The chimney plays three main functions when organizing heating systems. All of them can be achieved by installing a chimney yourself. It doesn’t matter at all what kind of combustion products the smoke will come from, whether it’s a wood-burning or a gas boiler, if you do everything correctly, you’ll get a universal working system for removing smoke from residential premises. The described principle is absolutely equally suitable for organizing a chimney in a house, bathhouse, country house or garage.

DIY chimney installation

Main functions of a chimney

- First of all, the chimney is designed to remove combustion products, which are extremely harmful and often destructive to the body of the inhabitants of your home.

- In addition, the chimney must have insulating properties and protect the building structures of the floors and roofs from fire.

- And finally, a beautiful chimney also has an aesthetic function and decorates the roof of your house.

You can easily install the chimney yourself by following simple instructions.

Kunstkamera

Zhukovsky's blow in the chimneys

The boiler reached operating mode, that is, hot gases flowed through the pipe at the calculated flow rate, then the burner suddenly went out - the fan stopped, the gas continued to move by inertia, and accordingly left behind a vacuum zone.

The boiler was started in violation of the operating schedule, without pre-heating... more detailsPoor quality chimneys

Photo 1. Thermal insulation in the form of soft mineral wool mats with a density of 25 kg/m3 instead of 120 kg/m3 according to the project.

Photo 2. Absence of a condensate trap at the bottom of the vertical gas outlet of the boiler. Photo 3. Foreign objects on the diaphragm of the explosive... more detailsSmoke Leaning Tower of Pisa

Comments on the project The shape of the load-bearing lattice tower does not meet the requirements of SP 43.13330.2012 “Structures of industrial enterprises.

Updated version of SNiP 2.09.03-85.” The use of this design solution (rigid struts in the form of a system of volumetric trusses) is… more details30 meters, Du-500, Du-400, ...

1. The adopted design solutions of the “KM” section do not comply with the requirements of SP 43.13330.2012 “Structures of industrial enterprises.

Updated edition of SNiP 2.09.03-85”: – the shape of the load-bearing exhaust lattice tower does not meet the requirements of paragraphs. 9.4.8, 9.4.11; ... more detailsDestruction of load-bearing belts...

The only reason that can cause tensile stresses in the wall located along the generatrix of the cylindrical surface is water.

When water turns into ice, it increases its volume by 9.05%. Ruptures of seamless pipes, as they look in the photo, are typical for damage caused by ... more details

Main types of chimneys

Depending on the material of manufacture, chimney systems can be divided into those made of various types of metal (for example, cast iron or stainless steel), brick and ceramic. A modern chimney can be made of composite materials and have a multilayer structure.

You can choose the chimney modification that most closely matches your building.

So, for example, the cheapest option - a metal chimney - is most suitable for arranging heating systems for boiler rooms or baths, that is, non-residential premises. However, such an economical approach is hardly advisable to use in a home. The metal structure has poor sealing of the joints, as a result of which you will not be able to get rid of smoke penetration into the room. Also, metal does not have the most attractive service life, since it is extremely unstable to atmospheric moisture.

A pipe consisting of composite multilayer materials is more reliable and resistant to aging. But between the layers of such a pipe, a heat-insulating fire-resistant material is placed. Due to unjustified savings, many manufacturers place a low-quality insulator in the intermediate layer, which, after some time, may begin to crumble. So when purchasing such a pipe, carefully monitor the manufacturer’s reputation.

The cheapest option is to build a chimney from thin-walled stainless metal. The low weight of such a pipe allows it to be fixed in the structure even with the help of a minimal amount of fastening material. Also, a stainless steel pipe is very easy to process - it can be cut with ordinary metal scissors.

external chimney

A ceramic chimney is very complicated to construct, since its installation can only be done together with the entire house. In this regard, it is extremely rarely used, because in order to build it in a finished home, the construction team will need to dismantle part of the floors.

Chimney system configuration

The chimney design must be designed in such a way that its main part lies inside the heated room. Thanks to this, it is possible to speed up the heating of the smoke channel, minimize the appearance of condensation and significantly increase the efficiency of the heat generator.

If several stoves are installed in a room, then a separate smoke exhaust duct must be laid for each of them.

Please note that the main chimney must be installed vertically. There are situations when, due to the design of the building, a double deviation of the channel from the vertical line by up to 30° is allowed, while the distance of the pipe should not exceed 1 meter.

The connecting smoke duct is that part of the chimney that runs horizontally from the heat generating unit to the main smoke duct. The length of the connecting channel for furnaces should not be more than 1 meter, and for other heat generators - no more than 3 m. If it was decided to make the channel length greater than the specified values, the quality of traction should be checked. If the length of the channel exceeds 2 meters, it must be equipped with an inspection.

Picture Installation of revision

IMPORTANT! For safety reasons, smoke ducts must be located at some distance from electrical wiring, gas lines and other communications.

The total height of the chimney duct (from the grate to the mouth of the chimney) must be at least 5 meters. Fulfillment of this condition guarantees the required vacuum and excellent traction. It is also possible to operate lower chimneys, provided that they are installed in buildings that do not have an attic and provide an acceptable level of draft.

According to the standards, smoke ducts can have no more than 3 bends, and the turning radius should not be less than the diameter of the pipe.

Tools required for installing a chimney

In order to install a chimney in your home with your own hands, you will have to stock up on the following minimum set of tools:

- a grinder for cutting metal and a drill for drilling holes

- spatula, chisel and trowel

- a screwdriver, preferably with hex bits and a jigsaw, possibly electric,

- small hammer and Phillips screwdriver,

- protective gloves and glasses

What you need to remember when installing a chimney yourself

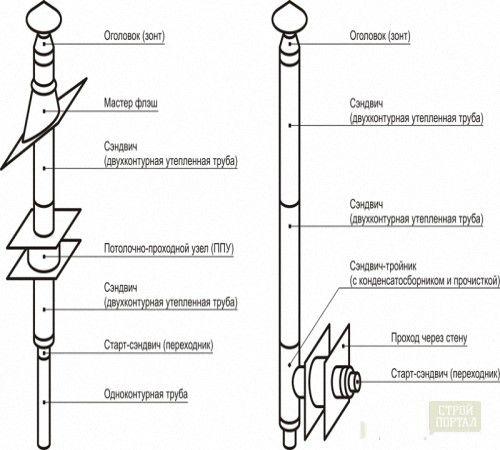

Based on the method of construction, chimneys can be divided into internal or external. Let us consider in more detail in which case you need to choose one or another option.

Thus, the internal structure of the chimney can be used for the construction of heating systems based on heating boilers or fireplaces. Such systems are usually installed inside walls. After installation, such chimneys are closed in the thickness of the wall and decorated. As an advantage, it can be noted that such a system is not subject to moisture condensation and is well protected from the influence of atmospheric moisture.

However, combustion products passing through the chimney have a higher temperature. Consequently, sections of walls running next to internal chimneys become very hot and can catch fire. Thus, it is not recommended to install internal chimneys in walls built from flammable materials. Also, such systems are not recommended for powerful boilers with a large flow of hot combustion products.

chimney components

It is recommended to install an external chimney for industrial and simply large heating systems. Usually they are arranged if the area of the heated room exceeds 500 square meters. Also, such a chimney can be installed if the installation of an internal chimney involves significant difficulties. So, in a building with concrete walls and ceilings, it is easier to break through a slab between floors than to drill a channel in the wall.

Rolling of stiffeners

To strengthen the design of products, you need to use special machines to create stiffeners. The process is carried out by bending the walls of the seal in increments of about twenty centimeters.

Such equipment includes two components that guarantee an even profile: a forming device and a welded bed. The first part most often looks like rollers with rollers.

The creation of stiffeners occurs simultaneously along the entire length. The key feature of this equipment is that the workpiece being processed is not subject to deformation.

How to install chimneys made of stainless steel or cast iron

The cheapest and easiest way to install a chimney is to install a metal pipe. The entire installation is divided into several successive stages:

- First you prepare a channel for the chimney.

- Then you actually install the chimney.

- And at the final stage you install insulation around the pipe.

The channel for the metal chimney should be approximately one and a half times its diameter. In this case, you will have space for insulation.

installation of a stainless steel chimney

The metal chimney itself consists of the following components: a metal pipe, adapters for mounting the pipes, a cap and a condenser. In a number of designs, a damper is installed in the chimney - a unit that increases draft in the system.

Stages of chimney installation

At the initial stage of chimney installation, you need to adjust the length of the pipes. Next, the resulting structure is placed in a previously prepared channel. After this, the condenser and the heating device itself (stove or boiler) are connected to the system. At the final stage, the head is installed.

In order to firmly fix the pipe, it must be attached to the wall at least every one and a half meters.

When installing steel and cast iron pipes, it is necessary to provide high-quality thermal insulation of the chimney. Only in this case will you be able to avoid fires in the ceilings and adjacent structures due to a suddenly leaky pipe. To insulate a metal chimney, it is best to use the classic method - fireproof clay. But in extreme cases, you can also use special fire-resistant foam.

You can also use clay to decorate the joints between a chimney made of a metal pipe and the ceilings and roof.

junction of a metal chimney with a ceiling

If you use a metal pipe, then it must be fixed to the ceiling and walls with fasteners every half meter. This is caused by the large weight of such chimney pipes. In addition, the mounting holes are made wider - approximately two pipe diameters.

A cast iron pipe will last longer as a chimney, but its installation is fraught with certain difficulties. So you can cut such a pipe only with the help of a grinder.

Correct installation of a sandwich chimney with your own hands

Sandwich chimneys made of several materials replace conventional metal pipes. The multilayer design allows for high-quality insulation of the ceilings from heating by the combustion products of the furnace. When installing such a chimney, no additional insulation is required, as a result of which the mounting holes can be made almost equal to the diameter of the pipe.

When installing metal pipes, they fit into each other like nesting dolls and no additional fixation is required to connect the elbows. In sandwich chimneys, the pipe elbows must be connected to each other using special construction glue. In addition to securing the knees, construction adhesive also prevents smoke from entering the premises.

Sandwich pipes are very sensitive to the formation of condensation from atmospheric moisture, so they are not recommended for use when installing external chimneys. Inside a building, such a pipe can last up to 70 years.

Installation of an external chimney

The most optimal material for the manufacture of an external stove chimney will be a pipe made of stainless metal. It weighs a little and can be easily processed with the simplest tools.

installation of an external chimney

In order to install an external chimney from a stainless pipe, carry out the following work:

- Punch a hole in the pipe adjacent to the boiler. It should be located no lower than half a meter from the top of the boiler.

- Place fasteners on the outer wall one meter apart from each other.

- Connect the chimney inlet to the heating device.

- Remove the bent pipe elbow from the room.

- Install the capacitor.

- Fix the pipe to the wall.

- Install the chimney cap and protection.

Don't forget about fire safety!

At this temperature, dry wood nearby can easily ignite. Hence, it is fair to say that installing a sandwich pipe near a tree is not possible. The distance from the chimney to combustible walls should be 25 cm (according to SNIP). If the temperature is lower in the area of the sandwich pipe, then the distance may decrease to 7.5-10 cm - but not less. The best thermal insulation is air. You should not fill the box through which the chimney was passed with expanded clay or fill it with mineral wool. This technique will only improve heat transfer. For example, you can sew up the gap in the roof left under the chimney with galvanizing, placing a sheet of asbestos under it. When installing a sandwich pipe, one must take into account not only the heating of the pipe itself, but also the direction of the flow of hot air and sparks. If your roof is flammable, then the pipes should end at least one meter above the ridge, and not the surface of the roof. We wish you to carry out each stage of sandwich pipe installation correctly, and constantly consult with specialists. The best solution, if you do not know the installation principles and have no experience, is to use the services of competent specialists who have been working with these types of pipes for a long time.