Standards for organizing a heating system

The type of pipes used for the system will depend on what type of heating device is installed and what fuel it runs on. Gas equipment is installed in gasified houses.

Such a boiler has the following elements:

- pumps;

- automatic control;

- defense mechanisms.

In cases where there is no centralized gas supply, as a rule, solid fuel or electric boilers are installed.

There are a number of rules when assembling a heating system with such equipment:

- Various types of pipes can be used. The main thing is when choosing products, pay attention to the markings, which determine the scope of application of this type of pipe and its characteristics.

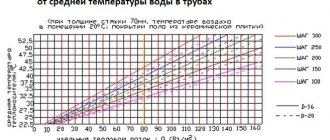

- As a rule, if the wiring is two-pipe with natural or forced circulation of coolant, metal-plastic heating pipes 16 × 2.0 are used.

- If the total heated area of the building is about 100 m2, the length of the pipes from the boiler to the radiators should not exceed 25 m.

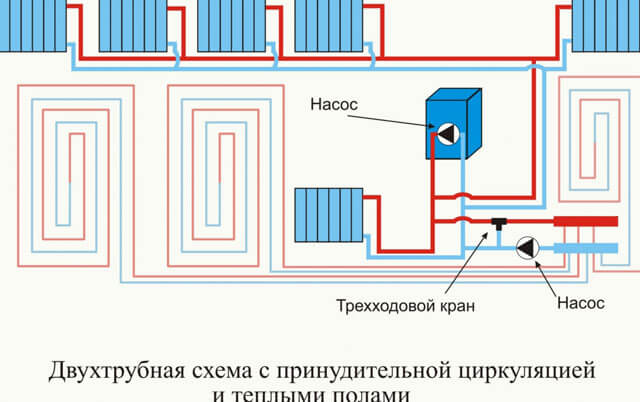

- In cases where the heating system is equipped with a large number of radiators, it is advisable to use double-circuit wiring with large cross-section pipes.

- A mandatory element of gas heating is the installation of an exhaust pipe to remove combustion products.

- The presence of any locking elements between the heating device and the security system is prohibited.

- Installation of the heating system should be carried out in compliance with the distance standards between elements.

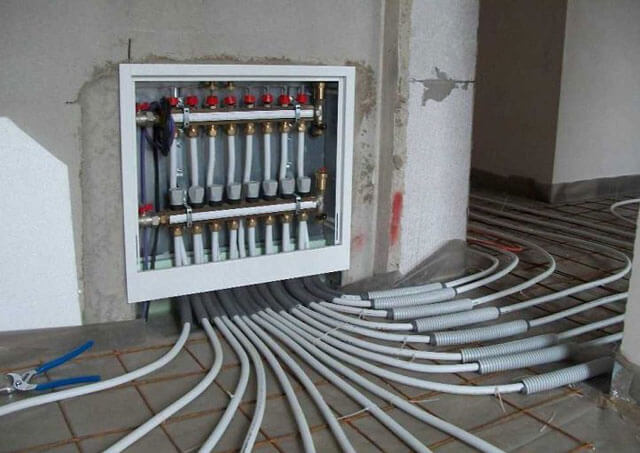

If forced circulation is provided in the heating, then it is advisable to install the filter in front of the pump. For beauty, contours for heating pipes are laid under the laminate.

Seamless pipe for heating and installation location of the heating device

So, first of all, the choice of seamless pipes for heating depends on the characteristics of the system itself. In this article we will refrain from thermal engineering and structural calculations; we have a different task - to help with the choice. The calculations should be carried out by heating engineers. There are simply no general conditions; they are different for each object and everything is calculated individually. The combination of a number of factors, the specifics of the tasks being solved, and the temperature regime of the facility’s operation are taken into account. But keep in mind that it is the design documentation that is the main criterion for choosing pipes and their characteristics.

Let's start with the features of the heating system as the main parameter influencing the choice of pipes. The most important thing is where the heating device is installed and what wiring diagram is used. There are two options.

Autonomous heating systems

The first option is a diagram of an autonomous heating system. It involves installing a heating device, often a boiler, directly at the site itself. In this case, internal pipe routing is performed. An important criterion for choosing a seamless pipe here is the installation method. There is an open, classic wiring. In this case, the decorative properties of the material from which the pipe is made come to the fore. Let's digress a little and talk about the materials from which seamless pipes are made. This refers to those that are used specifically in heating systems with an intermediate coolant.

There are few options, the most common are:

- carbon steel grades;

- alloy steel grades (simply “stainless steel”);

- copper, GOST 32598-2013 (pipes with a diameter from 6 to 267 mm), GOST R 52318-2005;

- aluminum and its alloys.

Less commonly used are bimetallic seamless pipes and pipes made of other non-ferrous metals and alloys. Please note that there are such options, for example, bronze, brass and others.

Let's return to the indoor open wiring. Copper, aluminum, and stainless steel have excellent decorative and performance characteristics. But they cost accordingly. Seamless pipe made from carbon steel grades is the most affordable. But with open wiring, an additional decorative layer must be applied to it, which is also protective. The easiest option is to paint it periodically. There are options that are more complex and less common. For example, perform chrome plating. We will refrain from talking about other exotics and design solutions.

The second wiring method is closed, the pipe is hidden in a wall or field (less often in the ceiling). Almost no one does this trick with seamless metal pipes. There is no point, but if there is one, then carbon steel pipes must be protected. In this case, we recommend using a galvanized seamless pipe or one with a polymer coating (more expensive, less common). Or at least paint it before laying it in grooves.

Centralized heating systems

This is the second option. In this scheme, one heating device is used to heat several objects. External pipe distribution appears, street between two objects. There are two installation methods - open and closed. In the first case, the pipe runs on the surface, in the second, it is laid underground. A seamless heating pipe in either of the two cases must have low thermal conductivity. This is necessary to reduce heat loss. And we also need protection from negative environmental factors. Such pipes are large in diameter and are made of carbon steel grades. This means that pipelines are susceptible to corrosion.

Previously, 20-30 years ago, they took mineral wool, wrapped it around a pipe, wrapped it with roofing felt, and tied it. Or they also applied a layer of bitumen. Now technology has come a long way. On the market you can buy insulated pipes for channel and non-channel underground installation. By the way, they are called pre-insulated, the second name is “pipe in pipe”. Insulation is performed using polymers and other materials. Among the most common options:

- PPU insulation, using polyurethane foam;

- PPM insulation, poly-polymer mineral foam is used;

- VUS insulation, reinforced, made from extruded polyethylene.

Aboveground installation is carried out using pipes with a galvanized steel shell and a layer of polymer underneath. There are actually many options for protective and thermal insulation coatings. The main thing is to protect the seamless pipe from corrosion, mechanical stress and reduce heat loss to a minimum.

Parameters of systems with natural or forced circulation

The decision which pipes are best to use for heating will also depend on the method of circulation of the coolant.

There are two types of system:

- with spontaneous circulation;

- with forced circulation.

With a spontaneous type of coolant movement, no additional devices are required - a heating boiler is enough. But forced circulation is provided by an installed pump.

It is worth noting that for the successful operation of a system with a natural type of circulation, precise adherence to slopes and distances between elements is required.

But in heating with a pump, it is possible to regulate the efficiency and pressure in the system. In this case, the equipment operates regardless of the temperature of the water in the pipes, their length or level differences.

It is noteworthy that the working pressure in a system with natural circulation is 1.5-2 bar, and with forced circulation it is 2-4 atmospheres.

What should heating pipes be like?

Of course, not only the efficiency of the entire heating system, but also its durability will depend on the quality of the pipes, since they are operated under conditions of increased load.

The first characteristic that determines the quality of a pipe is its reliability, which is maintained over time.

In addition, regardless of which pipes you choose for heating your apartment, they must be impermeable to oxygen. This will avoid oxidation and corrosion of the pipes from the inside, and their premature wear.

The tightness of the connections directly affects not only the heating mode, but also its maintenance. If the pipe is strong enough, the coolant will not be able to leak through it and will not damage the heating devices. The operating temperature loads and strength of heating pipes depend on the raw materials used for their production.

In addition, the noise level from water passing through the circuit is also an important factor. If everything is assembled correctly, the coolant circulation will not produce unnecessary sounds and will not cause discomfort. And, of course, communications should look aesthetically pleasing, because sometimes it is impossible to hide them.

Seamless pipe for heating - other selection options

Let's continue the conversation about the characteristics of the heating system and point out other parameters. It is important not only what temperature of the coolant and its pressure the pipe can withstand. That is, wall thickness is, of course, an important parameter, but there are others. There is also such a thing as throughput. It affects heat transfer, the amount of thermal energy required to heat the room. The throughput capacity directly depends on the diameter of the seamless pipe. There are three main parameters:

- outside diameter;

- internal nominal diameter (nominal diameter);

- conditional pass.

Moreover, the diameter affects not only heat transfer. In systems with natural circulation, the mobility of the coolant in the system and its circulation depend on these parameters.

Seamless pipes must be marked with the basic characteristics listed above.

The process of selecting pipe products for heating

So, to understand which pipes can be used for heating, you should pay attention to the following factors:

- placement of communications;

- operating temperature and network pressure;

- circuit installation type;

- system configuration (smooth or flexible pipes).

It is worth noting that the type of pipes for the heating system depends on its type. That is, if we are talking about a centralized network in a high-rise building with a working pressure of about 16 atmospheres, then the pipes must be very durable and reliable. At the same time, simpler products are suitable for private homes, because there the operating pressure in the network does not exceed 2-3 atmospheres.

As for the type of installation, the wiring can be external, hidden, or inside boxes or niches.

The fact which heating pipes are best for an apartment is also determined by the need for quick access to batteries and other elements for their repair. The type of coolant circulation also determines the type of pipes.

Standard distances between individual elements of the heating system depend on their diameter and material.

How to choose heating material

When choosing the right option, you need to consider the following aspects:

- laying method. The layout of heating pipes in an apartment can be both hidden and external. In the first case, the installation can be carried out in the walls, under the floor, inside the frame for wall panels or drywall.

- heating system diagram. From this point of view, it is necessary to take into account the type of room in which the heating pipes are laid. It can be either heated or unheated (for example, a basement);

- coolant temperature and operating pressure in the system. These indicators must be taken into account first.

- complexity of implementation. The heating circuit can be complex with additional configurations or simple, not requiring labor-intensive installation work.

- ease of repair or replacement. In addition, the answer to the question of which pipes are the best to use for heating an apartment largely depends on freedom of access to the batteries.

The choice of pipes and the method of connecting them largely depends on the type of network laying - hidden or open

Additionally, the performance characteristics of the material and its installation requirements should be taken into account.

Types of heating pipes

All pipe products intended for heating installation are divided into three groups:

- made of polymer materials;

- made of metal;

- metal-plastic.

Polymer products are made from polypropylene or cross-linked polyethylene, which correspond to the operating characteristics of the systems. Such pipelines are quite often laid underground. Metal-plastic products combine layers of polymers and metal.

As for rolled metal pipes, in the production of such products both non-ferrous metals, such as copper, and steel - stainless or ferrous - are used as raw materials. Often heating is installed from galvanized pipes. Their main advantage is their low susceptibility to oxidation and corrosion. Consequently, they deteriorate much more slowly.

Galvanizing is carried out by diffusion or hot method.

The diffusion galvanizing method is carried out by depositing zinc atoms on the pipe at a process operating temperature within 400℃. But hot-dip galvanizing involves immersing pipes in a bath of molten liquid zinc, the temperature of which is 450 ℃.

It is worth noting that steel, stainless and galvanized pipes are optimally suited for organizing a heating circuit with a spontaneous type of circulation. In this case, you need to comply with all standards for slopes and indentations and use pipes with a large cross-section - 25-50 mm.

Basic types of heating pipes

In order to understand what is best to use for heating a private house, you need to analyze the basic qualities of the wiring elements. Like any technical element of the complex, they are classified according to the following criteria:

- on basic materials;

- by production method;

- by diameter (working section);

- according to permissible parameters of pressure and temperature.

Steel

More common for multi-storey buildings are steel products connected to a common heating system. When organizing multi-storey heating, connection using electric arc or gas welding provides a reliable and durable connection that can withstand heavy loads. Steel pipes for heating in private construction are still popular due to their following qualities:

- resistance to high thermal influences that do not affect their characteristics;

- low susceptibility to water hammer and mechanical stress;

- high thermal conductivity;

- compatibility with fittings, shut-off valves made of brass, stainless steel, etc.;

- traditional methods of connecting elements using electric and gas welding.

For all its positive qualities, the most important disadvantage of steel pipes is their low corrosion resistance. This leads to the formation of iron oxide in such pipelines, which negatively affects the operation of circulation pumps, shut-off valves and automation. Complexes mounted from high-alloy steel (stainless steel) are quite rare, since the heat-conducting elements themselves, as well as their installation, are quite expensive.

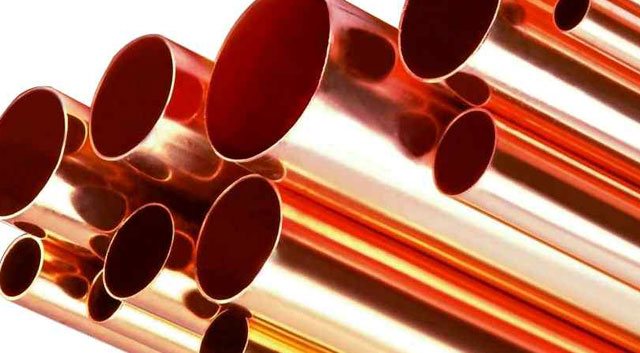

Copper

Not everyone can afford copper pipes due to their considerable cost. Their installation can only be carried out by specialists who understand how to work with copper and various types of solders. However, they have advantages, including:

- long service life, reaching 70-100 years;

- plasticity, allowing the pipe to be bent at sufficiently large angles without heating;

- low coefficient of resistance to the fluid moving inside;

- unique aesthetic appearance;

- ability to withstand freezing of the system.

Polypropylene

Products made from propylene are the most popular in heating systems of private houses. Their wide distribution is due to:

- prevalence and low price;

- small expansion coefficient;

- variety of colors, pleasant appearance of polypropylene structures;

- ease of installation, which even a beginner can handle;

- variety of types of reinforcement;

- no corrosion;

- high service life reaching 30 years.

Cross-linked polyethylene (PEX)

Cross-linked polyethylene pipe is a high-tech product that is becoming increasingly widespread in various systems. For production, polyethylene is used, processed on high-tech equipment with gas, peroxide, electron flow in an electromagnetic field, or using nitrogen compounds.

The processing process is called "cross-linking", so the products are said to be made from "cross-linked polyethylene". Installation of this type of pipe is carried out using compression fittings, and the technology is in many ways similar to the installation of metal-plastic pipes that have long been known on the market. Among the main advantages of PEX pipes it is worth noting:

- absence of fatigue stresses and high resistance to cracking;

- high flexibility with a “memory effect”, allowing it to take its original shape after the next heating;

- low specific gravity, facilitating the design;

- low specific expansion when heated;

- internal surface on which deposits do not form;

- ability of long-term operation at temperatures up to 95 ºС;

- 50-year service life.

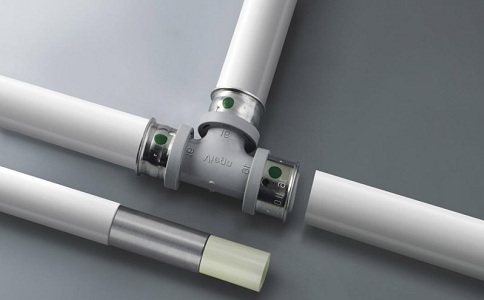

Metal-plastic

Metal-plastic pipes in heating circuits have been used for a long time and have earned a good reputation as reliable in operation and easy to install. This type has the flexibility of polymer and the strength of metal. Essentially, this is an aluminum thin-walled heat conductor, which is covered on both sides by a layer of polymer. The advantages of metal-plastic pipes include:

- high plasticity, allowing you to bend them by hand at the required angle;

- relative ease of installation;

- high resistance to mechanical and temperature loads;

- ease of transportation in shipping bays.

The pipe itself has a relatively low price, but fittings made of brass or high-alloy steel are quite expensive. In addition, at the joints they narrow the flow area of the pipe, which increases the resistance to the coolant.

In addition, long-term exposure to sub-zero temperatures, which leads to changes in the properties of the polymer and its cracking, is not desirable for this type of pipe. Therefore, it is not recommended to create heating circuits using metal-plastic in country houses or cottages where the owners do not live permanently.

Disadvantages of black steel heating pipes

Black steel pipes have long been used for heating installations, since such products are quite durable and resistant to high pressures and temperatures.

There are two types of black steel pipes - seam and seamless or seamless. Products with seams are obtained by bending and welding sheet iron.

Although both types of products can be used for various purposes, the strength indicators of seamless pipes are higher.

However, black metal pipes have a number of imperfections. They are prone to oxidation and corrosion, so the inside begins to overgrow over time, especially if the pipeline is empty in the summer. The inner surface of the pipes is not too smooth, and installation is carried out only by welding.

The outer layer of protective paint must be periodically restored. But it is impossible to apply such protection from the inside at all. Compared to other products with a similar internal diameter, steel pipes have thicker walls, which makes them quite heavy (about

Advantages of steel pipes

The problem of metal oxidation and corrosion can be solved by assembling heating from stainless pipes.

The most significant advantages of black pipes are:

- mechanical and shockproof strength;

- ability to withstand high pressure and temperature, as well as water hammer;

- no need for compensators;

- sufficient hardness of the product.

Since the linear expansion of steel is very small, steel pipes are able to function without failure even at high temperatures. All this makes them optimal for installing heating systems with a combined or natural circulation method.

Such pipes are used for heating circuits where it is practically impossible to regulate the water temperature and compliance of slopes with standards is mandatory. In particular, this applies to networks with solid fuel boilers or stoves. The operating features of such heating require that the pipe be able to withstand emergency boiling of the coolant.

Installation

There are several ways to connect steel heating pipes. Each of them has its pros and cons, which must be kept in mind when installing a heating system. Only compliance with the technological process will allow you to avoid unpleasant surprises during the heating season.

Steel pipe with tap on an aluminum radiator.

Methods for connecting steel pipes for heating:

Gas welding. Mainly used for connecting thin-walled pipes. As a result of gas welding work, a reliable, durable connection is obtained. Often used in tight spaces when using other connection methods is physically impossible;

Electric welding. Most often used for welding pipelines with thick walls (main heating networks). Electric welding allows you to heat the entire thickness of the pipe, which is difficult to achieve with gas welding;

Threaded connection. This is done using special threaded fittings. In addition, you need to cut the threads on the pipe yourself, which increases the installation time of the system.

Important! Galvanized pipes can only be installed using threaded connections; the use of welding is highly undesirable. The fact is that during the welding process, under the influence of high temperatures, the zinc coating simply burns out. Zinc is not able to withstand temperatures above 900°C.

Use for heating systems of copper pipes

One of the options for installing a heating system is copper pipes. Their oxidation occurs only under the influence of eddy currents, if such a circuit passes near electrical wiring, as well as in contact with aluminum.

It is noteworthy that copper products function stably even with strong differences in coolant temperatures - from negative values to 500 ℃.

In addition, due to the smoothness of the walls and the anti-corrosion properties of the material, the service life of such products is up to 100 years.

Among the advantages of copper pipes are their good thermal conductivity and high throughput, tensile strength and resistance to high pressure. The material has bactericidal properties and does not allow oxygen to pass through.

There are two methods to assemble a circuit from copper pipes:

- low temperature;

- at high temperatures.

The first one involves the use of flux, and is more preferable. The price of copper pipes is higher than other analogues. It is optimal to assemble heated floor systems under laminate from such products.

Criteria for choosing pipes for a heating system

The market currently offers products of various price categories and quality, made from materials with unique properties. And although technical characteristics are important, the final decision is influenced by a complex of individual factors for each object. Therefore, first of all, the consumer should know:

- area of the heated room, purpose of the rooms (kitchen, garage, nursery, etc.);

- boiler parameters (what fuel is used, power, etc.);

- the necessary and sufficient diameter, which determines the throughput;

- Is there special equipment for self-installation, or should you purchase it or hire a specialist?

It is important to consider what type of heating pipe system there is - closed or open. The difference is not only in design. In the open type, the coolant is only water that comes into contact with oxygen. This leads to corrosion of metal elements.

The closed type is sealed and can use antifreeze solutions. The wear-resistant system can withstand high pressure and high temperatures.

If communications are to be hidden in the floor or walls, then you need to understand that not all products are suitable for this. We are talking about “warm floor” systems and other ways to hide highways.

There is a difference in how the coolant will circulate - forced (using a pump) or natural (due to convection). The latter method requires a larger diameter and precise calculation for proper operation of the circuit.

It is worth considering that autonomous systems are not subject to changes in pressure and temperature, unlike houses connected to a central heating supply. This means there is a difference in the choice of pipes for heating a private and apartment building.

The answer to the question of which heating pipes are best suited, as well as studying the properties of the materials used for manufacturing, will allow you to make a choice.

Characteristics of metal-plastic pipes

The structure of metal-plastic pipes consists of two layers of polymer, between which a metal foil is laid. It can be cross-linked polyethylene, polypropylene and other polymers. This design allows you to achieve perfect smoothness on the outside and inside.

When choosing this type of pipe, you need to make sure that the coolant temperature in the system does not exceed 95 ℃ - these are the values that metal-plastic pipes are designed for. Such a high threshold determines their popularity.

Products of this type do not have linear thermal expansion, therefore they are acceptable for laying water-heated floors under laminate or in walls without compensation devices. They are also used for structures with forced or spontaneous circulation of liquid.

When are polypropylene pipes used for heating?

Polypropylene pipes for heating systems are used quite often. It is desirable that they are reinforced with aluminum or fiberglass. This frame makes it possible to minimize the linear thermal expansion of pipes. This is very important if the pipeline is installed into a wall. Note that in the absence of reinforcement, the pipes may stretch too much and damage the fasteners.

The maximum threshold that aluminum or fiberglass reinforced pipes can withstand is 95 ℃.

Polypropylene pipes are preferred for heating installations in private homes, when the coolant temperature can be adjusted. Moreover, the hotter the water, the lower the pressure in the circuit.

Comparative analysis of metal and plastic pipes

Despite the diverse range of materials that are offered for wiring heating systems, pipes made by rolling metal still remain in key positions.

Black metal

The lower limit of the melting temperature of steel products is 1500 degrees Celsius, which is a definite plus. Another advantage is the inherent rigidity of steel pipes, which allows the use of a minimum number of fasteners. But the material also has a number of disadvantages. Due to the high coefficient of thermal conductivity, the movement of the coolant to the radiators is accompanied by considerable losses. In addition, steel products are easily corroded, which means that they cannot be used in hidden wiring.

Stainless steel pipes

They have high performance qualities, being resistant to most external factors and characterized by their own rigidity. Therefore, it is worth noting the following number of positive characteristics:

- lack of response to electrochemical influences;

- resistance to high pressure;

- aesthetic appearance that does not change over time.

When assembling a system from this material, practically no various difficulties arise. They serve well both with open and internal wiring. The only negative quality of such a system is its high cost.

Copper pipes

The use of this material in the heating system will ensure decades of trouble-free operation. An additional advantage that ensures the long service life of copper pipes is obtained due to the fact that the connections used in installation are not susceptible to thermal destruction. However, the cost of such a system is also quite high. In addition, assembling copper pipes is very time-consuming due to the fact that connections are made by soldering. It should also be taken into account that aluminum batteries cannot be used with copper wiring, because these two metals enter into an electrochemical reaction.

Plastic pipes

The base material for the production of plastic products is polypropylene, and for greater strength it is often sewn together from several layers. Plastic has a number of advantages, the main one of which is complete chemical inertness. This means that the material does not react at all with the coolant, and it is also not susceptible to oxidation or corrosion. In addition, the substance has high plasticity, which makes it easy to install. There are three types of plastic products on the modern market.

Polypropylene

Reinforced polypropylene is used for heating system pipes; in this case, aluminum is used as a reinforcing frame. Among the positive properties of such a material, it is worth noting tensile strength due to metal reinforcement, a preference for a hidden installation method and high technicality of installation. All connections are made by melting the surface with a special soldering iron; this procedure can only be performed after undergoing special training.

Cross-linked polyethylene

This material undergoes processing that allows it to be resistant to high temperatures and mechanical damage. However, pipes made by this method are inferior to analogues made of reinforced propylene in resistance to pressure. Therefore, they are practically not used for heating systems, although they are quite suitable for completing heated floors, where they have found their main application.

Metal-plastic

These are pipes made of two layers of cross-linked polyethylene, which are separated by an aluminum insert 0.4 mm thick. Before choosing pipes made from this material, you should always check their suitability for use in heating systems. A system of metal-plastic pipes is installed using special connecting fittings. Products made using this method are distinguished by the highest strength, are easy to install and are perfect for hidden wiring.

Heating pipes made of cross-linked polyethylene

For laying heating communications, pipes made of cross-linked polyethylene can be used, which contains additional molecular bonds that give the material strength.

Such products are capable of operating at a coolant operating temperature of up to 90℃ and a sufficiently high pressure. They are used for underground highways, as well as for laying under laminate flooring.

Pipe production is carried out by molding products from heated blanks that retain their shape after hardening.

The small mass of the products does not overload the supporting structures of the system, however, in any case, you need to pay attention to the characteristics of the pipe declared by the manufacturer.

As a rule, cross-linked polyethylene pipes operate under the following conditions:

- pressure 7 bar and temperature 90 ℃;

- 11 bar pressure at 70℃ temperature.

The assembly of a pipeline from such products is carried out using press fittings and special tools.

Is there an alternative to galvanized pipes?

Glass fiber reinforced pipe

So what alternative exists to galvanized pipes? Are we really forced to drink water flowing through rusty pipes? Naturally not. For many years now, low- and high-density polyethylene has been produced and used everywhere for water, and for hot water, the so-called PPRS pipes (polypropylene reinforced pipes) or, as they say now everywhere in advertising, are “calde”. Such pipes can withstand temperatures up to 90 degrees Celsius, although their service life at this temperature is no more than 6 months, but how many days a year does this temperature occur in our heating plants? But owners of private houses using polypropylene pipes in their heating systems should not forget about this. The temperature in an incorrectly designed or installed heating system can remain at the temperature limit for using polypropylene pipes for a very long time, as a result of which they can become covered with holes and collapse.

This defect is typical for heating systems with automatic regulators on heating devices. When the boiler is constantly at 85 degrees, and the heat is controlled by radiator regulators. This is as bad as the temperature in the heating system below 55 degrees, when condensation forms on the pipes, and especially on the external surfaces of the boiler and its chimney. They say that the boiler is crying, and naturally its surfaces, especially the chimney, even if it is made of stainless steel, are actively corroded.

The answer to the question - is it possible to use galvanized pipes for heating and hot water supply systems and is it better to use a “rusty” pipe or PPRS pipes?

If anyone else has questions or you need a heating system design for a private home and competent professionals to implement it, welcome to contact us. The company has been operating in this service market since 1985, has an SRO and certified specialists. Designs and builds roof and conventional boiler houses, installs heating systems for residential apartment buildings and private houses. Examples of our work, address and telephone numbers are on the next page.

Since ancient times, heating systems have been created based on metal pipes. Their demand is due to their high reliability and durability. Even despite the emergence of new modern materials, steel pipes for heating are still relevant today. They withstand enormous mechanical loads and high coolant pressure, the temperature of which can reach +100˚С. And if the pipe freezes, it can be warmed up using an open fire.

Air heating from a gas boiler

Heating a house from gas equipment can also be of the air type. In this case, the air is heated in contact with a special element. With this design, there is no pressure in the circuit and the temperature is low.

So, the gas boiler gradually heats up the metal conductor, which transfers heat to the air pumped into the pipes by a fan. Next, the air masses enter the room through pipes, heating it. It is noteworthy that flexible corrugated foil pipes or metal pipes with thin walls would be optimal in such a scheme.

A similar heating option is provided and designed during the construction of a house.

If the duct is placed in the wall, it often makes a lot of noise and takes up a lot of space.

Based on the type of air circulation in the circuit, systems are distinguished:

- straight-through;

- closed type;

- recirculation with external pumping.

It is optimal if air recirculation occurs, which, after installing filters (mechanical, chemical or electronic), provides a flow of clean air. It is noteworthy that such a system has an efficiency of more than 90%, allows you to abandon batteries in favor of pipes, is economical and visually presentable.

What to do in case of a heating surge

Broken heating pipes must be repaired very quickly. First of all, they call a plumber or an on-duty team. They will be able to quickly get to the location of the problem if the installation is done correctly.

If you need to make a decision very quickly due to a threat to property or human health, measures should be taken to localize the accident site, not forgetting, however, about the high temperature of the water in the circuit.

The first thing you can do is place a container of water under the leak so that the wooden flooring does not get damaged. Next, you need to get to the riser and turn off the water supply. It can be either in the basement, or in the apartment, or on the supply main branch.

Remember safety precautions - use thick rubber gloves when working to localize bursts in the heating system, because the water in it is very hot.

VGP pipe, suture or seamless

15.01.2019

|In Pipe

|By SEO

Long products

- Rebar, wire rod

- Beam, channel

- Corner

- Circle

- Stripe, square

Sheet metal

- Hot-smoked sheet

- Cotton sheet

- Galvanized sheet

- Corrugated sheet

- Expanded metal sheet (PVL)

- Stainless steel sheet

Pipes

- Pipes h/d

- Cold pipes

- VGP, electric welded pipes

- Stainless steel pipes

- Pipeline accessories

Stainless steel

- Circle, square, hexagon

- Strip, corner

- Stainless steel pipes

- Stainless steel sheet

- Stainless steel hardware

- Accessories for stair railings

- Pipeline details

Hardware and metal raw materials

- Calibration, silver

- Wire, ropes

- Mesh, tape

- Radiators, electrodes

Non-ferrous metals

- Aluminium, duralumin

- Copper, bronze, brass

- Tin

- Lead

- Zinc

The ligaments are tied with steel tape or wire in three places. It is not allowed to transport thin-walled pipes together with regular pipes due to the high probability of damage. However, the size range of steel pipes according to GOST 10704-91 is very large, not only due to the large number of diameters, but also a very large selection of wall thicknesses. Electric-welded straight-seam pipes, like water and gas pipes, are widely used not only for the construction of pipelines, but also as a structural material in the production of metal structures for various purposes - from poles, supports and lighting masts to fences and enclosures. Packaging, labeling, storage and transportation. Other sizes of electric-welded steel pipes produced in accordance with GOST 10704-91 have no analogues in GOST 3262-75.

VGP pipe, suture or seamless

Steel pipes are stored in open, flat areas, specially adapted for storing rolled metal products, with a hard surface. Each bag is affixed with a tag indicating the diameter, wall thickness, length, steel grade, batch or melt number. Electric-welded steel and water-gas pipes are packaged in bundles (bundles) weighing from 2 to 5 tons. Steel pipes are transported in bulk in open vehicles - gondola cars or cars with an open body. The exceptions are thin-walled pipes with a wall thickness of 0.7 to 2 mm and pipes made of cold-rolled steel with a high surface quality. "TrustMetal" V or D according to GOST 10705-80.

VGP seam pipe

Such pipes are packaged in closed boxes or stored in warm heated warehouses.

see also

- Seamless stainless steel pipes

The use of a pipe in any structure can have a load-bearing, decorative or decorative-load-bearing value, therefore stainless steel pipes are made with...

- Seamless stainless steel pipe

Certificates. The disadvantage of the hot method is the complex and lengthy production process. The standard thickness of finished products can reach up to 75...

- Buy stainless steel seamless pipe

Stainless steel seamless pipes, according to the production method, can be hot-deformed (h/d) or cold-deformed (c/d). Their diameter varies in...

- Buy stainless steel seamless pipes

In this regard, a distinction is made between thin-walled and thick-walled stainless steel seamless pipes. They are used in energy, construction (heating systems),…

- Buy stainless steel seamless pipe

Seamless one-piece pipes do not need to be primed or painted. These include: resistance to aggressive external environments and corrosion,…

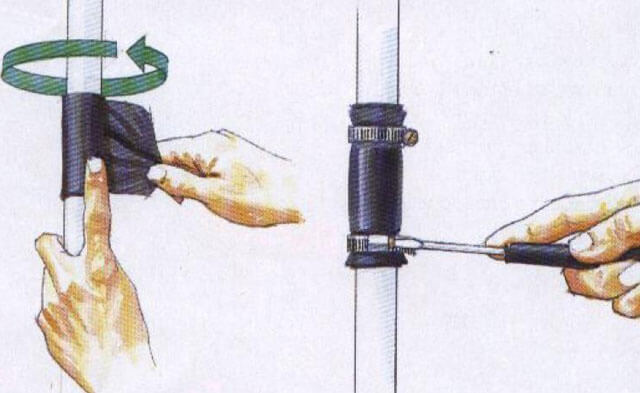

Work on sealing the emergency section of the pipe

While you are waiting for the emergency crew to arrive, you should localize the location of the leak and temporarily seal it to prevent water from leaving the system. A piece of rubber, for example from an old bicycle inner tube, as well as a screw clamp can be useful for this.

The procedure in this case will not differ depending on the type of pipe.

So the procedure is:

- The emergency section of the pipe is wrapped in several layers of rubber tape, and then secured along the edges with clamps.

- If you don’t have clamps at your disposal, you can replace them with a thick cord or wire.

- To complete the sealing procedure, the entire section of the pipe to be treated must be wrapped in thick fabric and secured with several layers of tape.

Such actions will only slightly slow down the leakage of coolant from the heating circuit, since during the emergency period the water pressure will be quite intense. It is worth noting that steel pipes themselves, made of stainless steel or coated with zinc, are quite durable. The weak points in this case may be threaded connections in which the seal is not installed.

Classification of metal pipes

Among the types of metal pipes are:

- Stainless steel pipes. This is a reliable option for a variety of reasons. This material has a colossal service life, which approaches 100 years. Stainless steel is not subject to corrosion. The strength of the steel is at a high level and can withstand tests according to safety criteria. The attractive appearance of these pipes produces an additional effect on the buyer. But there are still some downsides. First of all, this is the price: steel pipes are the upper price segment on the market. Installation is also more expensive.

- Steel pipes. Pipes of this category are durable, thermal conductivity is high, which is important for heating systems. The service life is shorter than that of stainless steel pipes, but also quite long. The main disadvantage of steel is metal corrosion. With prolonged use, a layer of rust forms, which affects the quality of water. Blockages in pipes also occur for this reason. Steel pipes are in the budget segment and are often chosen for heating, but you need to be prepared for future replacement.

- Galvanized pipes. This type differs from steel ones by the presence of an additional zinc coating. This layer is necessary to protect against rust formation.

Note! It will not be possible to completely avoid corrosion on steel pipes, but it is still quite possible to slow down its formation by using various anti-corrosion coatings.

- Copper pipes. The advantages of using this type of pipe are due to the characteristics of copper. The metal is practically not afraid of corrosion, and with proper installation it lasts a very long time. The elasticity of copper allows you to install pipes in hard-to-reach places. High temperature changes are not a problem for copper pipes; they do not crack at low temperatures. Copper has bactericidal properties, which increases the quality of the resulting water. The only disadvantages include instability to mechanical stress; external damage very quickly wears out the surface of the pipes.