External waterproofing of walls

To protect against the penetration of atmospheric moisture and extend the service life of the building, waterproofing of the walls is carried out on the outside. Measures for external waterproofing of walls are carried out at the construction stage or already during the operation of the building. Relevant work is carried out in the warm season, when the level of air humidity is minimal, in order to achieve maximum effect.

Purpose of waterproofing

The main purpose of waterproofing walls is to provide a continuous layer of waterproofing to protect structures from moisture.

What does waterproofing the walls of a house provide:

- Extending the service life of a building: moisture makes even the most durable materials brittle, gradually destroying them. A house without waterproofing work quickly loses its strength and very soon becomes dangerous for living.

- Protection from pests - it is in a damp environment that all conditions are created for the proliferation of fungi, including mold. This is fraught not only with an unpleasant odor, but also with health complications: allergic reactions, bronchopulmonary asthma and other diseases.

- Waterproofing the walls outside helps to retain heat inside the home, because wet walls tend to freeze.

- Protecting external structural elements from destruction, including waterproofing foundation walls, helps maintain the support of the building.

- Protection of basements - due to the enormous load and close proximity of groundwater, they require special waterproofing of the walls.

Pasted waterproofing

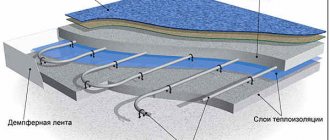

An adhesive-type waterproofing coating is a continuous waterproof carpet made of roll, film or sheet rot-resistant materials. It is used for waterproofing the underground part of building walls, applied to a concrete or brick surface.

Types of adhesive waterproofing:

- Ruberoid, hydrostekloizol, other bitumen-based materials

- Materials based on a synthetic polymer base - film made of polyethylene, polypropylene, polyisobutylene, PVC

The coating option is selected depending on the hydrostatic head. The number of layers is affected by the hydrostatic head and relative humidity in the room.

Technologically, the process of installing adhesive waterproofing includes the stages of rolling, gluing and rolling the sheets. The waterproofing carpet is glued layer by layer on the outer surface of the structure on the side exposed to water. Priming is carried out first. It is impossible to glue canvases from different layers mutually perpendicular.

The bubbles that appear during installation of the carpet are pierced, then the air is released until the adhesive composition appears from the puncture. If there is no composition under the bubble, the canvas is cut crosswise, the cut edges are folded back, coated with an adhesive along with the base and glued again.

Particular attention is paid to the weak point of the adhesive waterproofing – the joints of the panels. The canvases are glued with a shift relative to each other so that the seams are spaced apart.

If the height of the surface to be waterproofed does not exceed 3 m, bitumen-based roll materials are glued immediately along the entire height from bottom to top. At a greater height, the canvas is glued in pieces 1.5–2 m long from bottom to top with an overlap along the length. Polymer films are cut into pieces of the required length and welded into enlarged sheets on workbenches.

As adhesives, mastics or glues are used, the viscosity of which is sufficient to prevent the canvas from sliding off the vertical surface until the mastic sets. For bitumen-based roll materials, hot or cold bitumen mastic is used; for polymer materials, synthetic glue is used.

The adhesive waterproofing should not be subjected to constant shear or tensile loads. The coating is protected from mechanical damage by pressing it with a protective structure.

Waterproofing active leaks

Treatment of wet surfaces with protective compounds with a penetrating effect may be difficult due to the presence of local areas of active water leaks. The incoming liquid will wash out the active substances from the applied solution, preventing it from gaining strength. The creation of hydraulic seals in problem areas can be carried out using the repair composition “Klmastop” or the injection composition “Kaltmatron-Inject”.

To waterproof leaks with Klmastop material, it is applied to an embroidered ditch or hole in the required location. The recess is made (preferably in the shape of a “dovetail”) with a width of at least 20 mm and a depth of at least 30 mm. At high pressure intensity, in order to relieve pressure, a drainage tube is inserted into the leaking crack, which, after the main seal has hardened, is also sealed with a repair compound.

The Kaltmatron-Inject injection solution is injected into the leak area not on the surface, but deep into the building structure element. The material is delivered through a system of holes (boreholes) drilled with an inclination of 600, into which it is pumped under pressure up to 2 atm.

Recommended materials:

- CalmatronBuy

- Calmatron-InjectBuy

- Kalmatron-EconomyBuy

- Calmatron-AcrylastBuy

- Kalmatron-SuturalBuy

Waterproofing concrete and brick walls

The porous structure of concrete and especially brick is easily penetrated by moisture rising from the foundation or falling onto the surface with precipitation. Then the moisture spreads through capillaries throughout the wall. Carrying out waterproofing measures solves the problem.

Waterproofing methods:

- Coating - covering the surface with mastic, the material is applied with a brush, spatula or mechanized method to the underground part of the wall, under tiles or other finishing coatings, recommended for crack-resistant structures

- Hydrophobic impregnation - treatment with a water-repellent liquid composition; after application, the material is completely absorbed into the wall and becomes invisible

- Additives to concrete - waterproofing additives are added directly to the solution at the stage of preparing the concrete mixture

- Injection - pumping a waterproofing compound into the wall under pressure through drilled holes; in addition to sealing, the injected compound strengthens the structure

To install a barrier against such a phenomenon as the capillary rise of groundwater, the wall is cut off from the plinth and foundation. The horizontal surface at the cut-off point is leveled, dried, coated with bitumen mastic and roll-type waterproofing material is laid. The cutoff must cross the entire thickness of the wall, including the inner layer of plaster. To create a cutoff in already constructed buildings, injecting the wall with a repair compound is used.

Range of materials for waterproofing walls

Coatings.

Protection of brick and concrete walls from moisture is most often ensured using polymer mixtures based on synthetic resins, polymer-cement mastics, various sealants and elastic bitumen compositions. They are applied to surfaces using hot and cold coating methods, which makes it possible to create a durable moisture-proof seamless layer on the walls.

Rolled.

The group of rolled materials used for waterproofing walls includes PVC films, polyethylene membranes, roofing felt, etc. Such coatings are laid in several overlapping layers, and their adherence to the surface is ensured using mastics and resins.

Injectable.

Waterproofing brick walls using injection compounds is considered one of the most modern and advanced techniques. The use of these materials is the best way to prevent moisture from penetrating into the thickness of the walls and its further spread through pores and microcracks. Injection waterproofing allows you to create a reliable protective barrier inside the cavities and voids of the structure.

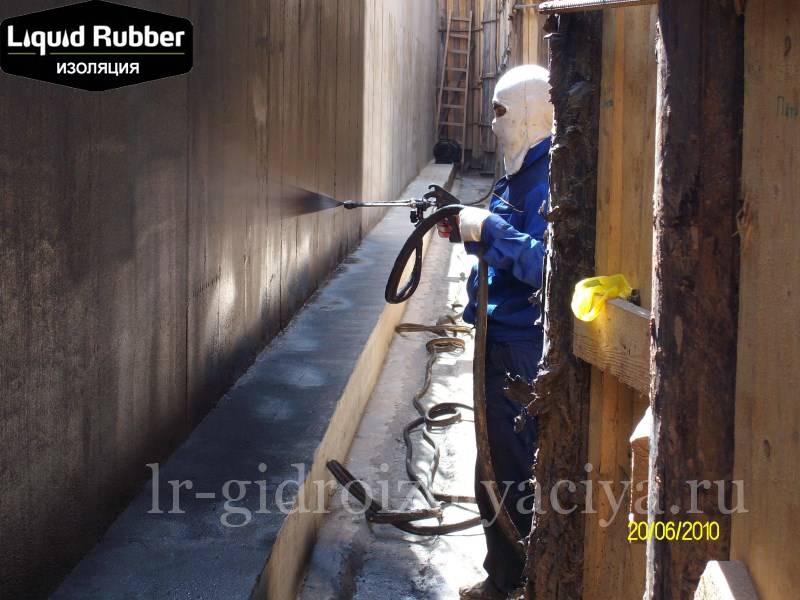

Liquid.

This category includes polyurea. This composition for waterproofing walls is obtained by mixing isocyanate polymers and amines in certain proportions. Polyurea is applied by spraying using equipment designed specifically for this purpose. As a result, a uniform, seamless, durable layer of waterproofing is instantly created on the surface.

Wall protection with waterproofing plaster

Plaster mixtures with waterproofing properties are used for exterior and interior work and allow additional insulation of the wall. Widely used in humid climates. Applied manually or mechanized.

Types of waterproofing plaster:

- Waterproof - characterized by increased density, contain liquid glass or other sealing additives

- Hydrophobic – the composition includes water-repellent additives, the plastered surface repels moisture

- Sanitating – vapor permeable, used in the restoration of old buildings, protecting structures from waterlogging

The plaster solution cannot be applied to a loose or crumbling base, gypsum surface, or walls that are shrinking. The plastered surface can be painted, tiled, or covered with other finishing materials.

Protecting walls from moisture

An important stage in the construction of any house is waterproofing the wall. There are several types of this work, intended for external or internal processing of certain premises. Each facade material requires its own nuances in protection from water. Let’s try to figure out how to choose waterproofing and why it is needed at all.

Why do walls become covered with fungus?

Most often, mold forms in corners.

Dampness on the walls in an apartment or house is far from a rare phenomenon. Sometimes this process is so advanced that the enclosing structure becomes covered with a black coating (fungus), the wallpaper falls off, and the wall itself begins to collapse. At the same time, there is an unpleasant smell, the room becomes cold and chilly. Waterproofing the wall in the apartment from the inside can temporarily solve this problem, but in the future more serious measures will be required. Causes of dampness:

- constant ingress of water onto the wall from the outside;

- lack of horizontal waterproofing between the wall and the foundation;

- roof leak;

- leaky joints of slabs in panel houses;

- insufficient degree of insulation of the building envelope;

- mistakes when insulating walls.

Waterproofing walls from the inside will help get rid of the consequences, while the cause of the negative phenomenon will not disappear anywhere. It also happens that the cause of dampness is internal factors, for example, water in the bathroom. This is where you can’t do without internal waterproofing of the walls in an apartment. In a previous article, we wrote about what materials are used for waterproofing a bathroom and how to work with them.

Before building a greenhouse with heating, you need to calculate the required amount of thermal energy so that the temperature is at the required level.

Read how to quickly repair heating pipes with your own hands here.

Will internal waterproofing of walls give results?

Insulation paint masks the fungus, but it doesn’t go away.

As we have already said, when moisture appears on the inside of the walls, you need to deal with the cause of its appearance. Let us immediately note that such events cost a pretty penny. There are cases when, for some reason, it is impossible or impractical to carry out capital measures to eliminate orphanage. Then you can resort to applying waterproofing to the walls from the inside, and use insulating paint as the material.

According to reviews, a layer of a few millimeters of paint with ceramic vacuum spheres helps prevent mold on interior walls. It works as insulation, but does not allow steam or water to pass through. The same applies to waterproofing walls inside the house, but again, only if absolutely necessary. By the way, any material that does not allow moisture to pass through is suitable as waterproofing.

Waterproofing is the ability of one of the layers of a building’s structural elements to retain moisture. The point is in the properties of the material, not in its name.

Internal waterproofing of walls in an apartment can be an auxiliary measure to the main work carried out outside the premises. In this case, the following materials are very effective:

- bitumen and latex mastics;

- coating compositions – waterproofing solution for cement-based walls;

- silicone sealants;

- impregnation;

- cement based plaster.

The same materials are used in bathrooms for the internal treatment of vertical and horizontal surfaces. In this case, it is not necessary to apply them in a continuous layer from floor to ceiling; it is enough to treat only the places where there are communication outlets. These include the bathroom, toilet and bidet areas, as well as sinks.

It is quite difficult to repair a heating circulation pump on your own, without specialized knowledge. Still, it is better to entrust this matter to specialists.

Learn more about repairing bimetallic heating radiators with your own hands here.

Waterproofing brick walls in an apartment

It is necessary to think about waterproofing any structure at the building design stage, including the cost and required amount of construction waterproofing materials in the estimate. Carrying out this type of work will help prevent moisture from getting into the building from the external environment. No heavy rains or snow will interfere with your home comfort. The process of implementing waterproofing protection can be applied to any concrete, reinforced concrete and brick structures.