- Inter-crown insulation Polytherm is a specially developed heat-insulating material that is recommended for use when used in the construction of wooden log houses. Like any product, it has its advantages over other insulation materials with similar properties, but it also has disadvantages. To make the right choice, the owner of the future building must familiarize himself with the characteristics of the synthetic insulating fabric.

Selection criteria for Polyterm

The material appeared on the market recently, it is produced by different companies, so when purchasing you need to pay attention to the following features of the product:

- high-quality insulation Polytherm should have a shade close to freshly cut wood;

- no pungent odor;

- uniformity and equal thickness of the tape along the entire length.

In order for Polytherm (inter-crown insulation made of synthetic material) to fully exhibit its properties, you need to buy tapes slightly wider than the cross-section of the timber or the width of the hewn log.

Materials technology

The technology for using insulating fabric is quite simple. Strips of inter-crown insulation made of jute and flax are folded along the long side and laid between the crowns (with the folded edge inside the house), not reaching 5 mm from the edges of the beam. To securely fasten the inter-crown sealant tape, staple it to a log or timber using a stapler.

Thus, from planed timber or rounded logs, without additional internal cladding, you can get beautiful walls with perfectly even sealing seams.

The number of layers and thickness of the insulating sheet are selected based on the quality of the building wall material - timber or logs. If the beam is bent, uneven and damp, then you will need a fairly thick tape of inter-crown insulation, usually from 8 to 15 mm thick. Moreover, in this case, it is likely that significantly more tape of inter-crown insulation along the length will be required - for its additional investment in the uneven voids of the lower groove of the log or timber.

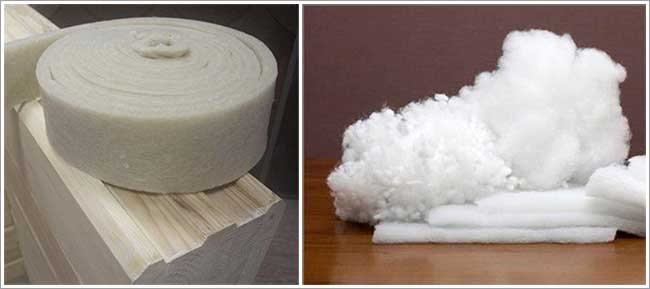

Photo: jute insulation - jute tape for laying between logs of wooden log houses and jute tow - tape for laying between logs in log houses and bathhouses.

Photo: which inter-crown seal is best to choose for timber? Our answer: absolutely - jute tape will be the best choice for many important parameters of wooden block house construction.

If a wooden house or bathhouse is built from rounded logs or planed timber with good geometry along the entire length, then it is possible to use inexpensive inter-crown insulation with a thickness of 5-6 mm. The technology for its use is the same. Inter-crown insulation made of jute and flax is bent along the long side and placed between the crowns (with the folded edge inward of the house), not reaching 5 mm from the edges of the beam. To ensure secure fastening of the inter-crown sealant tape, staples are attached to a log or beam using a mechanical stapler.

What jute material is still worth buying?

Photo: It is worth buying a jute rope to cover the crown joints between logs for decorative purposes when finishing a wooden frame.

Insulation material Polytherm and its characteristics

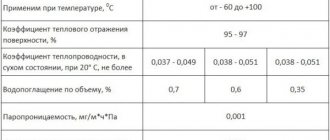

Inter-crown insulation is a non-woven material made of polyester fibers. In its production, glue and other substances are not used to hold individual threads together: soldering is done by heating to a high temperature. After production, the canvas is cut into strips 3-25 cm wide and delivered in this form to trade organizations, i.e. the material is completely ready for use in log construction.

The different densities and thicknesses of Polytherm allow it to be used in any climatic conditions. But when purchasing, you need to take into account the characteristics of your area and purchase a denser Polyterm inter-crown insulation for construction in cold regions, and its lighter varieties for sealing the seams between logs when constructing a wooden house in warm regions of the country.

Manufacturers produce several types of insulation for central Russia:

- Standard - the density is 300 g/m³, and the thickness is 1.5 cm, which allows it to be used for sealing the joints of a log house made of rounded logs and timber;

- Economy - with a lower density (200 g/m³), it has a greater thickness (2 cm) and can be used for the same conditions;

- Light - suitable for profiled timber and has a smaller thickness (0.8-1 cm) and density (170 g/m³).

Selection and laying of jute

The jute is spread along the groove and secured with staples.

Based on the existing varieties of materials and your financial well-being, you choose an inter-crown seal. It must be of natural origin and have qualities similar to wood, the main of which is to allow moisture to pass through, that is, to breathe. The wood for building a house is dried before cutting the grooves and assembling the structure, but moisture still remains in the wood. Therefore, after assembling the frame, it is allowed to stand for about a year and a half, no less. During this period, the house will shrink and dry out.

The role of interventional insulation in this process:

- release moisture emanating from the core of a log or timber;

- Fill the joints evenly so that there are no cold bridges.

The thicker the seal, the easier it is to work with. Laying jute on a log:

- the tape is placed in the connecting groove;

- so that the insulation does not move when it is pressed by a log, the jute is fastened with a stapler at intervals of about 50 cm;

- if the tape is too wide, the edges turn inward;

- the tape is also placed in the bowls.

Laying jute on timber is a mandatory requirement when constructing wooden houses. According to the technology, it is not necessary to caulk the joints after this, but in practice it is still recommended to carry out this procedure. After shrinking, the logs sometimes twist strongly. It may happen that on one side a gap of half a centimeter is formed, and on the other side of the beam the seal is clamped very tightly. Leaving walls with gaps is somehow not according to Feng Shui, it needs to be brought to mind.

You can caulk it with the same tapes or tow, but only after the structure shrinks, not earlier than a year and a half after construction. Some architects, when laying the inter-crown seal, do not tuck the ends, which end up hanging between the crowns. In this case, select a tape much thicker than the cross-section of a log or beam. Then, when the house stands and shrinks, these hanging ends are driven into the joints. The problem with this method is that in 1.5-2 years the insulation deteriorates under the influence of wind, moisture and sun. As a result, low-quality material is clogged between the joints, which may not be enough to completely seal the crowns.

To heat a cottage with gas correctly, you need to take into account many factors. Some of them: area, heat loss, circuit volume, etc.

Are you wondering what is the cheapest way to heat your home? Then click here.

Disadvantages of Polyterm

When using wet logs or timber, the shrinkage process occurs more slowly than with traditional materials. This effect is due to the low hygroscopicity of the insulation, which almost does not remove moisture from the wood. Polytherm is best used for insulating a dry log house.

The obvious disadvantage of the material at this time is its high price in comparison with tow, jute, etc. With the emergence of a large number of competing manufacturers, this disadvantage may disappear over time.

Artificial materials

When answering the question - how to choose inter-crown insulation for timber, you cannot ignore artificial materials. Today this option is the most popular. One of these materials is called “holofiber”.

This insulation is made from polyester fibers using the non-woven method. The material is produced in rolls and plates, each type has its own density.

Holofiber has high elasticity. This feature is very convenient for thermal insulation of crown joints, especially when using laminated veneer lumber or non-profiled timber.

This material has no pores, which means it can warp when drying. If insulation made from natural material is used, then the appearance of cracks is inevitable. When using holofiber, additional sealing of the crown joints after the timber has dried is not required. The fibers of this material will fill the cracks that appear on their own.

Holofiber does not absorb water and retains its thermal insulation properties

In addition to a high degree of elasticity, holofiber has a number of other advantages. Experts include the following among the most significant of them:

- has low water absorption rates, less than one percent. This means that holofiber will not absorb moisture and will retain its thermal insulation properties longer even in a humid climate;

- the material does not burn even at high temperatures. This property is very important for thermal insulation of wooden buildings;

- Insects “don’t like” the material; they definitely won’t live here. In addition, holofiber is not afraid of mold;

- not only has high thermal insulation properties, but is also an excellent sound insulator;

- Holofiber has a long service life, and even over time does not require additional caulking.

You should not think that holofiber can have a detrimental effect on human health. This material does not cause allergies, does not emit harmful substances and is absolutely environmentally friendly. There can only be one drawback. If wood that was too damp was used during construction, it may be prohibited. Holofiber does not allow the walls of the house to “breathe”.

Another common inter-crown insulation for wooden houses made of profiled or laminated timber is “shelter”. This material is made from polyester fiber. Just like holofiber, it has high elasticity, which allows you to fill all the cracks newly formed as a result of shrinkage of the house. Shelter does not rot, does not absorb moisture and retains heat perfectly.

There are also more modern materials, for example, “polytherm”. At its core, it is a type of holofiber, but with greater elasticity. According to the manufacturers, the material can last 50 years. But polytherm appeared not so long ago, only about ten years ago, so it is not possible to test this in practice.

Inter-crown insulation “Polytherm” can last up to 50 years

Brief installation instructions for Polyterm

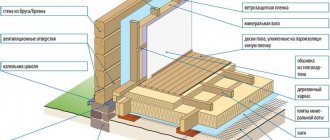

Tape insulation is easy to lay between beams and logs. They are used to seal joints between walls, door or window frames. Sheet varieties can also be used for other types of building insulation (frame walls, floors, doors, etc.)

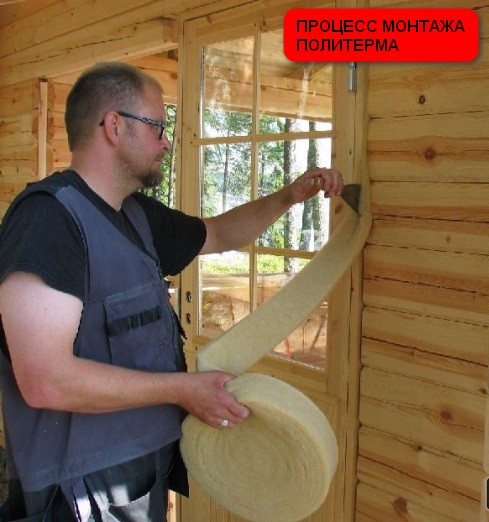

As an interventional insulation, Polyterm tape is used as follows:

- Roll out the roll over the surface of the timber or log. Attach the tape with a stapler.

- Wrap the material around the locking parts of the logs and spread it in the grooves.

- Having laid the next crown, cut off the excess width of the tape, leaving 1-2 cm at the joint of the logs.

- Carefully caulk the remaining material into the gap.

To achieve the thermal insulation effect, it is enough to lay 1 layer of Polytherm insulation in the joints between the crowns.

Advantages of jute insulation

Among all inter-crown heat insulators, jute has a number of advantages that are unique to it. Let's look at them:

- Bonding ability

. Jute contains lingin in large quantities. It is a natural resin that prevents rot and mold. In addition, it is capable of gluing fibers and timber together, making the seam airtight. - High rigidity

. This quality is responsible for the fact that jute practically does not wrinkle over time, which means it does not lose its thermal insulation characteristics. - Highly environmentally friendly

. Good quality material contains exclusively natural components, so jute cannot emit any toxic volatile compounds during operation. - Easy to install

. To lay jute in the inter-crown space, you do not need any special tools. All work can be done independently. The material does not emit dust and does not irritate the skin and mucous membranes. - Good vapor permeability

. This quality guarantees that an optimal climate will be maintained inside the building. - Versatility

. Felt jute, thanks to its good compressive resistance, can be used to insulate not only seams in wooden houses, but also floors, walls, and roofs. - Aesthetics

. The material has a golden natural color that matches perfectly with the color of natural timber or logs. Therefore, no additional decorative processing of jute is required.

Polyterm manufacturers and cost comparison

The cost of Polytherm from different manufacturers is almost the same, but prices may be affected by the distance of a settlement from the central regions of the country. Manufacturers of Polytherm are:

- the Termopol company, which produces other synthetic materials;

- the Winter House group of companies produces Polytherm insulation in slabs and in the form of tape;

- The production enterprise “Center of EcoInsulation” specializes in the production of various types of thermal insulation and is considered the leading manufacturer of Polyterm in Russia.

Tow and jute tape insulation - which is better to choose?

Jute insulation is available in different forms - in the form of tape and tow. To figure out when it is better to use which material, let's compare how they are similar and how they are different.

Jute tow:

Composition: 100% combed jute without any impurities. During its production, jute is combed and not torn, due to which it fully retains its properties. Fibers that are not stitched or punched together can be disassembled by hand into individual strands; they do not have any technological connection with each other.

Type of delivery: in bags or bales (requires additional ventilation to prevent moisture).

Application:

— For insulation of crowns in hand-made houses and bathhouses. The grooves in this type of wood have an uneven structure, so a combination of tape and tow will be, in this case, the best solution.

— When laying on the surface of the crown for other log houses, tow can also be used, but doing this is much more difficult than using tape insulation. Therefore, this option is not popular.

— Jute tow is also suitable for insulating corners in timber houses and houses made of rounded logs

— An excellent solution is jute tow insulation for caulking cracks and crotches between logs

— More than other types of insulation, it is suitable for sealing the crowns of baths and saunas (tow is resistant to moisture), but this option is not suitable for insulating residential buildings in severe cold conditions, since tow has low rigidity and density.

Jute tape

Composition: natural textile fiber from environmentally friendly coarse fiber non-woven material. Jute fibers are punched and intertwined on a machine with special needles, after which they are formed into a smooth jute fabric, uniform in density.

Type of delivery: in rollers, the width corresponding to the width of the groove, and a length of 10-20 m

Application: Unlike tow, it is more convenient to use jute in the form of a tape at the time of installation of the log house. The tape is selected according to the width of the groove for laying in one layer, or a little more, in order to subsequently close the resulting openings between the crowns of the house, which appear during the process of wall shrinkage. The technology of application is much simpler than that of tow - we simply roll out the tape and secure it with a construction stapler. Jute tape is a very convenient material to use.

Conclusion: both materials have excellent heat-retaining properties, since they consist of natural raw materials without chemical additives.

But it should be noted that jute tape is much more convenient to use when laying between the crowns, and tow is more suitable for caulking a house or a bathhouse made of timber, since its softness is almost like flax. The choice is yours!

Some advice from expert Zelentsov Yu.N.

Jute inter-crown insulation is considered the best choice in the construction environment associated with wooden housing construction. Jute tape is a natural product, unlike artificial gaskets such as holofiber, polytherm, avaterm and thermojute. Chemical additives used in non-natural chemical insulation materials have an extremely negative effect on logs and beams due to their antagonism.

Therefore, people who have long been involved in the construction of wooden houses from timber and logs never use chemical inter-crown spacers when working with wood. The reason for this is the high probability of logs and beams rotting at the joints where chemical seals are laid.

What is the best way to choose the required material?

In the video you can watch the recommendations of a construction expert on choosing inter-crown insulation.

The width of the inter-crown insulation is usually selected as a multiple of the width of the inter-crown seam (groove) or slightly (5 millimeters) less. Recently, construction organizations engaged in wooden house construction have been installing inter-crown insulation with a thickness of 5-6 mm. bend the tape of inter-crown insulation (sealant) along the long side and lay it between the crowns (with the folded edge inside the house), not reaching 4-5 mm from the edges of the beam.

For hand-cut wooden log houses, it is best to use insulating tape 8 - 10 mm thick.

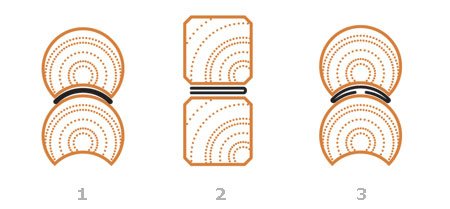

The most common laying schemes for inter-crown insulation.

Photo: laying the seal into the groove of a rounded log.

Photo: in a cobblestone wall of a wooden house made of laminated veneer lumber, jute insulation is laid in the joint groove between the veins of each beam. To insulate the joints of laminated veneer lumber, as a rule, laying a sealant 5-6 mm thick is sufficient.