Price ranges

Entry-level compressors have basic functions. The pumping speed ranges from 10 to 35 liters per minute. In general, you should pay attention to compressors with a pumping speed of 25-30 liters per minute. Compressors with such values will be the best choice in terms of price/pumping speed. Compressors in this price range have analog pressure gauges and a cigarette lighter connection type. Such compressors are suitable for most drivers, due to their low price.

Mid-price compressors with additional functions: built-in flashlight, battery connection. In general, the pumping speed of such compressors is 35 liters per minute. Such compressors are the “golden mean” among price categories, due to the ratio of basic parameters to price. If you have that kind of money, these compressors are definitely worth paying attention to.

Compressors in this price segment have wider functionality. For example, some compressors have built-in sensors for testing the generator and testing the battery. The functions are quite good, especially in terms of primary diagnostics. The speed characteristics of such compressors reach an average of 40 liters per minute. In some devices you can find not only a direct connection from the battery, but also the presence of a digital pressure gauge, which will make it easier to monitor indicators. Such compressors have a total of 4-5 meters of wires, which makes it much easier to carry the hose from one tire to another. Such compressors are worth buying for those who are willing to overpay for additional functions of primary diagnostics of the generator and battery.

As a rule, compressors in this price range have an average pumping speed of 55 liters per minute, are connected directly from the battery, and have long hoses

7 meters required for drivers of long trucks. Some are packed with additional functions: digital pressure gauge, generator tester, overheat protection. Also, such compressors can be used in wide temperature ranges. Such compressors are suitable for drivers of large trucks.

Make the right choice, happy shopping and see you again!

Purpose and scope

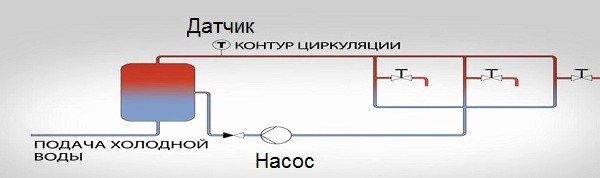

Hot water recirculation pumps have a very important function. With the help of such devices, closed pipelines through which hot water is transported operate in the required mode. By pumping liquid into the pipeline due to the rotation of special elements, recirculation electric pumps increase the pressure of the liquid medium they pump and, accordingly, the speed of its movement.

Most often, heating systems are equipped with recirculation pumps, which increases not only the efficiency, but also the cost-effectiveness of the latter. Most of these systems, as is known, operate using a coolant, which, moving through a pipeline, releases heat into the room. Heating of the coolant (in this case, before it is supplied to the pipeline) is provided by a boiler, boiler or water heater. After passing through the entire heating circuit, the water must return to the heating equipment, where it is again given the required temperature.

DHW recirculation scheme

Without the use of special pumping equipment, water circulation in the heating system will flow slowly, and in some cases may not flow at all, since the pressure of the coolant flow, which is not further increased in any way, will be dampened by the pipeline elements. The result of this is unevenly heated heating pipes and, accordingly, an uncomfortable temperature in the premises of the house.

A circulation pump for hot water supply increases the pressure and pressure of hot liquid moving through a closed pipeline circuit. The use of circulation pumps for hot water is especially important in the pipeline systems of houses with an area of more than 200 m2, in which there are several water intake points, and the boiler is installed in a separate room or in the basement. Water in such pipelines (as a rule, quite long), if they do not have a recirculation system using a special pump, cools down quite quickly. This leads to the fact that when you open the tap you have to wait a long time until liquid heated to the required temperature flows out of it.

In addition, when some taps at water intake points are opened immediately, the water pressure in them drops, because the pressure of the liquid moving through the pipeline by gravity is not additionally supported by anything. To solve precisely these problems faced by owners of private and apartment buildings, a hot water pump is designed to provide forced movement, as well as the creation of stable water pressure and pressure in the hot water supply system.

The recirculation pump should not be installed near tanks or water heaters, the heat from which could affect the thermostat.

Using a circulation pump for heating and hot water supply to a private home, in addition to the above advantages, allows you to save on energy costs. Since in systems with recirculation, water from the boiler is transported through pipes forcibly and reaches all water intake points and heating radiators much faster, its temperature during such transportation decreases slightly. A boiler, if forced water recirculation is provided in the pipeline it serves, requires less time to heat it, and accordingly, the consumption of energy carriers used to operate the heating equipment is reduced.

Pumps for circulating hot water are actively used to equip “warm floor” systems, the design of which assumes the presence of an extended pipeline circuit of a complex configuration, consisting of small-diameter pipes. In such cases, the circulation pump ensures constant movement of the coolant through the pipes.

The circulation pump is a mandatory element of the underfloor heating system

Design Features

For DHW circulation, centrifugal pumps with a “wet” rotor are mainly used. The operating principle of such a circulation pump is quite simple.

- Water entering the chamber of the recirculation pump through the inlet pipe is captured by the blades of the impeller, which is rotated by the drive motor shaft.

- Centrifugal force begins to act on the water, which throws it towards the walls of the working chamber, where increased pressure is created.

- Under the influence of pressure generated by centrifugal force, the liquid is pushed into the pressure line of the recirculation pump.

- The suction of the next portion of hot water into the working chamber occurs due to the fact that air rarefaction is created in the central part of such a chamber during the processes described above.

Design of a centrifugal circulation pump with a “wet” rotor

It should be borne in mind that a conventional centrifugal water pump is not suitable for heating and hot water supply, since the operating conditions of such equipment do not provide for a high temperature of the pumped liquid. For the manufacture of pumps that recirculate hot water, materials are used that are resistant to increased loads and high temperatures. In addition, such electric pumps, which operate primarily indoors, must be low-noise so as not to make living conditions in a private or apartment building uncomfortable. No less important characteristics of electric pumps for DHW circulation are compactness and efficiency in terms of electricity consumption.

When selecting pumping equipment that will need to work with hot water, you should also keep in mind that pumps for DHW recirculation differ in operating conditions from devices used to equip a heating system. Thus, pump models for a boiler room are designed to pump water whose temperature reaches 90°, while devices that circulate hot water can work with a liquid medium heated to 65°. As such, they are not interchangeable, although if necessary, an electric heating pump can be used to circulate hot water in DHW systems. However, replacing such devices cannot be done in the reverse order.

Domestic pumps are designed to recirculate water in small hot water systems

Wheel inflation rules

If you have a compressor, but no experience in inflating wheels, then you should conduct exercises. To do this, it is enough to know the rules that will help you act in a certain sequence:

- take the compressor and free it from the protective cover;

- install next to the flat tire;

- unscrew the nipple cap and place the hose tip on the fitting;

- take the plug and connect it to the cigarette lighter;

- we return to the wheel and turn on the toggle switch on the compressor;

- after pumping up the required pressure, turn off the toggle switch;

- remove the compressor in reverse order.

The pump hose tip has a lock. In the vertical position, the valve is closed and the tip is ready to be attached to the wheel fitting. After moving the lever to a horizontal position, the tip is fixed on the fitting, opening the nipple for air supply.

Main characteristics

When choosing a circulation pump for domestic hot water or heating, you should pay attention to the following characteristics:

- productivity - the amount of liquid that the recirculation electric pump is capable of pumping per unit of time (m 3 / hour or liter / min);

- pressure or pressure of the liquid medium created by the pump (meters of water column or Pa);

- power consumed by the recirculation pump (W);

- method of controlling the device (using a timer or temperature sensor).

Does water flow through the circulation pump when it is turned off?

Posted by Billy T. Joy » 12 Apr 2020, 07:22

Do I need to turn off the circulation pump for the summer?

Post Fatal Error » April 12, 2020, 10:59 am

Do I need to turn off the circulation pump for the summer?

Post by Proctor Hydra » Apr 12, 2020 11:50 am

Do I need to turn off the circulation pump for the summer?

Post by Olix » May 22, 2020, 07:33 pm

Do I need to turn off the circulation pump for the summer?

Post by Rik0 » May 22, 2020, 7:36 pm

Do I need to turn off the circulation pump for the summer?

Post by Proctor Hydra » May 22, 2020, 7:48 pm

Do I need to turn off the circulation pump for the summer?

Posted by Henkel » May 22, 2020, 10:28 pm

Do I need to turn off the circulation pump for the summer?

Posted by Martian Doctor » May 23, 2020, 5:51 pm

Do I need to turn off the circulation pump for the summer?

Message -=GadZZillA=- » May 23, 2020, 6:00 pm

Do I need to turn off the circulation pump for the summer?

Post by SanTekhNik » May 23, 2020, 6:14 pm

beginner » April 13, 2006, 12:51 pm

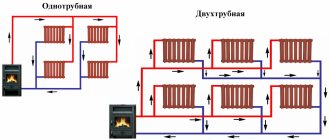

Please tell a beginner: we assembled (or rather, reassembled it again, after complete freezing last winter) heating with natural circulation at the dacha (single-pipe 50th pipe around the perimeter of the building, batteries connected according to the “Leningrad scheme”, Zhukovsky boiler 30 kW). The circulation is good, but of course at the end of the circuit (the last battery) is not hot enough. We additionally connected the circulation pump according to this diagram

Equipment control methods

Since the consumption of hot water by the residents of the house is carried out periodically, as needed, there is no point in having the DHW recirculation pump operate in constant mode. The operation of a water recirculation pump in periodic on and off mode reduces the load on both the equipment itself and the pipeline as a whole. There are two ways to ensure the operation of recirculation pumps in periodic mode:

- using temperature sensors;

- using a timer (turning on and off the electric pump according to a schedule).

The difference between such recirculation pump controls lies in both their design and operating principle.

Control via temperature sensor

This method of controlling the operation of a recirculation pump involves the use of a temperature sensor, the working part of which is in constant contact with the liquid transported through the pipeline. When the water temperature in the DHW system or in the heating system drops to a critical value, the sensor automatically turns on the recirculation electric pump, and when the liquid temperature rises to the required level, it turns it off. The use of a temperature sensor to control the operation of the recirculation pump allows you to maintain a stable temperature of the liquid in the serviced pipeline. It is also convenient when using a temperature sensor that it can be adjusted to any temperature value at which it will operate.

Grundfos recirculation pump with thermostat (temperature sensor)

Timer control

Household recirculation pumps can be equipped with timers that will turn the equipment on and off according to a specific schedule. The timer response time and equipment operation duration are calculated depending on the length of the pipeline and the volume of liquid in it; the calculation also takes into account heat losses in the pipes and pump performance.

Using a timer, you can increase the period between turning off the recirculation pump and its subsequent activation by up to a week. This option is especially relevant in cases where there is no need for hot water during a certain period; accordingly, there is no point in turning on the pump and loading it idle.

Recirculation pump with built-in timer

When using a pump to recirculate water, it is also important to know how such devices are connected to heating and hot water systems. There are two main schemes for connecting a recirculation pump:

- sequential (the electric pump is connected to one pipeline circuit that serves all water intake points);

- parallel (recirculation equipment is connected to several pipeline circuits along with the collector).

In a residential building there is a need for hot water circulation. To circulate water in a closed circle, as well as for the efficient functioning of the hot water supply system, a DHW pump is used. Thanks to DHW circulation pumps, you don’t have to wait for hot water to flow from the boiler. This is especially effective if the distance between the water heater and the tap is large. This unit significantly saves water.

A circulation or recirculation pump ensures constant movement of water through the pipes. With its help, the pressure in the main pipelines increases to the required level. The device allows you to obtain hot water of the same temperature and pressure on all floors of the house, even if several taps are open at the same time.

Installation diagrams

Depending on the number of connection points and the length of the pipes, the method of connecting the circulation pump and pipe routing is selected:

- serial connection with one circuit;

- parallel connection with the collector.

In the first case, all water intake points are connected in series and in one circuit. This is beneficial if you can easily combine the bathrooms and kitchen with one water pipe without unnecessary material costs and a fairly short route. There is only one feature that concerns the pressure pump rather than the circulation pump. If several water intake points are open at the same time, the pressure in each of them will be divided equally. Alternatively, this can be solved by installing a gearbox on each tap and choosing a more powerful pump.

The simplest installation diagram for a recirculation pump

Parallel connection solves the problem with pressure and water distribution using a manifold group and compact placement of gearboxes. In this case, recirculation pumps must be installed in each individual circuit or one more efficient pump must be selected for all groups at once. Such wiring is necessary if there are several bathrooms in the house, spaced far from each other and from the kitchen, or when, with a serial connection, the total length of the route becomes too long.

The water pressure in the boiler itself may be insufficient to provide the cottage with hot water. To recirculate hot water through the boiler, it is necessary to properly install the DHW system with the installation of a circulation pump.

In large country houses, experts recommend installing a hot water supply (DHW) system using a centralized method of heating water, through a gas and electric water heater (you can also use a single-circuit gas boiler). In this case, in order to provide the necessary supply of hot water, an indirect heating boiler must be installed in this system.

The volume of the boiler is calculated taking into account all the people living in the house (for a family of 4 people, a boiler of 100-150 liters will be enough). The water in the DHW system is heated using a heat exchanger, which is connected to a heating source (boiler, water heater).

The DHW system boiler has several inputs and outputs. The design feature of indirect heating boilers is that a coil in the form of a spiral-shaped metal tube is mounted into it, through which hot water from the boiler passes. Due to heat exchange between hot water in the coil and cold water in the boiler, the liquid inside the boiler is heated. This creates a preliminary supply of hot water for human needs.

The entire DHW system has a closed operating cycle. If hot water is not used for a long time, it begins to cool down. When a person wants to use hot water, he will probably face the problem of initial lack. When you turn on the tap, the system itself is activated and water heating begins. But it may take several minutes until it heats up to the desired temperature.

In order to be able to use hot water immediately after opening the tap, a circulation pump is installed in the system, which ensures water recirculation throughout the circuit constantly, regardless of whether a person uses hot water or not.

Uninterrupted recirculation of water through the boiler is carried out by installing additional equipment: an expansion tank, check and safety valves, and an air drain valve.

Thus, hot water is recirculated through the boiler using a circulation pump, a heat exchanger and additional equipment, which is mounted into a single DHW system. As a result, a person will not have to wait for the water to heat up by running water for some time.

Types and device

Devices of this kind are divided into two groups :

- with wet rotor;

- with dry rotor.

The main design of circulation pumps for water supply looks like this:

With wet rotor

Devices belonging to the first group are distinguished by the fact that their rotor rotates in the coolant itself . In this case, water acts as a lubricant. The stator is isolated from the rotor using a sleeve.

Such pumps have their advantages:

- simplicity of design;

- small dimensions;

- small weight;

- reduced noise level;

- large selection of models.

The disadvantages of such devices include:

- the likelihood of the rotor jamming due to the fact that lime deposits accumulate on its surface over time;

- small range of ambient temperatures at which the pump can be used.

With dry rotor

Pumps equipped with a dry rotor have their own characteristics. The rotor in this case is connected through a mechanical seal to the impeller shaft . It does not come into contact with the coolant in any way.

The advantages of such devices include:

- the possibility of using electric motors of higher power, which directly affects productivity;

- wider range of ambient temperatures.

Such units also have disadvantages.:

- quite large dimensions;

- higher noise level.

Recommendations for selection

The standard temperature range at which both types of pumps can operate is 2–110°C .

If home owners leave for a long time in cold weather, turning off the heating, they will need equipment capable of working with low-temperature . In this case, the system must be filled with non-freezing coolant.

start such a device at a temperature in your home of -10-15°C without hassle, but a pump operating in the normal temperature range may break down in this case.

When selecting a circulation pump for hot water supply, it should be taken into account that the housings of devices for hot water systems must be made exclusively of bronze or stainless steel . The impeller is usually made of heat-resistant plastic.

If you install a unit with a cast iron body into the hot water system, then, of course, you can save a little. But this is not worth doing, because the iron content in the hot water system will increase , and the likelihood that the rotor will quickly jam due to a large accumulation of deposits will increase sharply. This may damage the electric motor.

There are units on sale that are not afraid of jamming. They are equipped with a spherical rotor . The magnetic field in this case is transmitted through the conductive parts of the pump in the aquatic environment.

A spherical electric motor, unlike a traditional one, does not have bearings. The chamber in which the rotor is located is separated by a spherical glass made of stainless steel from the stator. Therefore, such pumps are less susceptible to impurities contained in water and lime deposits.

To clean the device, you need to disassemble it. In this case, the housing does not have to be removed from the pipeline. You will only need to disconnect the engine from it by turning the threaded ring .

To improve system reliability, a dual pump can be used . It has one impeller, which moves thanks to two electric motors that turn on alternately. Both motors are located in the same housing. If one of them breaks, the second one will turn on automatically. In a normal state, they replace each other after the same time intervals.

How to use a car compressor

A car compressor for inflating wheels is an electric motor with a piston and cylinder. To supply power to the electric pump motor, a long wire with a plug is used. The plug design is designed for quick connection to the cigarette lighter socket. Simply plug into the cigarette lighter and then press the switch on the compressor. Everything should work.

What to do if the cigarette lighter does not work? A new problem appears due to a blown fuse. You can open the fuse box and check the elements for thread integrity. If this turns out to be the reason, then it can be easily eliminated by installing a new fuse.

The cigarette lighter continues to refuse to work, and there is no time to search for the causes of the problem. You will have to connect the compressor to the battery directly. To do this, cut off the plug from the cable. Next, strip the ends of the wires so that the wire can be made into a loop around your finger. These will be the terminals. We put improvised terminals on the battery (red wire “+”, black “-”). Turn on the compressor. If the battery is old, it is recommended to pump the wheels with the engine running. In the future, after repairing the cigarette lighter, the cut plug must be connected to the cable, and the twisted wires must be insulated.

Connecting equipment

Installing such equipment is not too difficult . It needs to be embedded at some point in the pipeline and connected to the electrical network.

The unit can be installed on a return or direct supply pipe . For example, if the apartment is equipped with a heated floor system, it is advisable to connect the pump to the return pipes. This will stimulate the movement of water.

When it comes to a continuous hot water pipeline , it is advisable to install it on a direct supply pipe. Then the people living in the house will receive hot water in the quantity they need.

Installation of a circulation pump in a water supply system is carried out in several stages:

- Assembling the pump in accordance with the instructions included with the device.

- Choosing an installation location.

- Shutdown of water supply.

- Cutting or removing part of a pipe.

- Connecting the unit using flanged or threaded connections.

- Sealing all joints.

- Connecting the device to the electrical network.

- Testing and setting up the device.

Instructions for use

In fact, using a car compressor is not at all difficult; all you need to do is know the whole process and remember the recommendations.

Tire inflation process

The compressor has a power cord. If it is a cheap model, it will have a cigarette lighter socket. On more expensive devices, this wire is bifurcated, with terminals for connecting to the battery. Thanks to this, the power increases. Of course, if we are talking about a high-quality battery. You can choose one at https://www.rimir.by, where a wide range of batteries is presented.

- First you need to connect the wire so that the electric pump has something to power from.

- Then you need to tightly screw the compressor hose to the wheel nipple. At this stage, you can see the tire pressure on the tire pressure gauge and understand how much it needs to be increased.

- Now the last stage. It is necessary to switch the device switch to operating mode. The tire inflation will begin. The main thing here is not to overdo it and inflate the wheel to the required volume - it can be tracked on the pressure gauge.

Also, do not forget about a very important operating rule. It is necessary to inflate the wheels or simply check the tire pressure in a place where the conditions are the same as when operating the car. Also, the tires should not be cold after the trip.

In order for the tires to become normal temperature, after use you need to wait about half an hour, depending on the weather. If you do not follow this rule, the pressure will be incorrect, and besides, it may differ in each wheel. If the wheels were inflated in the cold, then when the temperature changes to positive, the pressure will rise, and this can lead to dire consequences.

Installation Tips

When installing the pump, remember that:

- It is not advisable to install the device before the air has been removed from the system and it is filled with water. When running dry, the unit may deteriorate;

- When installing equipment with a wet rotor, you need to ensure that the shaft is horizontal ;

- you should not install a pump with a higher capacity than necessary , as this will lead to noise in the system;

- Before starting the unit, it is necessary to thoroughly flush the system ;

- you need to make sure that it is possible to remove air from the pump and pipes . If this is not possible, you will need to purchase a device with an air vent;

- equipment equipped with a thermostat must not be installed next to heating tanks, which will overheat the device;

- if the system is closed , the unit must be installed on the return pipeline, since this is where the lowest temperature is observed.

Launch rules

After installing the pump, it will need to be started. When performing such work, you should perform the following steps :

- fill water pipes made of copper, steel or metal-plastic with water and create static pressure in the system;

- using automatic air vents or a tap, remove air from the unit;

- turn on the heating device (boiler);

- turn on the pump and make sure that water circulates in the system;

- let the unit operate for several minutes;

- turn off the device and remove any remaining air from the system.

Main types of breakdowns and ways to prevent them

Pumps can fail for several reasons:

- dry running - the device should not operate when there is no coolant in it. This may cause the device to overheat;

- water hammer - to avoid it, you need to manually fill the pump with liquid before starting. Otherwise, water will flow into an empty vessel, which will damage the blades;

- freezing of water in the equipment housing - when it is not in use, liquid cannot be left in it, and it is also prohibited to turn on the device at a temperature not specified in the operating instructions.

Before purchasing, it is advisable to contact specialists to calculate the required parameters of the equipment , since it is quite difficult to do this on your own. Then the device will provide the house with hot water and supply it uninterruptedly.

- Author: Maria Sukhorukikh

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

How to choose a flushing pump for heat exchangers?

Prolonging the service life, increasing the interval for replacing gaskets and plates, and also increasing the efficiency of heat exchange equipment helps with its timely maintenance and compliance with in-place cleaning intervals. The issue of servicing heat exchangers is easily resolved by using flushing pumps and professional installations for flushing heat exchangers, depending on the power of the equipment and the task at hand. For more efficient flushing and reduced chemical consumption. cleaning agents for heat exchangers installed in the heating of residential buildings or installed in a boiler room must be cleaned annually before the start of the heating season.

When planning to purchase a unit, you should pay attention to the material from which the container for the special solution is made. The tank must be strong enough, because the washing procedure is often carried out with the participation of sulfuric or hydrochloric acids. At the same time, installations often have a compact design in which all units are mounted on a tank, so the tank must be light in weight and compact in size.

The tank volume is often 10, 20, 40, 100 or 150 liters and is usually selected from a ratio of 1/10...1/20 to the system volume, depending on the type and extent of the system. So, with a pump with a 20-liter tank, as a rule, you can easily flush a system with a liquid volume of up to 200 liters. At the same time, to flush a system with a volume of 2000 liters, you will need a pump with a tank volume of at least 150 liters or more.

The power, efficiency and speed of flushing depends on the pressure of the circulation pump; the pressure of centrifugal type pumps, single-stage design, is typically from 1.0 to 2.0 bar. To flush the risers of heating systems, a pressure of 2.0 bar is not enough, so multi-stage (4 or 5 stages) anti-corrosion pumps manufactured by E8 LLC are used, the outlet pressure of which is 7.0 bar, which corresponds to a pressure of 70 meters (water column) .

To remove hardness salts (calcium and magnesium) and rust deposits, reagents based on orthophosphoric acid, which is relatively safe (relative to such types of acids as hydrochloric acid), are usually used. It should be noted that to select the type of chemical reagents, it is better to contact specialists, since an error in choosing an acid can lead to the destruction of the equipment being washed.