How to connect plastic pipes without soldering and welding: polypropylene, HDPE, PVC

Relatively recently appeared plastic pipes are now everywhere replacing their metal counterparts in arranging communications for a variety of purposes. Their popularity is due to their low cost, long service life and lack of corrosion. Methods for connecting plastic pipes without soldering allow you to do without complex equipment during installation.

Why is it necessary to connect plastic pipes without soldering?

The cost of a special soldering iron is several thousand rubles, so purchasing it for one-time installation on your own is impractical. Even experienced craftsmen use alternative methods in cases of:

- when you need to connect only 2 - 3 joints;

- when replacing a damaged pipeline section;

- for laying plastic pipelines with low hydraulic load, for example, sewage;

- to create detachable connections if there is a need for regular disassembly of the pipeline for preventive maintenance;

- when installing temporary pipelines.

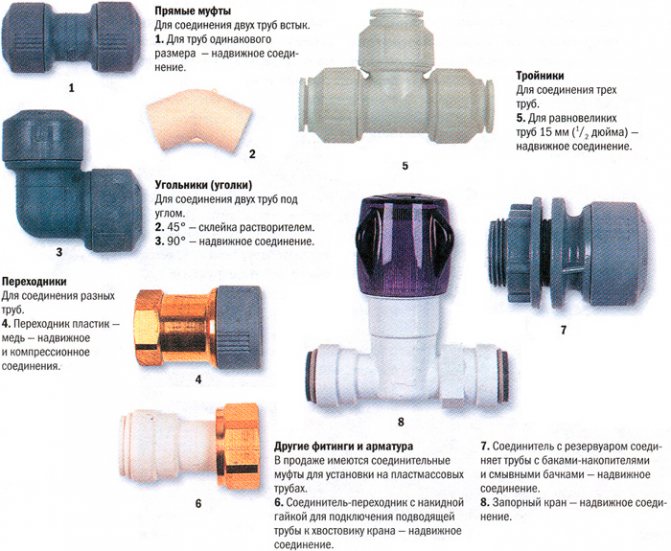

Connection using fittings

Compression fittings are used to connect polypropylene pipes without soldering. With their help, you can lay branched plastic pipelines with bends at different angles in low-rise buildings. If the diameter of the pipes, including HDPE (low-density polyethylene), does not exceed 50 mm, no special equipment is required. However, installation will require more time than with other methods, since it will be spent on carefully crimping the joints.

The advantages of this type of connection include:

- lower financial costs compared to soldering;

- High qualifications are not required to carry out the work;

- Can be used for assembling pipelines with pressures up to 25 atm.

Structurally, the fitting is made of a steel or cast iron body with a sleeve and cover, clamping and thrust rings (they are sometimes combined into one), the tightness is ensured by an O-ring. Before connecting with fittings, the ends of plastic pipes are cut strictly perpendicular to the axis, cleaned of burrs, dust, and degreased. After preparation, nuts removed from the fitting are put on them, and clamping rings are installed. Then the ends are inserted into the fitting until they stop, the nuts are tightened on each of them.

Methods for connecting plastic and cast iron pipelines

Methods for joining cast iron and plastic lines:

- flanged;

- fitting;

- using rubber gaskets;

- caulking of tow or sanitary linen;

- silicone sealing.

The last method is used if the condition of the cast iron piece is good, and when inserting a plastic product into it, a gap of less than 2 mm remains. The end of the cast iron line is thoroughly cleaned and dried with a construction hairdryer. The connecting part of the polymer pipe is wrapped with plumbing thread and installed in the socket to a depth of 8–10 mm. The cracks are filled with silicone sealant.

Until the silicone has completely dried, no impact on the joint is allowed. Hardening occurs in approximately 5 hours, but it is better to start the system 24 hours after sealing.

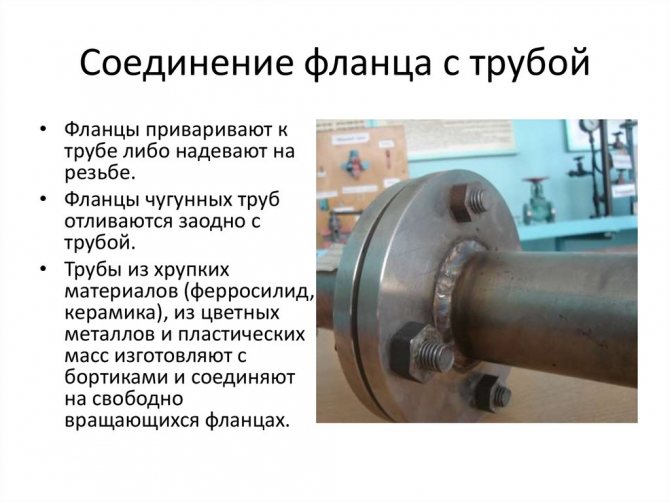

Flange method

If the pipe cross-section is large, it is better to use the flange method. Two discs with holes are used. The joint is formed by pressing them tightly against each other. When connecting a cast iron branch to a smooth plastic pipe, adapters are used. When choosing a connecting element, carefully check that it is free of burrs or sharp edges, as they can damage the polymer layer.

Nuances of installing a flange connection:

- strong joining can be achieved by using a straight collar with a tapered transition;

- for highways with a cross-section of more than 200 mm, use a loose flange supported by a conical collar;

- For light pipes with a cross-section of up to 150 mm from any materials and heavy polymer products of the same diameter, loose flanges supported on a free collar are used.

Before joining, cut the cast iron as smoothly as possible in the area where the joint is planned. Place a loose flange with a rubber gasket on the edge with an overlap of no more than a centimeter. Then slide the flange onto the seal and secure with bolts, tightening them evenly.

Application of fittings

Water pipe fittings

Connecting cast iron and plastic sewer pipes using crimp or cast fittings is used if the cross-section of the products is no more than 110 mm. A cast polyvinyl chloride fitting with a thread on one end and a socket for connecting a plastic pipe on the other is preferable if the end had to be cut off on cast iron.

To create a transition, clean the cast iron product from dirt and paint and cut a 30-50 mm thread on it. Re-clean from dust and metal filings and shavings, wind several turns of FUM tape or flax. Screw on the fitting and insert the end of the pipe section into its collar.

If a cast, threadless product is used, first install a sealing ring into the socket, fixing it with special glue, and then insert a narrow fitting pipe into it.

You can also use compression fittings, which have a special ring for crimping with a cut. It allows you to avoid rapid failure of the connecting element and the occurrence of leaks in sewer pipes.

Use of rubber gaskets

The transition from a cast iron sewer pipe to a plastic pipe using a similar method is carried out if, after eliminating the defective part of the old sewer system, there is an undamaged section with an even socket. First, a rubber cuff is installed, and then a piece of plastic is inserted into the cast iron pipe to a depth of 5–8 cm.

Sometimes it happens that the remaining section of the cast iron pipe does not have the required socket. In this case, an adapter is used. You must proceed as follows:

- The cast iron is thoroughly cleaned of dirt and rust, then dried, and a layer of sealing compound is applied to the inside.

- The outer surface of the adapter is also coated with sealant and inserted into the cast iron.

- The end of the plastic pipe is inserted into the free end of the adapter until it stops.

At the end of the work, all joints must be additionally treated with a sealing compound.

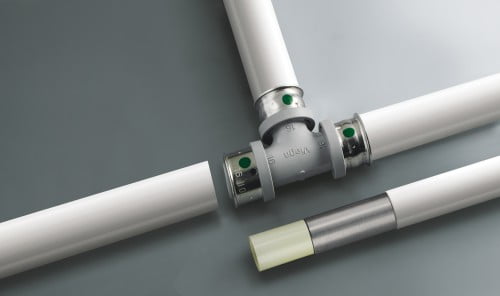

Press-fitting technique

The method is chosen if it is impossible to connect the sections of the highway in any other way. Rules for caulking with tow or flax:

- In the place where the connection is supposed to be made, several layers of sealing material are wound around the end of the plastic pipe.

- The pipe is inserted into the cast iron socket until it stops.

- Using a wide negative screwdriver or a narrow spatula, the winding is compacted tightly into the gap between the pipes being joined.

- A mixture of cement, PVA glue and water is applied several times to the junction of cast iron and plastic.

After a day, the mixture sets, and you can start using the new pipeline. Such a connection of waste pipes has a service life limitation of up to 12 months. After this period, everything will have to be redone again or a more reliable pipeline will be installed.

With the right choice of joining methods and high-quality materials, a hybrid of old and new sewers will last for many years.

Coupling connection

The design of a conventional coupling consists of a cast iron body, a pair of nuts, rubber gaskets, and four washers. When purchasing, you need to pay attention to its compliance with the diameters of the plastic pipes being connected. To join, the pipes are inserted inward until the ends touch in the middle of the coupling, passing through washers and gaskets. The nuts are tightened with sufficient force to compress the gaskets.

The tightness of connecting pipes with a coupling is 100%, however, when laying them close to a wall or floor, this method is unacceptable. Then clamping couplings come to the rescue. Before joining, the end of the plastic pipe is cleaned and the coupling is unscrewed. Fasteners are put on the prepared area in the correct order. The sealing ring is placed at a distance of at least 10 mm from the end.

The clamping coupling is inserted inside the plastic pipe and the previously put on parts are pushed towards it, and the bolt is tightened. The degree of clamping is checked by lightly twitching the body; if it moves, continue tightening. A fitting with a union nut is screwed onto the thread on the opposite side, installed in the next section.

Types of sewer pipe connections

The quality of functioning of the sewer system as a whole depends on whether the sewer pipes are connected correctly. To know how to properly connect sewer pipes, you need to carefully study the features of each method.

Types of sewer pipe connections

The connection of sewer pipes is classified according to several parameters. The main one is based on the type of material used to make the pipe. Various methods are used to connect plastic, ceramic and metal pipes. The connections can be permanent, which are considered more reliable and durable, or detachable, which are made using additional devices. If you adhere to the installation rules, then both connection options will ensure high-quality functioning of the sewer system.

Another criterion by which sewer pipe connections are classified is how exactly one pipe is connected to another. Here are the options:

- “into the socket” - the most common method, used mainly for joining plastic pipes;

- the adhesive method involves the use of special adhesives;

- welding - carried out using a welding machine;

- using a coupling - a method that requires additional elements.

Each method has its own scope of use. These methods of connecting sewer pipes are used when installing the sewer system of private mansions and apartments in multi-storey buildings.

Types of sewer pipe connections

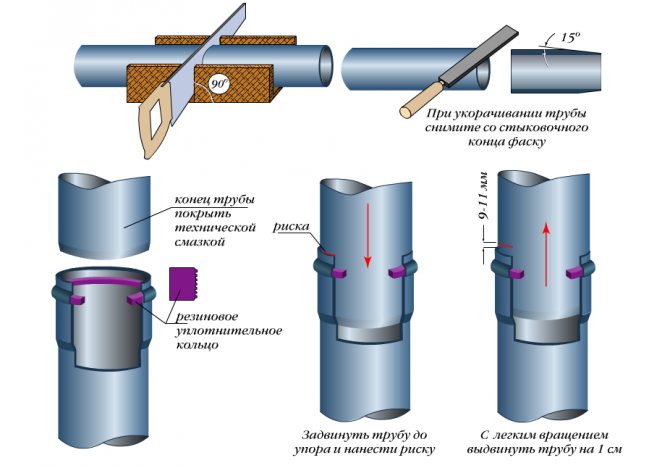

"Into the bell"

This option is the most used and simplest. It is used during installation work using plastic sewer pipes. To do everything correctly, you need to adhere to a certain sequence.

- We fix the sewer pipe on the supporting surface so that the socket is in the opposite direction with respect to the flow movement.

- We insert a rubber ring into the socket of the pipe that is already installed. This is necessary to seal the connection.

- Next, carefully insert the second pipe with the smooth end. To ensure that the work is carried out smoothly and easily, it is recommended to lubricate the elements with a concentrated solution of laundry soap.

- We fix the structure and continue working, but the pipe we have already installed is the main one and is located on the supporting surface.

Connecting pipes into a socket

This method is used primarily to connect sewer plastic pipes that are equipped with a socket - a slight thickening at the ends. Pipes through which water will flow under high pressure should not be connected into a socket, for example, during the installation of a water supply system.

Using glue

The connection of PVC sewer pipes is often done using the adhesive method. There is nothing difficult about gluing the pipes together. To work you will need a special adhesive.

Pipe connection

The first step is to clean the areas where the glue will be applied and treat them with degreasing compounds. To properly apply the adhesive to the surface of sewer pipes, it is recommended to use a special brush. Now we connect both pipes, hold them in this position for several minutes so that the glue has time to grab them. For reliability, cover the joint with a thick layer of glue.

Note! To ensure a tight connection, it is necessary to apply the adhesive in a thick layer so that the adhesive protrudes and forms a bead around the pipes.

This method is an excellent solution for connecting sewer plastic pipes. Just don’t try this option for the purpose of joining cast iron or steel products. There are other connection methods for metal pipes.

Connecting sewer pipes with glue

Welding

Welded joints are used when working with different materials. The main advantage of this method is its reliability, because the seam is very difficult to undo. If the work is done well, the sewer system will last without leaks or other problems for a long period.

Each material has its own type of welded joint. In any case, you will have to stock up on special equipment, protective clothing, and goggles. The connection of cast iron sewer pipes is carried out using conventional welding. But to decide how to connect plastic sewer pipes, you should use the cold or diffuse welding technique.

Note! If the welding machine is handled incorrectly, health problems may occur. For example, working without a mask will result in very painful eyes, and when they are closed, sparkling flashes may appear. This can cause insomnia, disturbance of calm, and increased irritability.

Welding sewer pipes

Using a coupling

The connection of corrugated sewer pipes is carried out mainly using fittings. This method is justified if not all pipes need to be connected to the system, but only a few. The connection involves the use of special couplings with an elastic band. The work process consists of several stages.

- Before connecting sewer pipes with a coupling, it is necessary to disassemble the elements.

- Now we put the locknut on the pipe and seal it with a rubber ring.

- Next, a sewer pipe is inserted into the coupling fitting and the locknut is tightened.

This method of connecting pipes is the fastest. Getting the job done will not be difficult even for those who have never had to deal with plumbing work before. The disadvantage of such a connection is its unreliability. The fact is that during operation, the locknut gradually loosens and unscrews, as a result of which the sewer pipe begins to leak and requires repair.

Pipe connection

Using flanges

This connection is made using adapter bushings welded to the ends, or slip-on steel flanges (profiled and smooth) with threads on one side. They are installed without welding. Among the advantages, the high reliability of the joints is noted, withstanding high temperatures and pressures of up to 16 atm. The connection can be made on pipelines of different diameters from 2 to 120 cm.

Docking begins by pulling the flange onto the pipe and putting on the rubber gasket. It is installed at a distance of no more than 10 mm from the end. The flange is moved towards the gasket, and another pipe is prepared in the same way. The bolts are tightened carefully so as not to crack the plastic.

Common methods for joining cast iron and plastic pipes

You can choose a method for connecting a cast iron water pipe to a plastic one from the two most popular ones - a flange or a fitting connection. If we are talking about the flange method, then two disks with holes are used, which are tightly pressed against each other with bolts, forming a joint. This method is often used if the cross-section of the pipeline is large enough.

But when making a transition from a cast iron sewer pipe to a plastic one, the cross-section of which does not exceed 110 mm, you can safely use fittings - your choice, crimp or cast. A cast fitting means a product that has a socket in which a sealing gasket is pre-installed. But compression fittings are prefabricated connections, and their installation is somewhat more complicated. They have a crimp ring in which there should be a cut. It will prevent quick fitting failure and leaks in sewer pipes.

According to the type of installation, fittings are classified as press fittings and compression products. Installation of compression fittings is somewhat easier and faster, they allow you to create a reliable connection. However, after some time after installation, the fasteners may become loose, which will lead to leaks and loss of tightness of the system.

An alternative option is to use press fittings. Such connecting elements provide a reliable connection without any risk of depressurization. Therefore, subsequent monitoring of the connection status is not necessary.

Among the types of fittings on the market, you can always find suitable products for sewer pipes.

Please note that the joining of cast iron and plastic sewer pipes can in no case be done using cement.

Fitting into socket

In this way, sewer systems are assembled from polypropylene and PVC pipes, one end of which is made in the form of a socket. The use of this connection reduces installation time and is cheaper, since there is no need for additional connecting elements. The assembly of pipelines using this technology can be carried out by any beginner independently.

Before joining, you need to make sure that the end without a socket is perpendicular to the axis, otherwise the pipeline may bend during operation. The edge is chamfered with a file so as not to damage the rubber sealing ring in the socket. It is cleaned of dirt and dust. To achieve increased sealing, the prepared end of the pipe is lubricated with silicone grease, then inserted into the socket until it stops. At the place where its edge stopped, a mark is placed and moved back 1 cm. The resulting gap is necessary to compensate for the linear expansion that occurs during heating.

Connecting sewer plastic pipes: the best methods

Installing a sewer system in a house is quite a complex and time-consuming job.

Here you need to select the right products in terms of diameter and material of manufacture, and install them so that no leaks appear at the joints.

The last point raises the most questions; let’s consider it in more detail.

articles:

PVC pipe connection

In what ways can plastic pipes be connected?

Most houses already have plastic water and sewer pipes , so the task will be to connect similar products. It can be solved in several ways.

Socket connection

Connecting plastic pipes into a socket

The first method is a socket connection. This method is considered the simplest and is often used in practice. In order to do this work, you need to do the following:

- clean the bell and smooth end from accumulated dirt;

- make sure that the socket is equipped with a special rubber seal, which is necessary to ensure the tightness of the joint;

- Lubricate the smooth end of the pipe with special silicone grease and insert it into the socket until it stops. In this case, you need to make a mark on the product with a pencil indicating the depth of insertion of the pipe;

- Next, you need to pull the pipe towards you so that it comes out of the socket by 1 cm (approximately).

Plastic pipe elements

Such a connection of sewer plastic pipes will be quite reliable and airtight and will not require a lot of time and effort from you.

Connecting pipes with glue

Adhesive for plastic

You can consider another method of connecting PVC products. Here you will need to use special glue. The work will be as follows:

- clean and degrease the areas where the products will be glued;

- apply special glue to the desired section of the pipe using a brush for this purpose;

- insert the pipes into one another and hold them in this position for about a few minutes so that the glue has time to set;

- Apply another layer of glue over the previously made connection.

Bonding plastic pipes

Since the glue has low mechanical strength, it is used in combination with special fittings or for joining plastic pipes with sockets. A composition based on epoxy resin and hardener is usually used to connect plastic water pipes through which cold water is supplied. But there are brands of glue that can withstand high temperatures.

Fluid types are sold in packages where the liquid components are placed in different containers. They are mixed before use. Compounds for “cold welding” are sold in the form of bars similar to plasticine, in which the top layer consists of a hardener and the inner layer is made of a plastic mass. When purchasing, it is better to purchase two-component glue with additives that improve adhesion. In this case, you need to be interested in what materials it is intended for, since not every composition is suitable for gluing polypropylene pipes.

The advantages of gluing include:

- reliable sealing of joints;

- a large assortment of glue brands makes it possible to choose the composition for working with a specific type of plastic;

- the compactness of the joint improves the presentation of the pipework.

Work is carried out at an air temperature of +5 - +35˚C wearing protective gloves. Since the glue is highly flammable, there should be no open flame sources nearby. The prepared composition is used within 20 minutes, otherwise it will harden. To apply the glue you will need a brush with natural bristles. It is usually included in the package.

The ends of plastic pipes are cleaned of burrs and sanded to make the surface rough. After degreasing with methylene chloride, it is covered with a thin layer of glue. The composition is applied to the area that will be inserted into the fitting or socket and 2/3 of the length inside them. The ends are inserted all the way and held in this position for 30 - 60 seconds. After 15 - 20 minutes, the glue will set, but will gain maximum strength within a day.

Polypropylene

For polypropylene water pipes, two connection methods are also used.

Welding

How to connect plastic water pipes using low-temperature welding?

Here is a list of the necessary tools.

| Tool | Functions |

| Low-temperature soldering iron (240 - 260C) with a set of nozzles | Melting of the surfaces of connected elements |

| Miter knife | Cutting pipes to size |

| Calibrator | Chamfering |

| Shaver, trimmer | Stripping aluminum reinforcement outside the pipe and between layers of polypropylene, respectively |

The actual development is this:

- The soldering iron is equipped with a nozzle of the appropriate size and is heated to operating temperature.

- The pipe is cut to size using a miter knife.

- The external chamfer is removed from the pipe using a calibrator.

- Aluminum foil (with pipes reinforced with it) is removed from the welding field. It can lead to delamination of the material and depressurization of the connection.

- the fitting and the pipe are combined with the nozzle for a couple of seconds and, after melting is completed, they are connected by a smooth back-and-forth movement. At the end of a short period of exposure, the hardened plastic is actually not inferior in strength to the monolithic section of the pipeline.

Push fittings

With their help, it is possible to connect plastic water pipes without welding. A push fitting is a simple design with a locking ring and a stainless steel ring with claws that prevent reverse movement of the pipe; final fixation is ensured by a union nut with a conical inner surface.

How to connect plastic water pipes using a push fitting?

- The reinforced pipe is inserted into the fitting with the nut loosened.

- The nut is tightened by hand until it stops.

Useful: on sale, albeit quite rarely, it is possible to find push fittings for metal-plastic.

Pros and cons of plastic pipes

The advantages of using plastic pipes for assembling water supply pipelines are due to them:

- Absolute corrosion resistance.

- High cross-country ability.

- Light weight. They are easier to transport and install.

- Resistant to acids and other aggressive environments.

- Elasticity, thanks to which communications do not break when water freezes.

- Ecological cleanliness. Plastic is safe for human health.

- Soundproofing property.

- Low electrical conductivity.

- High technology. Plastic pipes are easy to cut. They fit well at the end, connection with fittings or soldering is not difficult.

- Affordable price.

- Durability. Depending on the type, plastic pipes can last from 20 to 50 years.

- Attractive appearance.

The disadvantages include:

- Low fire resistance.

- Intolerance to exposure to direct sunlight.

- Not suitable for high pressure systems.

- Loss of strength under impact loads.

Connecting a cast iron sewer pipe with a plastic one

There are various ways to connect a cast iron sewer pipe to a piece of plastic. It all depends on the condition of the highway and the connecting zone. Before starting work, you should collect tools and additional equipment, as well as dismantle old communications.

Preparatory stage

First of all, prepare your workplace and select the necessary tools and consumables. Some of them are necessary for any joining method, but some depend specifically on the joining method. It is necessary to think over the technology in advance.

To carry out the work you will need:

- plastic pipe of the required size;

- adjustable wrench;

- grinder or hacksaw;

- mallet.

Depending on which joining method is chosen, a hand press, thread cutter, or welding machine may be required. You should also select elements for connection: fittings, adapters, rubber seals.

When drawing up a new wiring diagram, do not forget to include inspection hatches in the project. They will make it easier to diagnose the system if blockages or other problems occur. You also need to take into account that for a riser with a diameter of 110 mm, the best option would be to use pipes with a cross-section of 50 mm.

Dismantling an old pipe

Cast iron pipes do not need to be broken; it is better to cut them with a special saw.

The junctions of old highways were sealed with tow and cement mortar. First you need to carefully remove all the insulating materials, and then try to remove the pipe from the connecting unit.

It is necessary to disconnect the pipes by twisting, and in no case by rocking.

You can use a mallet carefully, but not a metal hammer, which can crack cast iron. If there is a possibility of damage to the bell during the undocking process, you can carefully trim it with a cutting machine.

Once you have cut a cast iron pipe, do not try to break it off. The broken area will be uneven, and you will have to cut again. It is best to make a cut around the entire circumference of the pipe.

Types of plastic pipes

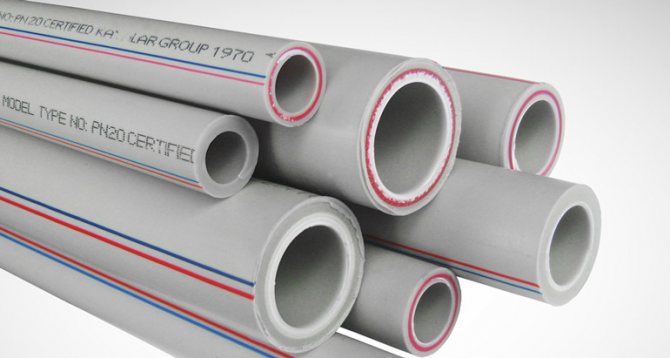

The group of plastic pipes includes a wide range of products. They differ in the composition and proportions of raw materials, wall structure, and technical characteristics. Plastic pipes come in the following types:

- Polypropylene (PP). These are universal products that are resistant to cold and hot water. They are manufactured in sections 4 m long and with a diameter from 16 to 125 mm, and can be operated under pressure of 10, 16, 20 atmospheres. Can be grey, white, black or green. Available in two versions - single-layer and multi-layer wall construction. Single-layer pipes are flexible and soft, therefore they are used only for assembling low-pressure cold water supply systems or installing heated floors. Polypropylene pipes reinforced with fiberglass or aluminum are rigid and have a low coefficient of linear expansion. They are more durable and resistant to baric overloads. These properties make it possible to use them in heating systems, hot water supply, and drinking water supply.

- Polyvinyl chloride (PVC). PVC products come with a smooth or structured wall. The material is characterized by high strength, ductility, and increased chemical resistance. PVC does not burn well, does not conduct electricity, is resistant to rust and deposits, but becomes brittle at sub-zero temperatures. This is the cheapest type of plastic pipes. They are mainly used in the construction of external and internal sewer networks, as protective boxes when laying electrical wires, television and computer cables.

- Made of metal-plastic. These are products with a multilayer wall structure, where the outer and inner layers are made of ordinary or cross-linked polyethylene, the barrier layer is made of aluminum or copper foil with a thickness of 0.2–0.5 mm. An adhesive mass is used to bind the layers. The presence of a metal layer increases the strength of metal-plastic pipes and reduces their temperature deformation. The scope of application of such products is cold/hot water supply and heating systems operating with a working pressure of no higher than 10 atmospheres and a temperature regime of up to +95 ºС.

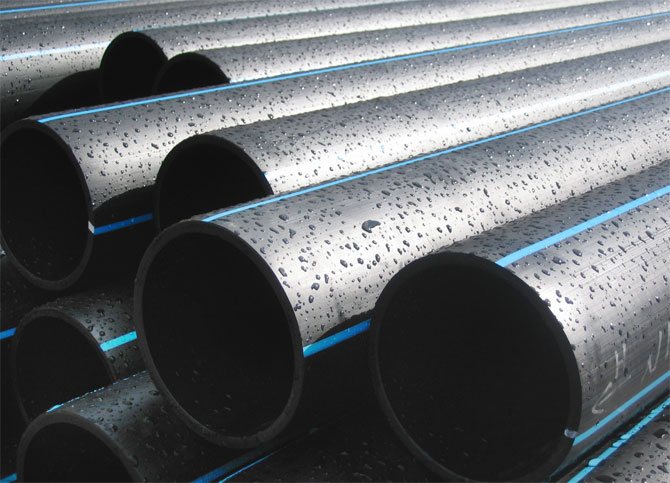

Another option is polyethylene pipes. There are 4 types of such products:

- Made from high-density polyethylene (HDPE). They have a limited scope. They are usually used to construct pipelines for drinking water or other liquids.

- Made from low-density polyethylene (HDPE). They have high hardness and density, dielectric properties, so they can be installed in pressure water and sewerage systems, gas pipelines, for laying electrical wires and cables.

- Flexible corrugated pipes PE. Due to the corrugated shell, they are endowed with high resistance to mechanical loads, stretching and compression. They are used for the installation of non-pressure water drainage, sewerage, power supply, communications systems, as well as for connecting plumbing fixtures.

- Made from cross-linked polyethylene (PEX). Products made from cross-linked polyethylene have maximum resistance to high temperatures (up to +90 ºС) and frost, increased mechanical strength, and chemical resistance. Used in heating and hot water supply systems.

Connection methods

Do-it-yourself joining of plastic elements can be done in the following ways:

- Bell-shaped.

- “Cold welding” - using special glue.

- Threaded type connection.

- Diffusion welding method.

- Flange.

- Collet connection.

- Electrofusion welding.

Next, I will tell you which connection methods are suitable for the above pipes.

Polypropylene

This type of plastic material is connected in several ways:

- Compression fittings. Installation of the compression fitting is extremely simple. First, cut a piece of pipe of the required size and clear the end of burrs. Then put on the crimp nut, split ring and push the fitting all the way. The crimp nut is tightened tightly first by hand, and then with a wrench or adjustable wrench.

- In the bell. The simplest connection technology is used when assembling sewer lines. The end of another is inserted into the socket of one piece of plastic pipe. An O-ring is used to ensure the tightness and strength of the connection.

- Thermal welding method. Used for connecting large diameter polypropylene pipes. The work requires a welding machine, which, using automation, fully controls the process of joining parts. The master only cuts the plastic parts evenly, removes burrs from them and installs them in the device.

Connection of steel structures

Steel pipes are rarely used in construction. And there are quite reasonable reasons for this: bulkiness, which increases transportation costs, and low resistance to corrosion, which leads to rapid wear of the system. The latter reason has made it almost impossible to use steel structures in the sewerage system, because wastewater often contains aggressive chemical elements that accelerate the process of destruction of structures.

But, despite all the disadvantages, steel pipes are sometimes used to transport wastewater. They are often necessary when installing floor sections or structures located in areas with high pressure (for example, under a highway).

Welding equipment is used to permanently connect such structures. The implementation of this method is quite complex. When performing the work, the following difficulties arise: only a trained person can perform high-quality welding, expensive equipment is required, welding reduces the resistance of the structure to corrosion and leads to rapid wear.

For the above reasons, detachable technology is usually used to connect steel structures in a sewerage system. In particular, the thread helps with installation. This method ensures excellent tightness and strength even under high pressure.

You can also separately mention a special threaded connection called “American”. It is a part equipped with a union nut. The seal can be a gasket or tapered pipe ends. This method allows for easy undocking. It is enough to unscrew the union nut. Dismantling possible. American allows you to combine structures from different materials. It itself is usually made of ductile cast iron.

How to solder plastic pipes without a soldering iron

To solder plastic pipes, use a special soldering iron. But if you don’t have one, you can use a gas burner. The connection will be of high quality if the pipe extends into the fitting by 1.5–2 cm. In order not to violate this standard, you need to measure this distance from the edge of the pipe part in advance and put a mark with a pencil. Then you need to heat up the elements to be connected: the pipe from the outside, the fitting from the inside.

Well-heated parts are inserted into each other until the mark is applied. The formed compound should be cooled for 2–3 minutes without being exposed to any external influence.

To heat small-diameter parts, you can also use an old iron by attaching a Teflon nozzle to it. Further actions will be similar to the previous device.

How to properly connect plastic pipes through plastic fittings

To obtain a high-quality connection of plastic pipes through plastic fittings, I advise you to adhere to the following rules in your work:

- The cut on the pipe must be made even, at an angle of 90° to its axis.

- The end of the part must be thoroughly cleaned of burrs and dirt.

- Be sure to chamfer the end to eliminate the risk of material scuffing.

- A mark is placed on the surface of the pipe, beyond which the end of the fitting should not go.

- The parts fit into each other more easily if the end of the pipe is treated with liquid soap.

- Do not rotate the product inserted into the fitting. Otherwise, the structure of the material may be damaged and waves may form on its surface.

- The plastic pipe must be inserted into the fitting until it stops, especially those reinforced with aluminum foil.

- The nut must be tightened with care so as not to overtighten the joint being formed.

An educational video on the topic can be viewed at the link

Scope of application and advantages of press fittings

Press fittings can be used not only to connect cast iron and plastic pipes, but also to eliminate problems in a finished sewer system. Please note that such products have a service life of about 50 years, and the acceptable pressure is up to 0.1 MPa.

First, they cut off a piece of cast iron pipe without looking to see whether it has a socket or not. The resulting cut is cleaned with emery and a file so that the end is absolutely smooth, without burrs. Next, the outer surface of the pipe is lubricated with grease or mineral oil and a thread 3-5 cm long is cut on it, after which plumbing thread is wound on it. Now you can simply screw the plastic fitting onto the pipe.

There is no need to exert significant force when screwing on the fitting so as not to deform the cast iron. To avoid water hammer, it will be possible to finally tighten the threads after the system has been started.

A crimping collar is placed on the plastic pipe and inserted on the other side of the fitting, after which the crimping is performed with a special tool. It is worth noting that the press fitting provides a very high-quality and durable connection, since a rubber sealing ring is installed on one side, and the threaded connection is sealed on the other.

Types of plastic pipes

Different types of plastic pipes can vary greatly both in performance characteristics and installation technology. There are the following types of products:

- Polyethylene. They are used for the construction of external and internal water supply networks; due to their elasticity, they can be used at low temperatures and significant pressure levels.

- Cross-linked polyethylene. Widely used in hot water supply networks.

- Polyvinyl chloride (PVC). They represent the optimal combination of high durability and low cost.