How to understand that the water in the heating system does not meet standards

Water from reservoirs, wells and city water pipelines is guaranteed to have high hardness so that it can be used directly in the boiler, only with different indicators. Any of them is dangerous for the boiler and water heating equipment.

You can verify this yourself by performing express tests using test strips to determine water hardness. They can be purchased at hardware stores or pet stores.

Paper indicators are treated with reagents; when they get into water, they acquire a certain color, which is compared with a standard scale.

Water hardness is determined in degrees (°F). According to GOST No. 31865 of 2012, the following hardness indicators are established by which natural water is classified:

- not higher than 2°F - soft;

- not higher than 10°F - average;

- above 10°F - extremely hard.

For use in boilers, water with a hardness of 2-5°F is already dangerous because it promotes scale formation, so it will need to be purified with water softening.

The danger of poor quality water

What threat does low-quality and untreated water pose to a gas boiler? First of all, there is the danger of mechanical contamination. After all, although the water in the centralized water supply system is processed at water treatment facilities, nevertheless, on the way to consumers it goes a long way in metal pipes, the condition of which is far from ideal. It washes away various pollutants from their surfaces and carries them straight into the gas boiler. And if a protective filter is not installed at the inlet, then the heat exchanger will very soon become clogged with these contaminants.

Elements dissolved in water - hardness salts, for example - are no less dangerous. And although they are not even visible, nevertheless, the threat from them is even greater than from mechanical pollution. Why are they so dangerous? First of all, if a double-circuit gas boiler is installed in an apartment or house, this means that there is no centralized supply of hot water and all work is done with cold water. Based on this, we can say that the entire load not only for heating, but also for providing hot water falls on the gas boiler, as well as on the pipes through which hot water is supplied. Therefore, it is very important to install special filters that soften water by removing hardness salts.

Reagent-free filters cope best with this problem. Such water filters for gas boilers are good because they require virtually no maintenance, which is a huge plus for owners of private houses - there is no need to tighten, change, level or clean anything. As they say, set it and forget it. In addition, such filters can last more than ten years - hardly any other installation can boast of such durability.

Types of water softening filters

The domestic market is overflowing with offers for water purification filters, both domestic and Western-made. The user needs to understand which softener is best suited for the boiler and autonomous heating system. Next, you will need to select the most appropriate purification method for the initial composition of the water.

Polyphosphate filter

The most affordable and cheapest water softening filter for a boiler, and at the same time a very effective cleaning option. The ion exchange polyphosphate filter module consists of the following basic elements:

- Plastic container in the form of a flask, transparent;

- protective cover for cartridge replacement;

- drainage;

- softening chemical reagent—polyphosphate salt.

Raw or tap water enters the filter container, circulates through a chemical reagent in the form of polyphosphate salt crystals and is impregnated with sodium polyphosphates, forming a phosphate film. It envelops hardness salts, thereby neutralizing their scale-forming properties and protecting boiler heating surfaces from salt deposition.

Polyphosphate is a toxic substance, so after contact with it, water becomes undrinkable. These softeners must be used carefully in hot water supply systems, since due to possible leaks in the structure, water may enter the hot water supply or hot water supply line.

The service life of polyphosphate filters, or rather dissolving polyphosphate salt, is short. The standard consumption of the reagent is 5 grams per 1 ton of water. The reagent is replaced when its volume in the flask is halved. This happens after about six months of filter operation. The cost of polyphosphate ion exchange filters ranges from 500-1400 rubles, and replacing polyphosphates will cost the owner up to 350 rubles.

Magnetic filter

This is the most expensive and effective cleaning method. If you install a compact permanent magnetic filter in front of the boiler, you will not need to constantly regenerate it or change the filter material. It cannot soften water, that is, remove hardness salts from it.

The principle of its operation is different and is based on the transformative effect of a magnetic field on water, as a result of which its structure changes briefly.

Passing through the magnetic filter element, boiler water changes its own physical qualities, while the crystallization process when heating the liquid occurs more intensely, but not on the surface of the heated boiler walls, but in the water column. In connection with this, sludge is formed, which is easily removed by blowing or in a mud pan in front of the boiler.

A characteristic feature of this method of softening boiler water is the temporary nature of magnetization of water, therefore such a filter is installed as close as possible to the boiler unit.

The advantage of this treatment is that when water passes through a magnetic filter, it does not become technical and harmful to humans, therefore it is applicable in double-circuit boilers with hot water heating.

The service life of such softeners is practically unlimited, since the device has no moving or rubbing parts. The cost of installation ranges from 1,500 to 25,000 rubles, depending on the brand, design and hourly productivity of purified water.

Electromagnetic

At a high temperature of hot water in the boiler circuit and a high circulation speed, complete separation of hardness salts from water only with the help of magnetic treatment often does not occur, especially for natural waters with high hardness. To enhance the magnetic effect, electrical treatment of the water is added by placing a specialized electrical treatment on the magnet.

Such a device also functions by treating the source with a magnetic force field, the strength of which is regulated by an effective electrical processor. This pair makes it possible to get a longer lasting effect.

The operation of such a device does not depend on pressure changes and temperature conditions. Transforming hardness salts not only do not harm the boiler, but also act as softening agents for previously deposited scale. Installation cost: from 5,000 to 30,000 rubles.

Choice

Choosing a filter for a gas boiler is a responsible task, since your decision determines how reliable and safe your gas supply system will be. Today, the market for heating equipment and components offers a wide variety of filter units, which can be classified according to a number of characteristics. In particular, there are direct-flow and rotary filters, which differ from each other in the direction of gas movement. Depending on the design features, angular and linear devices are distinguished. They are made mainly from steel or aluminum. Moreover, these can be either welded structures or components produced by casting.

If you decide to purchase a filter for a gas boiler, start by assessing the filter material. There are two main types of material – mesh and hair.

In the first case, a special metal woven mesh is used as a filter element, which effectively traps small dust particles. The hair filter is a cassette with pressed horsehair or nylon thread impregnated with viscine oil.

Let's look at popular products that are in demand in Russia to learn more about what a gas filter is.

The best filters for the boiler

Before making a choice, you need to refer to the factory instructions and familiarize yourself with what the manufacturer offers as water treatment for the boiler. Then, in any SES laboratory or even from a water supply company, you need to take complete results of an analysis of the water that will be used to feed the boiler and heating networks. Before you begin selecting possible modifications, choose from a line of boiler or water heater filters.

In addition, when choosing, experts also advise paying attention to the following parameters:

- Productivity - determines the hourly volume of purified water, m3/hour.

- Dimensions and installation area so that the purifier can be integrated into the existing free space in the boiler room.

- Thread diameter - it must correspond to the diameter of the heating systems.

- Brand - it is safer to purchase a filter from a popular manufacturer and in branded stores. Unfortunately, there are many counterfeits in the retail chain, and in addition, in branded stores you can issue a reliable guarantee and consult on the procedure for using the filter.

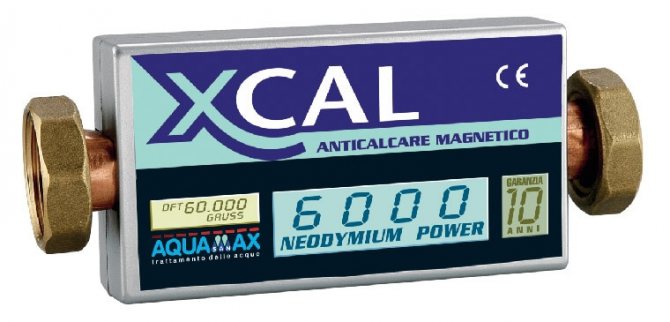

Magnetic filter Aquamax XCAL MEGAMAX

Aquamax XCAL MEGAMAX 1/2″ is an Italian highly efficient magnetic anti-scale filter for boilers and boilers. It cleans the heating surfaces of boilers from limestone formations. Designed for heat supply systems with high circulation rates.

The MEGAMAX magnetic softener is made of first-class non-corrosive steel and is considered not dangerous to people. The device does not require changing filter materials. Suitable for boilers with 1/2" piping and can purify water 0.8 m3/hour. Price: 1860 rub.

Phosphate filter Ecosoft SCALEX 200

The filter for the heating boiler Ecosoft SCALEX 200 prevents the formation of scale in heating systems and contains an ecological filter media that does not have polyphosphate, which allows its use not only in heating boilers, but also in hot water supply systems.

The SCALEX 200 filter has the function of chemical water purification and performs mechanical purification of suspended solids and rust products up to 100 microns in size.

Ecosoft SCALEX 200 does not remove hardness salts from make-up water, but has a comprehensive effect on them thanks to the simultaneous use of 3 protection mechanisms:

- Stopping the growth of hardness salt crystals.

- Destruction of the beginnings of foci of scale crystallization.

- Prevents the connection of scale-forming crystals with each other.

The filter can operate without replacing the filter material for 6 months. Cost 1260 rub.

Anion filter SVOD-AS sbb10

A powerful softener can be used not only in domestic heat and power engineering, but also in industrial boiler houses. The device purifies water from hardness salts, heavy metals and any suspended pollutants and impurities.

Water is processed in a special anion exchange cartridge, the reagent of which is processed using a special technology with chemically active components. As a result, Ca and Mg ions in the water are replaced by Na ions, thereby creating easily soluble sodium salts that do not deposit on hot boiler surfaces.

The filter housing is made of plastic that can withstand medium pressure up to 6 atm. One cartridge can process 262 m3 of water and has a shelf life of three years. Price 6700 rub.

Magnetic filter Caleffi XS

The Italian filter is designed for boiler water treatment and combines two types of cleaning: mechanical and magnetic, using a neodymium magnet and a transparent sludge collection chamber to visually control the process. The device can operate in an environment at a pressure of 3 atm. and hot water temperature 90 C. Hourly productivity for make-up water is 3.5 m3/hour. Warranty - three years. Price: 5600 rub.

Criteria for choosing a filter for gas boilers for water

The choice of a cleaning filter must be approached with all responsibility, because the further operation of the equipment depends on it. If you have doubts about purchasing a particular device, it is better to consult with knowledgeable people or be guided by general selection rules.

- Focus on water quality and frequency of filter use. An electromagnetic cleaner that does not require disassembly and replacement of main parts is suitable for regular use. When paired with an expensive boiler, it will show maximum operating efficiency.

- For very hard and dirty coolant, it is better to use double protection and softening, focusing on different degrees of water purification.

- If your budget is limited, you can give preference to a polyphosphate filter or a cartridge filter.

- Consider the dimensions of the filter so that there is enough space for its installation.

- Buy products from trusted sellers who provide a quality guarantee for their products and the possibility of warranty service.

- Focus on well-known manufacturing companies, because... they are more difficult to counterfeit, and in the event of a breakdown, parts for such devices will be easier to find.

If you do not ignore these recommendations, you can purchase a high-quality filter with a good price-quality ratio.

Connection to the heating system

In order to independently install a filter in the heating system, carefully study the manufacturer’s instructions and the wiring diagram. Typically, boiler filters have threaded connections: ½ or ¾ inches.

Filter connection location in the heating system

It is installed at the inlet in front of the heating boiler on the return line of the heating system. The distance to the boiler should not exceed 2 meters.

Pre-prepare the filter for installation. For example, a polyphosphate filter needs to be washed to remove small particles of filler, and a cation exchanger needs to be regenerated, that is, pass a saline solution through it.

Next, install the filter using a threaded connection, sealing it with fum tape. Before placement, pay attention to the direction of movement of the coolant, the permissible temperature and pressure of the water passed through. To be able to service the filter, it is cut off from the heating return line with two valves and a bypass line is made.

Features of installing a water filter on a gas boiler

A gas boiler, like the entire heating system, will not tolerate amateurism, so the installation of the filter element should be done by a person who understands this. The general procedure depends on the type of device selected.

Before starting installation, you need to prepare the necessary tools and materials. To work you will need:

- brush for cleaning pipes leading to the boiler;

- a device for cutting and sealing pipes if the pipeline is plastic;

- a device for cutting threads if the pipeline is metal;

- pliers;

- tow;

- sealing tape.

You need to make sure that the purchased filter matches the diameter of the gas boiler pipes, taps, and whether there is enough space for its installation. It is recommended to mount the device in an easily accessible place so that it can be serviced later. As a rule, this is the place before the pipe enters the heating boiler. When using an electromagnetic cleaning device, you need to think about the connection and install the device based on the availability of an electrical outlet.

Manufacturers usually include installation and operating instructions for their products, so read the instructions carefully. Installing a filter involves several steps.

- The pipe is cut at the place where the filter is installed.

- The first shut-off valve is installed and soldered. It is fixed with tow or sealing tape.

- The filter itself is installed and fixed.

- The second swelling valve is installed according to the same principle as the first.

For reliability, it is recommended to install filters for gas boilers for water on special brackets on which they will be supported.

After completing the installation work, you need to start and check the functionality of the system. First you need to run the water and see if there are any leaks. If everything is dry, turn on the gas.

Whether the electromagnetic device works or not will be immediately clear, because it is connected to the network. If filters of a different type were used, it may take some time to check them.

The duration and efficiency of the filter for gas boilers for water directly depends on the periodic and scheduled maintenance of the device. During the heating season, it is recommended to clean the device at least once a month. To do this, turn off the water in the area where the filter is installed. The coolant is poured into a previously prepared container, the internal mesh is removed from the device and it is thoroughly cleaned under running water. After this, the structure is assembled in place, the taps are opened and the liquid is released into the circuit. To avoid mistakes at any stage, it is better to invite an experienced specialist.

What is and what types of heating filters are there?

Each of us has a heating system at home. It is impossible to imagine any modern home without heating devices that provide full temperature conditions at any time of the year.

However, you need to remember that it is not enough to simply install a pipeline, connect the boiler to it and put it into operation. It is also necessary to take care of the quality of the water inside the pipes. A filter for the heating system copes well with these tasks.

Filter in the heating system

What is a heating filter, why is it needed and what is it like? Let's figure it out now.

1 Why is it needed?

Let's imagine the design of the pipelines of an ordinary private house. Its heating system in 95% of cases consists of pipes and radiators that transport hot water.

Heating a house using pipes and water is an extremely convenient and effective way. However, many people forget that, just like when working with pipe systems for water supply, heating pipes and the heaters themselves also need to be protected from working with low-quality media.

Unfortunately, we cannot guarantee the quality of the water in the pipes, even if we get the bulk of the water from a well drilled ourselves.

Tap water often contains coarse and small particles of dirt, sand, small fractions of waste, chlorine, etc. Let's not forget about small organic waste or various metal elements.

Cleaning unit at the inlet to the heating circuit

The same applies, although to a lesser extent, to the quality of water from a well. It also happens that a well was not drilled in the best area. For example, the soil on your site has too much iron. In this case, the water will gradually become saturated with small iron elements, which negatively affect the insides of the pipes in the heating system.

But this is only a superficial analysis of several reasons why you may need a water purification filter.

1.1 What happens if you don’t install a filter?

Many people will ask, why do you actually need a heating filter? What's the use of it? This is not a water supply system, the water from which we constantly use for personal needs, hygiene, food, etc.

These questions are very reasonable. We will try to answer them. The main thing you need to understand is the importance of the heating system as a structure. Few people pay attention to it, especially if there are no breakdowns inside the house. However, believe me, if the heating system of a private house fails, you will notice it immediately.

Alternative Mitigation Methods

In fact, in well-executed individual heating systems, leaks in the system are very small, and water is practically not replenished throughout the entire heating season. In such a situation, an alternative way to install water purification systems may be to purchase and fill the circuit with already purified water.

To do this, the user can use the following options:

- purchase purified water of the required volume, purified in powerful water treatment plants, for example, in industrial boiler houses;

- purchase distilled water in a retail chain;

- pour boiled water prepared at home.

All boiler manufacturers must indicate in the technical documentation the permissible composition of water for the boiler and methods of its preparation. It is best to follow these recommendations, then the owner will not have problems with either the boiler or warranty service. It is prohibited to independently add any reagents to the water: vinegar, alkali or acids for pre-boiler water purification.