Home / Boiler rooms

Back

Published: November 30, 2019

Reading time: 2 min

0

371

Although infrequently, news about exploding boilers still appears in emergency reports from time to time. And what’s most interesting is that the reason is not always a faulty stove or an unextinguished cigarette.

It also happens that the heating boiler becomes the culprit. We are accustomed to the fact that all devices whose names contain the word “industrial” are used in manufacturing enterprises, on the territory of factory workshops and large workshops.

In fact, this is not always the case. Companies involved in the production of heating equipment offer consumers large installations for autonomous heating of apartment buildings.

Consequences of a boiler rupture

And although they are used in residential buildings, they are still called industrial. The reason is the high power, which is quite enough not only for a multi-story building, but also for a warehouse and a large production line.

But they also tend to fail. The only problem is that the consequences can be dire.

- 1 How does an industrial boiler explode?

- 2 Safety precautions

Features of ignition of gas heating boilers

Each heating device is equipped with automation. The ignition procedure depends on its design and features. Modern boilers are equipped with piezo ignition or automatic start. Rarely in villages, there are still old KST boilers that can operate on solid fuel and gas. During the conversion, the heating devices were equipped with primitive automation, where the igniter was ignited with matches.

Ignition features depend on the gas boiler automation

Regardless of the boiler model and its automation, preparatory measures are carried out before ignition:

- Before the first start after the summer season, all components of the gas supply line and automation are checked for the absence of gas leaks. This can be done easily with soapy water. If a thread or connection is gassed, soap bubbles will appear.

- It’s a good idea to check the heating system itself for leaks. Make sure there is enough coolant. To do this, in a closed system, the pressure is checked on a pressure gauge. If the heating is gravity-fed, make sure the expansion tank is filled with water.

- After renovations, a lot of dust is generated in the house. With the help of draft, it partially enters the boiler furnace and settles on the burners. A similar situation occurs if the heating device at the dacha has been idle for a long time. Before ignition, try to clean all burner units with a vacuum cleaner or other devices.

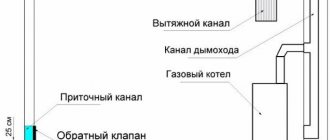

- Immediately before starting ignition, check the presence of draft. This can be easily done with a strip of paper. If it is pulled inside the firebox, then there is a draft.

After the preparatory activities, they move on to the process of igniting the boiler.

To properly ignite a gas appliance, you need to know the features of the automation. Important! When using a new gas boiler for the first time, you should carefully read the instructions from the manufacturer.

The ignition process begins by opening the gas supply valve to the boiler from the main line. If the heating is equipped with a circulation pump, be sure to put it into operation. Further actions depend on the features of the automation:

- Old KST with ancient automatic equipment are lit manually. First, a burning match or splinter is inserted into the window and gas is supplied with the regulator. After igniting the igniter, allow it to warm up for a couple of minutes. The regulator lever is moved to the next position. The main burners are ignited.

- Modern budget boilers are also started manually, but with the help of a piezoelectric element. Press the flame regulator with one hand. Continuing to hold it, press the piezoelectric element button with the other hand. With each action, a click occurs and a spark is formed near the igniter on the electrodes. The action continues until the flame appears. After the pilot light ignites, the regulator is held for about 30 seconds to allow the thermocouple to heat up. Now you can release it and turn it to light the main burner.

- Expensive gas boilers are equipped with electronic start. There are even models that are controlled from a remote control. Ignition of such devices is carried out with one click of the “Start” button. Then the automation will do everything itself. It is only important not to forget to connect the unit to the electrical network.

Setting up the automation is trusted only to a specialist.

Each gas automation has its own characteristics. The regulators are marked with numbers, stars, and circles. They indicate different positions at which a spark is supplied, the burner is ignited, and the temperature is set. All the nuances of a particular model are described in the manufacturer’s instructions. It must be studied before starting ignition.

Reasons for the attenuation of atmospheric gas boilers with an open combustion chamber

Atmospheric gas boilers usually go out due to external factors, but malfunctions in the internal components can also be the cause:

- blockage of the holes of the gas burner device;

- failure of communication of the emergency electrical circuit;

- lack of draft or wind blowing into the chimney;

- poor supply ventilation or clogged duct;

- insufficient fuel supply pressure in the lines.

According to the safety rules in the gas industry PB No. 12-368-00, if the boiler goes out suddenly (if this is not an automatic operation), then it is strictly prohibited to start re-igniting without finding out the reason for what happened! Failure to comply with this requirement may result in a fire, explosion or carbon dioxide poisoning of people.

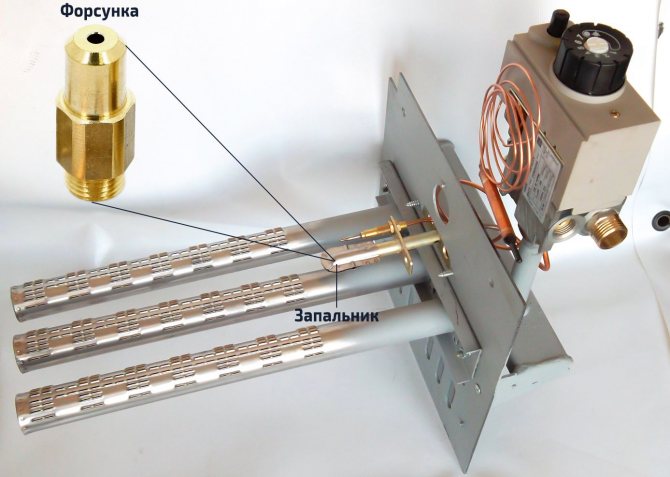

Clogged nozzle or burner filter

If, when the control knob is switched to the “START” position, the igniter (wick) does not ignite, this is a sure sign that the starting elements of the unit are clogged: nozzles (nozzles) of the ignition nozzle, a fine-mesh filter at the inlet or a pilot burner filter. They can be easily cleaned using available products.

The location of the pilot nozzle on the burner block of a floor-standing gas boiler.

The filters are simply blown through in any convenient way (air sprayer, handheld vacuum cleaner or mouth) until air flows freely through them. But the injectors will have to be more thoroughly scraped off from carbon deposits (with thin copper wire) - until the design diameter of the nozzles returns. Under no circumstances should the nozzle be damaged or the diameter of its orifice specified by the manufacturer be changed.

Thermocouple, circuit contacts, or solenoid malfunctions

If communication with the thermocouple is disrupted, incorrect signals are sent to the solenoid valve that there is no flame, and accordingly the gas supply is stopped.

It doesn’t matter whether the gas boiler goes out immediately when you release the start button, or after turning on another mode - this behavior indicates problems in the circuit:

- contacts of the thermostat, thermocouple or vacuum sensor are broken;

- the thermocouple does not provide the required voltage or does not enter the flame zone;

- unsuitability of the thermostat, electromagnet coil or thermocouple.

The gas water heater does not light well: how to troubleshoot

Most of the most common malfunctions that affect the operation of gas equipment can be quickly eliminated with your own hands.

As for external factors, you can independently adjust the supply of gas and water, clean the internal pipe to remove combustion products.

Water pressure can be increased using a special pump. Chimney - check for ruptures, clean from dust. If the draft does not increase, then you will have to call special workers to clean the ventilation ducts.

In addition, if:

- After diagnosing the condition of the equipment, a clogged inlet filter of the water intake unit was discovered; the part should be cleaned with high water pressure or the filter should be replaced;

- The membrane of the water block has ruptures or the gasket is pulled to one side - replace the part (in this case, it is better to install a new silicone membrane, the service life of which is longer than that of a rubber one);

- The automatic speaker does not turn on and the power indicator does not light up - replace the batteries;

- The column ignites poorly and makes popping noises - clean the ignition wick (if this does not give a result, then replace the solenoid valve or servomotor);

- The column works for several seconds, after which it does not light up, even if ignition sparks occur frequently - clean the ionization sensor electrode.

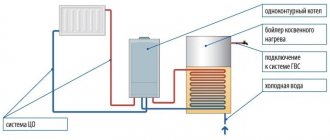

Typical problems of double-circuit boilers

Double-circuit modifications of gas boilers, intended for the preparation of coolant and hot water, can also fade for all the reasons described above. But if there are no signs of the above breakdowns, perhaps the problem is caused by the specific features of the unit.

These include those that arise due to the operation of the water overheating protection system, namely:

- mixing hot and cold running water;

- thinning of the walls of the gearbox membrane.

The instructions for boilers with an additional heat exchanger for domestic hot water usually warn that two taps cannot be opened at the same time. It is better to initially select the most suitable temperature for heating hot sanitary water in the settings.

The fact is that when cold water is turned on, the consumption of hot water decreases, and heat is generated in the same mode, overheating the heat exchanger. Due to overheating, the automatic system is activated, which shuts off the gas supply and blocks the operation of the boiler.

There are many more reasons why a DHW boiler goes out due to the peculiarities of its design. The problem can be solved quite simply: to avoid overheating, choose a comfortable water temperature by changing the regulator on the control panel

If operation is carried out according to the instructions, but the dual-circuit unit still turns off, you need to change the gasket of the water unit. Most likely it is worn out.

Why do boilers explode?

One of the reasons for explosions of household boilers is the freezing of heating systems (expansion tanks) with the cessation of water circulation. This leads to a sharp increase in equipment coolant pressure.

Freezing of heating systems, as a rule, occurs in attic spaces with uninsulated or insufficiently insulated expansion tanks in cases where boilers are operated on solid fuels (wood, peat briquette or coal) intermittently or in the presence of drafts affecting this system.

Illiterate operation of boiler equipment can lead to the destruction of not only the boiler, but even the building. In the first case, when the fuel burns, water boils, accompanied by an increase in pressure. When a critical indicator is reached, the boiler is destroyed. Due to the release of a large volume of steam into the room in which the equipment is installed, pressure increases and, as a consequence, destruction of the load-bearing parts of the building with their subsequent collapse.

There must be a serious approach and understanding that igniting a domestic hot water boiler is far from a simple operation. Their installation in organizations and the residential sector should be carried out only by specialized organizations. In this case, it is necessary that the workers performing installation and commissioning conduct training for users with a note about this in the boiler passport.

To prevent boiler explosions, it is recommended:

– make sure that the shut-off devices on the supply and return pipelines to the boiler are open, and that all shut-off devices installed on the heating system are open;

– drain condensate from the lower pocket of the chimney for boilers operating with natural draft;

– inspect the chimney heads and make sure that they are not frozen or blocked. If a malfunction of chimneys and ventilation ducts is detected, the use of this equipment is prohibited;

– before starting the boiler ignition, open the heating system make-up line and the control line for filling the expansion tank. The flow of water from the control line indicates that the heating system is not frozen. In this case, it is necessary to make sure that the pressure on the pressure gauge installed on the boiler does not increase;

– if no water flows from the control line for filling the expansion tank, and the pressure on the boiler, determined by the pressure gauge, increases and reaches the pressure in the water supply network, this indicates freezing of the heating system. In this case, lighting the boiler is strictly prohibited! It is necessary to determine the place where the heating system freezes (as a rule, this is the connection of the expansion tank with the heating system), warm it up, and only then, when water flows from the control line (with the make-up line open), can the boiler be gradually ignited. In this case, you need to constantly monitor the pressure on the boiler using a pressure gauge. If the pressure on the boiler begins to approach the maximum permissible according to the device’s passport, it is necessary to urgently stop firing and remove all fuel from it.

All these measures will significantly reduce the risks during the operation of domestic hot water boilers and preserve the life and health of people.

Marina AGEEVA, senior inspector of the SPiVO Goretsk Regional Emergency Situations Department

Repair of wall-mounted and turbocharged units

Wall-mounted gas boilers with open and closed combustion chambers are more complex devices equipped with modern electronics and safety elements. But here, too, some problems can be solved on your own. All the manipulations described above with checking traction, fuel supply and sensors are just as relevant for wall-mounted atmospheric heat generators.

To find faults in a wall-mounted electric gas boiler, you need to arm yourself with the product’s operating instructions and a Phillips screwdriver; you are unlikely to need other tools. The technical data sheet contains the fault codes displayed on the heater display, and a screwdriver is needed to remove the front panel.

Non-volatile boiler goes out

Conventional atmospheric gas boilers also have a number of features that lead to troubles in the form of burner extinguishing.

- When trying to ignite the boiler, the pilot light goes out immediately after releasing the gas supply valve button. In this case, it is worth blaming a malfunction of the thermocouple, which heats up from the wick and maintains the solenoid valve in the open state.

- Even the burner and igniter do not ignite. Most often, this is a weak contact in the electrical circuit between the automation unit and the traction sensor. It is worth cleaning the contacts with fine sandpaper and tightening their connections.

- The wick burns weakly or the yellow flame flickers unstable. The reason for this is a clogged gas supply nozzle, namely the nozzles or strainer, or both at the same time. The problem is solved by cleaning and blowing out the listed elements.

Let's summarize. There are many reasons why a gas boiler goes out. If this does happen, I recommend first trying to determine the cause yourself rather than calling the gas service. After all, everyone wants to make money. It’s as easy as shelling pears to cheat an amateur (owner) out of money from an experienced gas worker. And the reason may not be in the boiler at all.

External fault factors

So, your gas water heater does not light up, what could be the reasons for this? If the main burner does not ignite, the cause may be improperly installed pipes. The water heater system is installed in such a way that if there is any malfunction in the column that interferes with normal operation, the gas simply does not turn on. Therefore, it is necessary to check the correct connection of all inlet and outlet pipes, to ensure uninterrupted flow of water, connect the pipes correctly.

The most common and common reason for the lack of ignition of gas in the column may be the lack of traction.

When it becomes clogged with dust or any foreign objects, combustion products are not removed and extinguish the burner. Accordingly, a special protection system is activated, which automatically shuts off the gas supply. Finding out whether the problem is really a clogged chimney or not is quite simple. With the window open, you need to place your palm or a lit match against the chimney. If the draft is sufficient, then the flame of the match will deflect, and you will feel a blow with your palm.

Before calling a specialist from the relevant services, check if anyone has installed an antenna above your chimney; this is prohibited, as it interferes with the free exit of gases. If gases do not freely leave the room, they will enter the apartment, which creates the risk of carbon monoxide poisoning, which is very dangerous.

The column may light up, but go out after a short time. The reason for this may be that the protective relay is too sensitive. When the windows are closed, especially in the summer, the special relay overheats and its protection is triggered. In this case, you just need to open the windows or window. Of course, this is a temporary measure; the relay needs to be replaced.

Also, the reason for the unit not working may be discharged batteries or

, but this only applies to those speakers that have automatic ignition from batteries or accumulators. Despite the fact that manufacturers promise continuous battery life for many months, as a rule, its energy runs out much earlier.

You don't need a technician to fix this problem. You need to check the power button (on/off) and change the batteries. If the cause is discharged batteries, then this procedure will eliminate it.

Weak water pressure or its complete absence can also cause the gas water heater to not ignite. Check the water pressure in another tap by turning on a tap with cold water; if the pressure there is weak, then the reason is in the general water supply network, but if it is normal, then the reason is in the column itself. If the reason is in the general system, then you need to postpone water treatments until better times, when the pressure normalizes.

Advice from professionals

To prevent the burner or wick from going out unreasonably, gas equipment requires care. Experts advise periodically performing preventive inspections and washing components to look for gas leaks. It is optimal to clean chimneys and fireboxes once every six months.

A blue flame indicates proper burner operation.

If a device under warranty breaks down, you cannot carry out independent work. It is best to contact customer service. The same goes for electronic boilers. Complex automation cannot be repaired without special instruments and tools, as well as experience.