From the author: Hello, dear readers! Any heating boiler, be it electric, solid fuel or gas equipment, has two main functions. Firstly, this device must heat the coolant. Secondly, keep it hot for as long as possible. The faster the water gives off heat, the more often it requires heating. Accordingly, your costs for replenishing fuel or paying for electricity will be quite high.

Fortunately, such expenses can be avoided if you know how to insulate a heating boiler. In principle, any such equipment is usually made of materials that retain heat well. Some of them also have an internal insulating layer. However, additional protection against heat loss will always come in handy. The better it is, the less resources you will spend on heating the coolant.

So, let's figure out how this operation can be carried out and what materials are best used.

Insulation process

Insulation of a heating boiler can be done in two ways: heavy and light. The first is usually used for solid fuel equipment. Since in this case we are talking about a periodically opening firebox in which a fire burns, fire-resistant brick is used as an insulating material.

The process is carried out in the same way as any other work with brick. The boiler is lined on all sides with blocks, which are fastened together using cement mortar. In essence, you end up with a stove with heating equipment hidden inside.

For other boilers, light insulation methods are more suitable. They are carried out using rolled or relatively hard materials: for example, various cotton wool, polystyrene foam, etc. In any case, all actions are carried out in the same sequence.

- The first step is to render the boiler inoperative. For electrical equipment, unplug it. Turn off the gas device and shut off the fuel supply. In the case of a wood boiler, wait until the combustion process is complete. Also, for all varieties it is necessary to close the coolant supply and outflow channels.

- The outer surface of the walls of the device must be thoroughly cleaned of dirt and treated with a product that prevents corrosion.

- Now you need to weld or otherwise securely attach a metal frame to the boiler. It is made of slats and has the appearance of a lattice.

- An insulating layer is attached to the frame. If it is any type of cotton wool, then it is simply wound so that the resulting thickness is about 40 mm. If you are dealing with semi-cylindrical insulation or slabs, then the elements should be placed close to each other and securely attached to the grid.

- Attach a metal mesh over the insulation, which will hold the entire structure in its original position.

- The next layer should be applied with a lime-slag composition, then wait until it dries completely.

- The last step is painting the lime-slag layer.

There is also a method of insulation using roofing felt. This material is applied directly to the boiler screen and secured using the same metal mesh. An asbestos cement composition is applied on top of this structure. This method is attractive because there is no need to mount a frame.

Boiler room roof insulation

When constructing outbuildings such as a boiler room, in most cases a flat roof is installed. This is a more economical and simpler option. But in any case, roof insulation is required. In most cases, the floor for a flat roof is a concrete slab. Insulation of a flat roof is carried out from the outside:

- A waterproofing layer is installed. You can use bitumen mastics or rolled materials, for example, roofing felt.

- A layer of insulation is laid. It is recommended to use rigid types of thermal insulation materials, such as polystyrene foam, polystyrene foam, polyurethane foam. The insulation sheets are attached using special glue. The seams are taped. For reliability, you can additionally secure the insulation using special plastic dowels.

- A cement screed is created. A 15-20mm layer of cement mortar is poured over the insulation, leveled and left to dry for several days.

- The outer covering is installed. You can use roofing felt, mastic, bitumen. They will serve as additional waterproofing for the roof. You can use modern built-up materials based on bitumen. They come in rolls and are quite easy to install.

Material selection

As you can see, the insulation process is almost always the same. But the result depends not least on what kind of material you will use for this. Each of them has certain advantages and disadvantages. The latter, of course, must be taken into account at the planning stage of boiler insulation work.

Most often, various rolled wool acts as insulation material. The two most famous varieties are:

- mineral wool. Yellowish material. It performs well as insulation because it has low thermal conductivity. At the same time, it is inexpensive, easy to install and does not raise any special questions at all. The only negative is that mineral wool is very sensitive to moisture. If water gets in, the material, firstly, will instantly lose about 90% of its insulating properties, and secondly, it will not dry out. That is, if the mineral wool gets wet, you will have to remove it and do all the work again. There is only one way out of this situation - to foresee the possibility of getting wet in advance and eliminate it;

- glass wool This material was once very popular, which is not surprising. In terms of its thermal insulation properties, glass wool is no worse than mineral wool, but at the same time it lasts much longer and is absolutely indifferent to moisture. When exposed to water, the material dries quickly, does not rot, does not mold - in general, it is resistant to many types of influences. But there are some downsides here too. Glass wool begins to crumble after a dozen or two years. This releases glass dust into the air, which can be inhaled by people living in the house. Naturally, this will not bring any health benefits. Therefore, glass wool is, as a rule, not used for residential premises. An exception may be the case when the boiler room is located in a separate building that is not in contact with residential buildings. But even then, it is advisable to limit the glass wool to a high-quality layer of paint or another finishing option through which glass dust will not penetrate. When carrying out work, do not forget that you can work with this insulation only in protective equipment: gloves, overalls and goggles.

External insulation of boiler room walls

It is recommended to insulate a boiler room in a private house from the outside.

This is explained by the fact that there is no reduction in internal space, the formation of condensation is eliminated, and the choice of thermal insulation materials is significantly expanded. When thermally insulating a boiler room from the inside, it is not recommended to use flammable and flammable insulation materials. These include polystyrene foam, polystyrene foam, and polyurethane foam. They can only be used for external insulation. If they are used for internal thermal insulation, then high-quality finishing of the room is necessary, eliminating the possibility of fire of the insulation. External insulation is usually done during the construction of a building, but it can also be done with existing buildings. Insulation of the boiler room from the outside includes the following steps:

- Cleaning and repairing a brick or concrete wall. Large cracks and chips need to be plastered and the wall surface leveled;

- Pasting walls with thermal insulation materials. Most often, foam is used for this. It has good thermal insulation properties, is waterproof, lightweight and easy to install. Special glue is applied to foam sheets either spotwise or in a thin layer over the entire surface. During the insulation process, the foam is pressed tightly against the wall. Installation starts from bottom to top. The joints are sealed using polyurethane foam;

- Reinforcement of the insulation surface. The foam is covered with a layer of glue, into which a plastic mesh is embedded;

- Finishing. After complete drying, the surface is plastered. Decorative or simple plaster is used. In the latter case, subsequent painting of the walls or installation of finishing materials is carried out.

What to look for when choosing a boiler?

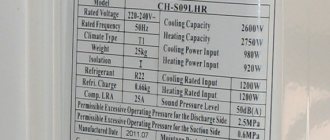

When choosing a boiler, experts recommend paying attention to several important factors:

- What power does the heating equipment have?

- What are its technical characteristics: size, number of fuel combustion chambers, performance level and others.

- Is the automatic process control system included in the package?

- Is it possible to convert the boiler to gas fuel if desired?

- How safe is a heating boiler for homes?

Example of installation and piping of a solid fuel boiler

Who should you trust with insulation?

The insulation, developed by Ecotermix specialists, meets the requirements of fire safety, durability, reliability and strength.

In order to insulate a chimney pipe by applying polyurethane foam, it is necessary to use special equipment and have the appropriate skills to work with this liquid heat insulator. It is best to entrust thermal insulation work to professionals such as the Ecotermix company. Our specialists have extensive experience in insulating cylindrical containers of various shapes and sizes.

The insulation, developed by Ecotermix specialists, meets the requirements of fire safety, durability, reliability and strength. A polyurethane foam thermal insulation layer with a thickness of 2 cm is completely comparable to the energy efficiency indicators of a 20 cm layer of mineral wool. The polyurethane foam coating does not increase the load on the chimney pipe, and the chimney system itself can be used within 2 hours after spraying the polyurethane foam.

Rules for calculating power

In relation to solid fuel devices, the same principles apply as when calculating indicators for gas-fired boilers. The following formula is used: to heat 10 square meters of area, one kilowatt of boiler power is needed, while the ceiling height is no more than three meters.

For example, if you have to heat a building with an area of 150 square meters, you need to install a boiler with a power of 15 kW.

When determining power, the degree of thermal insulation of the room is also taken into account. If the building has a good thermal contour, a coefficient of 40 is applied. If the level of insulation is not high enough - sixty.

So, when the ceilings reach a height of 2.5 meters, with a coefficient of 40 the formula will look like this: 150 × 2.5 × 40 = 15 kW. If the coefficient is sixty, you get a different result: 150×2.5×60=22.5 kW.

In addition, if it is decided to use a solid fuel boiler not only for heating, but also to heat water, its design capacity increases by another 50%. Producing hot water will require significant boiler power.

External view of the solid fuel boiler Cooper Praktik-8 and the basic diagram of its operation. The boiler is designed for installation in rooms with an area of 40−80 m2.

Thermal insulation of pipes included in the boiler design

When thermally insulating boilers, do not forget about insulating the pipes connected directly to the boiler structure itself. An important aspect when insulating a boiler is the thermal insulation of its chimney.

Insulation of chimneys of gas boilers is carried out using thermal insulation materials such as mineral and basalt wool and polyurethane foam.

Insulation with mineral and basalt wool slabs

The modern building materials market offers special half-cylinders designed for insulating round pipes. Such semi-cylinders are made of basalt fiber and greatly facilitate the process of installing insulation. Chimneys of rectangular and square cross-sections are insulated using pierced mats made of basalt or mineral wool. The thickness of the thermal insulation layer for a gas boiler should be 20-30 mm.

Insulation technology

It is necessary to connect the frame elements in such a way as to prevent the formation of gaps between them

Before insulating the chimney from a gas boiler, it must be cleaned of contaminants. An outer frame made of galvanized metal is installed around the chimney pipe. The outer frame for the chimney should be in the form of separate metal elements, 0.8 to 1 meter long. This design of the outer frame will facilitate the installation of the heat-insulating layer, and, if necessary, will provide quick access to the chimney pipe.

Heat-insulating slabs of mineral or basalt wool are mounted on the pipe, which are attached to the chimney using standard fasteners or foil tape. The thermal insulation layer is covered on top with a metal frame, the elements of which are connected by bolted studs. It is necessary to connect the frame elements in such a way as to prevent the formation of gaps between them that violate the integrity of the outer skin of the thermal insulation layer.

The insulation on top, which is located between the metal casing and the chimney pipe, is covered with cement mortar.

Insulation with polyurethane foam

Polyurethane foam prevents corrosion of steel pipes, thereby increasing their service life.

Polyurethane foam is an innovative insulation that reliably protects the surface of the chimney from destruction and prevents the formation of condensation inside the chimney system. Polyurethane foam has high fire resistance, durability, moisture resistance and low thermal conductivity. Polyurethane foam makes it possible to obtain a monolithic thermal insulation layer and is suitable for insulating chimney systems of various configurations. Read more about the insulation of industrial facilities using polyurethane foam here - /promyshlennoe-uteplenie/uteplenie-drugih-prom-objektov/.

The thermal insulator has high adhesion, which allows it to be used for insulating chimney pipes made of various materials. It is advisable to use polyurethane foam to insulate steel chimney pipes, since the insulation creates a double monolith with the metal and gives additional rigidity to the thin-walled structure. Another advantage of the material is its high anti-corrosion properties. Polyurethane foam prevents corrosion of steel pipes, thereby increasing their service life.

Polyurethane foam is sprayed directly onto the chimney pipe, which must first be cleaned of contaminants. The insulation is resistant to environmental influences, temperature changes and mechanical stress, so there is no need to install an additional metal frame around the chimney pipe with a polyurethane foam thermal insulation layer.

What types of solid fuel boilers exist

The modern market offers many options for heating boilers for the home. Before purchasing equipment, you should carefully study the features of each of them. The main differences relate to the fuel used in the boiler, the material from which it is made, as well as the fuel combustion technology used in the device.

- Traditional unit made of cast iron or steel. In appearance, the design of the firebox and chimney, and the principle of operation, such devices are similar to conventional stoves. They usually run on wood or coal. This option is considered to be as simple and reliable as possible. It does not use complex electronic devices, which makes the cost of the units quite low. In addition, automation often becomes the most vulnerable point: in traditional boilers it is simply absent. The coolant temperature is regulated using a mechanical regulator. Such boilers operate without failures for a long time.

- Pyrolysis (gas generator) boiler. Such a unit is capable of operating on a small amount of fuel and at the same time has high efficiency. It produces the same amount of thermal energy as a traditional device, but uses significantly less fuel. In a pyrolysis boiler, the combustion process of fuel takes place in three stages: first it is dried, then combustible materials are synthesized to a gas state, and then burn, releasing heat. About 85% of the fuel is used in the synthesis process. Fresh air is supplied to the firebox using a fan. The combustion intensity increases due to the supply of secondary air, which has already been previously heated.

- Long burning devices. These boilers run on wood or coal. Their main feature is the minimum maintenance requirements. At the same time, they are quite efficient, which is due to the use of a certain method of fuel combustion. There is no open flame in the combustion chamber of such a boiler, and heat is produced due to the smoldering of the fuel layer.

- Heating boilers using pellets. Here, pellets are used as fuel - small granules made from wood processing waste. Such solutions are suitable for regions where the wood processing industry is well developed. Combustible material is supplied to the combustion chamber automatically.

Modern universal single-circuit solid fuel boiler "Cooper OK-9". This is an example of compact equipment for installation in any room with an area of up to 90 m2

Advantages and disadvantages of individual insulation materials

All types of insulation have their advantages and disadvantages. Therefore, it is worth talking about the pros and cons of insulation separately.

Polyethylene foam

This is a new generation material. The closed cell structure provides it with such advantages as:

- low thermal conductivity;

- moisture resistance;

- does not rot;

- easy installation.

Available in the form of canvas (may have one or two-sided foil coating) or tubes. Polyethylene foam is cut into strips and wrapped around the pipe. The presence of a foil layer allows you to create additional thermal insulation and a waterproofing layer.

Thermal insulation paint

A relatively young type of thermal insulation. A special formula created by Russian scientists allows you to achieve optimal results even if you apply it in a thin layer. Apply thermal paint with a brush or spray. For hard-to-reach places, this is simply an irreplaceable option. The main disadvantage is the high cost, which is several times higher than the cost of other insulation materials.

As you can see, the choice of material for insulating heating pipes on the street is great

When choosing, the first thing to pay attention to is the characteristics of the material, then the complexity of installation. Last but not least, look at the price.

Remember that cheap insulation can quickly become unusable and then the money will be wasted.

Video: Thermal insulation of pipes: comparison of types

Laying mineral wool

Installation of insulation is carried out along the attic floor.

Useful loading chamber volume and power

When choosing a solid fuel boiler, you should pay particular attention to the balance of useful volume and loading chamber the unit has. These indicators differ for different types of devices. The most efficient models have this characteristic optimally: the indicator is higher.

We present the indicators of the combination of useful volume and power for different types of boilers.

- Steel 26 l/ 13 kW = 2 l/kW;

- Steel 61l / 32kW = 1.9;

- Cast iron 21l / 12 kW = 1.75;

- Cast iron 73l / 35 kW = 2.

For equipment operating using pyrolysis technology, a different scheme applies: one refill is enough for the unit to produce heat for six to ten hours, with an efficiency of 90%. These home heating boilers have two combustion chambers, and the dimensions of the loading chamber are larger than in traditional boilers. The balance is as follows: 86l / 25 kW = 3.44; 138l / 36 kW = 3.8; 110l / 25 kW = 4.4; 294l / 60 kW = 4.9.

The indicators for pellet units are different: 725l / 24 kW = 30 l/kW; 725l / 45 kW = 16 l/kW.

For long-burning models, other parameters apply: 200l / 10 kW = 20; 350l / 20 kW = 17.5; 500l / 40 kW = 12.5. In equipment of this type, it is enough to load fuel into the chamber so that it burns, or rather smolders, for 12-24 or 48 hours. This effect is achieved due to the fact that the combustion process occurs from top to bottom along the fuel layer. This leads to coke, coal or firewood slowly smoldering gradually.

Connecting a solid fuel boiler to the heating system

Basic rule: cold water should not be supplied to a working boiler if it does not have a cast iron heat exchanger. Otherwise, liquid condensate will inevitably form in the firebox, which will begin to mix with soot. The result will be a sticky mass that will reduce the efficiency of the system and will be extremely difficult to remove.

In this regard, a special piping system with a three-way valve and bypass is used. The temperature in the valve is fixed at about 50 degrees.

To connect the boiler you will also need:

- shut-off equipment;

- expansion tank;

- pump.

After the system is completely installed, it is filled with water and a pressure of 1 bar is injected into it.

Choosing a gas boiler for heating

The choice of a gas boiler depends on the following criteria:

- Design power;

- Assigned tasks;

- Control system functionality;

- Manufacturing materials;

- Often – the country of origin.

A comprehensive comparison of these indicators forms the basis for selecting the type of gas boiler, and accordingly its design. Basic knowledge of the design of gas boilers for heating will help you choose a more rational option for a heat generator.

( , 1 today)

Features of using a solid fuel pyrolysis boiler

Regardless of what you use to heat a solid fuel boiler, the principle of its use remains the same.

Option for lighting the unit with coal:

- small wood chips and additional paper, which is required for quick ignition, are placed in the fire door;

- Larger firewood is placed in the loading door, with a small amount of coal placed on top of it;

- the paper is set on fire, you need to wait a certain time before the wood chips are ignited and you can close the door.

After these operations, the device will solve the problem of maintaining the temperature independently. The owner’s only task will be to stir the coal from time to time, since some types of coal tend to coke. If you do not want to carry out such operations, it is better to spread the fuel in layers. That is, firewood, the above-mentioned black fuel on top, the other two layers in a similar sequence.

Connecting a hot water boiler

All connection work must be carried out by a specialist with relevant experience. Connecting the boiler is carried out in several steps:

- electrical connection;

- connection work on the chimney side;

- connection work on the gas supply side;

- connection work on the side of the heating circuit;

- work on connecting emergency lines.

The hot water heating unit is connected to the electrical network using a cable with a plug.

230 volt power cables and low voltage cables are bundled separately.

The chimney connection should be made along a shorter path, without kinks. It is necessary to drill a measuring hole in the chimney pipe and install its thermal insulation. The required diameter of the measuring hole is 10 mm.

The connection of the hot water boiler on the gas supply side must be in accordance with TRGI '86/96 and TRF 1996. In this case, the gas connection pipe is R 0.5. Next, you need to install a gas pressure control relay.

The efficiency of an autonomous heating system depends on the power of the boiler. Therefore, it is necessary to be able to calculate it before purchasing a hot water boiler, in order to avoid unnecessary costs.

Read how to maintain a hot water boiler here.

To operate on natural gas, it is important to configure it correctly, since the pressure control switch is initially configured for operation on liquefied gas. A leak test is carried out and air is removed from the gas supply line.

To connect on the heating circuit side, you must first thoroughly flush the heating system and connect the heating circuits.

Exploitation

First of all, you should remember that a solid fuel boiler for heating a private house should not be overheated, especially if the house uses polypropylene or metal-plastic pipes. If a situation arises that the coolant temperature at the boiler outlet is 110°C, such pipes will simply melt. However, if the heating system is built on copper pipes, which can withstand much higher temperatures, overheating of the boiler is not a problem.

Solid fuel boiler Teplodar "Kupper Praktik".

However, if the heating system is built on plastic pipes, it should be protected from overheating. For this purpose, solid fuel boilers are equipped with cooling heat exchangers and thermostatic valves. If the coolant temperature exceeds the maximum permissible value, the valve will drain overheated water into the sewer system and pump in cold water instead.

Note! Solid fuel boilers are highly inert. They cool down slowly, so even if you forgot to add fuel in time, nothing bad will happen.

Ignition of the boiler occurs in almost the same way as any other stove or fireplace, but with its own nuances. To do this, you need to put paper and wood chips in the combustion chamber, and logs in the loading chamber. If you burn with coal, you still need to first load a few logs on which the coal is poured. After the wood chips have ignited, close the chamber and wait for some time until the main fuel ignites. If the house is not heated, you need to set the boiler to high heat output, and after the system has warmed up to the required temperature, we reduce the heat output level.

Important! Do not use special lighter fluids.