Diesel boilers Kiturami

Kiturami is a large concern, considered one of the best manufacturers of heating equipment in South Korea. The company has been successfully operating in the market for more than fifty years. It all started with a modest production, which over time turned into a major concern.

This provides an opportunity to successfully improve manufactured products, as well as guarantee their high quality.

Diesel boilers from this manufacturer have been repeatedly awarded with various diplomas and awards for high technical performance and reliability. The company has certificates that meet international standards, and all products are exported worldwide.

All the information of interest and the most up-to-date information about equipment and more can always be found on the official website of the company kiturami.ru.

The lineup

The company, which occupies a leading position in the market for the production of heating equipment, regularly creates new models.

Today the product range includes boilers:

- diesel;

- gas;

- bifuel.

The product line of diesel equipment is represented by the Turbo and KSO brands.

The Turbo brand represents models for home use.

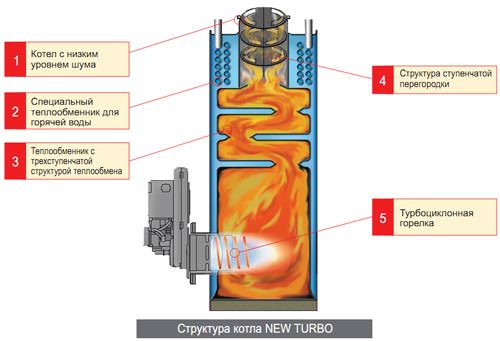

The KSO brand is similar in design to equipment operating on gas. But after replacing the burner, the equipment can operate using other types of fuel. Models of this type use a turbocyclone burner, which makes it possible to achieve the highest efficiency and almost complete fuel combustion.

Boilers from this manufacturer are characterized by a simple design, which greatly facilitates their use and maintenance. An acceptable pricing policy only increases the already high demand for this equipment.

The most effective solution in the product line of this manufacturer was bi-fuel equipment. This technique functions ideally in regions with an unstable supply of electrical energy, since it has the ability to work not only on liquid fuel, but also on solid fuel.

At the same time, during the burning of coal or wood, the boiler automatically switches to burning diesel fuel. Boilers of this brand are equipped with a forced circulation mechanism, which made it possible to achieve the highest efficiency levels. Such equipment is represented by 2 models, which differ in power ratings.

Solid fuel

Solid fuel boilers are suitable for use in rural areas. To obtain thermal energy, the units consume biofuel: wood and coal. It is possible to use briquetted and granular materials of various origins.

Features of operation:

- availability of fuel material;

- limited time on one tab;

- the need to constantly manually service the boiler: load new portions of fuel and clean out the ash several times a day;

- the chimney and pipe periodically become clogged with soot deposits.

We recommend: Draft regulator for the boiler - how to install, do-it-yourself setup

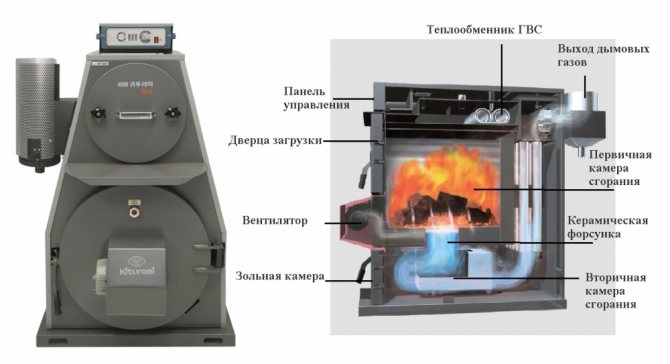

Solid fuel boilers come in classic and pyrolysis types. In the first case, the unit has one combustion chamber.

The second option is structurally more complicated. The firebox of such a device is divided into two parts. Fuel is placed in the upper chamber and heated until pyrolysis occurs. The wood gas generated in the process is forced through a nozzle into the lower chamber and burned there.

Pyrolysis boilers are more efficient. Another advantage is their low waste.

Kiturami KF

The series is represented by the KF-35 model with a power of 24 kW. A pyrolysis type boiler is capable of heating rooms up to 240 square meters. m. One full load of fuel allows continuous operation of the unit throughout the day. The heating rate of domestic water is 14.7 l/min. Efficiency - 91.5%.

Design advantages:

- spacious loading chamber for 50 kg;

- stainless heat exchanger;

- a ceramic nozzle between combustion zones 1 and 2 promotes complete combustion of fuel and pyrolysis gases;

- large loading hatch;

- the boost fan maintains a stable fireplace in the firebox;

- the secondary combustion chamber is equipped with a device for removing pyrolytic liquid;

- Ash receptacle in the form of a box.

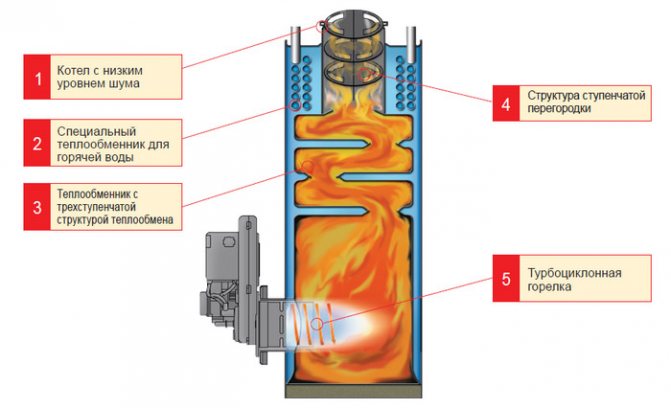

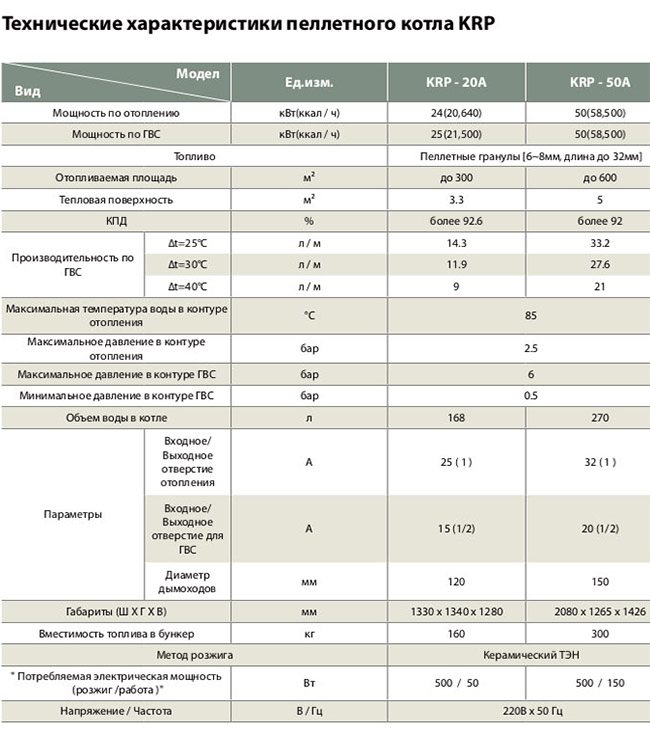

Kiturami KRP

The KRP line includes pellet boilers that use granulated wood waste. Granule diameter: 6–8 mm, length: 1–3 cm. A full hopper allows the equipment to work without interruption for up to 5 days. The model range consists of 2 sizes: 20A and 50A.

Technical features:

- automatic fuel supply via a screw mechanism;

- built-in expansion tank and circulation pump;

- ash pan in the form of a box;

- pellet burner in the shape of a bowl with an increased ignition area;

- automatic vibration cleaning of grates.

Advantages and disadvantages

All products of this manufacturer are a guarantee of high quality, the design is made in accordance with the trends of the times, maximum functionality and an affordable price range. The most popular models include STS boilers, since thanks to their power it is possible to provide heating for a room of almost two hundred square meters.

It is possible to use not only kerosene as fuel, but also light petroleum products. If you change the burner, it is possible to switch to using natural gas.

Another advantage of this model is the presence of safety sensors in the equipment, which allow monitoring of all critical processes. During their creation, the latest technology for removing residual combustion elements was used.

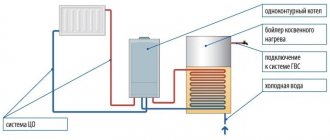

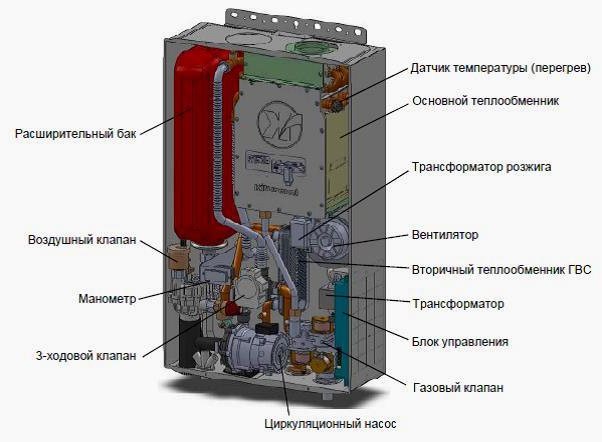

The Turbo series consists of diesel heating boilers with a floor-mounted installation option, which can not only supply heat to the room, but also guarantee hot water supply for current domestic needs. Here you do not need to purchase additional equipment, since this equipment is a boiler-type model.

An important advantage is the highest degree of protection, which became possible thanks to the use of:

- sensors;

- built-in thermostat;

- control panel;

- forced exhaust gas removal system.

An important factor in the entire product line of this manufacturer is the ability to work in any conditions, which is very important for Russian users. It is not difficult to purchase spare parts for equipment from this company, since the manufacturer has a decent number of dealer companies.

The boilers of this South Korean company have a number of advantages in comparison with similar models from other manufacturers. They are among the most economical in terms of diesel fuel consumption. At the same time, the average performance level of this equipment is two dozen liters of hot water every minute.

The most significant advantage of this equipment for the consumer is its reasonable cost. It is possible to purchase a boiler from a company from South Korea in the price range from 20 to 29 thousand rubles.

However, it is necessary to keep in mind the “weak” points of this manufacturer’s equipment:

- Significant heating costs. Installation of equipment that runs on diesel fuel will not cost very much. However, the heating price, even taking into account the use of light fuel, will be the highest of all existing options. For the most part, electric heating costs will be lower.

- The boiler requires regular human control and supervision. Despite the fact that the heating system as a whole operates in automatic mode, it requires regular human presence. Of course, it can be left in working condition for at least half a day, but under no circumstances should this be done for a week or a month. The reason is that the fuel is not of very high quality, as a result of which the boiler will stop working from time to time. If this happens during a period of cold weather, and the equipment is turned off for a whole week, then the water in the heating system will freeze and damage the pipes.

Operation and repair of Kiturami boilers

The Kiturami gas boiler stopped in operation due to error 95, that is, lack of water. But the water is okay. I replaced the sensor, but the error continues to appear. What could it be? In such a situation, either a damaged sensor or low water pressure is to blame. If the sensor was changed, then that is not the reason. Perhaps the malfunction can be easily fixed, for example, by replenishing the system with water to the required level. Try cleaning clogged contacts. But if the board burns out, it will have to be replaced. The Kiturami gas boiler requires servicing. What work needs to be done? Maintenance includes the following work: cleaning and setting up the gas burner, setting up and adjusting the automation, checking seals and shut-off valves, testing mechanisms. All sensors and filters are checked and replacements are made if necessary. Tell me, does the Kiturami boiler measure the temperature using water or only ambient air? Until the room gets colder, it does not turn on to heat itself. This is right? The boiler operating mode depends on the automation settings: what parameters are set, these are what the boiler will support. Maybe your device only sees room temperature and will “drive out” the corresponding indicators, or it focuses on the outside temperature. These models usually operate based on internal temperature. The Kiturami Twin Alpha boiler is in operation. The heat exchanger is clogged with scale. Can it be washed? Or is it easier to buy a new heat exchanger? In most cases, chemical cleaning of heat exchangers of cast iron units is used. In the process of washing the heat exchanger of a steel unit with acid, it may be damaged. A Kiturami gas boiler has been installed. It works well for heating, and when heating water it supplies water continuously until it starts to overflow from above. If the DHW circuit is not turned on, there is still warm water at low pressure. What is the reason? Typically, the DHW circuit and the heating system operate independently. In your case, there is a breakdown of the secondary heat exchanger when the coolant flows from high pressure to low pressure. That is, the systems are connected, and warm water with a closed DHW circuit is water from the heating system. In this case, the boiler is not repaired, since the heat exchangers are assembled at the factory. Either the hydraulics of the unit are broken, or the electrochemical reactions in the system are damaged; a factory defect is also possible. The Kiturami world boiler is malfunctioning and stops periodically. I clean the flame sensor and the unit works fine for a while, but soon the same thing happens again. He also began to smoke heavily. Maybe the problem is that the chimney is short, and it needs to be lengthened? Your boiler needs a burner adjustment. If necessary, the nozzle must be replaced. Before this, the firebox is pre-cleaned of soot. This procedure is mandatory at least once a year. Most likely, the increased soot is due to a clogged firebox and an unregulated burner. After adjustment, the burner operates much more efficiently and economically in terms of fuel consumption. After a power outage, the Kiturami-2000 gas boiler went into error: error codes 96 and 02 flash alternately. Restarting does not change anything. What could have happened? Obviously, the errors arose under the influence of external forces and do not correspond to either overheating of the water in the apparatus or a failure in the flame detection system. The constant display of these codes on the display indicates that the most likely cause of the violation is a burnt out electronic board. Malfunction of the Kiturami Twin Alpha 13 boiler. It does not work and shows error 95, although there is enough water in the system. What else could be the reason for such an error? If we rule out a malfunction of the water level sensor in the boiler, then we need to check the following factors: the gas valve is clogged, and therefore there is no gas supply. There is no flue gas outlet and the flue gas temperature is too high. There was a voltage drop and a phase burned out. The Kiturami boiler is malfunctioning, it is impossible to start it: error 01 on the display. How to fix? The error means that there is no combustion process due to the flame control sensor not detecting the flame. You can do the following: remove the sensor and carefully clean it with a clean cloth to remove any dust or soot. Then return the sensor to its place. This sensor can be found on the burner. A Twin Alpha 16 kW wall-mounted boiler was installed. About once a month error 07 pops up. Can the device restart itself if the temperature drops below the set temperature? Error code 07 – problems with smoke removal, not with the set temperature. It is necessary to check the fan impeller, the main heat exchanger for clogging factors, and the smoke exhaust duct itself. The world-5000 gas boiler is in operation. After a summer of inactivity, it stopped turning on when the hot water tap was opened. Otherwise it functions normally. Please tell me the reason. Thank you. Check the flow sensor at the cold water inlet. There is a turbine inside the plastic tube; when clogged, it stops rotating and the sensor does not work. The Kiturami 5000 boiler recently began to malfunction (after 5 years of operation). Everything that can be changed has been changed. It seemed to work fine, but after 2 weeks of normal operation the pressure began to drop sharply, dropping to zero overnight. You dial the water up to 1.5 - it works fine. What could be wrong? Most likely there is a leak in the heating system. Check the fill valve. Also check the operation of the expansion tank inside the device and the additional expansion tank on the heating system. World 3000 30r boiler installed. Recently it started turning on with noise (pop, detonation). I changed the fan speed, but it didn't help. There is a digital pressure gauge. Where can I find out the static and dynamic pressure for the 35kW model, gas valve VK-8105C to check its operation, Kiturami boiler malfunction, error 01 flashes. Restarted many times, does not help. Please help me solve the problem. Error code 01 – no combustion. It is necessary to check the fuel system and ignition system. Most likely it also needs maintenance. Boiler WORLD 5000. I open the hot water tap, hot water runs, then cold, the device works and heats the batteries, this does not always happen. I tried to close the heating valve, the boiler went out. The circulation pump burned out, replaced it with a new one. The world 5000 boiler started working at first, worked for several hours, and raised the temperature in the apartment by several degrees. I decided to check the “shower” mode - the water was cold. I restarted and then the unit began to hum (ignite) for a few seconds and went out. And this is always the case - 3 attempts to set fire and it gives error 01. The gas is on, the chimneys are not clogged, it is connected through a stabilizer (there are no other devices). I noticed something like this yesterday. I turn on the device. The fan turns on, the first attempt to ignite the burner, a couple of seconds, reset. Second attempt, I remove the front cover from the device and the burner lights up. An icon appears on the remote control in the upper right corner (candle) and the unit starts working. And only this way, with the cover removed. But the heating is somehow poor; through the viewing window you can see that not all the burners are burning, but only a few on the left. There can be many options: 1) the photocell is faulty, 2) the gas valve is faulty, etc. We recommend calling a specialist. Gas boiler Kiturami twin alpha 13. Installation in the house, from the very beginning there was a problem with noise when starting, when heating only for the shower, there is no such problem, when heating for heating it rattles loudly, the water was drained from the heating, the adjustment was carried out by a service technician, what should I do? The wall-mounted boiler Twin Alpha 16 is in operation. This year we installed water and it is not clear how the SHOWER function works. How to set it up step by step and tell me whether the SHOWER emblem should be displayed in the Presence mode on the display. How to find out whether the SHOWER mode has been turned on/off. All data is in the boiler passport. Read your passport carefully. I want to put the Twin Alpha 25 boiler into operation. I bought it recently and am about to install it. The instructions say that you can connect both natural gas and liquefied gas. Liquefied gas, as I understand it, is gas from a cylinder, propane. Is it possible to immediately connect propane or is there something that needs to be changed? It is necessary to reconfigure, replace the manifold with injectors and then configure the device again. Please tell me, on the double-circuit wall-mounted gas boiler Kiturami WorldPlus-30 (without r) with the CTR-5700 Plus control panel, is the temperature set according to the coolant (i.e., according to the batteries)? I can’t display it in any way. How can I do it, can I put a different remote control? Otherwise there are inconveniences at room temperature. I want the batteries to always be warm. You can set the temperature according to the coolant. Everything is written in detail in the passport. I have a Kiturami gas boiler. I wanted to know if I need a red expansion tank. The operating instructions in the picture do not indicate the diagrams, but the seller said that it needs to be installed. An additional expansion tank is required for the heating system. Kiturami 5000 boiler, three-way valve leaked. I ordered it, time passed, I installed a new one, it stopped leaking. But upon startup, the pressure gauge was at zero, and an emergency discharge of water occurred. I removed the pressure gauge because... the device stood idle all summer, and it turned out that the entrance was simply clogged. I cleaned it with a needle, installed it, and the pressure immediately began to build up. But after 10-15 seconds. Loud knocking starts and error 96 is displayed. Tell me what the problem could be now, I think all the troubles are due to the fact that the boiler has not been working for a long time. What can be done? Today, after trying to turn it on (unsuccessfully), I tried the circulation pump, it was very hot. Can it burn out if water dripping from the three-way valve gets on it? Yes, most likely the circulation pump is faulty. Perhaps the thermal relay inside the pump is triggered; the pump sometimes works, sometimes it doesn’t. The kiturami world 5000 boiler is malfunctioning. The three-way valve has recently leaked. I ordered it and replaced it (nothing complicated). But the water does not fill up, up to 1.5 bar the water fills up and is immediately discharged from below, what can be done? Most likely, the pressure gauge or safety relief valve is faulty. Kiturami error 01. What could be the reasons? Error code 01 - no ignition. Most likely, the flame sensor needs to be replaced or the settings are set incorrectly. Wall-mounted boiler world 5000 25r. Apparently the fan burned out during a thunderstorm (I determined the cause by the characteristic smell and by disassembling it; the circuit board inside the fan was charred). I bought a new fan and installed it myself, since there is nothing complicated about it (three screws and a plug). Immediately after plugging the plug into the socket, the fan began spinning at maximum speed. Moreover, the device was not turned on from the remote control. Turned it on, the remote control shows errors 02, 07 alternately. The boiler does not try to ignite, the fan spins constantly, and turns off only by unplugging the plug from the socket. What could be the reason? There are suspicions that the brains were burned together with the fan. How to calculate a malfunction? Most likely, the control unit has failed (burned out). Replacement required. I have a Twin Alpha 25 boiler. Can I use it only for heating without connecting the DHW circuit to it? Yes, you don’t have to connect the DHW circuit. Boiler kiturami 2000 deluxe 30r when starting up there is a popping sound from the suction pipe. The unit needs to be adjusted and most likely maintenance needs to be done. The Kiturami Twin alpha 20 boiler is malfunctioning, very often it gives error 07. What could be the reason, the device has been in operation for 1.5 years. Error code 07 - incorrect fan operation. There may be several options: 1) the fan impeller is clogged, 2) the main heat exchanger (plates) is clogged from the outside, 3) problems with the chimney, 4) the voltage in the network is not normal, etc. The World boiler displays error 01, what options do you recommend for fixing it? It is necessary to check the ignition electrodes and gas line. A Kiturami 5000 boiler was installed. It has been in operation for 5 years. Several months ago there were isolated cases when it turned off and showed Er 06. After a restart, it started working normally. And now, when heating the water, it suddenly turns off, off. / on does not help - Er 06 again. Tell me, what could this be connected with? Error code Er 06 - incorrect fan operation. The fan needs either maintenance or replacement. Kiturami WORLD 3000 20-30R. First, error 01 - I cleaned the electrode (flame) - it went away and started to start. But it does not work smoothly, in one mode. Doesn't reach full capacity. Accordingly, when the heating is turned off, in shower mode, the water does not warm up properly. Tell me, please, what to do? Most likely the device needs to be configured and adjusted. The fan has failed. Which fan is suitable for the World 5000 16R boiler? Fan KVG-16D (world-5000 13R-20R) is suitable for you. Error code 95, nothing helps, the computer unit may fail? Failure is possible. We recommend that you first check the contact where the black wire is screwed onto the boiler body. You also need to pull the terminal off the level sensor and touch it to this screw that secures the black wire. If the error disappears, most likely the coolant level sensor itself has failed. The Kiturami world-2000 boiler was in operation and stopped working normally, i.e. It takes a very long time to heat up the batteries. What can be wrong? You may have salt deposits or rust in your main heat exchanger (the result of frequent water replenishment or an open make-up tap), which do not allow the heat exchanger to fully heat up. We recommend replacement. When the Kiturami 3000 boiler is operating for heating, error 04 first appears, and then error 96 appears, and it’s as if water hammers are occurring in the system. A little time passes, the unit cools down and operates as before. This mostly happens at night, but also happens during the day. Tell me what to check? The coolant movement is probably disrupted. It is necessary to check the internal filter installed in front of the pump. Also external filters installed upstream of the boiler, if available. We recommend adjusting the control unit to prevent boiling in the heat exchanger. Double-circuit boiler world-2000 deluxe. Recently, the heating switches on spontaneously and displays error 04. Please tell me what is causing this? Error code 04 – temperature sensor malfunction. There may also be a problem with the plug connection. Do you need to change the remote control or control unit if all the lights on the control panel blink or go out? The control unit needs repair. It is also necessary to check the power transformer (located on the right wall inside the device). Flashing indicators - lack of power.

Distinctive features

- All models of equipment are dual-circuit, that is, they can be used not only to supply heat, but also to provide hot water supply.

- The equipment operates automatically and is capable of maintaining a certain temperature level of air and water.

- The boilers are equipped with a closed combustion chamber.

- Use of special turbocyclone burners.

- Efficiency reaches 94%.

- The maximum possible number of different mechanisms and protection systems.

- Chimney blow-out protection system.

- Anti-freeze mechanism.

- Limit level of equipment configuration.

- Possibility of using several types of fuel.

- If necessary, you can change the type of fuel.

- Impressive lineup.

- Guaranteed reliability and long service life.

Advantages of Kiturami boilers

Kiturami equipment is not without its drawbacks.

Its weaknesses: demanding fuel quality and the need for periodic maintenance. If the recommended conditions are not observed, boilers made in South Korea can quickly fail. Main advantages:

- advanced automation and electronic control: maximum comfort and safety for the user;

- two circuits: for heating and domestic hot water preparation;

- economy and efficiency: the use of the latest developments allows for maximum use of fuel resources;

- efficiency: 84–98%;

- built-in protection against freezing of the heating system and blowing out the chimney;

- easy transition to another type of fuel by changing the burner;

- modest dimensions;

- wide power range: 9–465 kW;

- long service life - up to 10 years;

- self-diagnosis of faults;

- wide network of service centers.

In addition, prices for Kiturami boilers are much lower than for similar models from other manufacturers.

Installation and configuration

Remember that when handling heating equipment, it is necessary to comply with a list of certain measures, otherwise you may permanently put the equipment out of working order.

The very first thing any user encounters is installing a boiler. The best solution to this issue would be to entrust this important task to an expert who will be able to install the equipment in compliance with all necessary requirements and standards.

Often, a quick failure of this equipment occurs precisely due to incorrect installation.

Since the heating system includes a fuel tank, it also requires special conditions when used:

- It is necessary to fill it only with clean diesel fuel.

- Requires regular cleaning.

Before turning on the boiler, you should pour fuel into it and let it sit for twenty minutes, and only then can you adjust it. If your region is characterized by frequent surges in electrical voltage, then you should not neglect the purchase of a voltage stabilizer, which will maintain the functionality of the control unit and the mechanisms of the device.

Remember that after proper installation and use of the boiler, you will need to carry out regular preventive actions.

They consist of:

- mechanical cleaning;

- control of components for correct operation, as well as the absence of leaks.

Product varieties

As a rule, by default, Kiturami means diesel boilers, since it is they who have created such high popularity for the brand.

However, the Kiturami model range consists of equipment of varying degrees of power and modification. Most are represented by double-circuit models, which allow not only heating the premises, but also providing the living space with hot water. Depending on the type of fuel used, heating boilers are divided into:

1. Gas boilers - most widely represented by floor-standing and wall-mounted models. This is a fairly common and economical option for suburban construction. The main distinguishing feature is the innovative technology of the “turbocyclone” burner. Thanks to this, double ignition is carried out, allowing operation even at low pressure in the gas pipeline. The heat exchanger, made of alloy steel, prevents the formation of scale, thereby increasing service life.

Kiturami gas boilers include a gas leak sensor and multiple programmable security systems. The operating mode required for a specific season and room can also be adjusted. Gas options can be either single- or double-circuit boilers, providing the house, in addition to heating, with hot water. The main series presented here are Twin Alpha, World Plus, Hi Fin, STSG, TGB and KSG, differing in power, tank volume, dimensions, external design and installation method.

2. Diesel boilers are the second most popular due to the fact that not every home has a gas pipe. They feature economical fuel consumption, approximately 6 l/day, customizable heating modes, depending on which the room temperature is switched. Diesel heating boilers are presented by the manufacturer in the Turbo, STSO, KSO lines. All of these are floor-standing structures, high-power and compact in size. As an additional equipment or when modifying the fuel line, a KR-6 pump is installed in the standard configuration, which provides the necessary pressure to the fuel at the outlet. It would be a good idea to connect the drain pipe to the fuel tank, which will make it easier to regularly clean it of accumulated sediment.

For any floor-standing gas boiler manufactured by Kiturami, it is possible to replace the burner with an liquid fuel one. Plus, there is complete interchangeability of spare parts for gas and diesel boilers.

3. Solid fuel equipment is produced in two series – KF and KR. All boilers are equipped with computer remote control, remote thermostats and circulation pumps. Thanks to patented technologies, stable combustion and economical fuel consumption are achieved - one masonry can hold up to 40 kg, which is enough for more than a day. It is even possible to use damp and wet firewood.

4. Pellet boilers of the KRP series represent a separate type of solid fuel, the advantage of which is the unpretentiousness of the fuel material - these can be wood pellets, shavings, sawdust, husks, pine needles and much more. An important requirement is the lowest possible level of fuel moisture, which otherwise, according to the manufacturer, can reduce the performance and sometimes damage the screw mechanism. A 150 kg fuel tank allows autonomous operation for a week. The boilers are equipped with an automatic self-cleaning system. Thanks to a three-pass heat exchanger, hot gases ensure device efficiency of up to 92%. Kiturami pellet burners precisely dose the air supply into the chambers, thereby promoting uniform combustion of the fuel.

5. Kiturami biofuel combination devices are designed to use solid and liquid feedstocks. In this case, the combustion process automatically switches to another type of fuel when the first one is completely burned out. The efficiency is more than 92%.

A review of the model range reveals a number of shortcomings in Kiturami boilers. According to experts, some gas samples of this brand are slightly noisy. Diesel analogues are subject to high requirements regarding the quality characteristics of the fuel; they are also considered more expensive and require constant maintenance, thereby preventing fully autonomous operation.

Repair

To extend the life of the heating system, eliminate errors and adjust automation, inspection and preventive maintenance of equipment from this manufacturer must be carried out at least once annually.

If any breakdown occurs or the pressure level in the system drops, you should invite a specialist who will:

- thorough diagnostics;

- draining liquid from the system;

- replacement of worn elements and components;

- filling the system.

How to set up and adjust the Kiturami Twin Alpha boiler

_______________________________________________________________________________

_______________________________________________________________________________

The Kiturami Twin Alpha 20 gas boiler does not start. If you keep the start button pressed, the burner operates. If you release the key, the unit immediately goes out. Can you tell me the reason for the breakdown? We assume that the thermoelement is defective or there is a problem with the gas valve. Low gas pressure in the supply pipeline may also occur. In some cases, there is a lack of voltage on the electronic board. We have a problem. The start is difficult. The pilot burner is on, but there is no fire on the main burner assembly. Help me figure out what is the reason? Most likely the ignition device is faulty. You will need to check the device and clean the ignition device. Why does the Kiturami Twin Alpha 13 wall-mounted boiler not stop working after it reaches the set temperature? Heating goes up to 90 degrees, then a failure occurs. When restarting, the problem reappears. It looks like the board is not in order, the temperature sensor is faulty, and the overheat protection button is broken. It cannot be ruled out that there was a violation of the automation regulations. Tell me why the boiler does not heat above 70C? We want to raise the temperature, but the screen displays that this is the highest value. How to increase heat? If the unit does not perform a cycle of increasing the temperature in the heating circuit, then the following factors are possible. In the parameter settings there is a limit on the highest heating temperature of no more than 70 degrees. There is a decrease in chimney draft. Kiturami Twin Alpha began to work incorrectly during the heating stage of the hot water supply system. Alternating cold and hot water flows from the tap. Explain why this happens? Factors causing the problem may be as follows. There is an admixture of cold water due to the fact that the 3-way valve is damaged. The heat exchanger is clogged. It needs to be cleaned. There is a tap at the bottom of the boiler from which water constantly leaks. The device itself does not work. What do we have to do? Obviously, the coolant exits through the safety group valve. In this case, this indicates increased pressure in the system. In addition, the system filling valve may be open or it is recommended to pump up the expansion tank. Please tell me what is the reason why the pressure very often increases and at the same time the liquid release valve opens? The display lights up the heating icon each time the appliance heats up. What to do? There is a problem with the heating circuit temperature sensor. There is no adequate water circulation in the heating line. Why did the wall-mounted boiler Kiturami Twin Alpha 20 periodically turn off? For example, recently the ignition element did not function at all. Maintenance of the device was carried out that month. What could it be? It looks like there is a problem with the chimney system. The chimney needs to be inspected. Failure to perform electric ignition functions means a defect in its component due to inconsistent voltage or water penetration. Can anyone help clarify the situation with the chimney duct? Soon it will be three days since there is a return draft, due to which the smoke immediately enters the kitchen. I made the chimney myself. It is a steel pipe. It seems there are omissions in the calculations. The boiler normally produces hot water, but if you turn on the heating, the water quickly boils and the device turns off. What could be wrong and how can I fix it? The circulation pump is probably broken, the control board is faulty, or the temperature sensor is broken. At the same time, the filter mesh may be clogged. In the hot water supply cycle, the boiler alternately supplies hot and cold water. It's not clear what the relationship is. How to stabilize water heating? Apparently, there is contamination in the heating system or the heat exchanger needs to be cleaned. In addition, the flow sensor may be faulty or the circulation pump may be broken. The main reason is the incorrect configuration of the chimney duct. The pipe may become contaminated with combustion products, which will significantly weaken its functionality. In addition, it is necessary to check the ventilation openings in living areas. We put into operation the Kiturami Twin Alpha 13 gas boiler. It sharply raises the temperature above 96 degrees, and then stops with overheating. Later, when it cools down, it goes to reboot. What is this connected with? Suspension of work due to overheating indicates a lack of coolant circulation. It is mainly recommended to check the heating radiator taps. They need to be opened. Then the filter element is inspected for clogging, and you should also make sure that the heat exchanger does not contain scale. I installed this model in 2020. About three months later, the device suddenly began to make noise. Explain why the noise occurs? Probably the presence of scale in the heat exchanger. If the water is hard, then over time lime will build up in the radiator pipes. Would you like to install a Twin Alpha 16 gas wall-mounted boiler into your heating system? Would you like to know how to properly put this device into operation? To properly commission this device, the following procedures are required. Turn on the power supply to the device. We open the gas valve. Then turn on the main burner. Finally, set the desired temperature. We have plans to perform maintenance. Please advise how to drain the water from the device yourself? According to the manual, this operation is performed in the following order. Disconnect the unit from the electrical network. Close the gas valve. Open the automatic air vent. Open the drain tap. Then collect the leaked water. Otherwise, it is possible to drain the liquid through the relief valve. This valve is mounted at the bottom of the unit. Can you tell me how to check the functions of the 3-way valve? There is a suspicion that he does not complete the opening all the way. The last radiators are not pumped for heating, however, in the hot water supply mode, the pipe for supplying heating water under the boiler is heated. You are right, it is necessary to check the three-way valve for acidification of its stem in the middle position. In turn, we advise you to diagnose your heating system. We operate Kiturami Twin Alpha 25 in the apartment. Until yesterday evening it worked without interruption. But now, after five seconds after start, the device goes out. It seems that it cannot drive coolant into the system. Help, please, what is this reason? A likely factor for this failure is the ignition electrode, which does not register fire, or a lack of circulation process. A few days ago, a problem with this model came to light. In heating mode, it began to whistle. I tried to restart - the attempt was successful, but it still whistles. Maybe someone can tell me what the problem is? In many cases, a strong whistle occurs if the pressure on the burner nozzles is incorrectly adjusted. The set value must be checked and corrected if appropriate. The boiler was recently filled with water, and the unit began to function intermittently. Let’s say we set an arbitrary temperature, but the heating only goes up to 24 degrees Celsius, and then the device crashes. Explain what happened? If the control board unit has been flooded with water, it is likely not working correctly. It is necessary to reset it by completely disconnecting the device from the power supply. Then turn it on again and check its functionality. I have a Kiturami Twin Alpha 30 installed. Today, at startup, the wick burns for five seconds, but the main burner does not take on the flame, and because of this the unit goes out. What is the best way to fix the problem? The ignition machine is probably faulty or there is a problem with the burner. In any case, you need to see if the phasing has been disrupted when connecting to the electrical network. I launched the same device in early August. About 3 months later, a malfunction occurred in the hot water supply, although it functions normally in heating mode. I tried to open the hot water tap, but the device only displays the temperature and does not consider it necessary to produce heating. Help, how to fix it? The problem is probably with the three-way valve. It needs to be replaced. Could you tell me why a safety temperature sensor is installed in the boiler system? The temperature sensor does not allow gas to flow to the burner if the water in the primary system overheats. I was advised to wash and clean the main water heat exchanger. Tell me what operations to perform in order to remove it according to the instructions? The primary heat exchanger is easily removed from the boiler unit using a simple screwdriver. Below is a description of the removal procedure. We drain the water from the device using the outlet tap. At the next stage, we empty the hot water supply system of water. Unscrew the fixing screws of the main heat exchanger and pull it out of the frame. The repairmen installed this unit. After about a few months, the water pressure in the device decreased. It constantly resets it and turns off. More precisely, it does not hold pressure at all. Why doesn't he hold the pressure? When the device does not increase water pressure, it can be assumed that the make-up valve is leaking. If a shutdown occurs and the water pressure drops to the zero limit, then the 3-way valve is defective. Tell us how to clean the cold water filter? First, you need to drain the water from the hot water system. The next operation is to unscrew the nut of the flow sensor. Next, remove the sensor along with the filter from the recess. After removal, clean from impurities and dirt. The device used to hum at startup, but now it rumbles even louder. At first the sound disappeared quickly, but now it lasts longer. I haven't heard from you for long, have you encountered this problem? The appearance of excess noise can be explained by the presence of limescale on the internal walls of the heat exchanger, which does not heat up equally due to different wall thicknesses. The more clogged the heat exchanger is, the stronger the noise, and the heat transfer decreases. The unit is functioning, although there is clearly no water circulating in the system. The return pump became very hot. How to fix this? The filter is probably clogged or a tap is closed somewhere, and this is slowing down the flow of coolant. The circulation pump could also be broken. Why did the hot water stop heating? The water coming from the tap is very warm. Help me understand what is the reason? Problem detection can be done in several ways. For example, there is a problem with the DHW temperature sensor; it should be replaced. There is also a high probability that the power settings for heating water have gone wrong. Often I observe the flame stopping at the moment of ignition. The burner is clean, the chimney is normal, the draft is good. Where to look? The device does not register a flame due to a weak impulse from the combustion mechanism. It is recommended to diagnose the wires between the ionization sensor and the electrode. Perhaps it needs to be tightened up. There may also be damage to the sensor insulation, which requires replacement.

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers

- Electric boilers

- Boiler error codes

- Troubleshooting boilers

- Gas water heaters

- Malfunctions and repairs of geysers

- Water heaters

- Troubleshooting water heaters

- Repair of indirect heating boilers

- Troubleshooting electric convectors

_______________________________________________________________________________

- BAXI ECO FOUR

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

- BAXI LUNA

Peculiarities. Installation and assembly. Automation components.

- BAXI MAIN FOUR

Technical specifications. Installation. Adjustment and checking. Maintenance.

- BAXI SLIM

Adjustment and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

- BAKSI - REPAIR

After starting, a malfunction appeared. It doesn’t want to turn on, it worked for two years, now the whole display lights up, just like when the boiler is turned on, when the self-diagnosis mode is in progress, then it clicks, turns off for miles and seconds and turns on the whole display again. It turned on once, but it gives error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me, what could it be?

- BAXI - OPERATION

In operation, the Baxi main four 240 boiler shuts down with error E35 (stray flame). Tell me what to do? First season in operation.

- BAXI - SETTINGS

We installed and connected the Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW device?

- BOSCH - REPAIR

Bosch 6000 24 kW boiler, single-circuit with built-in three-way valve. The boiler sensor does not see it and gives an error. Tell me how to do it so that it doesn’t give an error and works normally for both the heating and the boiler?

- BOSCH - ADJUSTMENTS

If you turn off the DHW flow sensor, maybe it will be possible to reprogram it into a single-circuit device through menu L3?

- ARDERIA - REPAIR

We installed an Arderia esr 2.13 ffcd boiler. If my coolant pressure drops slightly by a couple of notches over 2-3 days, could the reason be a faulty three-way valve (there are no leaks from the radiators)?

- ARDERIA - ADJUSTMENTS

The gas boiler Arderia 2.35 is in operation. Tell me about reducing power. I heard something about modulation, fan speed, etc. Is it really possible to reduce power?

_______________________________________________________________________________

- BUDERUS FLOOR

We installed and connected the Buderus Logano G234-WS-44 kW boiler, automatic Logomatic 4211. Heating is based on cylinders without hot water, and the jets for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the outside temperature was +16+18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and the red button light on the front wall came on. We pressed the button, turned the power back on and everything worked. This happened several times, then the boiler was turned off completely for the summer, what could be the problem?

- BUDERUS WALL

In the single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is used for DHW?

- VAILLANT - REPAIR

Tell me, for Vaillant wall-mounted gas boilers, are there real/actual differences for the better in the new generation turboTEC plus VU/5-5 compared to /3-5?

- VAILLANT - ADJUSTMENTS

There is a malfunction in the boiler, the green LED (power) is flashing, the instructions say that the thermal protection has tripped, the green indicator is flashing, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is fine.

- DAEWOO

In operation there is a double-circuit gas boiler Daewoo Gasboiler with an electronic panel. When the DHW is turned on, the heating heats up, the operating mode is summer. I removed the three-way valve, there is no dirt or wear. It seems that the board does not control the three-way valve. How to check?

- ELECTROLUX

The Electrolux Basic Xi wall-mounted boiler has been installed and connected. A problem began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts it gave error E1. How can I fix it?

- KOREA STAR

Koreastar boiler malfunction. The heating works perfectly, the hot water comes intermittently, when you turn on the hot water tap, cold water comes out first, then boiling water. After a few seconds it’s cool, then boiling water again. What could be the problem?

- FERROLI

Malfunction of the Ferroli Domiproject 24 boiler - I set it to 60-70 degrees, it switches to minimum combustion, does not turn on, does not turn off. Restart is unstable. No pattern emerges. What to do?

- JUNKERS

In operation, a Junkers euroline gas boiler, when hot water is turned on, gas ignites, then goes out, and so on several times. If you turn it on while the heating is running, the water heating starts immediately. Tell me, please, what could be the problem?

- NAVIEN

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. It is not possible to adjust the fan run-on. I set it to 30 seconds, but still 2 minutes. spins.

- OASIS

Malfunction of the Oasis ZRT18 boiler. The unit starts, the gas lights up, then goes out. It lights up again and then goes out (this happens three times). Then it lights up and works fine. It doesn't give any error. What is the reason?

- SAUNIER DUVAL

Malfunction of the Senor Duval gas boiler - the water pressure sensor shows 0.0, the indicator flashes red, the hot water does not heat up, but the water pressure in the apartment is good. How to fix the problem?

- VIESSMANN

Where should a condensate trap be installed in a coaxial chimney? The boiler wh1d with a closed combustion chamber is located at a distance of 1 m from the wall.

- WESTEN

Problem starting the Westen Pulsar D boiler. Piezo ignition works, but there is no flame, error E01 after a crackling sound. I moved the fork around.

- BERETTA

The Novella floor-standing gas boiler is blocked - the green lights on the panel are on and nothing else happens. How to fix?

- ARISTON

An Ariston gas wall-mounted boiler has been installed and connected, which does not hold pressure at all: while cooling the heated water, the pressure drops to zero, although water is regularly filled. What about the pressure?

- SIME

Metropolis dgt 25 bf boiler malfunction. The hot water supply has stopped working, the heating is working, it does not display an error. What do you advise?

- SOLLY

Please tell me how to solve the problem. The Solly Standard boiler, whenever you try to turn it on or hot water, displays a GS error.

- WOLF

Wolf boiler in operation. Lately it has begun to behave strangely: during the pause between starts, it turns on the burner for one second five times, and 70 degrees appears on the display. Where to look for a problem?

- ACV

ACV Wester Line works very unstable: it often crashes, makes a characteristic knock and stalls when starting, but at times everything is fine. The unit is almost new, what's wrong with it?

- DEMRAD

In the gas boiler Demrad, the gas supply to the burner stopped. The piezo element clicks, but there is no ignition. There is nothing wrong with the gas stove, there is gas. What is the reason?

- KITURAMI

The Kiturami world boiler is malfunctioning and stops periodically. I clean the flame sensor and the unit works fine for a while, but soon the same thing happens again. He also began to smoke heavily. Maybe the problem is that the chimney is short, and it needs to be lengthened?

_____________________________________________________________

- IMMERGAZ - ERRORS

Errors of Nike Star, Eolo Star/Mini, Mythos boilers. Malfunctions of boilers with the possibility of automatic unlocking.

- IMMERGAZ - REPAIR

My boiler systematically raises the temperature to 80 degrees in winter mode. I called the repairman three times. He said that many models have this problem and suggested installing a programmer, but it’s not certain that it will help. Tell me how to solve this problem and will this programmer help?

- AOGV

Models 11.6; 17.4; 23.2; 29.3 kW. Specifications. Control elements of the automation unit. Installation and maintenance. Malfunctions and their elimination.

- AOGV - REPAIR

The AOGV gas boiler was installed and put into operation. Problem with hot water supply. The heat exchanger was washed. Less than a month has passed and the water is not flowing again. We put a filter on the water, but time passed, and again there was no hot water. What kind of breakdown could this be?

- AGV

Installation and installation. Start-up and adjustment. Malfunctions and ways to eliminate them.

- AKGV

Technical specifications. Installation and connections. Startup and operating procedure. Automatic adjustments.

- NEVA LUX

The boiler Neva Lux 7023 is malfunctioning. It gives error E7 twice a month. But after reboot it still works. Now it gives error E6. It will work for 15 minutes and turn off. What could it be?

- ROSS

Design and automation unit. Ignition order. Malfunctions and repairs.

- ATEM ZHYTOMYR

Tell me, is it possible that due to low gas pressure the Atem Zhytomyr boiler goes out, a click occurs and goes out. What is the problem? Is it possible to temporarily disable automation and how?

- LEMAX

We installed a Lemax KSG-12.5 Premium gas boiler. After turning off the main burner, a clicking sound occurs after a couple of minutes, what is the reason? Tell me?

- KEBER

A KS-G gas boiler of 250 sq.m. was installed and connected. m. When ignited, it does not turn off, the temperature rises, if I am not mistaken, automatic Arbat 1. The flame is not regulated - it is too large. What to do?

- LIGHTHOUSE

I installed the Mayak gas boiler and connected it. It works fine. But the reason is this. When it works on unit it squeaks a lot, if you turn the knob 2-7 the squeak disappears. Tell me, what could it be?

- DANKO

We installed and connected a Danko gas boiler with automatic Kare, it works great on the igniter, but as soon as you add power to the burner, it goes out completely, yesterday it went out within 5 minutes, today it works for about 20 minutes and goes out completely. Has anyone encountered this problem?

- GAZLUX

The gaseko 18 boiler is in operation. When hot water is turned on, the pressure in the system drops after replenishment, the pressure reaches 3 bar. Have to reset. What's wrong, how to fix it?

- NOVA FLORIDA

Water often boils in the boiler, causing it to fail due to overheating. The heat exchanger was recently washed, the system is not clogged. What's the matter?

- RINNAI

Rinnai 167 RMF boiler malfunction. Recently I started showing error 14. How can I fix the problem?

- CELTIC

The Celtic DS boiler heats up to 45 degrees and sits all day, does not turn off and does not heat the batteries, sometimes it shows error A3. How can I fix this problem?

- MORA

The hot water pressure in the Mora Top boiler has dropped. What is the reason?

- MASTER GAS SEOUL

The Seoul gas wall-mounted boiler stopped turning on due to a no-ignition error. How can it be eliminated? What exactly went wrong?

Consumer Opinion

“When it comes to hot water supply, this boiler is very comfortable - there is a “shower” option, thanks to which the equipment produces the required amount of boiling water in a short period of time.”

“We purchased this boiler as a backup for the heating system. It heats well not only the heating system, but also the water.”

“It works well for the whole family, as it provides not only heat, but also hot water. I will confidently assign an efficiency of 95%. 2 thoughtful operating options – “sleep” and “shower”. I’m very pleased with the purchase, especially since the price was attractive from the very beginning.”

Types of Kiturami liquid fuel boilers

The manufacturer offers three series of liquid fuel boilers, which differ from each other both structurally and functionally, and in addition, each series includes models with different power characteristics:

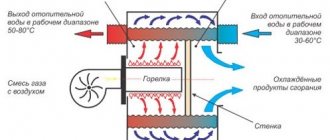

- The Kiturami Turbo series of boilers uses the principle of heating the coolant and hot water independently of each other, which allows the economical use of equipment for the hot water system throughout the year, regardless of the season. But the main distinguishing feature of this equipment is the presence of a turbocyclone burner, the operating principle of which is based on the additional use of thermal energy obtained from the combustion of gases in a special compartment. As a result, this leads not only to an increase in boiler productivity, but also to a reduction in the amount of harmful emissions;

- The Kiturami STS series of boilers is intended for use in facilities whose area does not exceed 200 m2, and the use of not only diesel fuel, but also kerosene, light oil products, and waste products is allowed as fuel. In addition, it is possible to convert the Kiturami STSO liquid fuel boiler to gas, if necessary.

- Kiturami KSOG series boilers are designed for installation in large country houses or industrial premises, the area of which does not exceed 400 m2, and are characterized by high performance when heating hot water. Maximum ease of use due to the presence of a remote electronic control. Stainless steel is used for the manufacture of the housing and heat exchangers. In addition, it is possible to modernize them and convert them to another type of fuel, for example, gas - for this, the nozzles are replaced with a burner of the appropriate type.

We recommend: Pellet stove: automatic pellet stove, pellet boiler with water circuit, long-burning heating stove

In the online store of our company ALFATEP you can buy Kiturami liquid fuel boilers at an affordable and attractive price. At the buyer's request, delivery of equipment to the site can be carried out by our company's transport service.

When choosing boiler equipment, our specialists are ready to provide the necessary advice - to do this, you should use the hotline or ask a question on the website of the online store alfatep.ru, using the feedback service. And all work on installation and connection of Kiturami liquid fuel boilers is ready to be completed quickly and efficiently by our qualified craftsmen.