Glass selection

Before you begin installing or manufacturing a door for an oven with glass, you need to familiarize yourself with the requirements that it must meet. It’s worth saying right away that the production process and source materials for this part will depend on how you plan to use the fireplace or stove. If, for example, the object will be used as a means of heating, then a minimum of two-layer, and preferably three-layer, material is required. In addition to this requirement, there are several more that fire doors with glass for a stove or fireplace must meet:

- Firstly, high resistance to elevated temperatures.

- Secondly, service life. Most often this parameter is determined in hours. That is, the time that the glass can withstand under temperature load is indicated.

- Thirdly, you need to take care of the overall strength of the glass door. Most often, this parameter is indicated in millimeters and amounts to up to 3 mm.

- Fourth, the noise isolation effect. Of course, for some time the noise and hum of a stove or fireplace will be pleasing, but over time a person will get used to it and the constant noise will begin to disturb greatly, so ensuring sound insulation is also an important parameter for the door.

Features of oven glass

As already mentioned, only heat-resistant glass is used to make the oven door, which can withstand oven heating up to 1000 degrees. This possibility is achieved due to the fact that the glass contains no impurities and it undergoes special processing, that is, tempering, impregnation with chemical reagents and polishing.

We recommend: Making wooden portals for a fireplace with your own hands

In terms of its heat resistance, glass is in no way inferior to metal. There is no possibility of chips, cracks or scratches on it. Often, a small area of the flooring is covered with the same material to prevent the surface from igniting if coal accidentally falls out.

Among the main characteristics of glass it is necessary to highlight:

- Single-layer glass can withstand temperatures up to 550 degrees, and multilayer glass up to 1000 degrees. The choice of one type of glass or another depends entirely on what fuel the stove will run on;

- The optimal insert thickness is 3.5-4 mm. The strength of the glass will depend on this parameter;

- Multilayer glass inserts are quite strong and durable, but for a home stove, a single layer will be sufficient;

- The glass surface is capable of self-cleaning. All soot that gets on the glass will burn and there will be too little soot left;

- If the stove is used regularly, it will be quite noisy.

Glass materials and manufacturing

In order to create a glass oven door with your own hands, you will need the following materials:

- silicone sealant;

- about 4 window glasses suitable for the size of the screen;

- stones for decoration;

- metal mesh or grate;

- a metal box, the size of which will match the size of the screen.

The design of a glass screen for a fireplace is quite simple:

- Silicone sealant is applied to all 4 glasses along their edges.

- All glasses are fixed in such a way as to create a parallelepiped shape. It is important to maintain right angles.

- The planes of the elements are pressed tightly against each other and remain in this position until the sealant has completely hardened.

- The remaining substances that protrude beyond the plane must be cut off.

In this simple way you can make a fireplace screen.

Material

Metal (often stainless steel or cast iron) is used as the basis for the fire door for a stove with glass. According to the characteristics of experienced craftsmen, cast iron is more preferable: it is distinguished by durability, it is not afraid of high temperatures, it is easy to clean, and it is quite durable. Stainless steel will become very hot when the stove is fired; it is not intended for open fire and will soon warp.

From glass

Glass doors are available in single or double door versions. One oven door usually has a large window to view the fire. There is no difference in functionality. A lot depends on taste here. In two-door ovens, the design is close to ancient forms. It is possible to look at the fire through 1 large glass or 2 small ones. Much will depend on the preferences of buyers and the interior of the room. Advantages of a stove door with glass:

- Glass can withstand the influence of elevated temperatures for a long period of time - this positively distinguishes it from devices made of steel. It is superior in fire resistance to cast iron.

- Fireproof special glass for stoves and fireplaces is approximately 0.4 cm thick and can withstand temperatures up to 2000 degrees.

- Compact dimensions and low weight.

- The main advantage of a glass oven door is the ability to look at the flame. Such an option will outweigh any disadvantages, forcing stove users to purchase stove doors made of a similar material, despite the short period of use and high price compared to solid metal doors.

We recommend: Izoplat: properties, characteristics, advantages and disadvantages, installation features

Flaws:

- The creation of glass doors for a furnace is considered to be a more labor-intensive process than production from a solid sheet. To avoid cracks during use, a little space is left when installing with a seal. The doors will trap sparks from the fire, preventing them from entering the room. Glass inserts are designed so that air blows over the material, preventing soot from lingering on it. Otherwise, the glass will be smoked.

- Fragility of the material. Fire-resistant glass sometimes cracks with minor impacts.

- The price of a device with glass inserts is higher than one made of solid material.

- Glass door ovens are much less efficient than cast iron ovens because heat dissipates through the glass. The larger the material, the less efficient the stove is at heating the room.

Important! Often a stove door with glass is combined with a metal device. In such situations, the frame is made of steel and the door is made of glass.

Advantages and disadvantages

Good quality panoramic glass allows you to see what is happening inside the firebox without getting hot. This door is absolutely safe . The door is fireproof . Unlike stainless steel, panoramic glass does not deform from high temperatures . For many homeowners, cast iron or iron elements in the interior seem rough. This cannot be said about panoramic glass, which harmonizes with any decoration .

Of course, such a door also has disadvantages . The first of these is fragility . If you accidentally hit a stainless steel door with a poker, it will not affect it in any way, but the glass will crumble. In addition, after each kindling it is necessary to remove soot , otherwise the glass quickly ceases to be aesthetic and transparent and takes on a sloppy appearance.

Photo 1. “HG” cleaner for heat-resistant glass, 500 ml, suitable for removing soot and soot from a glass door.

Heat-resistant glass is capricious; detergents with an abrasive composition are not suitable , as this will easily damage the polished surface of the screen.

Solid metal door

This category involves doors made entirely of metal. The installation process is quite simple and does not have any complications. The products retain heat well and are distinguished by increased fire safety. When the need arises, it is possible to make them yourself with minimal expense. Key advantages of metal products:

- Reasonable price. Compared to a stage on a glass device, it is much smaller, which is why it has a certain prevalence.

- Durability and reliability of such devices. With proper care (regular anti-corrosion treatment using paints that are classified as fire-resistant), they will last a long period of time without causing discomfort to the user.

Important! Despite the fact that such doors have their own consumer, the market demand is quite low, since they do not provide the opportunity to look into the flame.

Cast iron door

Cast iron doors, which are heat resistant, are considered the best for brick stoves. When parts made of steel deform over time due to temperature, those made of cast iron can last for decades. In the place of combustion, the temperature will reach 800 degrees, and for steel the working temperature will be 600. Therefore, a high-quality oven door is cast iron. The technology for making cast iron requires a foundry, so it cannot be obtained in a small business environment.

Main advantages:

- Excellent interaction with elevated temperatures.

- Durability and reliability. The cast iron fireplace vent door can withstand any load.

- Beautiful models can be easily created from cast iron.

All this optimally finds its own application in this area; many firebox doors are made directly from cast iron.

Description of glass door

Installing a door with glass not only brings aesthetic diversity to the design, but also allows you to constantly monitor the efficiency of the stove. However, there are several disadvantages that will have to be taken into account if a decision is made to produce such an element with your own hands.

The first disadvantage is low mechanical stability. Of course, during production high-quality heat-resistant glass with increased protective characteristics will be used, but it can still break quite easily. Because of this, you need to be extremely careful when removing soot from it.

An oven door with glass tends to get dirty quite quickly. However, to eliminate this defect, a firing process is often resorted to.

The last drawback is the use of only wood fuel. It will be impossible to use coal as a fuel material in a stove with such a door.

It is worth noting that quite often they resort to a combination of several materials in production. For decoration and to enhance strength characteristics, some casting or forging elements are often used. It is also worth answering that it is possible to use a cast iron oven door with glass, that is, a combination of cast iron and glass.

Making your own glass door

The most popular models are glass doors. They are quite functional and will allow you to open the firebox space for a panoramic view of the wood burning process. The design of such a door is based on the fact that special quartz glass for the fireplace, which has high heat resistance, is mounted on a metal frame. The glass is secured in a special recess; it is necessary to immediately provide for the possibility of dismantling it and maintain a certain gap between the glass and the frame to ensure expansion.

A home-made fireplace door with glass should provide protection, visibility, and access to the firebox. In addition, a homemade design must have an aesthetic appearance.

The simplest type of firebox design

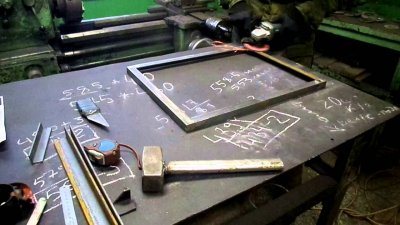

- Before making a frame, you need to take its dimensions correctly. The entire door should fit tightly into the fireplace opening. It is better to take a margin of 2 mm when determining sizes. If necessary, with the help of a grinder you can open the fireplace window to the desired extent.

- The frame is mounted from a metal corner. To comply with the geometry, it is necessary to carry out all work on a flat plane. The sides of the frames cut to size are secured by welding. After this, you need to check the right angles and compare the diagonals. Once you have ensured that the design is correct, you can weld all the seams. Then the welding areas are processed with a grinder.

- The glass will be attached to the frame using bolts that are screwed into the corner along the plane. Thus, these bolts only keep the glass from falling out of the frame, but do not secure it rigidly. The condition for thermal expansion is met.

- A similar frame is welded from the same corner, which will act as an external lintel for the door. This frame is decorated with a decorative frame around the perimeter. Depending on the style of finishing material for the fireplace, the door frame can be made of artificial forged elements or metal plates.

- The door and lintel are connected by means of canopies. With fairly accurate calculations, the dimensions of the lintel are slightly larger than the opening, and this is how it should be. We mark the boundaries of the lintel on the fireplace wall with a pencil and cut out a recess using a grinder and a cutting wheel.

We recommend: Do-it-yourself homemade pellet burner: drawings and manufacturing description

Adding forged elements to the door

- The door is inserted into the resulting recess. But before this stage, the glass should be removed to avoid damage. The outside of the lintel frame is wrapped with asbestos cord and coated with a heat-resistant adhesive solution. In order for the cord to fit into the opening, it will have to be pushed in with a screwdriver. This work is painstaking, so it is necessary to choose an adhesive composition with low adhesion properties. The asbestos cord is needed as a seal so that heat does not escape from the firebox through the gaps.

- Only after the glue has dried can the glass be installed in place. When installing a glass door into a fireplace, you may want to consider a lock and handle. Although this stage can be carried out at the very beginning of installation. The metal parts of the door should be painted with special heat-resistant paint. It will have to be applied in several layers to hide irregularities after processing the welding seams.

Manufacturing

The first thing you need to do before you start is to create a drawing. The main task when performing this point is accuracy. If you make a mistake with the dimensions at this stage, then most likely the object will end up smaller or larger than necessary.

The second stage of making a door is the availability of all the tools and the purchase of material. In order to assemble such a thing, you will definitely need welding, a grinder, a cleaning circle, a hammer and a drill. The listed tools will be useful if the door for a sauna stove with glass or for a fireplace is made from a combination of glass and cast iron or other metal.

Necessary materials for the production of the damper: metal, corner, handle, valve or glass. It is worth noting that the advantage of making such a door yourself is that you can purchase all the components in any store, and their cost is acceptable.

Stages of work

The first thing to do is cut out the corner. And then give the desired shape to the structure. In order to carry out this operation, you need to lay the corner on a flat surface, check the correctness of all connections, and then weld all the necessary parts. After finishing the work, you need to inspect the door again for correctness and compliance with the form.

Then you need to mark the inner contour of the frame on a sheet of metal. After finishing the markings and receiving all the measurements, you need to increase them slightly and leave a small allowance on each side. Taking these marks into account, it is necessary to cut out the part using a metal grinder. Since the door is planned with glass, it is necessary to have a piece of heat-resistant material that will be mounted.

Using the same tool, glass is cut to the required dimensions. Next, you need to weld the curtains to the frame. After this, you need to grab them to the common door frame. When this operation is completed, you need to make sure that nothing interferes with the opening and closing of the door. If this condition is met, then final welding can begin. The door handle is attached last.

Making a glass oven door with your own hands

Metal is used as the basis for the fire door with glass . According to reviews from experienced stove makers, cast iron is preferable : it is durable, resistant to high temperatures, easy to clean, and durable. Stainless steel becomes very hot when the stove is fired , is not designed to withstand open fire and quickly warps.

We recommend: Heating a garage with gas from cylinders: using a burner, gun, boiler and other heating equipment

Tools and materials

To work you will need:

- Bulgarian;

- Metal sheet;

- heat-resistant glass;

- construction gloves;

- composition for masonry;

- welding machine;

- level;

- fiberglass.

When choosing panoramic glass, you need to remember its fire resistance.

Stages of work

The door installation work consists of the following steps:

- execution of a drawing of the entire structure;

- cutting metal blanks for frames and sash;

- frame making ;

- fitting the frame onto glass;

- canopy baiting;

- welding frame parts, installing glass element;

- installation of canopies, valves and handles.

Attention! The task is within the capabilities of those who have at least basic experience in working with a welding machine . If you have not done welding before, delegate this task to a professional.

Creating a blank

First, measure the size of the fireplace . A corner is cut according to the established parameters

The frame is placed on a sheet of metal, the outline is marked . After checking all measurements, the workpiece is cut using a grinder or cutting wheel . This will be the lintel for the door.

The glass element is fastened with bolts screwed into the corner along the plane. They will prevent the window from falling out, but at the same time they do not interfere with thermal expansion.

The door is attached to the ceiling using awnings .

Attention! Before installation, the glass insert is removed from the frame!

The door angle is checked using a plumb line . To do this, use three-millimeter wire , previously burned and softened in the fire. It is inserted into the hole of the frame, folded in half and twisted tightly so that rings do not form at the ends. If you cannot do without them, the wire is flattened with a hammer.

A completely blind door, without a window, is less common. It is made according to the same principle, but without a transparent element. When the frame is ready, mark and cut out the future sash, making sure that it overlaps the hole .

Attachment to base

You can’t just attach a frame with a door to a brick. will be required . First, the contours are marked on the masonry, then a recess is cut out with a diamond wheel.

Most often, metal anchors are used for fastening. Before attaching the door to the base, check that it opens easily. If this is possible with visible effort, the workpiece needs to be modified.

The lintel frame is wrapped with asbestos cord , then coated with heat-resistant glue. The cord will have to be pushed into the recess around the perimeter with a screwdriver.

Reference! A free flow of air into the firebox is necessary. The preferred design is one with an oxygen supply regulator.

Before directly installing the door on the masonry, the base is painted with fire-resistant paint. When working, a respirator and goggles are required, as the composition is toxic and easily gets into the eyes and respiratory tract. The paint is applied in several layers to mask welding flaws.

Advantages of panoramic glass

Most often, it is recommended to use panoramic glass in such homemade doors. It has such advantages as: high thermal stability and a high degree of fire resistance of the material. Another very convenient property is safety when used in a bathhouse. Panoramic glass contains crystal ceramics and quartz, which makes them absolutely safe. The mixture of these components eliminates any possibility of the material exploding due to overheating.

Fireplaces are becoming increasingly popular again. People install them if there is a technical and financial opportunity. The fireplace has a number of advantages over other heating systems:

- Efficiency.

- Aesthetic appearance. Looking at a blazing fire through a glass door never gets old.

- Making a fireplace with your own hands with the appropriate construction skills is a very real thing.

The topic of today's material is not about arranging a fireplace as such, but about how to make heat-resistant glass with your own hands in order to equip a door in it.

Correct selection of fireplace glass

Before you start making a door with glass for the stove with your own hands, decide on the scenario for using the fireplace. If you plan to use it as a heating device, then you need to choose two- or even three-layer glass.

Important! If the room is small, then one layer will be enough.

In any case, fireplace glass must meet the following requirements:

- High temperature resistance.

- Duration of operation. This indicator is indicated in hours and shows how long the door can withstand in a given mode.

- The strength of the product directly depends on its thickness, indicated in millimeters. As a rule, it ranges from 3 mm.

- Soundproofing effect. It is important that the material effectively muffles the “humming” in the furnace. Of course, this is very romantic, but the constant noise is still annoying.

Types of fireplace screens

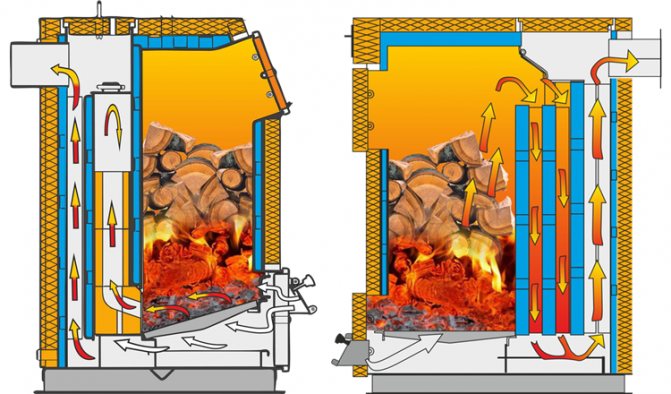

There are open and closed structures:

- The closed oven is equipped with a cast iron door, providing the greatest safety. The main advantage of closed furnaces is that they provide the greatest efficiency.

- Open stoves look more aesthetically pleasing. They are equipped with a glass screen that allows you to observe the burning of wood. Heat-resistant glass copes well with high temperatures, ensures fire safety and prevents combustion products from entering the room.

Important! For a fireplace screen, you need to choose quartz glass with a low linear expansion when heated.

Despite the dark shade, the transparency of this product is good. The glass product can be made in the following options:

- The simplest flat screen with one glass.

- Segment screen with three glasses.

- Circular design. Suitable for freestanding fireplace.

Important! Cases when a fireplace is considered as a self-sufficient heating device are rare. But in terms of aesthetics, the fireplace is beyond competition. That’s why a door made of transparent fireproof material is so relevant.

Do-it-yourself fireplace door with glass - manufacturing procedure

You will need for work:

- Silicone sealant.

- 4 window panes to fit the screen.

- Stones for decoration.

- Metal mesh or grate.

- A metal box the size of which matches the base of the screen.

The algorithm for making glass for a fireplace with your own hands is as follows:

- Apply silicone sealant to all 4 panes around the edges.

- Fix the glass at right angles to create a parallelepiped-shaped structure.

- Press the planes firmly against each other and wait until they harden completely.

- Cut off any remaining silicone using a knife or razor blade.

- The screen is ready, now all that remains is to complete the base. Apply sealant to the bottom of the glass box and press the glass to the metal box. The sides of the metal box must be wide enough to accommodate the metal mesh grille.

- Now let's set up the firebox. Place a can of helium fuel in the middle of the box. Place a metal mesh on the sides (it can be laid in separate pieces). Place stones on top of the mesh, remembering to leave gaps between them for ventilation.

The original fireplace of the simplest design is ready!

Care issues

Even self-cleaning surfaces require periodic cleaning. You can clean the fireplace glass only after it has completely cooled down. Working with hot surfaces is unsafe, and the material may be damaged. It is advisable to clean glass with a special composition, since it not only eliminates dirt, but also creates an additional protective layer, which greatly facilitates cleaning in the future.

Glass fireplace doors are a harmonious combination of beauty, comfort and safety

.A fireplace with a mesmerizing dance of flames, loved ones and children nearby - probably for many this is the picture of an ideal family holiday after a busy day at work. Beautiful, calm, cozy... But it’s not always safe! Fire is as terrible as it is beautiful. Flying sparks can cause a fire, small children do not always realize the danger of being near a fire, the room may become smoky from wood burning in an open firebox, and oxygen is burned.

This problem can be solved if you purchase and install a special door for the fireplace.

Necessity or unnecessary waste

By purchasing this product, you will eliminate these problems and make your home even safer and more comfortable. We will try to help you make the right choice that suits your needs.

The main factors determining the choice are safety, style and ease of use.

It is worth noting that the modern market offers a wide range of these products: metal, ceramic, glass or combined heat-resistant doors are produced.

Solid metal products seem more reliable compared to glass ones. They will certainly make the fireplace safe, but will block access to the contemplation of the hearth. Such doors are acceptable in homes where the fireplace serves only as a heating device.

The ideal and most in demand nowadays are doors with glass for fireplaces,

giving the opportunity to observe the beauty of the playing flame, while controlling the combustion, without opening the firebox each time. Fireplace doors prevent smoke and combustion products from entering the living space, protect against plaque, soot, and prevent the combustion of oxygen. The glass will also protect against the painful and unsafe thermal effects of the flame. The noise insulation created in this way will eliminate the annoying crackling sound of burning wood. And most importantly: a fireplace with such a door is much safer and even more economical than an open hearth.

Questions - Answers

1. We have an open fireplace, can we add a fireplace door to it?- When is the correct time to install a fireplace door, during the laying of the fireplace itself or after?

2. Sometimes it blows from the fireplace and soot flies into the house, will the door help?

3. Will the fireplace door protect against smoke entering the room?

4. Can tempered (tempered) glass be installed in the fireplace door?

1.

The main goal and task in the design of our fireplace doors is painless and quick modification of completely finished, lined, commissioned open fireplaces. The design of each door and its fastening is individual, specially developed for a specific sample of fireplace, stove, cladding options, size, shape, depth, and therefore installation of a finished product takes only 15-20 minutes. At the same time, the external clean appearance of the surface is not disturbed and no changes are made to the overall design of the fireplace, which makes it possible to easily dismantle the door and return the previous appearance of the open fireplace.

Material requirements

For fireplace doors, high-strength and heat-resistant thermal glass is used, which has undergone special hardening and processing. It can withstand up to 10,000 C for several thousand hours of direct use.

This glass contains elements such as heat-resistant quartz and transparent crystal ceramics. Quartz glass is the most popular because it has the smallest expansion when heated. This material is not inferior in strength even to metal products. Using ordinary thermal glass (for the sake of economy) is not advisable, since it cannot withstand temperatures exceeding 1500 C and may crack upon first use.

Glass can be of various sizes depending on the parameters of the fireplace, various geometric shapes and curvature.

It is possible to use tinted glass, which will muffle the bright light of the flame. Installed double or laminated glass will contribute to even safer use.

When choosing glass you need to consider:

- heat resistance, paying attention to the type of fuel;

- lifetime,

- thickness of the glass screen (at least 3.5 - 4 mm).

Fireproof glass has a disadvantage: it is quite heavy.

. This must be taken into account when choosing door mountings and methods of their operation, creating the most comfortable conditions for handling this device.

Door decoration

There are two operating principles for fireplace doors: mechanical or automatic

. With a mechanical principle of operation, the structure opens manually, with an automatic one, using a special electric motor controlled automatically. Given the rather large weight of the devices, automatic mechanisms are recommended, which also provide additional protection against burns.

Glass doors can be closed in several ways. There are lifting and sliding options.

The most common are double swing doors, in which both doors are fastened in the center and hung on side hinges, and swing doors, in which one of the doors is fastened on side hinges; the doors close upward. Modern designers have developed a model that opens according to the guillotine principle, allowing the fireplace to be used with both a closed and open firebox. It is possible for doors to converge using magnets. Magnetic doors prevent incomplete closure or accidental opening.

When choosing a mount, you should pay attention to the fact that complex structures will be more expensive than simple ones.

The fireplace door is secured using special hinges on a steel or cast iron frame. The handles are made of non-heating material. The choice between a steel and cast iron frame depends on the decorative preferences of the customer. However, recently preference has been given to steel frames, since cast iron, while withstanding high temperatures, is subject to physical wear.

The door is the front component of any fireplace, so when choosing it, not only functional, but also aesthetic parameters are important. The design depends both on the functions of the fireplace and on the wishes of the buyer. Both standard equipment is possible, including a frame with a metal frame, as well as individual options using decorative forged elements, ornaments, and stained glass.

When caring for glass fireplace doors, you must follow certain rules:

- Clean only after complete cooling;

- use special compounds that form an additional protective film and facilitate subsequent care.

To make cleaning easier, you can purchase self-cleaning fireproof glass coated with an invisible layer of metal oxide, which, with increasing temperature, promotes complete combustion of deposited soot.

The purchase and installation of fireplaces and related accessories is a trend in modern residential design. And by purchasing certified glass doors for a fireplace, you can be sure that you have made your home not only cozy, but also safe.

Fireplaces with transparent doors look impressive and fit into any design style. Transparent glass allows you to admire the mesmerizing flames of an open hearth, providing the same level of fire safety as a solid metal valve. Glass doors reliably protect furniture and decor from soot deposits, and also prevent the combustion of oxygen in the room. Heat-resistant glass for a fireplace is characterized by increased strength, resistance to high temperatures and temperature changes.

How to install a fireplace door

3543 Pechnik (Moscow) When you buy something in a store, you probably think: horror, I will never be able to install this without the help of professionals. So, glass fireplace doors can be installed by you yourself. And you won't have to pay anyone. The main thing is to find the necessary tools for installation, the list of which is provided below: • a screwdriver (cordless) • a hammer drill (impact drill) • a drill bit for an impact drill • a marker Most glass fireplace doors are sold assembled. The frame can be made of aluminum or steel. Keep in mind that aluminum doors are made from four separate pieces that are bolted together. This design allows you to install aluminum doors in almost any fireplace. But, on the other hand, aluminum doors are difficult to install if the walls of the combustion chamber are uneven or have unique elements. Steel fireplace doors are typically made from one single sheet of steel, giving them rigidity and strength. They are less flexible than aluminum fire doors, but are easier to install. This does not require regulators and the time required for conventional door installation is reduced by half. But, in any case, to install the fire glass door, you should read the instructions for its installation. Below is a summary of how to install a glass door on a fireplace:

TIP: Before installing a new glass fireplace door, you should remove the glass from the frame. This is, in principle, easy to do.

1) Install a door frame on your fireplace. Make sure the frame is flush with the fireplace.

TIP: Before you begin installing aluminum doors, you will need to install the brackets. 2) Locate the holes on the frame where the brackets or frames themselves will be attached, and make marks on the brickwork where the holes will be drilled to attach the frame to the wall.

3) Remove the frame. Use an impact drill to drill holes in each location marked with a marker.

4) Place the frame on the face of your fireplace. Check that the holes you just drilled match the holes on your frame and make sure the screws are the right size for mounting the fireplace door. TIP: Aluminum doors can be insulated with fiberglass if there are openings between the frame and the fireplace. 5) Use a screwdriver and tighten the screws into the fireplace frame.

6) Install glass doors on hinges.

End of work!

Installing a fireplace door may differ slightly from the instructions above, depending on the door manufacturer. But overall, with the right tools and a good attitude, you can easily install a glass fireplace door yourself.

Features of heat-resistant glass

Fire-resistant glass has a low thermal expansion coefficient (thirty times less than that of standard glass) and high heat transfer, which allows it to withstand heating up to 1000 degrees and not crack from sudden temperature changes. Glass doors for a fireplace, after thirty minutes of contact with fire, heat up only to 50-250 degrees, and the temperature of tempered glass during the same period of time rises to 500 degrees and above.

Transparent doors leave the hearth open for viewing

In the production of heat-resistant glass, practically no foreign impurities are added; special raw materials and special equipment are used. The second secret of the fire resistance of a fire-resistant material is in special hardening methods, thermal polishing, and chemical treatment. All this together allows us to obtain an elegant product that is not inferior in strength to metal products.

Correct transparent doors are not afraid of fire and temperature changes

Heat-resistant glass for fireplaces is almost impossible to scratch, break or damage. High strength indicators allow it to be used as a protective floor screen around fireplaces. Such a floor is not afraid of accidental falls of firewood, hot coal and metal pokers.

Fireproof glass products

Currently, heat-resistant glass products are increasingly conquering consumers and are in high demand. The fact is, with this design you can freely admire the process of burning logs and the blazing flame.

Glass fireplace doors, unlike metal products, are characterized by an improved aesthetic appearance. Thanks to this, they easily fit into the overall interior design. They can be made from expensive quartz or crystal ceramics, or they can be budget products.

Good to know: How to choose a ventilation grille for a fireplace, consider the basic rules

There are several types of fireplace door with glass:

- Single layer thick flat glass.

- Segmental, providing for the presence of three layers.

- Circular glass is used in cases where the fireplace stove is located separately from the wall.

Modern fireplace design

Don’t forget about products in which the fireplace door with glass also has metal elements. With this design, the iron element acts as a kind of frame.

When designing fireplaces of all types, the products may also have decorative elements represented by forged or cast parts. Increasingly, clients order tinting or lamination, mosaic and stained glass for their products. All this looks very organic in various designs.

A fireplace with a glass door, depending on its type and design, can open its firebox by lifting or sliding the doors. Which also looks quite attractive and original. In order to constantly keep the product clean during the construction of the fireplace, you should consider a firing system, thanks to which the soot will burn without settling on the glass.

How to choose a glass door for a fireplace

On sale you can find ready-made cast iron fireplace inserts with glass and separate doors designed for installation in brick fireplaces. The door should be purchased before the brickwork begins, otherwise it will be more difficult to find a product of the right size. It is important to remember that regular tempered glass is not suitable for a fireplace.

Types of transparent doors for fireplaces

Fire doors with glass are reinforced with a durable frame made of cast iron or steel and complemented with a handle. Ideally, the handle should be made of a non-heating material. Fireplace doors are distinguished by size, opening principle, frame material, and design. With the help of modern technologies, relief patterns and multi-colored ornaments are applied to the glass surface. Stained and tinted glass looks very impressive.

The most interesting from a design point of view are the doors that open according to the guillotine principle. They allow you to operate the fireplace not only closed, but also in the classic open form. Considering the large weight of the fire-resistant structure, it is worth taking a closer look at automatic opening mechanisms that provide additional protection against burns.

Technical characteristics of heat-resistant glass

When choosing a door for fireplaces with glass, you need to pay attention not only to the design of the part, but also to a number of technical characteristics.

- Heat resistance is the most important indicator of heat-resistant glass for a fireplace. The passport of each product indicates the recommended operating temperature; as a rule, it is 500-550 degrees. Maximum values (up to 1000 degrees) can be found in laminated glass. Here you should focus on the preferred fuel; for example, heating with wood requires higher heat resistance.

- The service life of thermal glass is indicated in hours. The higher the operating temperature, the less the glass door will last. Manufacturers recommend keeping the combustion temperature no higher than 550 degrees, while ensuring normal draft.

- The thickness of the glass screen for a fireplace determines its strength; in this case, it is better not to skimp and purchase a product with a thickness of 3.5-4 mm.

- Laminated glass is superior to single-layer glass in all respects, but experts believe that one layer is quite enough for a home.

- Self-cleaning fireplace glass is coated on the inside with a thin layer of metal oxide. The invisible coating increases the surface temperature, causing the soot to burn without a trace.

- Sound insulation protects residents from the pleasant, but quickly annoying sound of crackling burning fuel.

Patterned double door

Requirements for fireplace doors

On sale you can find ready-made cast iron fireplace inserts with glass and separate doors designed for installation in brick fireplaces. The door should be purchased before the brickwork begins, otherwise it will be more difficult to find a product of a suitable size. Fire doors with glass are reinforced with a strong frame made of cast iron or steel and complemented with a handle. Ideally, the handle should be made of a non-heating material. Fireplace doors are distinguished by size, opening principle, frame material, and design. With the help of modern technologies, relief patterns and multi-colored ornaments are applied to the glass surface. Stained and tinted glass looks very impressive.

The most interesting from a design point of view are the doors that open according to the guillotine principle. They allow you to operate the fireplace not only closed, but also in the classic open form. Considering the large weight of the fire-resistant structure, it is worth taking a closer look at automatic opening mechanisms that provide additional protection against burns.

One way glass door

- Heat resistance is the most important indicator of heat-resistant glass for a fireplace. The passport of each product indicates the recommended operating temperature; as a rule, it is 500-550 degrees. Maximum values (up to 1000 degrees) can be found in laminated glass. Here you should focus on the preferred fuel; for example, heating with wood requires higher heat resistance.

- The service life of thermal glass is indicated in hours. The higher the operating temperature, the less the glass door will last. Manufacturers recommend keeping the combustion temperature no higher than 550 degrees, while ensuring normal draft.

- The thickness of the glass screen for a fireplace determines its strength; in this case, it is better not to skimp and purchase a product with a thickness of 3.5-4 mm.

- Laminated glass is superior to single-layer glass in all respects, but experts believe that one layer is quite enough for a home.

- Self-cleaning fireplace glass is coated on the inside with a thin layer of metal oxide. The invisible coating increases the surface temperature, causing the soot to burn without a trace.

- Sound insulation protects residents from the pleasant, but quickly annoying sound of crackling burning fuel.

We recommend: Window film: what to do so that it is not visible from the street what is happening in the apartment (photo, video)

Patterned double door

Externally, stove or fireplace doors with glass, as a rule, look modest. And they are a metal rectangular “frame”, inside of which the same rectangular glass (sometimes double) is inserted.

A custom door will cost 2 or even 3 times more

True, there are some deviations in the design. For example, the frame is made rounded. They attach beautiful original handles to it and create fancy patterns on it. Or they install sprockets - decorative linings for glass in a checkered pattern.

The dimensions of fireplace doors with glass are determined by the dimensions of the fireplace itself. Those. it is 15-80 cm wide, and 15-60 cm high. The weight of stove doors is impressive: from 3 to 35 kg, depending on the size and specific materials.

Heat-resistant glass is slightly yellowish, but its transparency is high

How safe is a glass door for a stove or fireplace? We answer: 100%! After all, heat-resistant glass is used - quartz, which, unlike ordinary silicate glass, is more refractory. Plus, it is polished, treated with special compounds, and hardened. And it becomes practically “immortal” - it can withstand temperatures from 700 to 1000°C.

And to prevent soot from settling on the glass, it is subjected to pyrolysis treatment - the inside is coated with metal oxide (and there is a secret in the structure of the fireplace itself that prevents the glass from becoming dirty). The soot on the glass burns off when the fire flares up.

Is it possible to install plain tempered glass in oven doors? No, because the “tolerance threshold” of such glass is 150 °C. The temperature in the fireplace is much higher.

Frames for fireplace doors are made of steel and cast iron, which are also not in doubt. However, steel is still stronger, and when making a door, a small volume is sufficient. Cast iron is more friable, doors made of it are massive (more reliable) and heavy.

A stove, like a fireplace, is classified as a special heating unit, the structural elements of which are characterized by high heat. Often fireplaces are installed not for heating the room, but for interior design.

The main function of the design is still to heat the room; the requirements for heating units have been increased:

- If you make a fireplace door yourself, then you must use fire-resistant materials; it is better to pay attention to cast iron and fire-resistant glass.

- When installing doors, you need to take into account that air must flow to the combustion chamber. Now they produce designs that provide regulation of the oxygen supply.

- Doors must be fireproof. This is done for reasons of protecting the home and its interior; it is important to understand that even a spark can fly out through a gap.

Compliance with these requirements guarantees safe and durable operation of the fireplace.

Features of caring for glass fire doors

Even self-cleaning glass requires regular maintenance, but cleaning the glass surface is only allowed after the door has cooled down. Working with a hot surface can cause irreparable damage to the heat-resistant material.

For cleaning, it is better to use special compounds; they not only instantly clear the doors of soot, but also create an additional protective layer that facilitates subsequent cleaning. Despite the strength of the fire-resistant material, it is strongly recommended not to use abrasives - they can damage the polishing and the top protective layer.

U-shaped fireplace door

Making heat-resistant glass for a fireplace with your own hands is almost impossible. The experiment may result in injury and fire. Of course, it is possible to install doors on your own in an existing fireplace or one under construction, but if you do not have the appropriate skills, it is better to entrust this important work to specialists.

Video: presentation of fireplace doors

It is known that in the simplest classification, all fireplaces are divided into open and closed type devices. In addition to various technical nuances, the main distinguishing feature is the door for the fireplace. To emphasize its functional purpose, we will conduct a comparative analysis of some features of the operation of fireplaces of two different types.

Closed fireplaces are always associated with steel or fireplaces, which implement new technologies for the efficient use of released energy. But, despite this, classic fireplaces with an open firebox are not inferior to their popularity and occupy a certain niche among their consumers.

In addition, such a fireplace design provides some distinctive advantages. First of all, it is a living flame, which you can observe directly, admiring the magical dances of the tongues of fire.

Stove store assortment

The fireplace is a source of heat and it doesn’t matter how much of it is used to heat the room. Heat from the open structure is released using infrared radiation. This energy is believed to be more useful than heat from convection movement. Open fire can be adapted for additional purposes. They cook food on it by modernizing the fireplace design, and not the least important distinctive advantage is that an open fireplace can quickly warm up the owner who comes in from the street.

Naturally, such a fireplace has a lot of disadvantages, which are used by designers of closed types of fireplaces. The efficiency of a fireplace with an open hearth is slightly more than 20%. With such heat output, you cannot rely on a fireplace as a serious source of heat. Even during operation, the device is not capable of storing energy. This means that immediately after the wood burns out, the fireplace will stop heating the room. The low degree of fire protection should not be overlooked, especially when children are present. Sparks from firewood often fly outside the firebox and can cause trouble.

Finished design

Iron options

This fireplace door is characterized by the fact that the main material in its production is metal. In addition, all manufacturers claim ease of installation of the product, high ability to retain accumulated heat and no less degree of resistance to fairly high temperatures.

Choose the appropriate option for yourself

Ordinary or forged metal doors, in addition to everything else, are also reliable and can serve their owners for decades without losing their original appearance. In addition, if you have a special desire, you can make them yourself, or purchase them at a specialized store.

It is worth finding out what the advantages of a metal door are:

- The main advantage is the affordable price when compared with heat-resistant glass doors. However, in most cases they are chosen to decorate hearths in a bathhouse or in a country house, where strength still comes first rather than beauty. But in some modern styles, such doors can also be a great addition.

- As for maintenance, the metal must be coated with a composition that protects it from corrosion at certain intervals. In this case, you will not have to buy new fireplace doors for a long period of time, and their functionality will remain at the same level.

Good to know: Types and designs of fireplaces in a modern style