the manufacturer's recommendations when working with glue and cleaners for PVC products.

- Before starting work, put on work and protective clothing.

Basic recommendations

- Installation of PVC pipelines should be carried out only with the help of specialized PVC adhesives in strict accordance with the instructions.

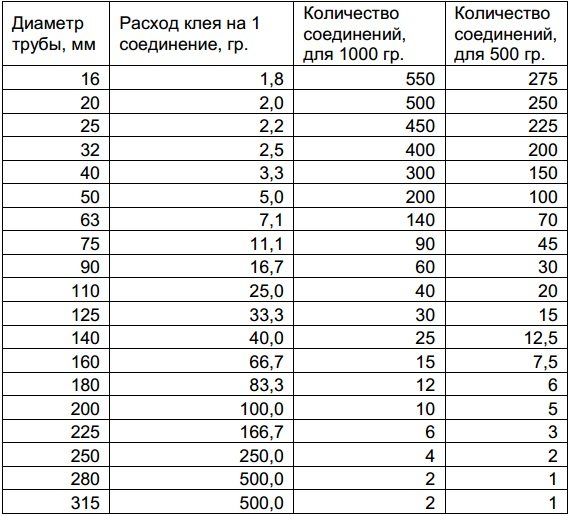

- For pipes with a diameter of 160 mm or more, it is necessary to use 3" brushes and liter cans of PVC glue.

- To obtain a high-quality connection and to obtain the required speed of applying glue to pipes with a diameter of 125 mm and above, it is recommended that two people apply glue to the fitting and pipe.

Drying time

The time it takes for the glue to dry completely depends on the density of the joint, air temperature, the amount of glue applied, and pressure. To completely dry joints with a diameter of up to 225 mm, it is recommended to leave for 24 hours, and with a diameter of 250-315 mm, for at least 48 hours. Such terms are relevant when drying compounds at air temperatures from +10 to +40 ºС. At lower temperatures it will take longer.

If it is necessary to conduct an operational test of the pipeline for tightness of connections, then the following drying standards are allowed (for air temperature from +10 to +40ºС and working fluid temperature not higher than +20ºС):

It should be noted that the minimum drying period before testing should not be less than 1 hour.

To make it easier for you to calculate the required amount of glue for installation work, we provide an approximate table of glue consumption depending on the diameter of the pipes and the fittings required for them and the volume of the glue can.

Features of installation of saddle bends

- Drill a hole of the required diameter for the saddle outlet in the pipe.

- Mark the area on the pipe that the saddle bend covers.

- Degrease the surface using a special cleaner or solvent.

- Place worm-type clamping rings onto the pipe, which will press the support to the pipe during the gluing process.

- Quickly apply glue to the pipe and support.

- Place the support on the pipe, making sure the male part fits into the hole.

- Secure the elements to be connected with clamping rings.

- Remove any remaining solvent and adhesive.

- Close the glue and solvent.

- Clean off the glue.

Attention:

- Let the glue dry. Leave the clamps for at least 24 hours.

- It is prohibited to glue a coupling by simply drilling a hole in the pipe and placing an appropriately sized coupling into it.

Application of transition couplings and bushings

Adapter sleeves

A reduction sleeve is a simple way to reduce the diameter of a pipeline in a specific location.

When installing adapter bushings, it is necessary to prepare all surfaces as described above in the instructions.

Example of application and installation of adapter sleeves

Application of adapters

Reducing fittings are used for coupling and sleeve connections.

Threaded connection

Connecting plastic to metal

Special fittings will help connect plastic and metal pipes:

- flanges

- combination couplings

- bushing threaded transitions

- coupling threaded connections

Plastic tends to expand or contract under the influence of the temperature of the working fluid with a much greater amplitude than metal. Therefore, it is not recommended to connect plastic to metal if the pipeline will experience temperature changes of more than 5ºC in order to avoid leaks.

Dismountable couplings are available with brass bushings or coupling threaded adapters.

A pointed screw-cutting head, which is specially designed for working with plastic pipes, will help you cut a thread in a PVC pipe. Cut threads in one operation without the use of lubrication. This method is only suitable for pipes with a diameter of up to 2".

Assembly of threaded connections is done manually. Tightening is carried out only with a wrench. Tighten carefully so as not to overtighten or strip the thread. When connecting plastic to metal, do not use pipe wrenches. It is recommended to use PTFE tape to seal and seal the connections.

Connecting measuring instruments

Connecting measuring instruments to a water supply or water treatment system is carried out by drilling the pipe in the most durable place and cutting a thread, as described above.

Such connections, when properly drilled and tapped, will be limited to Class C pressure.

Flange connections

Full section flanges come in diameters from 25 to 110 mm, and flange pins from 20 to 315 mm. When installing these types of flanges, use appropriate washers, gaskets, studs and seals.

Flange installation

Main stages of installation of PVC flanges:

- Make sure the flanges are clean and not chipped or damaged.

- Select the size of nuts, studs and seals.

- Assemble the flange connection, do not overtighten the threads.

- Make sure the bolt holes and flanges are aligned, the seal is properly positioned between the flanges, and that the flange cross-sections are parallel.

- Check that the correct size washer is installed under the bolt head and nut.

- Tighten the bolts and nuts in a diagonal pattern so that the load is distributed evenly on the flange and it is not damaged.

- Tighten all bolts.

Pipe laying methods

Water distribution in the apartment can be done with your own hands, leaving it open, or walled up in grooves. The first method is less time-consuming and cost-intensive - pipes made of any material are suitable, simple clips are used for fastening to walls, and the joints are always accessible for maintenance.

But open sections of the pipeline can spoil the design, so they are often hidden in walls or floors. Hidden installation has a number of conditions that affect the choice of pipes. They must have a low coefficient of thermal expansion, or be able to freely deform when heated.

It is necessary to provide free access to joints for preventive inspection and repair, and replacement of plumbing fixtures. It is most practical to wall up pipes without joints.

Metal-plastic, polybutylene or cross-linked polyethylene are suitable.

Before purchasing, you need to make sure that it is permissible to lay pipes in a hidden way by studying the attached certificate.

It is best to place reinforced products in walls that have an expansion coefficient that is 5 times less than non-reinforced ones. Additionally, they are placed in protective covers or plumbing corrugations. This compensates for temperature deformations on the DHW branches and prevents the appearance of condensation in the cold water supply sections.

Adhesive installation of PVC pipes

Glue for PVC pipes received a second name - cold welding. And this is by no means accidental. Such an adhesive composition ensures uniformity of the load, which, in turn, increases the strength and durability of the pipeline as much as if its elements were connected by real welding.

This substance is a reaction product of the decomposition of polyvinyl chloride in solvents. The gluing process consists in the fact that first the walls of the PVC adhesive pipe are softened, and then it is connected to a fitting also with softened walls. Therefore, this technology is also called chemical welding.

There is one caveat here.

Due to the fact that the chemical properties of additives and solvents can change, the selection of adhesive for PVC pipes must be carried out taking into account the type of thermoplastic compounds being welded. Typically, companies that produce plastic water supply systems give recommendations on how to solve this issue in the most optimal way. But in any case, it should be remembered that the same brand of glue cannot be used to connect pipeline elements made of CPVC and simple PVC (the abbreviation “CPVC” stands for chlorinated polyvinyl chloride).

Useful information! This type of connection of these products is used very often. It provides greater tightness of the structure compared to sockets with an O-ring.

During installation, use only those materials that are intended for this type of pipe

Step-by-step work algorithm

To install water supply distribution in an apartment, it is not necessary to undergo special training. It is enough to understand the principle of its operation and what devices perform this work. Work begins with the installation of an emergency crane.

Installation of ball valves

Ball valves are used as a throughput device, which makes pipe routing safe.

One such tap is installed for hot and cold water supply immediately after the central riser. With their help, the water supply to the apartment is regulated and an emergency shutdown of the entire water supply network is performed.

Installation of meters for hot and cold water

After the ball valves, units are equipped to measure the flow of hot and cold water. Each of them consists of a coarse filter, a check valve and DHW and cold water meters.

Gearbox installation

The reducer is needed to stabilize the pressure. Use mechanical and electronic devices. The latter prevent water hammer, which causes damage to washing machines, dishwashers, and other plumbing fixtures.

If you connect a boiler, you need to install a check valve, which also belongs to the control devices. It will prevent the backflow of water from the boiler tank into the riser. Reducers and check valves are installed after water metering units.

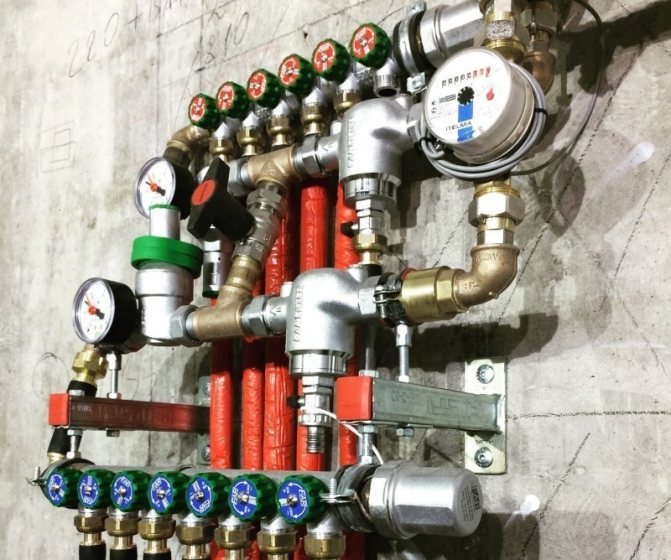

Collector installation

If the distribution system is radial, then the next step will be the installation of plumbing collectors. These devices are needed to distribute water between consumers. Collectors are selected with a number of outlets corresponding to the number of water collection points.

For emergency shutdowns of branches, a ball valve is installed at the beginning of each of them. If there is a need, pressure gauges for measuring pressure and devices for protecting against leaks are also placed here.

Installation of water pipes

The final stage of the distribution installation is the installation of individual sections of pipes through which water is supplied to consumers. They are laid according to a previously drawn up project.

The connection is made using the technologies provided for each type of pipe.

Possible mistakes

The open ends of the pipes are closed with plugs during installation, and before joining they are checked for clogging. This prevents debris from getting inside the pipeline, which can cause damage to the plumbing or defective operation.

When soldering joints of plastic pipes, it is important to prevent dirt or water from coming into contact with the welded areas - foreign substances reduce the strength of the joint.

When installing plumbing in an apartment at different levels, a separate hole should be drilled in the floor slabs for each pipe, rather than passing them all through one passage.

Enough space must be left between taps, valves and other fittings so that the wings and swing arms installed on them do not interfere with rotation. Simultaneously with the wiring, it is worth designing the sewerage route in such a way that the corresponding risers do not overlap each other. This will improve the conditions for maintenance and repair of networks.