When removing a chimney pipe, no matter how carefully the roofers try to lay the roofing material around it, a small gap inevitably remains in this place. Through it, water will penetrate into the under-roof space, destroying structural elements. Sealing the pipe on the roof is an important stage in the construction of a house, which must be taken with full responsibility.

Consequences of poor sealing of gaps around the pipe

The efficiency of stove heating directly depends on proper sealing of seams. If the chimney is poorly protected, as a result of temperature changes, condensation will form on its walls and flow into the pipe. When the heating is running, it will begin to turn into steam, creating increased pressure in the chimney on the roof. This will lead to a violation of traction and, as a result, a decrease in heating efficiency. Besides:

- moisture seeping through a poorly sealed gap near the pipe will fall on the inner surface of the roofing, which will lead to its rapid destruction and premature repair of the roof;

- the elements of the rafter frame are mainly made of wood - under the influence of water flowing from the roof, they will eventually begin to rot and collapse;

- When moisture gets on it, insulation loses its thermal insulation characteristics and does not retain heat indoors as effectively;

- Water leaking near the chimney on the roof becomes a source of dampness in the attic, which will lead to premature wear of the interior finishing.

To avoid unpleasant consequences that will be difficult to correct later, you need to know how to properly seal gaps.

Waterproofing requirements

Some time ago, craftsmen used improvised means left over from roofing work to insulate the chimney outlet assembly. Currently, construction stores have a huge range of materials, devices and devices with which you can easily waterproof a chimney with your own hands. The following requirements apply to them:

- Resistant to moisture. Since the chimney is located on the roof, it is constantly exposed to atmospheric moisture. To prevent it from deteriorating the insulation, the material from which it is made must have high moisture-resistant and anti-corrosion qualities.

- Resistant to temperature changes. The chimney of a stove can heat up to a temperature of 500-600 degrees, so waterproofing materials must have low thermal conductivity and tolerance to ultraviolet radiation.

- Wear resistance. Since the bulk of roofing materials have a service life of 15-20 years, the materials and additional elements should also last a long time so as not to have to be replaced every 2-3 years.

- Compatible with roofing material. To seal the joints between the chimney on a roof made of metal tiles, corrugated sheets and seam roofing, galvanized additional elements are used, for ceramic tiles - ceramic, for soft tiles - flexible, bitumen.

Important! Waterproofing a chimney pipe is never done with household silicone-based sealant, petroleum bitumen or cement. All materials are selected taking into account the temperature of the outer walls of the pipe at the outlet and the type of roofing material.

Materials for sealing gaps around pipes

To seal cracks, a variety of available materials are used, divided into two categories:

- Elements that serve to close the space between the pipe and the roof. To do this, they use various decorative aprons and collars, which you can buy ready-made in the store or make yourself. For production, non-corrosive materials are used - galvanized steel, silicone or rubber. The functional purpose of such additional elements is rough sealing of gaps.

- A variety of sealants for filling joints left after rough sealing. This category includes waterproof mixtures based on cement and mastic. Today, many modern sealing materials have appeared on the market, which are much easier to work with and the result of the work is of better quality, for example, adhesive-based tape.

The most commonly used sealants for sealing joints around a chimney are:

- Silicone sealant is a waterproof, frost-resistant material, easy to use and inexpensive. It can withstand temperatures up to 150˚C, so it is often used to seal seams near pipes in baths and steam rooms.

- Bitumen mastic. Before applying it, the base is thoroughly cleaned of dust and dried. The mastic is applied in a layer of 3-4 mm; if the gap around the chimney is too wide, then it is first filled with polyurethane foam.

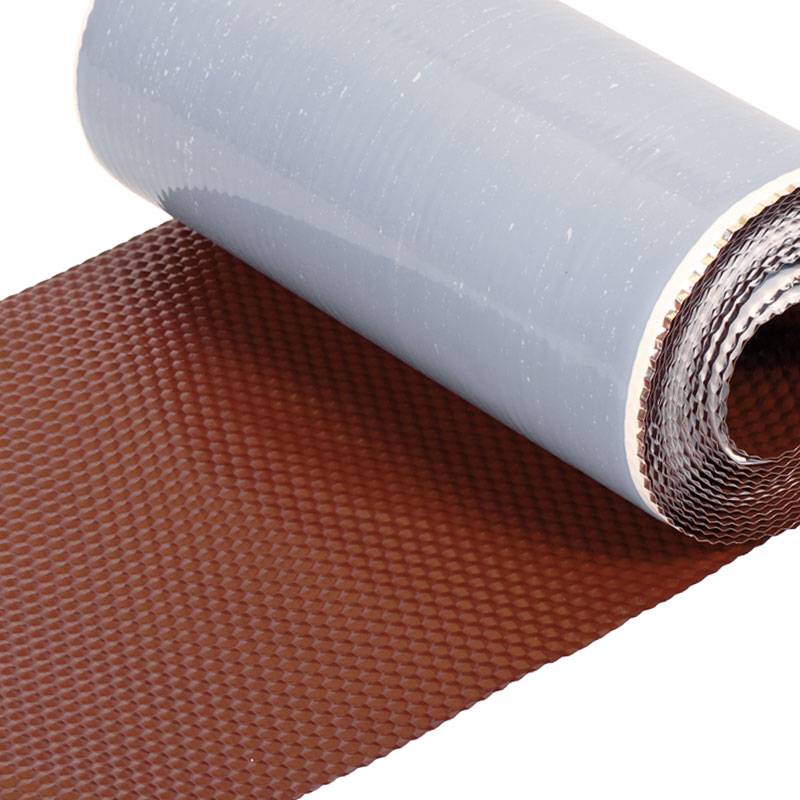

- Ecobit is a modern waterproofing material that provides high-quality sealing. It is a durable aluminum tape with an adhesive base; modified bitumen serves as a sealing layer. The ecobit tape is glued along the perimeter of the chimney pipe. To achieve maximum effect, the top is covered with a metal skirt.

- Enkryl is a German acrylic-based mastic for sealing problematic seams. The process of waterproofing a pipe is carried out in several stages. The surface of the chimney is degreased using a solvent and the first layer of sealant is applied with a brush. Then the pipe is wrapped with a viscose-based reinforcing fabric and, after impregnation, the next layer is applied. Manufacturers guarantee that a seam sealed in this way will last 10 years.

The method of sealing the seams between the chimney and the roof depends on their size, the roofing used and the shape of the pipe. If the gap is less than 5 mm, then it will be enough to seal it with silicone sealant. To seal wide gaps, more complex methods of sealing seams on the roof are used.

Types of waterproofing materials for pipes ↑

Many materials are used for waterproofing. Among them are polyvinyl chloride and heat-shrinkable tape, rubber sheet, heat-shrinkable sleeve, fiberglass, waterproofing, brizol, etc. They are durable and do not rot. There are as many types of communications as there are materials.

PVC tape ↑

Polyvinyl chloride, or insulating, tape is quite popular. It is mainly used to protect the outer surface of pipes from corrosion. Most often it is used in the installation of main oil and gas pipelines. Now this material is used during the repair of heating pipelines when replacing old waterproofing. It can also be used for household pipes.

A layer of glue is applied to one side of the tape for easier installation. Before use, it should be checked for cracks and bubbles. Even a small hole will significantly degrade the performance of the tape. It is sold in rolls, wound on plastic reels and packed in polyethylene to protect it from moisture.

This is what PVC tape looks like in rolls. It is packaged in polyethylene to protect it from moisture.

Rubber sheet ↑

Waterproofing of steel pipes and underground materials is carried out using rubber sheeting. It protects communications laid in the ground from corrosion and ensures reliable insulation of joints between pipes through which oil is transported. In addition to waterproofing against groundwater, the material is used to protect gas and oil pipelines, as well as brick and reinforced concrete sewer pipes.

Main advantages of the material:

- used over a wide temperature range;

- has excellent resistance to ozone, salts, oils and alcohols, as well as electric fields;

- high strength and elasticity;

- temperature changes do not affect the characteristics of the canvas;

- durability.

Rubber sheet is practically not used for waterproofing household pipes, since its transportation is impossible without special equipment, and installing such waterproofing is quite difficult for a non-professional.

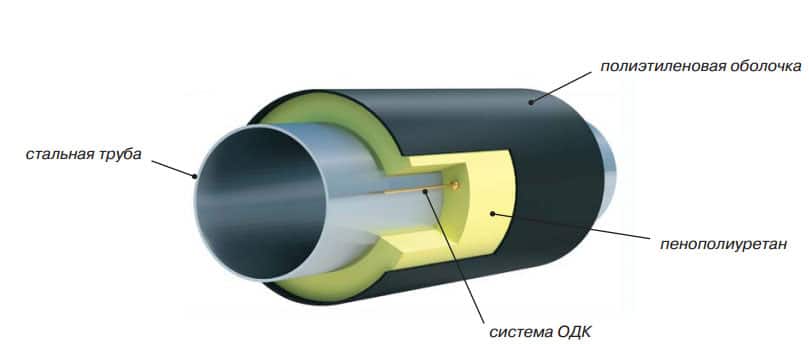

Polyurethane foam is widely used for waterproofing steel pipes. It reliably protects the pipeline from heat loss and corrosion

Heat shrink tape ↑

Used to waterproof welding joints to protect them from corrosion. It is not often used to protect the entire surface of the pipe. Heat-shrinkable tape should not be used to insulate pipelines at operating temperatures above 60 degrees.

This material is primarily used for waterproofing pipe joints. It provides reliable anti-corrosion protection of joints formed as a result of welding work. Heat-shrinkable tape consists of two layers: hot-melt and polyethylene film, which acts as a base. If a fixing agent - a primer - is used together with it, then the tape can also be used for pipes with a three-layer coating.

The tape is highly elastic, which allows it to be applied along the pipe diameter with almost no restrictions. Before coating, the pipe must be heated to 80 - 100 degrees. The material does not allow moisture to pass through and is difficult to ignite. There are many types of this tape offered on the construction market, and purchasing it is not difficult.

This material cannot be stored outdoors, as it loses its properties when exposed to sunlight.

To insulate one pipe joint, use a piece of tape equal to 3.5 times the pipe diameter.

Polyethylene heat-shrinkable sleeve ↑

For waterproofing joints of hot water pipelines, the most suitable material is a heat-shrinkable coupling, which is made of polyethylene. The advantages of this material are as follows:

- simple installation;

- excellent tightness of connections;

- thermal and chemical resistance to external influences;

- long service life.

Installation of polyethylene heat-shrinkable sleeve

Sealing gaps on tile roofs

This is the easiest way to seal gaps between a pipe and a slate or tile roof that you can do yourself. To seal, you will need a moisture-resistant cement-based building mixture, a container for mixing the mortar, metal corners, a decorative collar and water.

Sequence of work:

- The seam between the outer wall of the chimney and the roofing is lined with metal corners. If the pipe has a round shape, then a self-adhesive rubber seal is used for this purpose.

- A galvanized decorative collar is placed over the top of the pipe and secured with self-tapping screws.

- A waterproof solution is poured through the gap between the chimney and the collar and left for a day to harden.

- After the solution has completely hardened, an inclined surface is prepared from sheet steel for liquid drainage. To do this, cut a hole in the sheet corresponding to the diameter of the decorative collar, put it through the pipe and secure it with self-tapping screws at its base.

To seal the roof with a solution, it is necessary to use a high-quality waterproof mixture, otherwise, with the first serious rain, cracks will form through which moisture will enter the under-roof space.

Repairing pipe leaks on the roof

Before answering the question of what and how to fix a leak on the roof near the pipe, you need to decide what material it is made of.

It is very important. This is the starting point for repair work.

The chimney duct can be mounted from the following materials:

- bricks;

- metal;

- asbestos.

When eliminating a leak, you need to follow a certain sequence of actions, which can differ significantly for each chimney material. Therefore, the technology for eliminating such defects for each type of pipe should be considered in detail.

Fixing brick chimney leaks

If a pipe made of red brick is leaking on a roof, then to fix the problem you will need the following materials and tools:

- cement grade M 400 or M 500;

- sand, preferably river or sea, but quarry sand is also suitable;

- water;

- Master OK.

How to seal the gap between the pipe and the roof, having all of the above? You must adhere to the following sequence of actions:

- A cement mortar is made from the prepared materials by mixing 3-4 parts of sand and one part of cement;

- the detected leak site is thoroughly cleaned of dirt and remnants of destroyed bricks;

- The prepared mixture is applied using a trowel to the damaged areas.

Repairing metal chimney leaks

If a metal chimney is leaking, then to correct the current situation you will need:

- special clamps with a rubber gasket that can be secured to the pipe where the gap occurs. The diameter of the clamp should be approximately equal to the thickness of the pipe. Its width should be slightly larger than the size of the crack;

- in addition, small cracks can be eliminated using cold welding, instructions for use of which can be found on the packaging.

Repairing asbestos chimney leaks

If water flows through an asbestos pipe, then you can eliminate the leak by performing a number of the following actions:

- First of all, you need to stock up on cotton fabric and “Iron Lead” paint. You can buy such materials at any hardware store;

- then the chimney, namely the damaged area, should be cleaned of dirt and dust;

- the paint is applied in a thick layer;

- fabric is tightly wrapped over it;

- Then the paint and varnish material is reapplied.

Sealing seams on slate roofing

The easiest way to seal seams on a slate roof is to seal it with mortar. If you have an oval or round pipe, using this technology presents certain difficulties. You can solve this problem in the following way.

A ring is made from thick cardboard, wrapped in polyethylene and inserted into the gap between the roof and the chimney pipe. On the slate, a small semblance of formwork is formed from plasticine or any other plastic material. An asbestos-cement mixture is poured into the resulting space. After the cement has set, the cardboard and formwork are removed. An asbestos-cement ring remains around the pipe, serving as waterproofing.

Sealing seams on soft roofs

To seal brick chimneys on a soft roof, the covering is cut in the form of an apron, the edges of which are folded onto the chimney and framed around its perimeter with self-adhesive rubber-based tape, for example, Wakaflex or Onduflesh-super. For greater reliability, the tape is crimped with a case. The seams along the edges of the apron are sealed with bitumen mastic.

If there are large gaps, they must first be filled with fibrous material. Rope or tow impregnated with bitumen mastic are suitable for this purpose. You can also fill the top with cement mortar.

Gaps around round pipes on soft roofing are sealed with cap aprons, which are sold ready-made. All junctions of such aprons are glued with self-adhesive tape.

Adjacent rules

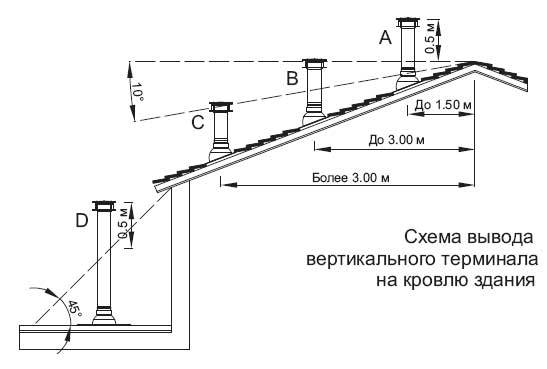

Construction norms SNiP do not have strict regulations on the location of the chimney, but contain instructions on the height of this element:

- The height of the chimney must exceed the height of the ridge by at least 0.5 meters, if it is located at a distance of 150 cm or less from the ridge itself;

- When located 1.5 - 3 m from the ridge, the chimney pipe can be equal in height to the level of the ridge or exceed it;

- If the distance from the ridge to the pipe exceeds 300 cm, then its height should be at the same level as the ridge, or not lower than a line drawn from the ridge at an angle of 10 degrees to the horizon line.

All other implementation features required by the device connecting the roof to the pipe remain without regulatory recommendations, and therefore can be carried out at your own discretion.

But taking into account the experience of professionals, it is better to install the pipe on the roof closer to the ridge, for the following reasons:

- This arrangement facilitates the process of high-quality sealing and provides coverage without leaks;

- The closer the pipe is to the ridge, the less space is left for snow and water to accumulate behind it, reducing the risk of leaks.

Attention! Condensation can form both inside and on the surface of the pipe, which leads to the formation of ice during the cold season. It damages the walls of the chimney, significantly impairing draft and reducing service life.

Round pipe

A roof equipped with a round chimney is one of the most common options for private construction.

To ensure a high-quality connection to the roof of such a pipe, standard three-layer structures are produced. The central part of such a multilayer system is made of heat-insulating material. The kit is complemented by a flat steel sheet and an apron-cap into which the chimney pipe is inserted.

It is worth choosing a suitable kit depending on the angle of inclination of the slope. Standard systems are produced for the most common angles. With the help of such structures, making your own high-quality connection is quite simple.

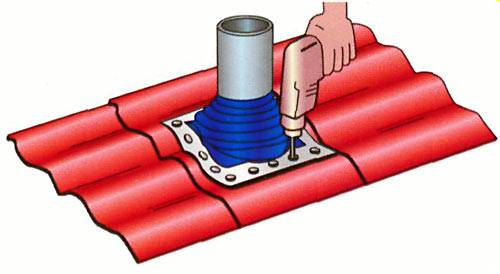

The abutment plate is tightly and rigidly secured to the roof plane. The top of the cap is cut off; the size of the cut should allow the pipe to fit tightly into the hole, with no gaps. The upper edge of the apron is pressed against the pipe with a steel clamp with a gasket made of heat-resistant elastic material.

Attention! All materials must be reasonably clean, as well as the roof surface. This will ensure maximum quality of sealing work. The plate is secured with self-tapping screws, using rubber or neoprene gaskets

The plate is secured with self-tapping screws, using rubber or neoprene gaskets.

If the angle of the slope does not allow the use of a standard type chimney installation system, then this can be done without the involvement of specialists. To do this, to create a sealed apron, it is necessary to cover the perimeter of the pipe with lead or aluminum tape.

It is also possible to use a finished oval-shaped lead part, which can be easily profiled onto the covering of a soft roof or a roof made of hard material using a rubber hammer or a wooden tool.

This lead self-adhesive is a material with high performance properties. It is resistant to temperature fluctuations, corrosion and ultraviolet radiation.

One of the ways to independently seal a round pipe on a metal roof is shown in the video:

Square pipe

For the installation of square and rectangular pipes, it is very rarely possible to select ideally suitable ready-made elements offered for sale. Depending on the type of roofing material, methods for arranging the connection of the pipe to the roof are also selected.

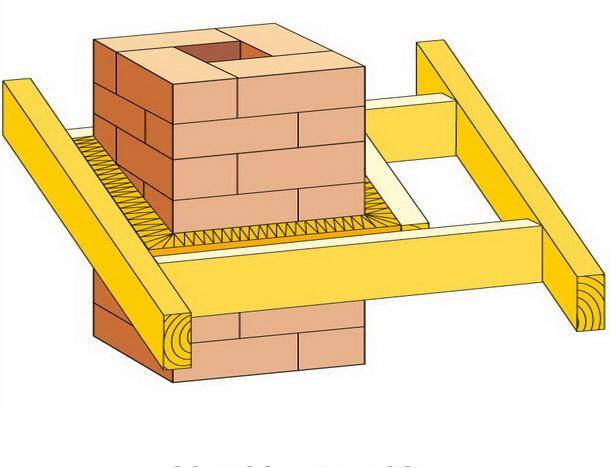

Roof passage unit

When carrying out construction work, partial dismantling of the roof sheathing is often required. At the same time, to ensure the rigidity of the structure, a frame made of wooden beams is mounted around the pipe, to which layers of waterproofing and vapor barrier are attached. The waterproofing is attached to the sheathing and counter-lattice. The vapor barrier is installed between the roof frame and the interior finishing materials. The space between the frame and the pipe must be filled, according to SNiP standards, with thermal insulating non-combustible material - stone wool.

Important! Particular attention should be paid to the quality of sealing of the joint between the vertical element and the roofing material. There should be no leaks at their connection points.