is one of the leading manufacturers of mineral wool fiberglass thermal insulation materials in the world. These insulation materials have proven themselves to be high-quality products with an optimal price-performance ratio.

From this article you will learn what types of Izover thermal insulation exist, their characteristics, and how they differ from each other. We will also study reviews and find out why these mineral wool insulation materials are better than similar products on the market.

1 Scope of application of Izover thermal insulation

Thermal insulation materials from the French company Izover, in addition to excellent insulating abilities, also have good noise-reducing properties, which significantly expands the scope of their application.

3 Isover KL 34

Slab insulation, the thickness of which can be 5 or 10 centimeters. This material is intended for frame installation and does not require mandatory fastening with dowels. Model KL34, as evidenced by reviews, is characterized by high elasticity, which makes it possible to install it on any surface.

KL34 slabs are supplied in double-pressed packaging, after opening which the material immediately returns to its original shape. The thermal conductivity of Izover KL34 is 0.034 W/mk, vapor permeability is 0.53 mg/mhPa.

Among the advantages of this model, it is worth highlighting recovery after any deformation and resistance to shrinkage. The nominal compressibility of KL34 under a specific load of 2000 Pa is 60% of the same, and the recovery after compressive loads is 98%.

KL34 corresponds to the flammability class NG - a completely non-flammable material, and can be used in the temperature range from -70 to +250 degrees. The moisture absorption of KL34 when completely immersed in water for 72 hours is 5% of the total mass of the slab, and when partially immersed in water for 24 hours – 1%.

Line of insulation Izover K (l - slab, t - roll)

4 "Pitched Roof"

A material designed to insulate the inner surface of the roof of a house. The release form is slabs 5 or 10 centimeters thick, 117 cm long, and 61 cm wide.

The advantages of Pitched Roof wool include its high hydrophobicity - the material practically does not absorb moisture even when completely immersed in water for a long time, which allows it to be used effectively in difficult wet conditions in which other insulation materials would lose their thermal insulation abilities.

Technical characteristics of Izover “Pitched Roof” are as follows:

- thermal conductivity coefficient - 0.035 W/mK as in ;

- vapor conductivity coefficient – 0.55 mg/mchPa;

- Moisture absorption during partial immersion in 25 hours – 0.08 kg/m².

The density of this material is 15 kg/m3, it shows good return deformation properties. In terms of flammability, “Pitched Roof” belongs to the class of non-combustible materials NG, which makes it possible to use it for thermal insulation of industrial premises.

The area of the slabs in one package of such insulation is 14.27 m², the weight of the package itself is 10.8 kg.

Installation of insulation Izover "Pitched Roof"

«

5 Isover KT37

Izover KT37 is a rolled thermal insulation material for insulating the internal parts of buildings made of concrete, brick, wood and aerated concrete. Consumer reviews indicate that it is perfect for insulating the inside of walls, attic or interfloor ceilings and joists.

KT37 belongs to the category of soft thermal insulation; the material has a density of 15 kg/m3, which does not allow the use of this material on surfaces experiencing severe mechanical loads.

Compared to the original volume of the roll, the packaged KT37 is compressed almost 2 times, which greatly simplifies its transportation; the volume of one package is 0.16 cubic meters, after opening - 0.71 cubic meters.

The thermal conductivity of Izover KT37, as well as comparable to other insulation products from this company, is 37 W/μ, which makes even single-layer insulation with this mineral wool quite effective.

The thickness of a KT37 roll can be 50 or 100 mm, length - 630 cm, width - 60 cm. The roll form of the insulation makes it possible to cover large surfaces much faster than can be done with slab material. In terms of flammability, the product is classified according to the European standard A1, which corresponds to our NG class (non-combustible material).

6 Isover KT40

Isover KT40 is a two-layer thermal insulation material, produced in the form of a roll, intended for insulating the walls of frame houses, installation in the middle of false walls and thermal insulation of free space inside hollow brick walls.

The thickness of the KT40 roll is 100 mm, and, thanks to the two-layer design, the product can be divided into two rolls of 50 mm each. The overall characteristics of KT40 are as follows: roll length – 700 cm, width – 61 cm, the area of one package of insulation is 17.08 m².

In terms of thermal insulation properties, KT40 is somewhat inferior to the rest of the company's products; its thermal conductivity coefficient is 0.04 W/μ. The material has high vapor permeability (about 0.5 Mg/mPa), which makes it the best option for insulating the walls of wooden and frame houses.

According to flammability standards GOST 30225 KT40 belongs to the class of non-combustible materials NG. This mineral wool is not intended for thermal insulation of surfaces subject to difficult wet conditions.

The moisture absorption of the material during partial immersion is about 15% of the total mass, as a result of which when installing KT40 it is better to install an additional waterproofing layer.

7 Isover “Venti”

8 "Standard"

Mineral wool "Standard" is a universal option for non-load-bearing thermal insulation of any surfaces. This is an excellent solution for insulating walls and facades of buildings made of any materials - wood, brick, concrete, gas silicate blocks.

Using Standard type slabs, you can successfully insulate the roof, attic, roof, floor or ceiling of a house.

Structure of mineral wool Izover “Standard”

«

This insulation has a density of 38 kg/m3, which allows it to be used as facade thermal insulation for subsequent application of wet plaster.

Technical characteristics of Standard wool are as follows:

- Thermal conductivity coefficient according to GOST 7076-99 – 0.035 W/mk;

- Vapor conductivity coefficient – 0.3 Mg/Mpa;

- Water absorption during partial immersion for 24 hours is 1% of the total mass of the slab;

- Nominal compressibility under a load of 2 kPa – 8%;

- Flammability class according to GOST 30244-94 – NG (completely non-combustible material);

- The permissible operating temperature range is from – 80 to +700 C.

Izover “Standard” is produced in the form of slabs, the width of which is 60 cm and the length of 120 cm. Thickness is 5 or 10 cm.

Mineral wool Isover (Izover)

is a modern energy-efficient solution to the issues of insulation of buildings and structures for various purposes. It is characterized by a high level of environmental safety, confirmed by the EcoMaterial Absolute eco-label, excellent noise insulation and a long service life (about 50 years). Complies with the European standard EN 13162, but at the same time it is quite affordable for the Russian consumer.

Types of Isover mineral wool insulation

Mineral wool Isover (Izover) in slabs.

A fairly light, elastic, dust-free material that can provide high thermal insulation with a single-layer fastening.

Izover insulation holds its shape well

, does not sag or cake for many years. Sheets of various thicknesses are used to insulate roofs, floors, walls, partitions and ceilings.

Thermal insulation from Isover mineral wool in rolls.

Izover insulation is a very convenient option for laying along joists, thermal insulation of pipelines and other non-flat structures, as well as for seamless installation with a large insulation area.

Solutions for ventilated facades

.

“VentFasad Verkh” slabs are light and thin, with high thermal protection. Izover insulation allows you to double the installation speed and reduce the number of fasteners by 40%.

“VentFasad Bottom” slabs eliminate the formation of air pockets due to the increased elasticity and elasticity of the fibers that fit tightly to the wall.

You can order Isover mineral wool from us by placing an order through the online store or by calling us at the number listed on the website. We will be happy to advise you during business hours.

Thermal insulation is an essential component of any construction. Currently, materials from this category are presented on the market in a very diverse assortment, so it can be difficult for the buyer to make the right choice.

Among the variety presented, ISOVER brand insulation is consistently popular. This is a trademark of the world-famous concern Saint-Gobain, which has been supplying its products to the domestic market for more than 20 years.

. During this time, a certain opinion has already formed about the Isover insulation. Therefore, we suggest that you familiarize yourself with the features and characteristics of this material.

Manufacturing technology "Izover"

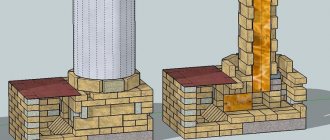

What is ISOVER? This is mineral wool-based insulation, which is available in rolls, slabs and soft mats. However, regardless of the shape, the products are manufactured using the same technology. The process looks like this:

- The raw material used is a mixture of quartz sand, limestone, soda ash, and microscopic glass particles.

The components are mixed and heated to a temperature of 1,300 degrees

. As a result of thermal exposure, solid components melt, turning into a viscous homogeneous mass.

The resulting composition is loaded into a special installation (centrifuge), the bowl of which rotates at enormous speed. The walls of the working container have holes through which the molten substance is squeezed out, forming thin threads.

Then the resulting glass fiber is mixed with adhesive based on polymer materials.

The mixture is repeatedly subjected to heat treatment, simultaneously leveling the layers with steel shafts.

At the final stage of production, the insulation is cut into strips, following the specified dimensions.

Types of thermal insulation

The ISOVER insulation line includes several items. Each type of produced material has its own characteristics, which determines the scope of application. In particular, the following categories of insulation can be found on the market:

- Classic stove.

- Sloping form.

Ventilated façade.

Plaster facade.

Floating floor.

Soundproofing.

Basic characteristics can be found out from the markings indicated on the packaging. It looks like this:

- OL-E

. The only material in the series that is used for outdoor use. The material has high density and non-porous structure.

KL

. Soft slabs designed for insulation of internal partitions and ventilated facades.

AL

. Insulation with this marking has a layer of aluminum foil on the surface that serves as a vapor barrier.

KT

. This is a roll insulation used to insulate large areas.

Knowing these features, you can easily select insulation to solve specific construction problems.

Characteristics of Izover

- Excellent thermal insulation properties - Izover thermal conductivity coefficient varies from 0.033 to 0.037 W/mK.

- High degree of sound insulation.

- Capable of operating in a wide temperature range (the material is sintered at 60,000).

- The hydrophobic properties of the material exceed those of analogues and are achieved by introducing water-repellent additives into the insulation composition.

- Environmental safety of the material - does not emit harmful fumes during operation;

- High biological resistance - Izover is not damaged by fungus, mold and insects.

- Convenient ergonomic packaging that minimizes the volume of material.

- Convenient and easy installation.

- Ideal price/quality ratio. Izover is produced in full compliance with the European standard EN 13162. Having a higher price than other insulation materials, it fully justifies it with its unique characteristics and long service life.

Scope of application of fiberglass products

“Isover” is considered a universal insulation material, therefore it is suitable for the following work:

- Heat and sound insulation of external wall structures.

Roof insulation.

Arrangement of ventilated facades.

Soundproofing of internal wall partitions.

Industrial ventilation systems, pipelines.

| The product's name | We recommend using it together with | |||||

| Classic | Classic Stove | Pro | Sauna | vapor barrier | hydro-moisture barrier | |

| Insulation of pitched roofs | fits | fits | we recommend | — | Yes | Yes |

| Insulation of external walls under cladding or brick | fits | we recommend | we recommend | — | Yes | |

| Insulation of walls from the inside | fits | we recommend | we recommend | — | Yes | |

| Insulation of frame walls | fits | we recommend | we recommend | — | Yes | Yes |

| Soundproofing of partitions | fits | we recommend | we recommend | — | ||

| Insulation of attic floors | fits | fits | we recommend | — | Yes | |

| Insulating the ceiling above the basement | fits | fits | we recommend | — | Yes | |

| Soundproofing floors using joists | fits | fits | we recommend | — | ||

| Soundproofing of suspended ceilings | fits | fits | — | — | ||

| Insulation + vapor barrier of internal walls and ceilings | — | — | — | Yes | ||

Material Specifications

With an optimal price/quality ratio, thermal insulation has the following technical characteristics:

- High thermal conductivity: 0.033-0.037 W/mK

.

Flammability class NG

: does not ignite and does not support combustion.

Wide operating temperature range: withstands heat up to 6,000 degrees

.

Density: about 15 kg/m2

.

Moisture absorption: 0.08 kg/m per day

.

It should be clarified that these are average indicators. Insulation is available in a wide range, so density and thermal conductivity may vary.

Izover - characteristics

Thermal conductivity and sound insulation. The thermal conductivity coefficient is very low, so the fibers retain heat quite well.

Izover insulation consists of glass fibers, between which there is an air layer. It is this layer that absorbs sounds, which elevates this type of thermal insulation material to a higher level.

Flammability and vapor permeability

Isover is a non-flammable material, since its density is 30 kilograms per 1 cubic meter. Therefore, it is safe for the construction of both a cottage and an ordinary high-rise building. The main thing is to comply with all fire safety rules during the construction of structures of any type.

Manufacturers of many insulation materials do not focus on moisture resistance. Therefore, such insulation materials are only good in conditions of relative dryness. If there is water in the room, then even glass fibers retain heat less well.

However, fiberglass gives back all the moisture it has absorbed. To do this, you need to make a gap of 2 centimeters between the insulation and the wall (for ventilation). This is important to do, because otherwise the thermal insulation will gradually decrease. 0.50–0.55 mg/mh Pa are indicators of the vapor permeability of the material.

Environmental friendliness of the material

The strength is not only technical characteristics, but complete harmlessness to the environment and humans in particular. This is explained by the fact that fiberglass does not emit any substances harmful to human health and the environment. This has been confirmed by scientists in Finland, as well as various cancer research centers.

Additional insulation characteristics:

- The density of the connection to the base decreases depending on the building that is to be insulated.

- Air permeability – 120*10–6m3/m×s×Pa.

In general, certain characteristics depend on the purpose and type of this insulating material.

Which is better, Isover or Rockwool?

These brands of insulation are direct competitors in the construction market, so consumers are interested in which material to choose. It is immediately necessary to clarify that both insulation materials have similar characteristics, however, they are produced using different technologies.

ISOVER is a mineral wool made from glass fiber, produced by a French company. ROCKWOOL is basalt wool produced in Poland. Considering that the second insulation is made on the basis of basalt rocks, the production technology completely eliminates the presence of glass. Therefore, Polish products are considered more environmentally friendly.

If we talk about which insulation is better, there is no clear answer: it all depends on the area of application. In particular, “Izover” is better suited for insulating the floors of the first floors, non-residential roofs, balconies and loggias.

This is due to the fact that non-compliance with installation technology can lead to microscopic particles of glass floating in the air of residential premises, which can have a detrimental effect on health. “Rockwool” does not suffer from such a “disease”, therefore it is optimally suited for interfloor and internal wall partitions.

Do not forget that ISOVER is much cheaper, which for many is a decisive factor when choosing insulation.

Briefly about the manufacturer

As mentioned above, ISOVER is a trademark of the industrial group. The company has a 350-year history

, the central office is in Paris.

The company has representative offices in 67 countries around the world

. In addition to ISOVER, Saint-Gobain produces insulation products of the ISOROC and ISITEC brands.

On the territory of Russia, enterprises are located in Yegoryevsk and Chelyabinsk near Moscow. The products are manufactured using original technology, are subject to mandatory international certification, and comply with GOST standards. It should be noted that since 2013

, the enterprises launched a production line for the production of basalt wool under the brand of the same name.

Modern insulation Izover is produced with a base of basalt or glass fibers. The material is obtained by processing quartz sand, mineral rocks of the basalt group and broken glass. The components are mixed, melted at ultra-high temperatures in special furnaces, and then drawn into fibers of different lengths and thicknesses, bonded with a special type of resin.

Isover insulation is produced in two versions: slabs and rolls using our own technologies patented in 1981 and 1957.

Main characteristics of insulation

Isover brand thermal insulation materials made from mineral wool inspire confidence and are in stable demand. Moreover, both slabs and rolls are rightfully considered one of the best thermal insulation on the market.

The main characteristics of insulation include:

- Thermal conductivity.

- Soundproofing.

- Flammability.

- Vapor permeability.

- Long service life.

- Environmentally friendly.

- Convenient release form.

- Light weight.

As a heat insulator, Izover insulation has managed to prove itself from the best side precisely thanks to its thermal conductivity coefficient equal to 0.041 watts per meter per Kelvin. The coefficient does not change during the operation of the insulation throughout its entire life; the fibers do an excellent job of accumulating and retaining air, preventing heat loss.

The material has excellent sound insulation properties. Fiberglass insulation with an air gap absorbs noise, guaranteeing an optimal level of silence, especially if you use specially adapted types of insulation to create a sound insulation layer.

The flammability index also matters. Thermal insulation materials with technical characteristics indicating a density of up to 30 kilograms per cubic meter are classified as non-flammable. The materials are successfully used in premises of any type and purpose, without fear of the spread of fire in the event of a fire.

Thermal insulation boards made of mineral wool with special technical characteristics indicating the presence of an additional layer based on aluminum foil or fiberglass are classified as slightly flammable.

Such materials are used subject to certain restrictions, which in fact are nothing more than a convention. In practice, insulators are appropriate almost everywhere; the main thing is to follow the fire safety requirements for structures prescribed in SNIP.

An important item on the list of technical characteristics of thermal insulation is vapor permeability. The insulation is able to maintain functionality even after contact with moisture. Unlike many modern analogs for thermal insulation, Izover products based on stone wool simply and effectively cope with the problem of moisture penetration inside the thermal insulation layer.

The insulation releases the absorbed moisture as quickly as it receives it; the main thing is to leave a small gap (2-3 cm) between it and the wall to maintain ventilation.

Neglecting this simple rule will lead to disruption of the material’s ability to remove moisture, which over time will negatively affect the ability to retain heat. Izover insulation materials have optimal vapor permeability values - from 0.50 to 0.55 mg/mchPa.

Analysis of the technical characteristics of the material also implies mention of such an important parameter as service life. The material not only does not allow heat to pass through, but is also able to serve properly for several decades. The manufacturer claims a service life for thermal insulation boards and rolls of 50 years with full preservation of functionality.

A special feature of the material is that it contains water repellents that can repel moisture, preventing the proliferation of insects, fungi and the formation of mold, which in turn ensures safety throughout the entire period of use.

Among the technical characteristics of the insulator, environmental friendliness and complete safety for health play a special role. Izover materials do not pose any risk to life and health, as they are made from natural raw materials.

The lighter weight of the insulation is not just one of the characteristics, it is a clear and undeniable advantage. If we compare the insulator with analogues, its weight is an order of magnitude less, which in turn allows you to expand the scope of application by combining the insulation with surfaces made from less durable materials.

The release form can be considered an excellent bonus from a manufacturer who places an emphasis on improving the technical characteristics of the finished product. Insulation materials are available in several versions - rolls, slabs, and less commonly - in mats (for example, ISOVER ISOTEC KIM-AL).

The average thickness of single-layer insulation ranges from 50 to 150 mm. Two-layer insulation has a fixed thickness of 5 cm with standard dimensions of 1 m by 1 m. The roll is produced in an area of 16 to 20 square meters with a constant width of 1.2 meters and a length ranging from 7 to 14 meters.

The technical characteristics regarding the flammability of thermal insulation material include the following parameters:

- flammability;

- flammability;

- smoke generating ability;

- toxicity.

The flammability of thermal insulation boards and rolls based on mineral wool varies within 30 kg/m3, if we are talking about a group of non-combustible materials. Semi-rigid and rigid slabs coated with film and foil from the group of slightly flammable materials are placed in a separate category.

Technical characteristics of Izover

The Izover material is made of the highest quality fiberglass, and this is achieved by using TEL technology. Izover currently has no analogues on the construction market. Izover has the following advantages:

- The thermal conductivity of the insulation is very small and is about 0.041 watts per Kelvin. This value makes it possible to retain heat well in the premises, but the main thing is that the thermal conductivity coefficient does not increase over time. Usually, on other models of insulation, due to the service life, the quality of the material decreases and the coefficient of thermal conductivity increases.

- Izover insulation is renowned not only for its thermal conductivity, but also for its excellent sound insulation . This is due to the structure of the fibers, between which there is a layer of air, and it actually absorbs all extraneous sounds. Separate Izover models are also produced, which are aimed more specifically at sound insulation.

- All thermal insulation materials that fall under the Isover category have a density of about 30 kilograms per cubic meter, and therefore they are non-flammable materials, and therefore can be used on any type of building, both from the outside when finishing the facade, and indoors.

- Vapor permeability of Izover , like all other insulation materials, is a big issue. As a rule, when moisture is absorbed, the quality of thermal conductivity deteriorates significantly. For the Izover material, vapor permeability reduces heat transfer by 10% if the moisture content of the insulation increases by only 1%. To prevent this from happening, it is recommended to leave a gap of at least 2 cm between the insulation material and the wall. The fiberglass from which Izover is made quickly releases moisture and requires space for steam circulation.

Types and application of insulation

The description of the main technical characteristics of the material confirms the fact that as an insulation material it is practically unrivaled. Plates and rolls are used for internal and external insulation, creating a thermal insulation layer for rooms and structures of various types and purposes. The heat insulator is presented in a fairly wide range in order to select the option that best meets the requirements.

Thermal insulation for pitched roofs is the most suitable option for insulation:

- pitched roof from the inside;

- insulation of the house under siding;

- insulating the pitched roof from the outside.

This type of material is characterized by improved moisture resistance, which allows it to be used for insulating roofs operating in conditions of high humidity.

Another option for insulation based on stone wool is to improve the quality of sound protection. The material is suitable for insulating partitions, insulating structures under siding, insulating floors along joists and walls inside a house.

Isover for sound insulation has excellent sound insulation properties and is indispensable for improving properties in partitions and other structures.

Another type of insulation based on stone wool is Izover Classic Plus. The material is suitable for insulating almost all types of surfaces and has a thermal insulation coefficient of 0.041 W.

Sold in the form of lightweight slabs with two thicknesses: 50 mm and 100 mm, in packs of 7 and 14 pieces. Classic slabs are easy to use and suitable for installation in rooms with limited space. The material does not require the use of special fasteners and is used for insulating partitions, suspended ceilings and other surfaces. You can buy Izover Classic Plus slabs at an affordable price.

Unlike Classic Izover Sauna slabs, it is a material based on fiberglass wool with an additional layer of foil. The products are produced in thicknesses of 50 mm and 100 mm, with a width of 1200 mm and lengths in two versions - 625 mm and 12500 mm.

From the name it is clear that the insulation is designed primarily for use in saunas, where stable high temperatures are maintained and additional protection against excessive steam release is required.

The thermal insulation material is safe, durable, sold in packages convenient for transportation with slab thicknesses of 50 mm, 100 mm, 150 mm.

Izover Profi, which is also produced in the form of rolls and slabs, also has technical characteristics different from the Classic insulator. The insulation has a 3D effect, which allows you to insulate surfaces with a tight fit to the base and consoles. In terms of the level of thermal protection, it is the Pro that is considered the most effective and has an indicator of 0.037 W.

The material is available in two thicknesses: Profi slabs 50 mm and Izover Profi insulation 100 mm (in rare cases up to 150 mm).

Special insulation materials are suitable for insulating ventilated facades. These are models for insulating the outer layer in the case of two-layer thermal insulation, guaranteeing minimal heat loss with high thermal protection performance.

Complete with insulation for the top layer, Izover VentFacade Bottom is also used for the bottom layer, also with excellent thermal performance. The thickness of the slabs (50 mm or 100 mm) is determined based on thermal engineering calculations.

To insulate single-layer ventilated facades, Izover Facade Mono and VentFasad Optima for low-rise buildings are used.

Another type of slabs with a thickness of 50 and 100 mm (in some cases 150 mm) is Isover KL34. The materials are tightly mounted on the frame without the use of additional fasteners. The slabs, just like Classic, are suitable for insulating both ventilated facades and multi-layer brickwork, while insulating horizontal and vertical planes is equally effective.

Isover KL37 is an insulation material sold in tightly compressed packages. Just like the previous options, it does not require additional fasteners and is suitable for installation between floors, insulation of roofs and walls with maximum adherence to the surface.

A variation of the previous model is Isover KT37, produced in compressed rolls. Installation of insulation for thermal insulation does not require additional fasteners; the elements adhere perfectly to the surface. Used for insulation of roofs, interfloor ceilings, attics and partitions.

Isover KT40 is a two-layer insulation in compressed rolls, suitable for thermal insulation of both vertical and horizontal surfaces.

Isover STYROFOAM 300A is a thermal insulation material, the installation of which is complicated by the use of fasteners. It is produced in hard, rough slabs and adheres well to concrete. The composition includes extruded polystyrene foam, due to which insulated cells are formed that improve moisture resistance. Both horizontal and vertical surfaces inside and outside are insulated with the material.

Another type of material ISOVER ISOTEC KIM-AL in the form of thermal insulation mats made of fiberglass. The material is developed using a special vertical fiberization technology, additionally covered with a layer of aluminum foil to improve vapor barrier and increase service life.

ISOVER ISOTEC KIM-AL mats are used to insulate air ducts of supply and exhaust ventilation systems, process equipment, fittings, pipeline flange connections, etc.

The main advantages of ISOVER ISOTEC KIM-AL include the special arrangement of fibers, due to which the material, during installation, retains its original shape unchanged, fitting as tightly as possible to the surface. In addition, the insulation increases the level of sound insulation in the room and is suitable for thermal insulation of pipes inside buildings.

The advantage of ISOVER ISOTEC KIM-AL is also its resistance to chemicals. If we compare KIM-AL with other insulation materials based on stone wool, its superiority is obvious - the material is not susceptible to moisture and aggressive environments.

When using insulation material (it doesn’t matter whether it’s Classic Facade, Pro or soundproofing slabs), you need to protect your hands and eyes with gloves and goggles.

Competition in the market for thermal insulation materials is fierce. Manufacturers try to offer new products every year that are superior to traditional materials in various respects. Some are trying to modify the old ones, giving them improved technical characteristics.

But among the insulation materials there are also those that remain unchanged in terms of quality, shape, structure and size. This category includes “Isover” insulation. This is a Finnish product that has been present on the Russian market for more than 20 years. So our compatriots have long been familiar with this brand and call it in Russian - isover.

In this article we are faced with the topic of the feasibility of using this heat insulator. The thing is that isover is mineral wool made from glass threads, or, more precisely, from fiberglass. Hence the technical characteristics that this insulation has.

Important.

Glass production is based on the use of only natural materials, which means that isover is an environmentally friendly material (cotton wool).

Currently, manufacturers have begun to add glass industry waste or recyclable materials to it. This did not affect the quality, but the cost decreased significantly. And this is again a big plus.

Minvata Izover - characteristics

Before you buy Izover and install it, in order to obtain high-quality thermal insulation results in your own home, it is useful to know what mineral wool is and what its distinctive characteristics are.

Mineral wool is a fibrous material that is sold in the form of rolls, mats and slabs. The basis is taken from exclusively high-quality fiberglass, manufactured using TEL technology.

The technical characteristics of Izover mineral wool are as follows:

- Isover thermal conductivity. The value of this parameter is minimal - only 0.041 watts per meter per Kelvin. For this reason, such material retains air well and does not change its performance in different climatic conditions, which is the problem with many other types of insulation.

- Izover sound protection. Mineral wool from this manufacturer does an excellent job of protecting against external noise. The maximum possible parameters are achieved according to current standards due to the presence of an air gap between the fiberglass fibers.

- Density of mineral wool. This figure may vary depending on the specific type of product, but on average it is 13 kg/m3.

- Fire safety. The flammability of mineral wool is determined by the Isover density. Thus, slabs with values up to 30 kg/m3 belong to the group of completely non-combustible materials. This makes it possible to use Izover for buildings of any type - commercial and residential premises, cottages and apartments in high-rise buildings. Rigid and semi-rigid slabs with aluminum foil are low-flammable, so they can also be installed almost anywhere. The main condition when using Izover insulation is strict adherence to fire safety rules during the operation of the house.

- Vapor permeability. The indicator corresponds to 0.50 - 0.55 mg/mhPa. The accumulation of condensation inside the insulation system is a problem with any modern material used for insulation. The advantage of mineral wool in this case is that glass fibers very quickly give back the moisture that they have absorbed, and special water repellents help repel it. The main thing is to leave a gap of at least 2 cm between the wall during installation to remove moisture.

- Life time. In this regard, the restrictions have a very wide range - from 50 to 100 years, depending on climatic conditions and the building material used to construct the walls.

- Ecological cleanliness. The component composition of Izover mineral wool is absolutely safe for humans. During operation of the insulation system, no harmful fumes are generated, so you can safely take it if you put environmental friendliness as one of the first points when choosing a suitable insulation.

- Weight of Izover mineral wool. This material is one of the lightest of the entire line of existing insulation materials, which means it can be used for installation even on surfaces with a small load-bearing load.

- Isover dimensions. As already mentioned, mineral wool of this brand is presented in various types on the market. Depending on the type of material, the thickness is 5-10 cm, the overall dimensions of the slabs on a standard grid are 1 * 1 meter, the rolls include a mineral wool area of 16-20 m2 with a roll width of 1.2 meters and a length of 7-14 m.

Specifications

Possessing a large number of advantages, isover immediately determined its superiority over other types of thermal insulation materials. He did not change the technical characteristics and this won the rating of modern insulation materials.

These are the characteristics:

- Since this is insulation, isover has low thermal conductivity. The indicator is 0.038.

- High sound protection. We can talk about this material not only as isover - insulation, but also as sound protection.

- Made from fiberglass, Isover is not susceptible to bacterial and fungal infection. It is not eaten by rodents and small insects. So it's great protection.

- The weak side of the characteristics of thermal insulation material is high moisture permeability. Many porous types suffer from this, including mineral wool.

Advice. Many insulation materials absorb moisture and do not release it, thereby losing their thermal insulation qualities. Isover behaves differently. Made from glass fibers, it dries quickly when exposed to rising temperatures or good ventilation. Therefore, it is laid so that there is a ventilation gap between it and the protective barrier.

- Low specific gravity (density – 13 kg/m³). This ensures simplicity and ease of use, transportation, loading and unloading. Installation can be done by yourself.

- Environmental friendliness was discussed above.

- High degree of resistance when the insulation is exposed to chemically active substances, where fuels and lubricants are released.

- Isover is an elastic material (cotton wool) that can be compressed up to 60% - these are mats and up to 75% - roll type.

- Service life – 50 years.

- According to fire safety requirements, isover belongs to the category of non-combustible materials (NG). This is also a big plus.

They use insulation for thermal insulation of any structure of the house, both indoors and outdoors. For the sake of fairness, it should be noted that isover is the owner of not only advantages. It has some disadvantages:

- It can be used in places where the ambient temperature does not exceed +250 °

C. For residential construction, this is a completely unimportant condition. - A tight fit to the insulated structure is mandatory. For isover it is necessary to prepare the surface with maximum evenness, without large flaws.

Insulation Isover Uteplyaev Crimea (0)

| UTEPLAYEV | |

| UTEPLAYEV Isover is high-quality heat and sound insulation in rolls. One roll contains 2 mats, each 50 mm thick. Thus, you can use the thickness that you need to insulate your home. The material is supplied in packaging compressed 3-5 times. This makes it easier to deliver and store. After unpacking, the material completely restores its shape and size. UTEPLYAEV Izover is produced in Russia and is fully certified. | |

| ISOVER Pro | |

| Special heat and sound insulation for pitched roofs with increased elasticity! Advantages of Izover Pro: • Increased elasticity. • The highest level of thermal protection from ISOVER. • Plates in a roll: thickness per roll 50 mm - 24 slabs; roll thickness 100 mm - 12 slabs; thickness per roll 150 mm - 8 slabs. • Thermal insulation can be conveniently cut to the required size. Installed between the rafters without additional fasteners. • Minimum waste when insulating uneven rafter structures. • Provides additional sound insulation of the roof. • Special markings on the packaging for convenient cutting of the material. |

| ISOVER Sauna | |

| ISOVER Sauna — lightweight mats made of fiberglass-based mineral wool, coated with aluminum foil. Advantages of Isover Sauna : • Special thermal insulation for insulation of baths and saunas. • Two-in-one material - effective heat protection and vapor barrier - saves installation time. • The reflective foil layer enhances the heat-saving effect of thermal insulation. • Suitable for rooms with high humidity conditions. • Reduces transportation costs, since the thermal insulation is compressed 3 times in the packaging. • Lightweight, elastic, easy-to-use material. | |

| ISOVER Pitched roof | |

| Special product for pitched roofs and attics. Advantages of | |

| ISOVER SoundProtection | |

| Especially for installing a soundproofing layer in partitions and other structures. Advantages of Izover Sound Protection : • Significantly reduces noise levels. The airborne noise insulation index of a single-layer plasterboard partition on a 50 mm wide profile is 45 dB. • Has acoustic test reports. • Belongs to the group of non-combustible materials (NG). | |

| ISOVER Classic Plus | |

| Universal thermal insulation in slabs. Advantages of Izover Classic Plus : • Wide range of applications: walls, frame walls, partitions, suspended ceilings. • Convenient to use: the material in the package is already cut, easy for one person to work with, convenient for working in small spaces, the slabs can be installed without additional fasteners. • Increased elasticity: tight fit to the wall, frame and slabs together. • Significantly reduces heating costs. • Belongs to the group of non-combustible materials (NG). • Safe for human health and the environment. | |

Characteristics of Izover insulation

This material is made from the highest quality fiberglass using TEL technology, which is patented. All this makes Isover one of the best thermal insulators, differing from its analogues for the better. Let's list its useful qualities.

Thermal conductivity

The thermal conductivity coefficient of this insulation has a tiny value - 0.041 watts per meter per Kelvin. Moreover, this value does not change upward over time (as is often the case with other heat insulators). Thus, Isover glass fibers, which retain air well, retain heat excellently.

Soundproofing

As for the ability to protect against external noise, fiberglass materials are excellent here too. This is again due to the fact that there is an air layer between the glass fibers, which successfully blocks extraneous sounds. Therefore, you will be guaranteed silence in a room insulated with Izover. For these purposes, special varieties of material have been produced.

Flammability

All thermal insulation materials with a density of up to 30 kilograms per cubic meter and called Isover are considered non-flammable. This is how they are defined by the corresponding GOST 30244-94, which assigns them the abbreviation NG. Therefore, it is quite possible to use such insulation in any home - the characteristics of Izover of this type allow this. Its use is absolutely safe for thermal insulation of both a one-story cottage and a high-rise building.

Rigid and semi-rigid materials, as well as those covered with Tyvek film, aluminum foil or fiberglass, are considered low flammable. According to GOST they are designated SG. There are restrictions on the use of such insulation, but there are very few of them. So they can be used almost anywhere. The main thing is to strictly comply with the fire safety requirements of buildings and structures set out in SNiP 01/21/97.

Vapor permeability

Now let's talk about resistance to moisture. After all, this parameter is the “weak link” of many modern heat insulators. They perform their function well only when the air in the room is dry. If it contains moisture, then even fiberglass's ability to retain heat may deteriorate. But glass fibers are good because they quickly give back all the moisture they have absorbed. And to do this, you must remember to leave a gap of at least 2 centimeters between the wall and the insulation for ventilation. If this is not done, the thermal insulation qualities of this material will begin to decrease as it absorbs moisture. Unfortunately, this is a drawback of all such materials. The vapor permeability of Izover is in the range of 0.50 - 0.55 mg/mchPa. When the insulation is moistened by 1%, the thermal insulation sharply deteriorates by up to 10%.

Life time

The most important parameter is the service life of the insulation. Even if it stores heat perfectly, but can last a year at most, it’s unlikely that anyone will like it. Insulating a house is a painstaking task, and doing it every year is not a pleasant task. But, fortunately, these claims do not apply to Izover. Having laid walls, floors or ceilings with this material, you can forget about insulation for many years. There are examples of using this insulation for more than 50 years without loss of thermal insulation qualities.

Isover also contains water repellents that have water-repellent properties. In addition, bugs and other insects do not settle in this insulation - they do not like such a habitat. Fiberglass insulation is also not suitable for mold.

Environmentally friendly and harmless

It's not just the technical characteristics that Isover can shine with. Fiberglass materials of this type are absolutely harmless to human health and life. During their operation, no harmful substances are released. Finnish scientists have been checking this fact for half a century. No danger was detected - this verdict was repeatedly made by specialists from the Institute of Cancer Problems.

Insulation weight

If we compare Izover with other heat insulators in terms of weight, it will turn out to be much lighter than the others. Therefore, in those buildings whose walls are made of not very durable materials or excessive load is unacceptable, the use of Izover will be an excellent way out.

Release form

For the convenience of consumers, this insulation is produced in various forms. These are rolls, slabs of varying hardness, mats. The thickness of single-layer Isover varies from 5 to 10 centimeters, and for double-layer Izover the thickness of each layer is 5 centimeters. Slabs are usually made no larger than meter by meter, but sometimes there are exceptions.

Other characteristics

- Density is about 13 kg/m3.

- The density of the connection to the base is not very good and may decrease depending on the object being insulated.

- Air permeability is 120*10-6m3/m×s×Pa.

In general, many characteristics will depend on the type of material and its purpose; all characteristics can be viewed in more detail on the official website of the Isover company.

The lineup

Like any building material, isover insulation is available on the market in several types. Each of them is designed for specific building structures:

- “Sound protection”

is intended for finishing partitions and walls. - For frame construction, insulation of the “ Framework

” model is used. - “Profi”

is used for insulating attics and pitched roofs. This is high quality insulation. Profi is offered on the market in rolls of thickness 50, 100 and 150 mm. - The classic

is widely used. He can insulate floors, joists, attic floors and other complex objects. Although Classic is a roll material, it can be used to cover huge areas at a time. Usually two layers of 50 mm are laid in a roll. So you can safely divide it or use it as is. - Classic Plus

. This heat insulator is used to insulate the external and internal surfaces of walls. Has high thermal insulation characteristics. A magnificent example.

Important

. Many models are classified as “interchangeable”. That is, one is freely replaced by another. In this regard, Pro and Classic Plus are universal insulation materials.

Types of materials Izover

For ease of use of insulation for insulating various structures, it is available in several varieties:

- Isover KL – lightweight mineral wool board for reconstruction and construction of industrial and residential facilities;

- Isover KL 34 – soft mineral wool board for insulating walls, ceilings, floors, roofs;

- Isover KL 35 - soft mineral wool board, used similarly to Isover KL 34;

- Isover KL 37 – lightweight mineral wool slab for insulation of floors, interfloor ceilings, attics and pitched roofs;

- Isover KL 37 100 – mineral wool board for thermal insulation of building facades;

- Isover KT – soft mineral wool roll for insulation of floors, basements, attics;

- Isover KT 37 – mineral wool roll for insulation of basement and attic spaces;

- Isover KT 40 – soft mineral wool roll, used similarly to Isover KT 37;

- Isover KT 40 twin – flexible mineral wool mat in the form of a roll, used for insulation of floors and ceilings;

- Isover RKL - semi-rigid mineral wool board for insulating facades;

- Isover OL and Isover OL-E are rigid mineral wool slabs for insulation of plaster facades.