How to choose?

What you need to pay attention to when choosing a burner device for a boiler:

- productive power - noise level during operation (applies to supercharged models) - type of heating equipment for which the burner is purchased - type of fuel - pros and cons of this device - provide for possible malfunctions in the operation of the local gas supply line.

Taking these factors into account, you can choose the most suitable burner device for your boiler so that it operates as efficiently as possible without the burden of frequent preventative maintenance.

How to prevent breakdown of the boiler automation?

The main purpose of automation is to maintain the operation of heating equipment in a safe mode, therefore its uninterrupted operation is very important. To extend the service life of the installation, it is recommended to carry out regular maintenance and cleaning of the equipment.

The ignition group is the most vulnerable to malfunctions and requires attention from the user. Clogs and soot lead to malfunctions, so manufacturers advise cleaning the device at least once a year. In this case, it is necessary to control that the size of the gaps remains unchanged. Cleaning the electrodes and ignition group extends the service life of the equipment without major repairs.

It is not recommended to configure or repair the device yourself, as this can negatively affect the installation itself, the integrity of property and human health.

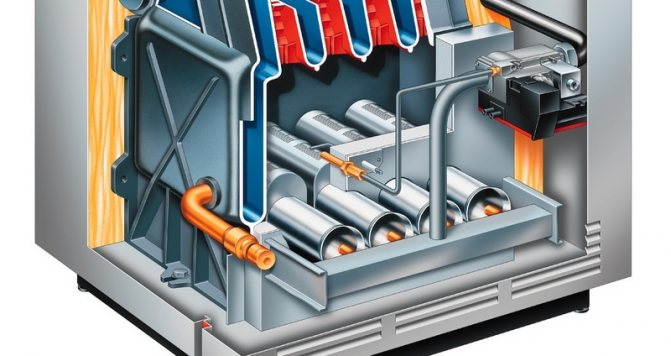

Combustion chamber of heating equipment

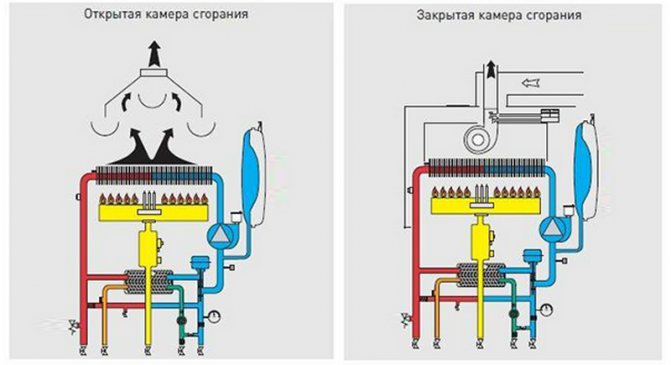

Gas boilers differ primarily in the design of the combustion chamber. It comes in two types:

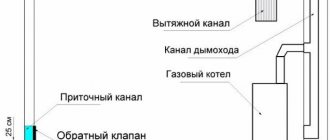

The open chamber is a fairly simple combustion device. It looks like this: above the burner there is a heat exchanger in the form of a coil of thin copper tubes. Thanks to the open design, the air required for the combustion reaction is supplied to the point of ignition of the gas from the environment.

As a rule, there is enough air from the room (provided good ventilation is organized). But there are wall-mounted models with air intake from outside, for which a special hole is mounted in the wall. Open combustion chambers require a chimney.

Most often it is installed for models of floor-standing gas boilers, and was also used to complete an old-style boiler (in this case, ignition was carried out by a pilot burner).

Combustion chamber design diagrams

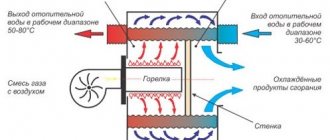

The closed combustion chamber is distinguished by the design of the heating block. The heat exchanger is located above the burner. The unit body is closed, combustion air is pumped by a fan installed in the chamber. Coolant is passed through the double walls of the chamber, heating it, increasing the efficiency of the boiler. The gas is burned almost completely, the combustion products are removed by a coaxial pipe under air pressure.

Automation: to trust or not?

Temperature sensor diagram for boiler automation.

The control system allows you to select the boiler operating mode depending on the presence of people in the room: the boiler setting should be such that during a long absence of residents, the temperature in the room is significantly lower.

However, you should only take advantage of the opportunity this setting provides if one of your neighbors is looking after the house. During a long absence, an emergency shutdown of the boiler may occur, and if the outside air temperature is low, then after a certain time the temperature inside may become negative, and the entire heating system will fail due to this setting. And there are plenty of reasons to stop the boiler.

This could be an emergency power outage or a decrease in the network voltage to a value below 190 V. Other reasons: strong wind entered the combustion chamber through the chimney and extinguished the burner; due to condensate freezing, the cross-section of the chimney decreased. A decrease in gas pressure, which is very likely in our time, can also cause an emergency shutdown.

Before using the settings provided by the automatic control system, you should ask your neighbors to monitor the condition of the boiler when the residents are not in the house.

A debate sometimes arises among experts about which mode of operation of gas boilers has an advantage: continuous or mode of alternating operation and shutdown, for example, as in a refrigerator. By what indicator should such settings be assessed? Practice shows that regarding the duration of operation of the fan, circulation pump, burner, igniter and other elements, none of the modes has an advantage.

If, in order to save money, you specifically reduce the gas pressure, then such a setting can lead to faster burnout of the burner.

Types of burners

According to their design and functional differences, burner devices are divided into:

By purpose:

- for high power industrial equipment

- for household equipment.

By fuel type used:

- devices for natural gas;

- devices for liquefied gas;

- universal devices.

By flame adjustment:

- single-stage – capable of operating on/off;

- two-stage (as a variation - models with smooth modulation) - operate at full power, when the desired temperature is reached, the flame is reduced by half;

- modulating - boilers with a modulating burner are characterized by smooth adjustment of the flame power.

According to the operating principle:

- injection/atmospheric. They operate by supplying air from the room. They are installed respectively in open combustion chambers. Also used for old-style boiler models.

- fan/supercharged. They work in isolated combustion chambers. Combustion air is supplied by a fan. According to their design features, they are divided into: - vortex (round-shaped nozzle holes) - direct-flow (shape of a narrow slot with a round/rectangular cross-section).

- diffuse-kenetic. Air enters two simultaneously: one is mixed with gas fuel, the second is added directly to the chamber during combustion.

Gas burner device for a boiler

Atmospheric and fan burner devices differ in their structure. This is due to the different ways in which oxygen is supplied to the chamber during fuel combustion.

Atmospheric burner device.

Air enters the combustion chamber directly from the room. Nozzles are located inside the burner channel. Gas is supplied to the nozzles, mixing with air, which also has access here. At a short distance from the nozzles there are outlet slots through which the finished fuel mixture is supplied. An area of reduced pressure is created between the nozzles and outlets, which promotes a constant supply of air for mixing.

A pilot burner is constantly running in the combustion chamber to ignite the main device.

Fan burner device.

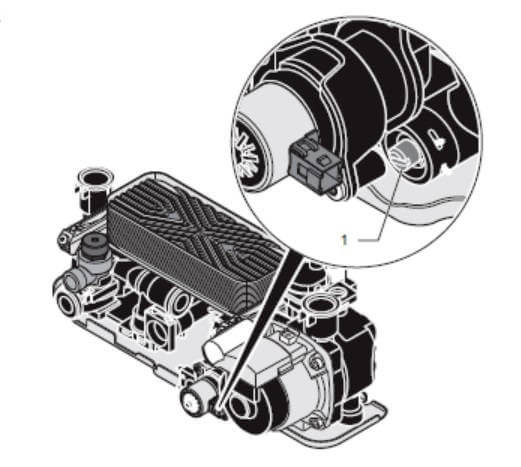

The device block consists of:

- engine;

- fan;

- automatic control unit;

- gearbox;

- air pressure switch;

- fuel mixer.

Air is forced from outside by a fan and supplied to the combustion chamber to form a fuel substance. The air to gas ratio can be adjusted using a damper and a fan.

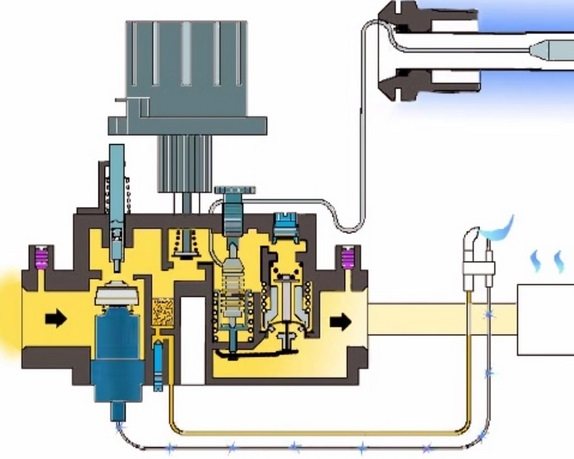

Operating principle of automation for gas boilers

The advantage of a non-volatile system is that no electricity is used during operation. Under the influence of temperature, a geometric change occurs in the control parts and thus the valve is activated.

Old models of non-volatile automation were difficult to regulate. In order to disable the device, it was necessary to use wire or electrical tape, and the safety of the entire heating system was significantly reduced.

This is not the case in modern systems. Therefore, the non-volatile automation 630 Euro Sit is reliable and safe. Main nodes:

- Pressure regulator.

- Flame protection system. If the main burner turns off, the gas supply will be automatically blocked.

- Main and outlet burner filters.

- A device for setting the minimum gas flow.

- Control knob with different positions: “ignition”, “off”, “temperature selection”.

- Fittings that are necessary to control gas flow.

- A thermostat that has the function of completely shutting off the main burner.

Depending on the choice of the consumer, the gas supply can be from below or from the side.

Burner flame

One of the indicators of proper burner operation is the color of the flame. Gas equipment is characterized by an even bluish flame without admixtures of other colors. The presence of yellow or red splashes indicates that the burner is not working well, which reduces the efficiency of the heating equipment.

First of all, this applies to injection burner devices, but sometimes it is also typical for fan burners. The flame may simply lack oxygen. Also, dust and other small debris can get in with the air, which will clog the device, reducing the efficiency of the boiler. All this directly affects the flame. If it hums, the burner is loud, or the fire has changed color, you need to adjust the correct operation of the device.

In what cases is it necessary to adjust the burner flame?

An atmospheric gas burner for heating equipment often fails. It is equipped with models of both wall-mounted and floor-standing boilers. The injection burner of floor-standing equipment reduces its efficiency for various reasons:

- Burner power is too high. This happens when a high-power burner is purchased for small heating equipment. At the same time, there is not enough space for combustion, the air flow for such power is weak, which leads to the transition of the flame from blue to yellow, sooting of the combustion chamber and chimney.

- If the chimney is poorly cleaned, the boiler draft deteriorates. At the same time, waste combustion products are poorly removed, and the air flow is small. This worsens combustion and the flame turns yellow.

- A defect in the burner itself does not make it possible to correctly adjust the complete combustion of the fuel.

- Due to pressure changes in the gas supply system, well-regulated equipment can release large amounts of unexhausted gas into the chimney. Partially it settles with soot and soot. A large layer of soot reduces traction and increases fuel consumption.

- Starting heating equipment after repair.

- The presence of extraneous noise during operation of the boiler or gas burner.

- Changing the type of fuel.

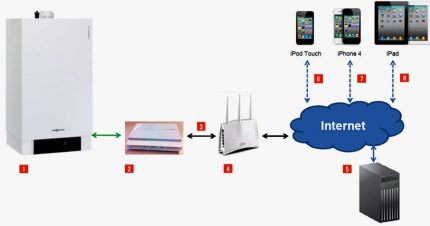

Operating principle of the control unit (controller) for boilers

Controllers are electronic devices that are designed to optimize the control of a gas heating device under changing environmental conditions. The capabilities and functions of different devices differ, but they are united by the presence of pressure and temperature sensors.

Example of controller connection diagram

The electronic gas boiler control unit (ECU) is responsible for the operation of the gas burner, heating of the coolant and the safety of the system as a whole. Its operating principle is based on the use of an electromagnetic valve.

The controllers of the latest heating devices are equipped with an automatic mode function, which allows you to regulate the operation of the device during the week without human intervention.

We recommend: Safety valve for a water heater: why is it needed, how to install

Connecting the computer to external temperature sensors and boiler control terminals allows you to configure independent changes in the operation of the burner.

For such a controller, it is necessary to install a voltage stabilizer and an uninterruptible power supply to ensure the operation of the boiler during voltage surges in the network or in its absence.

Equipment setup

Floor-standing gas boilers with an atmospheric burner can be configured independently. Pressurized systems are regulated by an automatic control unit and do not require additional configuration.

Scheme of actions for setting up single-stage equipment:

- Install the device on the boiler.

- Connect to the gas pipe.

- Check for absolute tightness.

- Remove the burner housing.

- Using a pressure gauge, measure the gas pressure at the inlet.

- Connect to electricity. Make sure that the jumpers and phases are connected correctly.

- Place a gas analyzer in the chimney pipe.

- Start the device.

- Using a pressure gauge, take pressure readings at the outlet of the burner block. Pressure readings must correspond to the parameters indicated in the data sheet.

- Adjust the air flow using the air damper.

- The gas analyzer readings must also comply with all gas equipment installation standards.

Setting up gas equipment should be carried out by specialists. The simplest open-type boilers can be configured independently if you have certain skills and knowledge of the design of the burner unit. The efficiency of the boiler, its level of efficiency, and fuel consumption depend on the quality of the burner. It is possible to superficially determine that the equipment is malfunctioning by the changed burner flame.

Private construction is gaining momentum, and with it the demand for modern heating equipment , uninterruptedly providing consumers with thermal energy for heating the house and heating water for household needs.

A gas boiler is the central link of a gas heating system created for such purposes. Being one of the most economical devices, it nevertheless needs to be properly configured to ensure proper fuel consumption and reliable operation.

Options for controlling the boiler via smartphone

Three solutions are available for remote control of a domestic gas boiler:

- GSM module connection;

- use of a “smart thermostat” via WI-FI communication;

- installation of thermostats.

We recommend: Do-it-yourself highly efficient solar collector

Each remote control method is good in its own way, and its choice depends on several factors: availability of the Internet, gas boiler model, financial capabilities.

Let's consider all three options - one of them may suit you, and as a result of a partial upgrade, managing the heating system will become much easier.

Option #1 – connecting the GSM module

This is the most common solution, applicable even in areas not covered by the Internet.

The gas boiler is controlled using a GSM unit - a compact controller module. A SIM card is inserted into it, which personalizes the owner and makes it possible to keep in touch with remote equipment

In order to save money, the homeowner can choose the most suitable cellular operator and favorable tariff.

The GSM module is programmable and its operating principle resembles a computer with limited functions. This block is connected to sensors installed both in equipment and in the environment - in rooms, on the street. Depending on the parameters produced by the sensors, the gas unit automatically changes the program or is controlled from a smartphone.

To communicate with the control unit installed in the house, you will need any electronic device - a laptop, tablet, but it is most convenient to use a smartphone, which is more compact and versatile

For ease of control, selection of modes and programs, developers have created applications for various operating systems: iOS, Android, Windows Phone.

There are several modes by which a gas boiler is controlled:

- Fully automatic control. The unit operates according to the specified parameters entered into the program in advance. If changes are required, the program should be adjusted.

- Transmission of alarm notifications in the event of emergency or repair situations. If there is a gas leak or the boiler suddenly stops working, a signal is sent to the smartphone.

- “Communication” using SMS messages. There is a list of commands that the automatic gas boiler recognizes and then makes changes to the operation of the equipment.

- Advanced management options. Using a special program, you can control all systems connected to the GSM unit.

The advantage of remote control via mobile communication is considered to be almost constant control and unlimited possibilities, depending only on the selected application and installed equipment.

A few more advantages of using a GSM module:

Image gallery Photo from Depending on the modification of the unit, you can connect several mobile phones to the module, and then from 2 to 10 people will be able to monitor the operation of the unit. In addition to the gas boiler, sensors installed in various rooms heated by the boiler can be connected to the module: in the kitchen, in the hall, bedrooms and even in the basement or attic In addition to the controller, key reader, antenna, sensors and power supply, you can connect a microphone, gate control unit and other “smart” devices By installing temperature sensors outside, you can set automatic mode changes depending on weather conditions Monitoring the operation of the boiler by all family membersConnecting additional sensors to the program Possibility of connecting basic or extended configurationsAutomatic operation of “weather” sensors

Problems can happen if the cellular connection is poor. The homeowner needs to carefully monitor the expenditure of funds - if the balance is negative, the ability to control the heating equipment will be interrupted.

Option #2 - using the Internet

If the Internet network extends to the area with your country home, then you can control the gas boiler using it.

A WI-FI router is installed in the house, and an Internet thermostat is connected to the boiler equipment. He is the link between the owner of the building and the heating equipment

As soon as the temperature in the room drops below normal, the sensor transmits a signal to the receiver, which interacts with the boiler and turns on the desired heating mode.

The user can control the entire process from a smartphone, monitor changes, and make adjustments. The provider acts as an intermediary between the home owner and the equipment. For continuous communication, it is important to provide access to the Internet both in the home and at the user’s location.

The advantage of the system is the unlimited number of gas boiler sensors - the heating level can be adjusted in all areas served by the building’s heating system.

As with remote control of a gas boiler via a GSM module, the homeowner can control the heating process remotely and make relevant changes. It is possible to install a program that changes the boiler operating mode depending on the time of day, days of the week, and season.

Thermostats, the operation of which depends only on the stability of the Internet connection, are different, but their operating principles are similar.

Portable temperature sensors with preset settings are installed in living rooms and other heated rooms. They are connected to an electronic thermometer, the program of which includes operating parameters

If desired, you can set an economical temperature regime for water used for domestic use or for heating “warm floors”.

The operation of the boiler and other equipment can be monitored using application diagrams or graphs. If an unusual situation occurs, the user receives alerts.

The boiler is controlled from an electronic device - a personal computer, tablet, smartphone, but there is also the possibility of manual control from a panel on the unit.

Option #3 – installing thermostats

If a router is installed in the house and the Internet is connected, it is possible to control even an old boiler model without electronic components and automation.

To do this, you need to buy universal type thermostats and create a network connecting all heating equipment. The system can be controlled via an Internet connection

The main element of the system is an electronic controller and a WI-FI transmitter “all in one”. It is programmed, after which it becomes possible to control heating functions in different zones. The number of such zones depends only on the capabilities of the homeowner - electronic thermostats can be installed on each radiator.

The controller is connected via a special channel to the boiler shutdown unit. If the need arises, the unit is turned off from a distance of hundreds of kilometers or from the next room. The controller is controlled not only wirelessly, but also manually, directly on the unit.

The thermostat system easily covers several zones, and up to 6 thermostats can be installed in each area.

Selection and configuration of equipment

Issues regarding the operation of the heat supply system of a private home, in contrast to centralized systems, fall entirely on its owners . And one of the problems that has to be solved is the issue of correct selection of gas equipment.

Experience in operating systems shows that a properly selected boiler should operate for at least 30% of the heating period.

The average value of boiler power consumption per square meter of a heated room ( with a ceiling height of up to 3 meters ) is about 100 watts.

Practice also shows that installing a boiler or burner with too high a power can create many problems associated with excessive gas consumption, difficulty in selecting the temperature in heated rooms and the reliability of the system.

After selecting and installing the heating system, as well as each time it is started, the following adjustments are made :

- Complete heating of the boiler.

- Full opening of the chimney damper.

- Setting the burner flame to maximum power (the flame should consist of blue and yellow segments).

- Shut off the gas supply valve when lowering to remove the yellow segment of the flame .

- Checking the safety automation and operating modes of the boiler.

Important! Setting the correct flame color of a gas burner is key to complete combustion of gas without the formation of soot that settles on the walls of the firebox and chimney, reducing the efficiency of the system and increasing gas fuel consumption.

How to adjust burner power

If the burner significantly exceeds the boiler in power, it may not have enough firebox volume , air flow through the dampers and from the pressurization. In this case, the combustion of the flame becomes uncontrollable, and the burner flame turns yellow.

Incomplete combustion of gas fuel causes soot in the firebox and chimney with combustion products, and part of the energy is dissipated into the surrounding space, increasing fuel consumption.

Photo 1. The shut-off valve helps regulate the gas supply in case of problems with the boiler.

In this case, the burner power can be reduced by closing the gas supply valve when lowering.

However, if the power is constantly set to the minimum value , this will reduce the efficiency and range of adjustments of the system.

Reference! When choosing a gas burner, in addition to the dimensions of the combustion chamber and the geometry of the torch , it is important to take into account the compliance of the passport values of the minimum and maximum power and methods of its regulation, as well as the gas consumption of the burner.

High gas consumption

The reason for high gas consumption is often the ineffective operation of the boiler heat exchanger. The coolant passing through the heat exchanger carries with it particles of scale and salts, which can be deposited on the internal walls of the heat exchanger, reducing its thermal conductivity and increasing the amount of fuel required for heating.

Typically, a problem with a heat exchanger is manifested by a characteristic noise emanating from a working boiler, reminiscent of a whistling or gurgling sound, similar to a kettle boiling.

In this case, you will need to manually clean the heat exchanger or wash it with a special compound.

The reason for high gas consumption can also be its reduced calorie content , caused by insufficient drying by the gas distribution company. The norm of the lower calorific value of household gas must be at least 7600 kcal per cubic meter , but in practice the calorific value of gas can be reduced to 4000 kcal.

Important! When purchasing gas equipment, it is important to take into account the composition and minimum pressure of the gas in a particular gas supply system so that the equipment operates reliably.

Lack of combustion air

A lack of air for gas combustion may be caused by a malfunction of the pressurization system . In this case, it is necessary to check the settings of the electronic temperature and boost controller , as well as the throttle valve.

If the burner ignites with a popping sound, this may indicate that the primary air inlets are closed or clogged with dust.

In this case, it is necessary to adjust the flame using air supply regulators or clean the holes from dust.

If the flame has a significant yellow segment, it may be caused by a defective burner. In this case, the burner power can be reduced by closing the gas supply valve when lowering.

Increased pressure: adjusting the gas supply valve

When the burner is operating, the following situations may arise:

- burner flame color is red-orange or red;

- the burner flame escapes beyond the allotted space;

- the burner flame lights up and immediately or after a while goes out , or lights up with a bang.

These signs may indicate increased gas pressure in the gas supply system, since in winter the gas supplier often increases the standard pressure from 200-220 mm of water. Art. up to a pressure of 280 mm water. Art.

In this case, you can reduce the gas pressure:

- closing the gas supply valve when lowering;

- installation specified in the passport for the burner of the throttle washer;

- installation of a gas pressure regulator.

Important! When purchasing gas equipment, especially imported, it is important to take into account its operation in a specific gas supply system , since each manufacturer produces equipment with its own optimal and minimum operating gas pressure values.

Weak boiler draft

Weak cravings can occur for various reasons. If the burner lights up and goes out immediately, or lights up with a bang, this may indicate that there is a large amount of soot in the boiler and or in the chimney, which is interfering with the creation of draft.

In this case, it is necessary to check the presence of draft in the chimney and in the boiler through the inspection window , and, if necessary, clean them of soot yourself or by contacting a special service.

Weak draft can also occur when the weather changes , which does not allow gases to leave the furnace and supply air to enter the boiler.

In this case, it is necessary to reduce the burner power by closing the gas supply valve when lowering, and also to organize sufficient ventilation in the room.

Reference! If the boiler draft is weak, it is also important to clarify the design of its chimney; it must comply with the rules of SNiP 2.04.05-91 and DBNV.2.5-20-2001.

Timing

If the boiler power exceeds the size of the heated premises, this can lead to frequent shutdown and switching on of the boiler for heating, or its clocking .

The clock frequency can reach 2-3 minutes.

To avoid clocking, you must:

- Select a boiler with a modulated burner flame height and a power suitable for the heated areas.

- If the boiler is controlled by the coolant temperature, it is necessary to maximize its volume in the system to cool it down for a longer time.

- If the boiler is controlled by a room thermostat, it is necessary to move the thermostat to the coldest room to increase the thermal inertia of the system, and also adjust the air temperature in the rooms using valves on the radiators.

Important! If clocking is associated with increased burner power, this can cause burnout of the main heat exchanger. In this case, the burner must be replaced in a timely manner.

System pressure norm

In empty pipes without coolant, the readings are stable at 1 bar. As soon as you open the shut-off valves and coolant enters the circuit, the values increase to 3 bar (depending on the model). If the pressure gauge needle shows less than 0.6 bar or more than 3 bar, the boiler operation is blocked. Until you eliminate the cause of the surges, the equipment will not start.

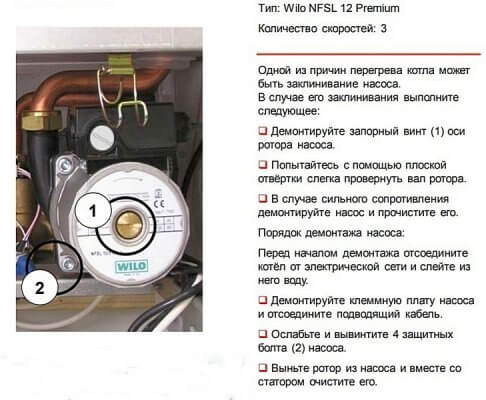

The pressure power is affected by the speed of the circulation pump, the cross-section of the pipes, the heating temperature, airiness and the presence of blockages. Each model of Arderia and “Baksi” has its own indicators. How much operating pressure should be is indicated in the instructions.

There are these types of pressure:

- Static. The greater the height of the pipes, the higher the value. Each meter rise is equivalent to 0.1 bar.

- Dynamic. Forced movement of liquid by a pump or expansion when the temperature rises.

- Working. Includes the two options described above.

- Excessive. It is fixed with a measuring device - a pressure gauge.

- Nominal. Depends on the type of design, materials, production technology.

- Maximum. Acceptable for normal operation.

- Crimping. High performance during testing at factories.

Maintenance of gas equipment

Properly selected and adjusted gas equipment may fail from time to time. In order for this to happen as rarely as possible, it is necessary to timely adjust the system settings and carry out preventive maintenance provided for in the equipment passports.

To eliminate accidents associated with gas leaks and damage to property and human health, installation of gas equipment must be carried out by authorized organizations (regionalgaz, raygaz, gorgaz) through enterprises licensed to carry out such work.

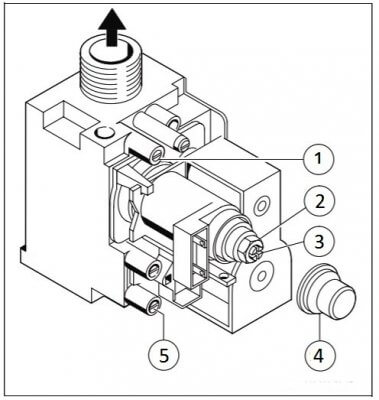

Setting up, adjusting the SIT gas valve

Gas valve SIT

Gas valve SIT. 1 - gas pressure measuring fitting at the valve outlet, in front of the burner; 2 — adjusting nut for maximum gas flow; 3 — adjusting screw for minimum gas flow; 4 — cover of the adjusting device; 5 - gas pressure measuring fitting at the valve inlet in the gas network.

Manufacturers of double-circuit gas boilers of many brands install a gas valve from the Italian company SIT on their boilers. The maximum and minimum power settings of the boiler burner are made by rotating the adjusting screws located on the valve body.

The boiler manufacturer Protherm Gepard (Panther) installs the SIT 845 Sigma gas valve on some versions of the boilers instead of the Honeywell gas valve. Such a gas valve is also found in gas boilers of the Vaillant series.

In the service menu of Protherm boilers with a SIT valve, lines d.52 and d.53 are missing.

How to regulate the minimum and maximum gas pressure at the outlet of the gas valve, see below in the video. The setup principle does not change.

The normal dynamic gas pressure at the gas valve inlet should be in the range of 1.3 - 2.5 kPa (13 - 25 mbar or 132 - 255 mm water column). If during measurement the dynamic pressure value falls outside the specified limits, then you must contact the gas service.

In order to eliminate boiler cycling in heating mode, reduce the minimum gas pressure at the valve outlet. screw counterclockwise .

Cycling in DHW mode is eliminated by reducing the maximum pressure. nut counterclockwise .

How to set the maximum and minimum gas pressure?

The maximum gas pressure is adjusted as follows:

- Unscrew the screw on the fitting and connect the pressure gauge;

- open the gas tap and set the mode switch to the “winter” position; it is necessary to ensure that the unit is operating at maximum power; You can also set high performance in DHW mode - to do this, set the hot water supply regulator to maximum and turn on the tap with a flow rate of 10 l/min;

- check the pressure on the burner using a pressure gauge; the indicator must correspond to the maximum pressure specified in the characteristics of the unit;

- if necessary, you can remove the cap from the valve and rotate the adjusting screw to set the appropriate pressure value.

You can also set the minimum pressure :

- set the mode switch to position “0”;

- disconnect the contacts of the temperature sensor;

- move the handle to the “winter” position;

- connect the contacts of the temperature sensor;

- using the screw on the gas valve, set the minimum power according to the technical characteristics of the unit;

- turn off the boiler and disconnect the pressure gauge, tighten the screw on the fitting.

Design features of Baxi gas boilers

…

Errors in Baxi gas boilers and how to eliminate them -

https://oteple.com/oshibki-gazovyx-kotlov-baxi-i-sposoby-ix-ustraneniya/

In small apartments, especially in the off-season, it is recommended to set the gas boiler to the minimum operating mode. For Baxi units, the lowest power is 40% of the maximum. For example, for a 24 kW model, the minimum performance will be 9 kW.

To convert a Baxi gas boiler to another type of fuel, simply change the nozzles in the burner. After switching to another gas, you will have to adjust the maximum or minimum power again.

How to get rid of “clocking” of a gas unit?

If the power of a gas boiler exceeds the required one, a problem such as “clocking” often arises - frequent switching on and off. This has a very negative impact on the condition of the device components and leads to increased wear and tear, as well as excessive fuel consumption.

For Baxi gas boilers, you can set the minimum duration between starts. The factory settings provide an interval of 3 minutes, it is possible to increase this value to 10 minutes.

If your Baxi unit model is not equipped with a thermostat, it is recommended to purchase and connect it. Controlling a gas boiler using this device will save fuel and prevent increased wear and tear on equipment.

Setting up and adjusting the power of a gas boiler when operating on antifreeze

Traditional antifreezes based on ethylene glycol or propylene glycol have a higher viscosity compared to water. As a result, the movement of coolant through the boiler heat exchanger slows down. In addition, antifreezes have a lower heat capacity. All this leads to the fact that the antifreeze in the boiler heat exchanger, which is designed for water, at maximum power instantly heats up to the boiling point and boils. Boiling of antifreeze, as a result of local overheating in the heat exchanger, manifests itself in the form of loud noise, roaring and gurgling.

A gas boiler, when operating on antifreeze, can only operate at a reduced power, lower than that specified in the boiler instructions for water.

To slightly increase the power of a boiler running on antifreeze, it is recommended to dilute the antifreeze with water and also increase the pressure of the circulation pump.

For example, for heating systems with wall-mounted gas boilers, it is recommended to dilute the contents of the original packaging with water in a ratio of 1:1. As a result of diluting the antifreeze, the temperature at which crystallization begins will increase from -30 °C

to minus 10 °C.

If the crystallization temperature of diluted antifreeze is not satisfactory, then select another antifreeze.

In any case, to prevent overheating of the heat exchanger, in the settings of the service menu and gas valve it is necessary to limit the boiler power in heating mode (in lines d.00 and d.52 of the service menu), and also set the maximum coolant temperature no higher than +70 °C, (in line d.71 of the service menu). It is also recommended to increase the response pressure of the bypass valve on the boiler (how? - read below).

The boiler manufacturer usually gives its recommendations on the choice of antifreeze in the operating instructions. So, for Protherm gas boilers, the instructions say: “It is not recommended to use non-freezing liquids in heating systems with Protherm equipment installed. The use of non-freezing liquids entails a decrease in the efficiency of heat exchange, higher surface temperatures on the walls of the heat exchanger and its rapid wear, an increase in the corrosive effect and viscosity, corrosion of gaskets and fittings, both in the boiler itself and in the heating system. A boiler malfunction associated with the use of non-freezing liquids will result in a warranty denial.”

Gas analyzers for setting up geysers and solid fuel boilers

In recent years, the pace of construction of private houses has increased significantly.

One of the reasons for this was the availability of autonomous heating equipment. Consumers have the opportunity to install a gas water heater, an automated gas boiler, and equipment that runs on liquid fuel. Solid fuel boilers are no longer exotic. Today it is difficult to surprise anyone that a classic stove has suddenly become an effective and easy-to-use compact size equipment. Such boilers are also fed with pellets, still rare in our country, made from shavings and sawdust. But such equipment has many prospects, due to the availability of raw materials. Whatever boiler property owners prefer, it definitely needs to be tuned. The experience of service specialists, who are armed with such precise instruments as gas analyzers, will help with this. A variety of gas analyzers for tuning boilers

To set up small geysers and boilers, you can use compact equipment such as the EUROLYZER ST series Bluelyzer ST. With its help, you can analyze exhaust gases, measure the amount of CO in the environment, draft and temperature. Its accuracy meets all international standards in force today in Europe. The device allows you to save protocols in HTML format, which can be viewed in any browser. This makes it universal, because the information received can be easily processed on any computer and transmitted over the Internet. An important advantage of the device is its small dimensions: the size of the gas analyzer is no larger than that of a mobile phone.

When setting up solid fuel boilers, you can use more complex equipment. The MAXILYZER NG gas analyzer has compact dimensions, but is capable of analyzing nitrogen and sulfur oxides, carbon dioxide and carbon monoxide, and oxygen. It comes in a durable and waterproof case that houses a computer and printer. This device impresses with its perfection and ease of use. Built-in mathematical functions allow you to make calculations quickly and efficiently, and the informative display is ideal for analyzing the data obtained. All analysis results can be transferred to personal computers for further processing or storage of information.

Afriso equipment is the standard of quality

The use of Afriso products for tuning modern heating devices is not accidental. This company has been creating perfect tools for monitoring technological processes for a century and a half. Any Afriso gas analyzer is today the standard for many other manufacturers of similar equipment. The company's devices are becoming more and more compact and multifunctional. This makes them convenient for commissioning crews who have to travel a lot to sites, because they take up incredibly little space.

Setting, adjusting the bypass valve

In boilers, the forward and return heating pipelines are connected to each other through a bypass valve - bypass, pos. 1.

At a certain pressure difference in the forward and return pipelines, the valve opens and part of the water flows from the direct pipeline to the return pipeline. As a result, the difference in water pressure in the forward and return pipelines cannot exceed the value specified by the valve setting. The operation of the valve helps to avoid water hammer when the circulation pump is turned on. In addition, the valve setting limits the maximum speed of movement (flow) of water in the heating circuit.

The valve response pressure is determined by the position of the adjusting screw, item 1 in the figure. The screw can be rotated 10 turns from one extreme position to the other. Factory setting - the screw is set to the middle position, rotating 5 turns counterclockwise from the extreme right position. The valve opens at a pressure difference of 0.25 bar.

If the heating radiators are heated unevenly in height - the top is hot and the bottom is cold (the difference is more than 15-20 o C), then it is necessary to increase the speed of water movement in the heating system. To do this, turn the bypass valve adjusting screw clockwise. The valve response pressure increases to 0.35 bar.

If noise is heard in the radiators or control valves during operation of the circulation pump, then the speed of water in the heating circuit should be reduced. To do this, rotate the screw counterclockwise. The valve response pressure is reduced to 0.17 bar.

The difference in pressure values that are displayed on the boiler display during operation of the circulation pump and immediately after it stops should not be more than 0.2-0.4 bar. If it is more, then you need to drain the water from the boiler, unscrew it and check the cleanliness of the bypass valve.

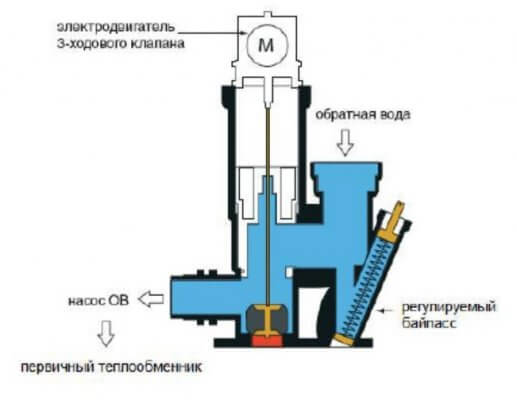

Three way valve for gas boiler

Three-way valve for a gas boiler in heating mode. In DHW mode, the rod with the valve moves upward.

To empty the boiler, the stem with the valve is set to the middle position through the service menu (menu line d.70).

Operating principle

The design of a double-circuit gas boiler allows it to operate in two modes:

In the first case, the coolant located inside the heat exchanger is heated. It serves as ordinary water. Depending on how hot it should be at the outlet and heating is carried out - from 35 to 80º C.

The heating mode is started by a thermostat that responds to changes in room temperature. When it decreases, it transmits a signal to start the pump, which creates a vacuum in the return pipeline. This process leads to the fact that the water heated in the heat exchanger enters the heating system, while the pressure is taken into account; if it is more than 0.45 bar, then the relay contacts are closed and the burner is ignited, which is controlled by the microprocessor.

Maintenance of gas boiler Protherm Gepard (Panther)

The boiler manufacturer prescribes scheduled maintenance of the equipment annually, before the start of the heating season.

In the Russian Federation, there are “Rules for the use of gas in terms of ensuring safety during the use and maintenance of in-house and intra-apartment equipment when providing public gas supply services”, approved by Decree of the Government of the Russian Federation No. 410 of May 14, 2013.

In accordance with current rules, in order to ensure the safety of gas-using equipment, household consumers must enter into a maintenance agreement with a specialized organization.

In December 2020, the Code of the Russian Federation on Administrative Offenses was supplemented with Article 9.23, which provides for punishment in the form of a fine of up to 30 thousand rubles for individuals for violating the rules for ensuring the safe use and maintenance of indoor and indoor gas equipment.

Fines are provided for:

- avoidance of concluding a mandatory contract for the maintenance and repair of gas equipment in homes;

- refusal to admit a representative of the organization to perform maintenance;

- avoidance of concluding an agreement on the performance of work on diagnosing gas equipment;

- avoidance of replacing gas equipment;

- actions that led to an accident or an immediate threat of harm to human life and health;

- untimely or poor-quality performance of work on maintenance and repair of in-house or in-apartment gas equipment.

Gas boiler does not heat hot water

Water flow sensor for gas boiler Protherm Gepard (Panther)

The DHW water flow (flow) sensor is a rotating turbine with blades, the rotation speed of which depends on the intensity of the water flow. From the operating experience of Protherm Gepard (Panther) gas boilers, it is known that a frequent cause of failure of the DHW heating function in these boilers is the turbine stopping due to foreign particles entering it. Although the turbine is protected from clogging by a mesh filter, it does not always cope with its task.

If, when you open the hot water tap, the boiler burner does not ignite and cold water flows from the tap, then check the serviceability of the DHW flow sensor. It is necessary to call line d.36 of the service menu, which displays the flow sensor readings. If, when the hot water tap is open, the flow readings in line d.36 are equal or close to zero, then we conclude that the flow sensor is not working.

The location of the water flow sensor is indicated by the green arrow in the figure above.

The water flow sensor is removed by pulling the fixing steel bracket to the left. After removing the bracket, you need to pull the sensor towards you and pull it out of the socket. Before removing the sensor, it is necessary to drain the water from the DHW circuit of the boiler, as described above.

To avoid failures in the operation of the flow sensor, it is recommended to supply water to the boiler through an additional tap water filter installed in front of the boiler.

Why does the pressure jump?

If you notice a slow decline in performance, check the heat exchanger for leaks . Microcracks appear as a result of poor quality material and rapid wear. Frequent use of reagents when descaling also leads to dire consequences.

To avoid problems, install softening filters. They extract magnesium and potassium salts from the liquid. Cracks are difficult to detect. Sometimes they appear as green spots on the surface. In tubular radiators, the hole can be sealed by cold welding or soldering.

Bithermal heat exchangers suffer from water hammer, causing their tubes to burst. They cannot be repaired, only replaced.

The make-up valve is not sealed . Inspect the part for wear; it should be in the closed position. The valve is used in cases where the pressure in the circuit is low, there is not enough coolant and it needs to be pumped up. If faulty, replace the tap. If you want to leave the valve permanently in the “closed” position, then remove the valve, fill the holes with silicone, connect the valve in the closed position.

Three way valve problems . The element is responsible for the movement of hot water in the system. For example, you have a dual-circuit device installed. When the mixer is opened, the valve switches the flow from heating to DHW and vice versa. If it is broken or clogged, a lot of liquid will leak into the heating circuit, which will lead to increased values. Clean the valve or replace it.

Pressure gauge clogged . This device measures the pressure in the boiler. If debris gets into its tubes, then it is necessary to clean them. During operation, you must constantly monitor the pressure gauge readings.

Leak in the heating system . Use a dry cloth to locate the leak. Inspect joints, connections, control valves, welding points, and make-up for serviceability. Check for water accumulation under the radiators. You may not immediately detect the location of the leak because moisture quickly evaporates from hot batteries.

In such cases, drain the water completely and connect a compressor to the terminals. During pumping, air will come out through the slots with a certain sound.

Damage must be sealed. You can use sealant or plumbing tow. Before doing this, clean the repair area.

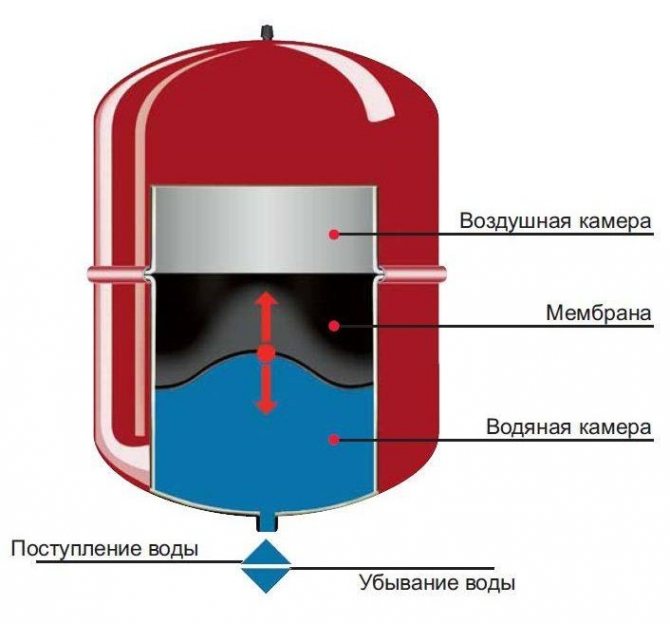

Wear of the expansion tank . Inside the tank is divided into two parts by a flexible membrane. One part contains gas under pressure. The other one receives excess liquid. If there is a gas leak or wear/damage to the membrane, compensation will not occur and the values in the circuit will not decrease.

How to pump nitrogen into the tank:

- Turn off the boiler.

- Close the valves from the boiler to the tank (usually it is equipped with two shut-off devices on both sides).

- Drain the water.

- Connect the car pump and pump up the gas.

- Wait for the values to increase.

Does the problem recur after some time? Replace the nipple, membrane, expansion tank.

Air accumulations . An air lock interferes with normal fluid circulation, which means it reduces pressure. Inspect the air vent. If it is covered with scale, remove the lid and clean everything. Bleed air from the system through Mayevsky taps. To do this, place the container and open the valve. Air will come out along with the liquid.

Do you hear gurgling noises when restarting? Repeat the steps until the sounds disappear.