How to insulate the floor in a bathhouse

Historically, the least attention was paid to the floors in bathhouses.

This was explained by the fact that there was no centralized sewage system, and all the water flowed through the floor covering into the ground. Constant moisture would lead to the appearance of bacteria, fungi and an unpleasant odor on the insulation, so the insulation for the bathhouse floor was simply not used. Photo of the final stage of insulation - tiling

Nowadays, when all permanent buildings have a connection to central sanitary systems, experts advise carrying out insulation work after all activities with the log house have been completed:

- Roof installation;

- Connecting the drainage system;

- Installation of doors and windows.

At the moment, such buildings are not just places for hygiene and relaxation, but also complex engineering structures, which are often installed on piles. Such structures must be adapted to work at high temperatures and high humidity levels.

Floors in the bathhouse

The service life of a bathhouse is related to the quality of its constituent elements. The most common floors are clay and wood. The timber may not withstand constant changes in dampness and temperature, and the clay first absorbs moisture and then cracks when it dries.

It becomes obvious that materials that are safe for human health and are good heat insulators quickly become unusable. In such conditions, laminate or linoleum can be used for a long time, but due to its synthetic component this is unacceptable.

Wooden floor

If you are wondering how to insulate the floor in the dressing room, then it is better to take a wooden board, and for the steam room the optimal solution would be concrete. The latter has high strength and does not enter into harmful chemical reactions when exposed to atmospheric influences.

But in order for floors made of concrete or timber to have good thermal conductivity, it is necessary to take measures to install thermal insulation.

What are the difficulties of insulating floors in a bathhouse? A bathhouse is a structure with high levels of humidity and temperature; in order to comfortably take water procedures, certain temperature conditions should be created throughout the entire volume of the premises, while taking into account both the design features of the building and the materials for the construction of individual elements.

For the southern regions of our country, the problem of insulation is not relevant, but in the northern regions, cold floors create significant difficulties. This concerns not only large heat losses from the interior, but also unpleasant sensations during washing. The cold has a particularly negative effect on young children; they are constantly either on the floor or in close proximity to it. Bringing a cold child home from the bathhouse is not the biggest problem.

Insulation of bath floors is especially important for families with children

In the article we will consider several methods used for insulating floors in a bathhouse, taking into account the purpose of the premises and the features of construction technologies. Insulation solutions will vary; you will need to make your own choice, taking into account the characteristics of your bathhouse, personal preferences and financial capabilities.

Insulating a floor with a screed on the ground - diagram

This method can be used for various bath premises and is characterized by good efficiency and reliability. We will consider the most complex multi-layer insulation option, and you can simplify it a little for yourself and refuse some work. It all depends on the climate zone where you live.

Step 1. Make markings.

The height of the last covering should be at the level of the subfloor; this must be remembered during marking. Therefore, take into account the number of layers of screed, the features of the insulation, etc. Use a hydraulic level to mark the subfloor mark on the walls and make marks from it for each layer in the reverse order.

Zero floor level mark

An example of how to mark the zero level

In our case, this will be a dry concrete screed (about 5 centimeters), a layer of foam concrete (about 10 centimeters), a layer of expanded clay (about 15 centimeters) and a sand cushion (about 15 centimeters).

Foam concrete - structure

Expanded clay in bags

You can add insulation from pressed polyurethane foam or polystyrene foam, replace one of the insulating layers we named with them, etc.

Pressed polyurethane foam

Styrofoam

Thickness is also not a dogma, we cannot know your specific conditions. But you must make vertical marks for each layer; constantly monitor the thickness of the layers made. Otherwise, the floor height in each individual bathhouse room will not be the same.

Step 2. Level the ground at a certain depth according to our advice. You need to level it with a shovel “by eye.” If you wish, you can check the horizontality with a level.

Level the prepared ground

Shovel

Step 3: Add a layer of dry sand. It will absorb vertical loads during soil heaving. Compact the sand using any available means. Under no circumstances should you pour water on it to shrink it! Apart from harm, this “technology” does nothing.

sand cushion

Sand pillow - photo

Compacting sand with a vibrating plate

Step 4. Add a layer of expanded clay. You can replace it with slag or other porous production waste. At the lowest level, it is better to use durable and moisture-resistant insulation; they cope well with all the adverse effects that arise during operation.

Add a layer of expanded clay

Slag - photo

Step 5. Fill the expanded clay with foam concrete.

This is an excellent material in all respects. It is made only from cement and sand in a ratio of 1:3; the porous structure is obtained by adding special additives. They can be purchased at construction stores.

Important. Do not purchase such additives from open warehouses; the additives lose their characteristics after freezing. Not a single seller will talk about this, and you won’t know it by touch. The fact is that in appearance, foam concrete made using low-quality additives is almost no different from normal. Only after it cools down will it be discovered that the material has almost no strength and crumbles under the slightest load.

For baths that are located on stilts, insulation is also protection that can extend their service life. Therefore, special attention must be paid to its quality and reliability; the installation instructions and other recommendations must be followed.

It should be noted that the manufacture of thermal insulation for wooden floors should consist of the following points:

- The logs are laid on the subfloor;

- The space formed between them is filled with insulation - expanded polystyrene, expanded clay or mineral wool;

- Work is underway to install waterproofing;

- The floorboard is being laid.

Important. When laying boards in this type of bathhouse, you need to maintain a slight slope so that the water drains.

Expanded clay insulation is rightfully one of the most popular insulation materials, which is why floor insulation is often done with expanded clay.

We invite you to familiarize yourself with the Deflector on the pipe to increase traction

Its thermal insulating properties are such that its only 15-centimeter layer is equal in thermal insulation qualities to a 25 cm thick wooden board or a meter-long brickwork. However, it makes no sense to make thermal insulation using expanded clay thinner than 15 cm in thickness, since this is the value at which its properties as a thermal insulator begin to appear.

The basis for the production of expanded clay is ordinary clay. During the manufacturing process, it is fired at a high temperature, about 1400°C. The result is granules with a porous structure, absolutely environmentally friendly and safe for human health, which makes it indispensable for insulating sanitary areas, such as the floor in a bathhouse.

The main disadvantage of expanded clay insulation is its high rate of moisture absorption, but with proper protection against water penetration into the expanded clay layers, there is no need to worry about this. Its advantages include high thermal insulation, sound insulation and lightness of the material, which makes it easier to transport the insulation and its use. Expanded clay insulation is supplied to the market in the form of granules; it is free-flowing, which is why it smoothes out surface unevenness when insulating it.

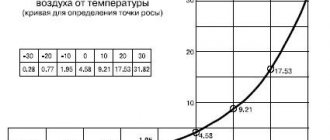

Table of thermal conductivity of materials.

All this justifies the widespread use of expanded clay. It is not expensive, and is even better suited for insulating floors than many other materials. Plus, it can withstand fairly high pressures, about 300 kg/m2.

There is expanded clay insulation of different sizes: from 5 mm to 4 cm. It is recommended to mix varieties of expanded clay of different sizes so that the space between large granules is evenly filled with smaller ones, which will make the heat-insulating layer more dense, eliminating its strong subsidence. To insulate the floor in a bathhouse, it is recommended to use larger fractions of expanded clay, since the cavities inside them are also larger than in small granules, and this increases the heat-insulating properties of the material.

It is better to use only intact granules to insulate the floor in a bathhouse. If they are split, their thermal insulation is reduced.

Materials

With a wide choice today, sewer insulation can be done with a variety of materials. The requirements for them, in addition to the basic thermal insulation qualities, are as follows:

- tightness;

- ease of installation work;

- fire resistance;

- corrosion resistance;

- durability;

- admissibility of reuse.

The following groups of insulation materials are distinguished:

- Types of mineral wool: basalt and glass wool.

- Based on polystyrene: polystyrene foam, polyurethane foam, expanded polystyrene.

Each section of the sewer line can be optimally selected for thermal insulation material of the appropriate type, type and required parameters.

Features of insulation

It is known that insulating material does not heat on its own, but only retains the heat coming from the source. All options for heat insulators have undeniable advantages and disadvantages.

Glass and mineral wool

The mineral wool insulation method is economically affordable and therefore popular. The main feature of the material is its hygroscopicity and the need for waterproofing. The need for an additional layer of insulation, low resistance to mechanical loads, or caking properties significantly reduce the value of such insulation. However, sewerage in the basement of buildings is often insulated using this traditional method.

- LiveJournal

- Blogger

Insulation of a sewer pipe with mineral wool

Modern insulation for sewer pipes is basalt fiber, or basalt mineral wool. Essential qualities are manifested in non-flammability, lightness, and moisture resistance. Can be purchased in rolls and hollow tubes. The disadvantage is the high cost, which makes its use economically unprofitable. But insulating underground sewer pipes with basalt wool cylinders meets all the necessary requirements.

Foamed polyethylene

Water supply and sewer lines in warm climates can be covered with protective layers of polyethylene foam. The advantage of the material is its reusability. For cool areas, it is recommended to use it in several layers by wrapping pipes with fabric in rolls or fixing them in the form of tubes of various diameters. Insulated sewer pipes will prevent moisture penetration. There are varieties with the addition of foil, which enhance the properties of polyethylene by reflecting heat. Disadvantages include the fragility of the material. Therefore, it is recommended to be careful and careful when working.

Styrofoam

A popular insulation material, one of the varieties of expanded polystyrene, pressed onto surfaces. An important characteristic is the waterproofness of the granules, which does not require additional costs for waterproofing. Light weight, reasonable price and ease of installation are its undeniable advantages. Polystyrene foam in granules is used for sewer thermal insulation in the form of special shell-linings covering pipes. You can purchase sheet material and cut it into pieces for placement in boxes prepared for the pipeline.

Expanded clay

Excellent insulation for sewer pipes in the ground, provided there are dry trenches without groundwater. An expanded clay pillow will exhibit insulating qualities and serve as a reliable filter, since the loose insulation can “breathe.” Additional important properties of expanded clay can be noted:

- environmental Safety;

- ease of use;

- fire safety;

- resistance of the material to the environment, chemical and biological soil factors;

- strength and durability;

- affordable price.

Expanded clay as insulation is a cheap material suitable for laying pipes buried in the ground. The main disadvantage is the need to use roofing felt or polyethylene film to insulate the damp walls of the trench. Additionally, the depressions are filled with sand about 10 cm high. In general, the volume of excavation work turns out to be labor-intensive and time-consuming. However, the use of expanded clay is a popular way to insulate a sewer pipe in the ground. In this case, an additional tubular insulator or equipped pipe boxes are often used.

WATCH THE VIDEO

The development of modern technologies accelerates the appearance on the market of new types of insulation materials, such as penofol and penoizol. Their features lie in special application techniques using equipment. The high cost and the need for professional participation have not yet contributed to the widespread use of these resources. All heat-insulating materials perform one main task: they create an air cushion that prevents the penetration of cold. The right decision depends on the location of the sewer networks, climatic conditions, financial costs and accessibility of installation.

Features of bathhouse thermal insulation with expanded clay

Expanded clay is a natural material, which means it is environmentally friendly. However, environmental friendliness is not the only advantage of this heat insulator. It is very popular when insulating a bath due to its many advantages, such as:

- Cheapness. Compared to most synthetic insulation materials, expanded clay has a low cost.

Durability. The material does not emit toxic fumes and does not decompose or rot.

High thermal insulation properties. The thermal conductivity of expanded clay is 0.12 W/mK, which is especially important when used in a bathhouse, where high temperatures are considered the norm.

Fire resistance. Expanded clay is a heat-resistant material. It does not burn or melt under high temperatures.

Light weight. This allows it to be used to insulate the ceiling of a bathhouse.

Pest resistance. Expanded clay is not attractive to insects and rodents.

- Versatility of use. Using expanded clay you can not only insulate, but also level the surface. In addition, it can be used in conjunction with heated floors.

As for the disadvantages of using the material, among them we can highlight the labor-intensive process of thermal insulation. In addition, when using expanded clay to insulate a bathhouse, it is necessary to pay special attention to vapor and waterproofing.

Before proceeding directly to thermal insulation work, calculate the amount of expanded clay that is required to insulate the bathhouse. It is better to purchase it with a reserve, since fragile granules may break during transportation. It is advisable to take material with granules of different sizes. This will allow it to form the most dense backfill and reduce further subsidence.

Pay special attention to vapor and waterproofing. The best option is Izospan or aluminum foil. But it is not recommended to use roofing felt. It is flammable and can become wet under the influence of high temperature and humidity.

Technologies for insulating floors in bathhouses:

- Simple flooring option. It consists of compressed soil, a mixture of sand and gravel, a concrete base, vapor barrier, expanded polystyrene, polyethylene film, and a reinforcing frame. To insulate it, you need to prepare the base, level it from bumps and cracks. A screed made of a special insulating mixture is poured over all layers.

- With screed on the ceiling. To insulate the structure, durable foam sheets and pressed mineral wool are suitable. The base is made of a concrete slab, which is fixed to the walls or strip foundation.

- According to the lags. It is better to use polystyrene foam or compressed material wool as insulation.

Insulation of concrete floor

If you have a concrete floor in the steam room and washing room, then at the beginning of construction the foundation for the washing room or steam room is poured, on top of which a concrete floor slab is laid.

Next, they put in waterproofing and insulation, after which they make a screed with a special reinforcing mesh. Now the heated floor system is laid, on top of which the tiles are glued.

Video:

Since the ceramic coating is usually cold and rather slippery, a removable wooden grid is placed on top of it, which is taken out of the bathhouse (washing room) for drying after each use.

To insulate a concrete floor with your own hands, perlite is most often used; expanded clay or glass wool are also used.

The layer of insulating material must be between two concrete layers.

Perlite insulation

If you work with perlite, be sure to close the door to the room so that it does not fly apart.

Perlite is excellent for thermal insulation of such rooms, as it has low thermal conductivity.

Mix the insulation with water 2 to 1, then add cement to the mixture and mix thoroughly. Now add 0.5 liters of water and a bucket of insulation so that no water is released in your solution.

When the insulating composition is ready, apply a thin layer of it to the concrete slab and leave to dry for about a week.

The next layer of concrete is applied to the dry surface. This way you will get reliable thermal insulation that will last for many years.

Foam insulation

You can insulate a concrete bathhouse with polystyrene foam, penoplex or expanded polystyrene - one of the simplest and most economical ways.

This material is easy to process and has a low mass; in addition, it does not absorb moisture and does not rot, and is also environmentally friendly and safe for health.

Insulation with extruded polystyrene foam can be done without special skills and tools.

Practical weightless slabs do not weigh down the already heavy concrete floors and foundation.

Most often, foam insulation is done in two layers, and the joints between the sheets are sealed with polyurethane foam or scraps of the same material. The layer thickness can be from 10 to 25 cm.

A reinforced screed is laid on top of the foam, and when it is completely dry, it is covered with tiles on top.

You can also install a heated floor system underneath.

You should know that before insulating with foam plastic, a layer of waterproofing must be laid on the concrete base to extend the service life of the insulation.

Insulation with expanded clay

Expanded clay insulation is also quite often used in the construction of baths. This is a porous material that is lightweight and has high thermal insulation properties.

The thickness of the material layer depends on the loads to which your floor will be subjected.

Beacons are laid on the concrete base using a solution, along which the screed will then be leveled. When the solution dries, the base is covered with expanded clay.

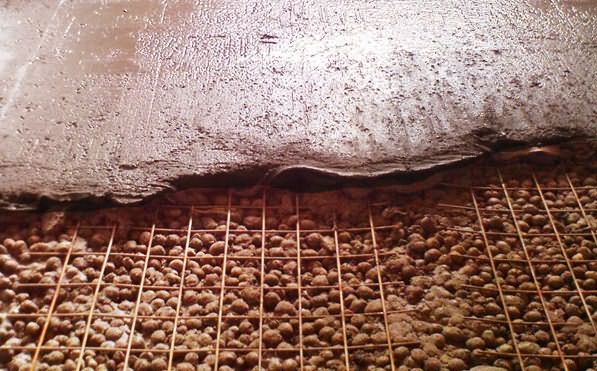

It is important that the expanded clay layer is laid level, without slopes or other defects. Next, the expanded clay is filled with a solution to seal the thermal insulation.

Cement can be reinforced with reinforcing mesh. This floor will be at its strongest a month after installation.

Types of insulation

Many owners doubt whether it is necessary to insulate the floors in the bathhouse. Without high-quality thermal insulation of the concrete base, ice will form on its surface in winter, and it will be impossible to get rid of the cold inside the room.

Perlite is a material that is similar in structure to sand. To use as insulation, perlite is mixed with cement, water, and mixed thoroughly. Apply the finished composition in an even layer to the base and leave for 7 days until completely hardened.

Advantages of perlite:

Perlite should not be used in ventilated areas. Any gust of wind will lead to its chaotic distribution throughout the room.

Expanded clay is made from clay. The feedstock is fired at a temperature of 1400°C. During heat treatment, individual granules are formed, which are used as a heat-insulating material.

Strengths of expanded clay:

- high levels of thermal insulation and noise insulation;

- absence of harmful substances during strong heating;

- low price;

- low specific gravity;

- resistance to high loads.

The main disadvantage is that it absorbs a large amount of water. Therefore, it is necessary to do additional waterproofing.

Rectangular slabs are made from polystyrene foam, which are convenient for insulating vertical and horizontal surfaces.

Advantages of polystyrene foam:

- high thermal conductivity and density;

- simple installation of individual plates;

- low price.

One of the significant disadvantages is fragility. .

You can also use:

- Jute felt. This is a material of organic origin, which has high strength and retains heat well. Fungus and mold do not form on it.

- Basalt slabs. Suitable for insulating concrete floors. Before laying basalt, you need to make high-quality waterproofing.

- Penoplex. It is manufactured in the form of durable slabs of different sizes. Externally it resembles polystyrene foam. Does not collapse under the influence of moisture.

An air layer to retain heat can be made from glass or plastic bottles.

Bathhouse insulation technology with expanded clay

The porous structure of the heat insulator granules significantly increases its thermal insulation characteristics. In order for energy saving to be as effective as possible, you need to correctly select not only the main insulation, but also other insulators.

When calculating the amount of material for thermal insulation of the ceiling in the bathhouse, keep in mind that the layer should be 20 cm or more. Insulation is carried out from the attic side. If desired, you can mix expanded clay in the form of sand and gravel. This will make the backfill as dense as possible.

We carry out the work in the following sequence:

- We overlap the vapor barrier membrane by 12-15 cm. If aluminum foil is used, the reflective surface should be located inside the room.

Carefully seal the joints with metallized tape. If you decide to use roofing felt, seal the joints with rubber-bitumen mastic.

We vapor barrier the rafters and chimney above the level of the future backfill. We attach the material using masking tape or a construction stapler.

We suggest you read how Finns go to the sauna

Make a layer of crushed clay about 10 cm and compact it thoroughly. This is necessary for additional thermal insulation.

We fill in the expanded clay and level it over the surface.

The thermal insulation of the flooring in the steam room must be taken care of at the stage of its construction or major repairs. It is also important to take into account the maximum permissible load when calculating the layer thickness.

During the process we follow these instructions:

- We spread the waterproofing bitumen material on the concrete covering with an overlap of 10 cm. The overlap on the walls should be about 15 cm.

Using alabaster, we attach “beacons” around the perimeter of the floor, which will show the thickness and evenness of the layer.

When filling between wooden joists, care must be taken to pre-treat them with antiseptic compounds.

We fill in expanded clay with a height of 15-20 cm. In this case, it is also better to use a mixture of fractions of different sizes.

We water the backfill with “cement laitance” (a mixture of cement, water and primer). This is necessary so that the individual granules “adhere” to each other.

A day later, we install a metal reinforcing mesh on top to give the structure additional rigidity and strength.

Fill it with a cement-sand screed about 3 cm thick and wait for it to dry completely. Please note that the drying of the screed can be determined with a glass jar. It must be placed with its neck to the floor. If it does not fog up, then you can begin further work.

We fix the waterproofing material.

If you decide to insulate with expanded clay over the ground in a bathhouse, then its layer will be significantly thicker (about 30-35 cm), which will raise the height of the floor. This must be taken into account at the stage of designing the height of the walls of the bathhouse.

Bulk materials can only be used for thermal insulation of brick walls of buildings. This process must be thought through during construction.

A brick bathhouse is insulated with expanded clay in the following order:

- We are building the first outer wall using brickwork, half a brick thick.

Inside, at a distance of 35 cm, we lay out a second wall of the same thickness in parallel.

We install jumpers inside every 10 cm.

We fill the expanded clay with a layer of 20-40 cm and compact it thoroughly.

We pour the cement mixture to “set” the individual fractions.

Insulating a bathhouse using expanded clay

It is no secret that a high-quality insulated bathhouse heats up faster, maintains a consistently high temperature longer, retaining heat throughout the day. Moreover, good thermal insulation of bath rooms largely determines the service life of the entire structure.

Expanded clay is one of the most commonly used materials for thermal insulation of bathhouse floors. It serves as an excellent protection against the development of unfavorable environments and resists heat loss.

As a rule, expanded clay is used to insulate concrete floors. If you plan to lay a wooden floor in the bathhouse, then in this case enhanced waterproofing is required.

Expanded clay is called the most natural thermal insulator, since it is produced on the basis of ordinary clay. Light granules with a porous cellular structure appear during the firing of clay at a very high temperature.

The absolutely environmentally friendly material does not pose any danger to human health and is ideal for use in places that are subject to increased sanitary hygiene requirements. And the floor in the bathhouse is just such a place! In addition, expanded clay is distinguished by good sound insulation and low weight, making it easier to transport and use. The free-flowing nature of the material allows you to smooth out the unevenness of the surface on which it is applied.

The sizes of expanded clay granules vary between 0.5 and 4 cm. It is recommended to take different sizes for the thermal insulation layer. In this case, small granules, penetrating between larger ones, fill the space and make the masonry denser and more efficient.

Important!

Check the expanded clay for damage to the integrity of the granules, otherwise damaged elements may cause a decrease in the thermal insulation properties of the material.

What needs to be taken into account when laying expanded clay as a thermal insulation layer is its high moisture absorption rates. That is why, in combination with it, high-quality waterproofing of floors in bathhouses is required.

So, the beginning of work on thermal insulation of floors in a bathhouse begins with the fact that a dense polyethylene film is laid under the expanded clay layer, creating a protective barrier against moisture coming from below. Next, a beacon system is installed to determine the plane of expanded clay backfill. Concrete or asbestos slides, boards secured with mortar, and an angle profile can be used as beacons.

Important!

When marking and laying expanded clay, take into account the floor slope required for damp rooms in the bathhouse.

After filling the expanded clay along the intended beacons, it should be leveled and compacted. The thermal insulating properties of expanded clay begin to appear at a thickness of at least 15 cm, so this is the minimum layer thickness. Some builders use a trick that does not affect the efficiency of the work, but speeds up and facilitates its progress. Instead of scattering the material, the expanded clay bags themselves are laid with holes pre-made in them. The same expanded clay is poured into the gaps between the bags.

Next, the expanded clay layer must be poured generously with liquid cement mortar, which is also called “cement laitance.” The composition is simple: cement, sand (3:2), water (20% of the total mass). Filling with the solution is carried out carefully so as not to disturb the structure of the laid granules. By filling the voids, “cement laitance” makes the expanded clay layer stronger and does not sag over time.

After the solution has hardened, work begins with pouring the screed (concrete or polymer floor). The layer is 3-4 cm thick. The screed made of concrete is leveled and reinforced with metal mesh. It takes a long time to harden, about several weeks. The polymer screed, in turn, requires piercing with a needle roller to get rid of air bubbles and dries faster - a week or a little longer.

At this point, work with expanded clay is completed. After the screed has completely dried, a waterproofing layer is fixed on the surface and the finished floor is installed.

designdachi.ru

Principles of work

After familiarizing yourself with insulation materials, you can begin to insulate yourself. To do this, you need to prepare tools, consumables, draw up a project, and carry out the work.

sharp knife;

- roofing felt sheets;

- ruler, tape measure, building level;

- sand, cement, water, container for mixing the solution;

- electric drill, whisk attachment;

- insulation;

- waterproofing.

The amount of consumables depends on the area of the room. On the thermal insulation material, the manufacturer writes how many square meters the package is enough for.

To properly insulate bath rooms, you need to prepare the base. To do this, you need to take into account some nuances:

- Insulation must be carried out at the main stages of building construction. If this has not been done, you will have to dismantle the floor covering and pour a new screed.

- The base must be smooth, without bumps, cracks, or chips. To level it, you need to pour fresh screed along the beacons.

- It is not recommended to cover the materials that will cover the walls and the floor in the steam room with antiseptics. They can release harmful substances when heated strongly.

The insulation process varies depending on the type of room.

Execution of work:

- When the concrete base is ready, it is necessary to create a frame to secure the thermal insulation. To do this, a rough base of bars should be filled on top of the lags. Intermediate slats are laid out between the beams.

- The next stage is laying the waterproofing.

- Insulation can be installed on top of the waterproofing material.

- The top of the heat insulator is covered with another layer of waterproofing.

The last stage of construction is laying finishing boards.

Execution of work:

- Preparing the base.

- Leveling the concrete slab.

- Laying waterproofing.

- Distribution of slab or bulk insulation.

- Laying reinforcing mesh. It can be knitted from individual metal rods.

If you only want to step on a heated floor, you can install a special system for forced heating of floor coverings. You need to choose what it will be - electric, water, infrared. Next, you need to purchase consumables and begin construction work. Main stages:

- Prepare the base and level the subfloor.

- Lay a layer of thermal insulation.

- Attach a reinforcing mesh over the heat insulator.

- Attach the system to the mesh.

- Connect the structure to a general electrical network or water supply system. Check functionality.

- Fill the subfloor.

- Wait for the concrete to dry.

All that remains is to do the finishing touches.

Insulating the ceiling in a bathhouse with your own hands

Installation of a thermal insulation layer is one of the most important stages in arranging a bathhouse. The following areas are subject to insulation: the roof, ceilings, walls and, of course, floors. It is the last item of the above list that will be discussed further. You are invited to find out which materials are suitable for insulating the floor in a bathhouse and how to work with each of them.

Types of insulation

Comparative characteristics of polystyrene foam and mineral wool insulation

Comparison of insulation table

Information on the most commonly used floor insulation materials can be found in the following table.

Table. Bathroom floor insulation

MaterialDescription

| Foamed polystyrene | Sold in the form of slabs consisting of small granules. Suitable for thermal insulation of both concrete and wooden structures. The material resists moisture well. Foamed polystyrene is extremely easy to process and install: it can be cut with an ordinary stationery knife, which allows you to adjust the slabs to the required dimensions, almost completely preventing the generation of waste. Important! This material can be used for floor insulation only in those rooms where a stable room temperature is maintained, because when heated, the foam can begin to release components that can seriously affect human health. |

Mineral wool insulation | Mineral wool and its “brothers” are the most popular and popular heat insulators. They effectively prevent heat from evaporating, do not burn and last quite a long time, provided that the rules of installation and operation are followed. Important! It is recommended to insulate floors with mineral wool only in rooms with a normal level of humidity, because... When interacting with water, the characteristics of the material deteriorate significantly. In view of this, the use of mineral wool for thermal insulation of any surfaces requires the installation of a waterproofing layer. |

| Expanded clay | Environmentally friendly clay-based material. Expanded clay has good thermal insulation properties, does not contribute to the spread of fire and lasts for quite a long time. Insulation is carried out followed by laying a waterproofing layer. When using expanded clay for thermal insulation of a concrete floor, certain difficulties may arise due to the need to arrange a surface slope in the direction of drainage. In this case, expanded clay is poured using guides. For greater convenience, the material is wetted with a weak cement mortar. |

| Perlite | Bulk material with good thermal insulation properties. Suitable for insulating floors made of concrete. It is used as part of a mixture including cement and water. The finished mixture is laid and evenly distributed on top of the rough screed, after which it is filled with the top leveling layer. |

| Penoplex | A well-proven representative of the family of “foamed” materials has many positive qualities: – excellent thermal protection; – resistance to moisture; – long service life; – high strength; - environmental Safety. At the same time, the material is relatively inexpensive and does not require much effort during installation - it is simply glued to the base. |

We invite you to familiarize yourself with what shelves are made of in a bathhouse.

Recommendations regarding insulation thickness will vary depending on the climate of the work location and the properties of the insulation itself. So, for example, it is traditionally recommended to cover expanded clay with a minimum 250-300 mm layer, while the optimal thickness of slab thermal insulation (foam plastic, mineral wool) is from 50-100 mm. You can take the recommendations from the following table as a basis.

Insulation thickness

The procedure for filling the thermal insulation layer will vary depending on the design of the floor of the bathhouse being equipped. There are few options:

- the floor is laid over logs installed on compacted soil;

- the flooring is made on top of logs placed on brick supports;

- the structure is represented by a concrete screed or reinforced concrete floor slab.

An example of floor insulation with expanded clay

Floor insulation with expanded clay

Choose your option, read the instructions specifically for it and get to work. The information is given in the table.

Table. Floor insulation with expanded clay

Type of floor constructionProcedure for insulation

| Floor on joists on the ground | It is assumed that the joists have already been installed and all that remains is to lay layers of insulation to create the final flooring. If you are insulating an already used wooden floor, you must first remove the flooring (damaged boards are replaced with new ones), replace rotten joists and thoroughly compact the soil. The subsequent steps are similar for both cases: – waterproofing is laid on top of the compacted soil. You can put either plastic film, roofing felt or glassine. Waterproofing is placed both in the space between the joists and on top of them. Lay the sheets with an overlap of 10-15 cm. Tape the joints with construction tape. You can attach the insulation to the joists using a construction stapler with staples or small nails; – a uniform layer of expanded clay is poured over the waterproofing. Further actions depend on whether expanded clay will be used as the only insulation, or whether a second thermal insulation layer, for example, mineral wool, is planned to be laid on top of it. If thermal insulation is performed exclusively with expanded clay, the order is as follows: – on top of a leveled layer of expanded clay with a thickness of 30 cm or more, the selected vapor barrier material is laid (preferably foil). The overlaps and fasteners are the same as when laying the material for waterproofing; – finishing of the floor is carried out at the discretion of the developer. If expanded clay is used together with other insulating material, the procedure is as follows: – a vapor barrier material is placed on top of a layer of expanded clay 10-15 cm thick (the specific value is selected taking into account the planned thickness of the upper thermal insulation layer). The recommendations are similar to the previous case; – expanded polystyrene or mineral wool is laid on the vapor barrier. The functions of the frame for placing the slabs will be performed by the logs - select the width of the thermal insulation elements according to the size of the spaces between the logs (or simply fill the frame with the required parameters from timber). If the height of the logs is not enough, nail a beam on top of them at the height of the top insulation; – the thermal insulation is covered with a layer of hydro-vapor barrier. The further procedure of work remains at the discretion of the owner. So, for example, if a concrete screed is to be poured, a reinforcing mesh is first laid on the insulation. If the floor is wooden, bars are nailed to the joists for laying the boards. |

| Floor on joists on brick supports | In this case, the procedure will differ little from the option discussed above. Minor differences are present only at the initial stages of insulation: – expanded clay is poured to the level of the logs laid on top of the brick supports; – cranial bars are nailed to the joists (the most commonly used option is 4x5 cm in size); – a rough flooring made of boards or wood boards is installed on top of the bars. Further actions are carried out similarly to the previous instructions. |

| Floor on concrete slab | The sequence of activities will differ little from the instructions you have already reviewed: – the base is covered with a water vapor barrier; – expanded clay is poured; – the backfill is covered with another layer of water vapor barrier. The further procedure is determined by the developer and depends on whether a concrete floor will be poured or a wooden structure will be installed. |

Expanded clay

Characteristics of expanded clay

Expanded clay - advantages and applications

High-quality thermal insulation is the key to maximum comfort in using a bathhouse and a guarantee of no extra heating costs. Insulation is carried out on 4 main surfaces: roof, walls, floor and ceiling.

It is with the nuances of arranging the thermal insulation of the last mentioned structure that you are invited to familiarize yourself further. While studying the information below, you will consider important information about insulation in general, the properties of existing thermal insulation materials, and also receive instructions for independently carrying out the relevant technological stages of work.

Heat leakage from a room can occur in three main ways:

- through cracks in the ceiling structure;

- when heat transfers to cold objects in the environment;

- when heated air masses pass through various types of monolithic/homogeneous barriers.

To eliminate all of these problems, a multi-layer ceiling structure is installed, which includes, among other things, a layer of heat-insulating material. If insulation is performed incorrectly or is completely absent, condensation will begin to form on the floors, warming up the room will require much more time and, therefore, more significant expenditure of energy resources.

A standard insulation scheme for a ceiling structure is shown in the following image.

Standard scheme for insulating a ceiling structure

Helpful advice! Try to lay each subsequent insulating layer perpendicular to the previous one. This will allow you to obtain the most reliable design with minimal deformation indicators.

Bathroom ceiling insulation scheme

In accordance with the design features of the structure, baths can be divided into 2 large groups: those with an attic/attic floor and those without one. The standard scheme for insulating the ceiling in a bathhouse without an upper tier was presented above. The procedure for thermal insulation of the ceiling in a bathhouse with more than 1 floor deserves separate consideration.

The technology for constructing a bathhouse with an attic floor involves installing a ceiling structure that is much more powerful in its performance. An additional obstacle to the flowing warm air masses will be the space under the roof itself, as well as, to some extent, the roof structure itself.

Bathhouse with attic

Attic in the bathhouse

In bathhouses that do not have an attic/attic tier, warm air masses encounter much fewer obstacles, and their strength is also noticeably lower. Despite this, ceiling structures both in bathhouses with an upper tier and in buildings without one need high-quality and competent insulation.

About the material

How to avoid heat loss in a bathhouse

When constructing and arranging a steam room, the main task set before the builders is to reduce the heat loss of the room as much as possible. Otherwise, heating difficulties arise, the room quickly gets cold, and heating costs increase. And the pleasure disappears in such a bath, to be honest.

That is why it is wise and correct to think about insulation during the construction period. It is important to insulate all elements of the room – walls, ceiling and floor – as effectively as possible. In our article we will look at floor insulation.

There is a point of view that it is not necessary to insulate the floor - a waste of time and money. This opinion is extremely erroneous - a cold floor can cause significant heat loss even with well-insulated walls and ceiling. A well-insulated bath floor will significantly extend its service life and make your enjoyment of the bathing process more complete.

Materials for floor insulation in a steam room

In the old days, the floor in the bathhouse was insulated with natural materials - flax, hemp, jute and even moss. Let's make a reservation right away - nowadays there are a sufficient number of effective modern thermal insulating materials, and moss can cause the appearance of fungi and mold.

The main requirements for insulation for a steam room:

- Non-toxic - high temperatures in a steam room can provoke the release of toxic substances and, as a result, poisoning of the body and even death;

- High thermal insulation properties - the effectiveness of the insulation in fulfilling its direct task depends on them;

- Non-hygroscopicity - a tendency to absorb moisture can cause excessive humidity and cause rotting processes of materials;

- Resistance to high temperatures, moisture and steam - the conditions in which the insulation will have to be located should not cause its destruction or reduce its insulating properties.

To insulate the floor in a bathhouse, both wooden and concrete, today a new generation of insulation is used - moss and jute with hemp are used extremely rarely and, as a rule, by lovers of antiquity. Expanded polystyrene, mineral wool and expanded clay are very popular. Each insulation product has its fans and opponents.

Expanded clay and its properties

Expanded clay has a fairly solid reputation among other thermal insulators used for bathhouse floors. The word "expanded clay" in Greek means "burnt clay". It is formed during the firing of intumescent clays with the addition of various additives.

Expanded clay is oval-shaped granules of different sizes. Used as bedding and as a filler for cement. Due to its light specific weight, it significantly reduces the load on the foundation when added to concrete. Expanded clay grains, depending on the brand, can have different porosity and density, on which the heat-insulating properties directly depend - the higher the porosity, the higher the heat-protective qualities of the material.

The popularity of expanded clay is explained by the following list of its positive qualities, which make it an indispensable insulation material:

- Expanded clay is highly environmentally friendly because it is made from natural materials without additives that could have a harmful effect on our body;

- It is an excellent thermal insulator and sound insulator due to its porous structure;

- Has high resistance to temperature fluctuations and humidity changes;

- Suitable for filling recesses and voids due to its free-flowing structure;

- It has a small weight, which reduces the load on the structure when insulated with expanded clay;

- The low price makes it affordable to use, which also has a significant impact on the popularity of the material.

https://www.youtube.com/watch?v=Vn_6FL3ZJlw

How to insulate the floor in a bathhouse with expanded clay

- Pour the concrete screed and wait for it to dry completely;

- We spread a waterproofing layer over the top of the screed in order to protect the insulation from the influence of moisture. It is quite possible to use polyethylene film as waterproofing. At the joints we fasten it with ordinary tape. We bend the edges of the film near the walls so that they rise above the planned insulation layer;

- We prepare an expanded clay mixture from granules of different sizes - from 5 to 20 mm. This will ensure good filling of all cavities with thermal insulation and create stronger adhesion of expanded clay granules to concrete;

- We set beacons to ensure perfectly even laying of the filler without slopes or holes. We make beacons from a metal profile and install them as often as possible;

- We rigidly fix the beacons using columns of steep cement mortar to give the beacons the required immobility;

- After we have made sure that the beacons are firmly fixed, we can fill in the insulation, constantly checking with the beacons how smoothly the layer lies. Slopes and unevenness are unacceptable. Please note that the layer thickness should be more than 10 cm;

- We fill our thermal insulating layer with a solution of liquid cement - this is necessary in order to remove the flowability of the layer and prepare it for pouring concrete. We cover our thermal layer on top with a reinforcing mesh;

- We pour a concrete screed along the top, leveling it with the level of the beacons;

- We wait until the screed dries - and this will happen no earlier than in 4 weeks. Periodically wet it with water - this will help avoid the formation of cracks;

- After we have made sure that the concrete is completely dry, we can begin laying the floor - wooden or ceramic tiles.

Conclusion

So, we are convinced that insulating the floor in a bathhouse is necessary and should be done using new generation materials, abandoning the “old regime” moss and tow. When choosing expanded clay, we can’t go wrong - its qualities speak for themselves, and we can do all the insulation work ourselves. And there is no doubt - you will definitely succeed!

First, let's understand what expanded clay is and what it comes in. The effectiveness of insulation largely depends on the choice of variety, so you should pay close attention to the nuances.

Photo of granules in section

Expanded clay is a granular material with a porous structure. It is obtained by firing easily intumescent clays. In addition to highly purified clay raw materials, the following is added to the mixture:

- peat;

- sawdust;

- solar oil;

- alcohol stillage, etc.

As a result of heat treatment, granules of different sizes are formed, inside of which there are sealed pores. Due to the large number of these pores, the thermal insulation effect is ensured: the high content of entrained air, isolated from the environment by walls of baked clay, significantly reduces the thermal conductivity of the material.

Comparative granule size

| Fraction | Particle size |

| Sand | No more than 5 mm |

| Crushed stone/sand | No more than 10 mm |

| Crushed stone | 5 – 10 mm |

| Gravel | 0 – 40 mm 10 – 20 mm 20 – 40 mm |

We suggest you read: The best way to insulate the ceiling of a bathhouse from the outside

When choosing a material, you should also focus on bulk density, which can range from 250 to 800 kg per cubic meter of material. The lower this indicator, the greater the volume of entrained air, which means the better the material will work as insulation.

On the other hand, the lightest fractions of expanded clay are not durable, so they are used where the load on the material will be minimal - for example, when filling an underground space when insulating the floor along joists.

Multi-fraction expanded clay in packaging

I present these rather boring figures only to make it clear that expanded clay can be different, and it should be selected in accordance with the task at hand. I usually focus on the following indicators:

- For insulation when pouring concrete, I take either sand or a sand/crushed stone mixture with a density of 500 to 700 kg/m3.

- For backfill I use exclusively gravel (medium- and coarse-grained), with a density of up to 400 kg/m3.

We've sorted out the types, now let's analyze the pros and cons. Let's start with the strengths:

- Expanded clay is a material based on natural raw materials. Accordingly, this insulation does not contain volatile substances and toxins, therefore it is completely safe for both humans and the environment.

- Porous granules retain heat well, in addition, they are a good sound insulator. This property will be very important when you decide to use expanded clay as a thermal insulation material in an apartment in a multi-storey building.

Raw materials are used for both internal and external work

- The small size of the granules and their high flowability make it possible to fill almost any cavity with raw materials. In principle, if desired, the substance can also be used as wall insulation - in any case, the efficiency of such backfill will be higher than that of large cavities filled with air.

- The low mass of expanded clay provides a significant reduction in the load on the foundation and supporting structures. Even in the case of using expanded clay concrete - a mixture of granules with cement mortar - the weight gain is quite significant.

This material is quite cheap, so you can save on insulation

- Finally, the advantage is the quite reasonable price of the material. A cubic meter of expanded clay costs about 1200 - 1500 rubles, and a bag (0.05 cubic meters) will cost us 50 - 80 rubles. So the savings on insulation compared to other materials are quite significant.

When deciding which expanded clay is best to use for floor insulation, we must not forget about its disadvantages. I would not call them fatal, but not talking about them would mean providing you with incomplete information.

- An important disadvantage is the fragility of the material. Fractions with low density break into pieces without any effort at all, so you need to store, transport, and stack granules with the utmost care. Damaged expanded clay gravel retains heat worse: efficiency losses can reach 15 - 20%.

- Water absorption can also be considered a disadvantage. Burnt clay is prone to moisture accumulation in the pores, therefore, for example, when insulating the floor in a bathhouse with expanded clay, I always lay one additional waterproofing circuit. At the same time, expenses increase slightly, but I guarantee that under the floor I do not have a “reserve” of moisture that I do not need at all!

The thicker the layer, the greater the heat gain

- Finally, the most important drawback, from my point of view, is the need to fill a thick layer. Expanded clay as a floor insulation “works” effectively only when laid at a depth of 20 cm (and on the ground, I would generally set the bottom level at 30-50 cm), so in low rooms a very significant rise of the floor is possible.

Recommendations

Attention should also be paid to floors that are fixed to pile foundations. Stages of work:

- Tie the pile heads together with special screw beams.

- Lay a layer of waterproofing on a wooden base made of beams.

- Place rough timbers on the lower sides of the beams.

- Lay sheets of thermal insulation and cover them with waterproofing film.

- Apply a finishing coat.

It is important not to confuse the method of laying the waterproofing film. Instructions are included on the packaging.

Concrete floors in bathhouses need to be insulated. If this is not done, they will be very cold despite the heating of the rooms. For thermal insulation, you need to choose one of several types of materials. It is important to take into account the features of insulation when carrying out work independently.