Choosing between atmospheric and turbocharged boilers

When choosing an underfloor heating device, many are interested in the question of which unit is better to choose - atmospheric or turbocharged.

It depends on the conditions of use. A gas boiler with an atmospheric burner is suitable if:

- the need to heat a large area;

- under conditions of operation on several types of fuel;

- with frequent problems with power supply.

A turbocharged unit is selected when:

- inability to allocate a separate combustion chamber;

- small heating area;

- heating device for an apartment in an apartment building.

Another positive aspect of naturally aspirated units is their lower cost compared to turbocharged ones. If you choose a model with minimal equipment, it will be inexpensive.

Note! Atmospheric boilers are prohibited from being installed in an apartment in a multi-storey building.

Criterias of choice

When choosing a boiler, you need to take into account functions, efficiency, power, price, dimensions, heat exchanger material and the presence of safety systems. The type of device location primarily affects the cost and complexity of its installation, and only indirectly affects the technical characteristics.

The efficiency for atmospheric boilers is in the range of 80-93%.

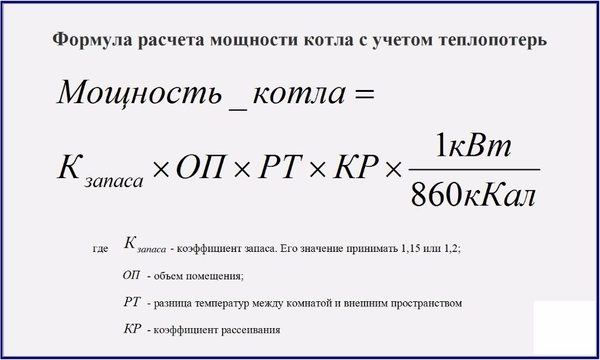

By power

The characteristics of a gas heater depend on the area of the heated room:

P (boiler) = UM * Pl * K, where UM is the specific power of the device (0.1 kW/m²), Pl is the area of the house, K is the correction factor of the geographic zone. For Moscow and Moscow Region this figure corresponds to 1.5, for the middle zone - 1.2-1.5, for the northern regions - 2-2.5, for the southern regions - 0.9. The resulting value is multiplied by the safety factor (1.15-1.2) and rounded up.

For example, for a house with an area of 80 m² in the city of Vladimir, the boiler should have a power of 12-15 kW.

For a more accurate calculation, you can use an online calculator. The service takes into account the following factors:

- maximum temperature difference between inside and outside the house;

- volume of heated room;

- heat loss coefficient (wall material and thickness, insulation, etc.);

- type of floors;

- type and number of windows.

The average specific power factor, taking into account losses, is 50-70 W/m² for buildings made of modern materials, 90-110 W/m² for houses with thermal insulation, built after 1990, 130-200 W/m² for old buildings without thermal insulation. isolation.

Important: for a double-circuit boiler, the design power increases by 20-25%. This part of the energy will be spent on hot water supply.

According to the material of manufacture

Most often, heat exchangers are made from cast iron, stainless alloy or steel with a corrosion-resistant coating. Boilers with a copper tank are less common.

For equivalent cost and functionality, it is better to buy a model with a heat exchanger made of copper or cast iron. It is also worth paying attention to reviews about the strength of the case.

On automation and safety

Independent protocols turn off the boiler in emergency situations, lack of draft, strong voltage drops, drop in fuel pressure, etc. The presence of a monitoring electronic unit allows you to determine the error without completely disassembling the installation.

The device's safety system consists of sensors for hydrocarbons, draft, temperature, flame, overheating and water level. The self-diagnosis function reduces the risk of unexpected shutdown of the boiler.

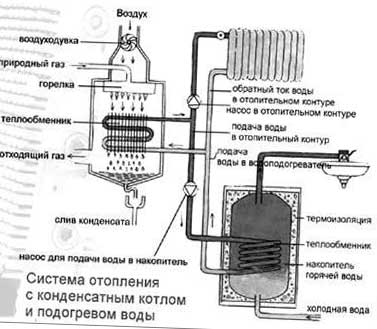

Single-circuit and double-circuit devices - what is the difference?

A single-circuit heating device differs from a double-circuit heating device only in that it is responsible only for heating the room. At the same time, a double-circuit boiler, in addition to heating, is also designed to solve issues of providing hot water supply.

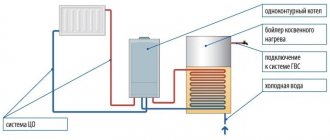

Owners of single-circuit boilers solve DHW problems by installing additional equipment. Most often this is an indirect water heating boiler connected to the boiler. What is more efficient: a single-circuit boiler or a double-circuit boiler? We'll figure this out now.

The main advantage of a single-circuit boiler in conjunction with a storage heater is that water is heated to a comfortable temperature without cooling the home. Whereas, with significant water consumption in a double-circuit boiler, the circuit responsible for heating is automatically switched off, and the unit only works to heat the water.

A single-circuit gas boiler with an indirect heating boiler completely solves the issue of hot water supply without disrupting the operation of the heating system

The following factors should be considered before selecting a heater configuration:

- Heated housing area;

- Number of water intake points;

- Distance from water intake points to the boiler;

- Number of residents.

In a house with a small heated area, with economical consumption of hot water and close placement of water intake points, the optimal solution would be to install a double-circuit boiler.

If hot water is simultaneously consumed from several water intake points, the water temperature may be lower than required. In addition, with a large housing area, additional inconveniences arise. In double-circuit boilers, the priority is DHW; when hot water is consumed, the circuit responsible for heating is turned off.

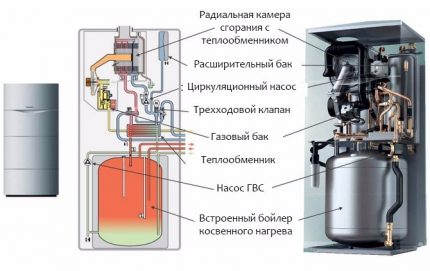

But these issues are also resolved at the level of the unit design. There are double-circuit boilers that heat water in flow mode and are equipped with a built-in boiler.

The latter provide a supply of hot water of 30-60 liters, but at the same time gas consumption increases slightly. In addition, the weight of the boiler and its overall dimensions increase significantly.

A floor-standing gas boiler with a built-in indirect heating boiler provides an adequate supply of hot water

We can conclude that if the needs are met, the optimal solution would be to install a double-circuit flow-type boiler. If you want to have a sufficient supply of hot water at a comfortable temperature at any time without cooling your home, then it would be preferable to install a combination of a single-circuit boiler with an indirect heater.

In addition, if it is necessary to increase the need for hot water, the boiler can always be replaced with a larger capacity boiler. As a result, the price of such a combination will be higher than the cost of a double-circuit boiler, but the issue of hot water supply and heating will be reliably resolved.

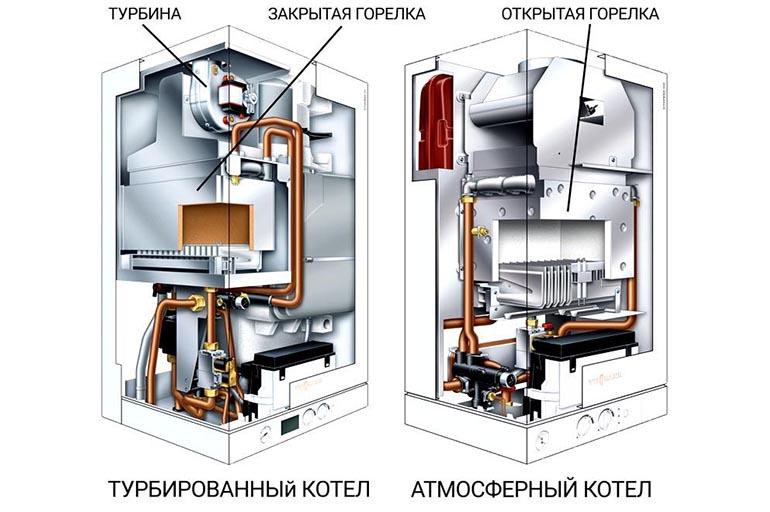

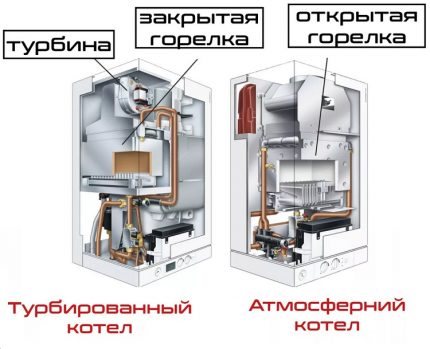

What is the difference between turbo boilers and atmospheric ones

The advantageous difference is as follows:

- A unit with a closed firebox does not take air from the room. This means that there are no special requirements for ventilation.

- The danger of fire and poisoning of residents from carbon monoxide or natural monoxide is eliminated (closed firebox). Thanks to this, the device can be installed not only in the kitchen, but also in the bathroom or pantry.

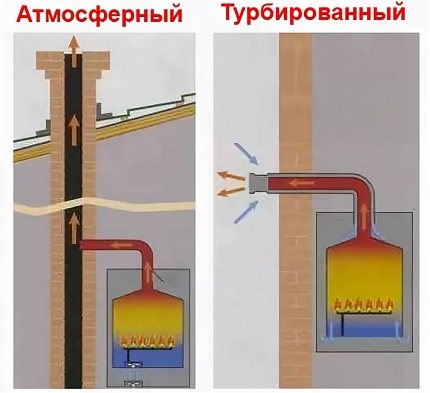

- The installation of the smoke exhaust duct is simplified. The coaxial pipe can be laid along an arbitrary trajectory and brought out at any level, as long as it does not interfere with passers-by. Chimneys for atmospheric boilers, designed for natural draft, are installed according to strict rules: vertically, with a height of 5 m, the cross-section is selected in accordance with the power of the heater.

- The flame cannot be blown out by the wind.

- Reduced gas consumption.

The efficiency of boilers with a closed combustion chamber is due to the following:

- Turbocharging forces more air into the fuel mixture than in the atmospheric version, so the gas is oxidized in full.

- The flow entering the combustion chamber is preheated due to contact with the smoke exhaust channel.

Turbo boilers are inferior to atmospheric ones in the following properties:

- They cost more.

- They make noise during operation.

- Unable to cope without power supply.

- They are more complex and therefore less reliable.

It should be noted that turbocharged devices have a night mode with reduced noise. If there are systematic interruptions in the power supply, an atmospheric heater becomes the only possible option.

Pros and cons of atmospheric boilers

Heating atmospheric gas heating boilers have many advantages:

- the device is able to operate successfully even with low pressure fuel supply, including values up to 15 mbar;

- boiler equipment provides a wide range of loads;

- there is no need for additional air supply for optimal combustion of the gas mixture;

- The heating unit is distinguished by its simplicity of design, long service life, and low cost of replacing parts.

A definite significant plus for a boiler installation with an atmospheric burner is quiet operation.

Among the shortcomings of the equipment, the following points are noted:

- the operation of an atmospheric boiler requires an open type of air supply, this reduces the level of safety of operation of the device, since there is a risk of fire or release of carbon monoxide;

- at low gas pressure, the wear rate of fuel supply parts increases;

- Heating equipment of this category is installed in special rooms for the boiler room, which causes difficulties when arranging small houses and apartments.

The big disadvantage of the designs is the difficulty of high-quality draft control and dependence on external factors, including the weather outside (changes in wind direction, air temperature) and limited supply air.

Types of boilers

It’s worth starting with a brief analysis of the main types of boilers in order to understand the system of their operation and the appropriateness of installation in a particular home.

Floor and wall types of equipment

The floor structure is distinguished by its high weight - up to 100 kg. Its installation requires a lot of space, and installation is labor-intensive, complex and expensive. Most floor-standing atmospheric boilers do not heat water to be supplied to mixers. During operation, the floor-standing unit makes a lot of noise, and the chimney requires regular cleaning.

Positive sides:

- high power;

- durability;

- lack of electronics.

Wall heaters are smaller in size and weight (up to 50 kg). Such boilers are predominantly double-circuit. The model is easier to install and does not take up much space. The boiler can be placed anywhere in the room. Wall-mounted atmospheric boilers are single-circuit and double-circuit.

Both floor-mounted and wall-mounted boilers are produced to serve one or two circuits. However, if space allows, it is better to take two: a floor-mounted single-circuit one for heating and a column for preparing hot water

Disadvantage: a wall-mounted boiler depends on electronics. If something burns out, you will lose hot water and heating. Boilers are installed mainly in small apartments and houses.

Single-circuit and double-circuit

Single-circuit and double-circuit boilers differ in the tasks they can perform. So, for example, a double-circuit boiler (following the name) performs two tasks: it heats the room and heats water to be supplied to the mixer.

The single-circuit one performs only one standard function - heating.

A double-circuit boiler, in addition to its standard function, makes it possible to obtain hot water for various needs, but it cannot be called a full-fledged “boiler”. The fact is that the pressure of water that passes through the unit must be very strong for the system to work. Therefore, such a boiler needs to be installed near the bathroom and kitchen.

We recommend: Leningrad heating system - advantages, disadvantages and modernization possibilities

A single-circuit boiler does not give you the additional function of a boiler, however, it costs several times less. The operating system of such a unit is simple, which means that if it breaks down it will be easier to repair. In addition to a single-circuit boiler, you can install an indirect heating boiler, which can operate on various fuels (gas, electricity, solid fuel), be floor-mounted or wall-mounted.

It works as follows: a central heating system is connected to the boiler (in a small circle); A flask with water is installed inside the unit, through which a coil passes. Hot water passing through the coil heats the water inside the boiler, and it can be used for personal purposes. When the heating is turned off, the taps at the inlet and outlet of the central heating pipes are closed, and the water in the boiler is heated using gas, electricity or solid fuel.

For more information on the structure and difference between single-circuit and double-circuit boilers, watch the video

How to choose a gas heating boiler: important characteristics and overview of the modern market

The range of gas boiler models on the market is quite wide.

They differ in functionality, installation method, and cost-effectiveness. To choose an atmospheric or turbocharged gas boiler, you should understand in advance the advantages of each type. We need to find out which type is optimal for individual heating. You will learn everything about the specifics of operation of equipment with an open and closed combustion chamber from the article we propose. We will introduce you to practical qualities, pros and cons of operation. Taking into account our recommendations, the choice of equipment for arranging a country property will be much simpler and easier.

Gas equipment, on the basis of which autonomous heating systems are built, is presented in two options on the market. The consumer can now purchase either a turbocharged or naturally aspirated (chimney) type.

The first group is equipped with a coaxial chimney, as well as a closed combustion chamber. Due to the minimum requirements for the ventilation system, it can be installed in apartment buildings. To operate an atmospheric boiler, a traditional chimney is required. It is installed in low-rise private buildings.

The main working unit of the atmospheric gas boiler, which is of the open type, takes air from the room. The combustion process with the traditional release of its products occurs openly, therefore, to install atmospheric equipment, a boiler room is installed, separated from the living area of the house.

An atmospheric burner is a set of small nozzles through which gas passes under pressure. During combustion, the required amount of air enters the chamber, which intensifies the flame. As a result, when heating water in the system, an atmospheric boiler consumes a minimum of fuel. Smoke is exhausted through a stainless steel chimney.

A turbocharged boiler has a closed combustion chamber. Oxygen is driven into the chambers through a coaxial pipe by a fan. Installation of equipment is possible anywhere.

The peculiarity of the wall-mounted turbocharged boiler is that the combustion chamber is made of copper, which limits the power to 35 kW. In floor-standing boilers it is made of cast iron, which allows you to significantly increase power.

For heating small apartments and offices, a turbocharged gas boiler is the best choice. It is safe, easy to operate and trouble-free. Consistently provides consumers with heated water in the volume they need.

Its advantages over atmospheric:

- if the power is up to 60 kW, the installation location does not matter;

- air is not taken from the premises for combustion;

- combustion products are removed by a fan to the street through the chimney;

- high efficiency allows you to use less fuel.

Turbine-type boilers are completely safe and can be installed in any room.

The main structural components of a boiler with a closed burner option:

- gas-burner;

- fan;

- DHW heat exchanger;

- built-in expansion tank;

- heating heat exchanger;

- circulation pump;

- temperature sensors;

- gas valve;

- security systems;

- coaxial chimney;

- electronic control unit.

The installation of such a boiler should be carried out on the outer wall of the house or near the ventilation shaft. Despite the fact that the cost of a turbocharged model is higher than that of an atmospheric model, you can save on equipping the boiler room and installing a traditional chimney.

Most dual-circuit units stop heating the room while hot water is supplied. Contrary to the opinion of the majority, the coolant does not have time to cool down and the temperature in the apartment remains unchanged.

Turbocharged boilers are equipped with a “Summer” mode. In this case, hot water is supplied independently from the heating system - this is a strong argument in favor of purchasing a model with a closed burner.

Advantages of turbocharged boilers:

- Air intake for heating is carried out not from the room, but from the street:

- sealed combustion chamber;

- no need to install a chimney;

- there is no need to build a boiler room (installation can be carried out in any room);

- compact dimensions;

- high efficiency and low energy consumption;

- high productivity (on average 10 liters of water are heated per minute);

- automated operation and electronic control system;

- high security;

- ease of operation.

Disadvantages include the high cost of equipment and parts for repairs and dependence on electricity supplies.

A single-circuit boiler is used to supply heated water to heating radiators. Dual-circuit models have a second heating circuit designed to prepare hot water. A boiler with a power of over 20 kW will allow you to heat the room and heat water.

However, the floor-standing unit is of low power, so it should not be “overloaded”. It is better to heat water with a gas water heater. According to the standards, it is allowed to install two separate boilers in one boiler room: wall-mounted and floor-standing. One of them will supply sanitary water, and the second will supply coolant.

Double-circuit models are divided into boilers with a bithermal heat exchanger and a separate one. The first is used for heating and hot water supply. Its disadvantage is sensitivity to bad water. Scale quickly forms on it and productivity decreases.

During operation, it is recommended to use descaling powder. A separate heat exchanger performs the same functions as a bithermic one, but is less sensitive to water.

Condensing boilers, in addition to the usual heat generation, additionally use the energy released during operation of the equipment during condensation of water vapor. Essentially, these models collect condensate to transfer its heat to heating devices. Such boilers allow you to save up to 17% of gas, and their efficiency reaches 108%.

READ MORE: Which is better for the dishwasher - powder or tablets, comparative review

Would you say that the efficiency of any type of heating equipment cannot exceed 100%? Maybe this is what condensation models confirm. They partially reuse the energy released during the combustion of one portion of fuel.

Main characteristics of atmospheric gas boilers:

- power - from 20 to 60 kW;

- large dimensions and weight;

- productivity - up to 30 l/min;

- average efficiency - 79-92%;

- electronic control panel.

This model is equipped with an open combustion chamber. Oxygen is taken from the room where the equipment is located, and combustion products are removed through the chimney. Leaks in the combustion chamber result in some of the gases entering the environment and can cause poisoning.

Therefore, a special room with good ventilation is equipped for atmospheric boilers.

Selecting a location for installation:

- the structure is installed in a technical building;

- powerful and large models require a building with a foundation;

- to ensure sufficient draft, a close location of the chimney with minimal bending is necessary;

- it is important to provide communications for the output of the coaxial chimney.

The operation of an atmospheric boiler is based on heating the heat exchanger material with a gas burner. It then transfers the resulting energy to the coolant or water prepared for use.

- nozzle;

- head;

- air regulator;

- ejection tube.

With partial, part of the gas enters directly, and the other part with air. At full - before entering the combustion chamber, complete mixing of gas with air occurs. In the CIS countries there are no models with full mixing.

Burners are available in one and two-stage types, with smooth switching of fuel supply speed and modulating. Cost savings depend on the complexity of the design. Some models allow the use of diesel fuel. But the price of such boilers is much higher.

The burners are equipped with CO2 and flame level sensors. If the draft is insufficient, the flame may go out, which will lead to gas pollution in the room. A similar problem is observed in home-made structures that are converted from solid fuel boilers.

Advantages of atmospheric gas boilers:

- stable operation even with low gas pressure (it follows that in this case the fuel supply elements fail faster);

- No additional air supply is required for efficient combustion of the mixture;

- silent operation;

- ease of operation.

There are also significant disadvantages. The most important thing is the possibility of carbon monoxide leakage and fire. Therefore, boiler equipment with an open type of gas burner requires a separate room (impossibility of installation in apartments).

Heating equipment differs from each other:

- dimensions plus weight directly related to dimensions;

- power;

- Efficiency

The maximum power of wall-mounted models of atmospheric boilers is 36 kW. This indicator is due to the design features.

To select the optimal power, you should take into account the area of the room and factors of possible heat loss (windows, cold floors and walls). It is recommended to choose a boiler that can heat an area 25% larger than the actual one.

In addition to power, when choosing a boiler, you should pay attention to efficiency. This indicator shows how much energy is required to heat water and how much is burned. Average figures for atmospheric boilers are 80-90%. More expensive models provide maximum effect - up to 97%.

Condensing boilers have 100% efficiency. The fact is that the exhaust gas heats up to 110°C. In turbocharged units this figure is 55 °C. In condensation rooms - 30°C.

The floor structure is distinguished by its high weight - up to 100 kg. Its installation requires a lot of space, and installation is labor-intensive, complex and expensive. Most floor-standing atmospheric boilers do not heat water to be supplied to mixers. During operation, the floor-standing unit makes a lot of noise, and the chimney requires regular cleaning.

- high power;

- durability;

- lack of electronics.

Wall heaters are smaller in size and weight (up to 50 kg). Such boilers are predominantly double-circuit. The model is easier to install and does not take up much space. The boiler can be placed anywhere in the room. Wall-mounted atmospheric boilers are single-circuit and double-circuit.

Disadvantage: a wall-mounted boiler depends on electronics. If something burns out, you will lose hot water and heating. Boilers are installed mainly in small apartments and houses.

Turbocharged models use air from the street, which enters through a coaxial tube. Unlike atmospheric boilers, they can be installed in the kitchen, bathroom and other living spaces. This is the best option for heating an apartment or oversized house.

How to choose a location for installation

To understand which boiler is better, atmospheric or turbocharged, to use for a specific heating system, you need to understand some design features and the operating principle of the devices.

An atmospheric gas boiler can be wall-mounted or floor-mounted, as well as single-circuit, intended only for working with the home heating system, or double-circuit (with an additional coil) - for heating water.

In such a boiler, an open-type combustion chamber is installed, that is, air is taken in directly, in a natural way. It is precisely because of this feature that atmospheric installations are located in special boiler rooms, which, as a rule, is not a particular problem to equip in a private country house. But if it is planned to install a gas boiler in an apartment, then this factor becomes not only a disadvantage, but also an obstacle.

In addition, to remove combustion products, a traditional chimney with access to the roof of the building is required, which, again, is quite feasible in a private house, but difficult in an apartment building. Exceptions may be apartments of old construction with existing chimneys, which still need to be modernized over the years, but the percentage of such houses is small. If it is planned to install an atmospheric boiler in a country house, then in addition to the boiler room equipment, it will be necessary to design and install a chimney at the initial stage of construction, taking into account all the rules and regulations. It is imperative that the furnace room be equipped with an effective ventilation system that will ensure the flow of oxygen necessary for the combustion process.

Differences between an atmospheric gas boiler and a turbocharged one

Gas equipment, on the basis of which autonomous heating systems are built, is presented in two options on the market. The consumer can now purchase either a turbocharged or naturally aspirated (chimney) type.

The first group is equipped with a coaxial chimney, as well as a closed combustion chamber. Due to the minimum requirements for the ventilation system, it can be installed in apartment buildings. To operate an atmospheric boiler, a traditional chimney is required. It is installed in low-rise private buildings.

The main differences between atmospheric and turbocharged boilers lie in the design and operating principle of the gas burner

The main working unit of the atmospheric gas boiler, which is of the open type, takes air from the room. The combustion process with the traditional release of its products occurs openly, therefore, to install atmospheric equipment, a boiler room is installed, separated from the living area of the house.

An atmospheric burner is a set of small nozzles through which gas passes under pressure. During combustion, the required amount of air enters the chamber, which intensifies the flame. As a result, when heating water in the system, an atmospheric boiler consumes a minimum of fuel. Smoke is exhausted through a stainless steel chimney.

An open burner burns oxygen from the air mass of the boiler room during operation. Even if we take into account that this is a priori a non-residential premises, a powerful ventilation device is required. After all, a constant supply of air is required for normal combustion

A turbocharged boiler has a closed combustion chamber. Oxygen is driven into the chambers through a coaxial pipe by a fan. Installation of equipment is possible anywhere.

The peculiarity of the wall-mounted turbocharged boiler is that the combustion chamber is made of copper, which limits the power to 35 kW. In floor-standing boilers it is made of cast iron, which allows you to significantly increase power.

Atmospheric varieties of gas boilers require connection to a standard chimney with a vertical duct. Turbocharged ones can be equipped with a coaxial chimney - it is easier and cheaper to install

Specific installation requirements

One of the important requirements for installing an atmospheric boiler is to ensure sufficient draft for complete combustion of the gas mixture with subsequent complete removal of combustion products from the room. According to regulatory and technical documents, equipment installation is carried out in compliance with the following recommendations:

- it is necessary to ensure the flow of an appropriate volume of air for gas combustion along with the organization of high-quality ventilation of the room;

- the cross-section of the chimney systems must correspond to the diameter of the smoke exhaust pipe of the boiler installation;

- According to the standard, the height of the accelerating (vertical) section of the smoke exhaust before the first turn must correspond to 2 d.

In addition, the required chimney height must be observed. According to the manual, the elevation of the pipe above the roof is:

- at least 0.5 m above a flat roof;

- at least 0.5 m above the ridge at a distance of up to 1.5 m from the ridge;

- not lower than the ridge if the pipe is located at a distance from 1.5 to 3 m from it.

If the chimney pipe is located at a distance of more than 3 m from the ridge, its height must correspond to a line drawn down from the ridge at an angle of 10° to the horizon.

Description of atmospheric gas boilers and operating principle

The heater is equipped with an open burner that draws air from the room. The combustion product emission zone is not separated by a sealed chamber, so the heating installation is installed in a separate room, regardless of power.

The heating boiler consists of a burner, gas compartment, heat exchanger, control unit, thermostat, pump, ignition and flame control electrodes, pressure gauge, smoke exhaust fan and pipe. At the entrance to the fuel tank there are coarse and fine filters.

An open burner consists of a set of small nozzles, the diameter of which regulates the pressure of the gas mixture. The intensity of the process depends on the feed rate and the amount of air that is mixed with the fuel before entering the combustion chamber. The domestic market mainly offers models with incomplete injection, so part of the oxygen required for the reaction is sucked in from the surrounding space.

In addition to combustion devices, the chamber is equipped with carbon monoxide and flame level sensors. They send signals to the electronic control unit, which turns off the device in emergency situations.

The combustion energy of the gas heats the heat exchanger, from which water enters the heating system. To avoid clogging of pipes, cleaning filters are installed in front of the coil.

During operation of the device, gas fuel under pressure is supplied to the chamber, where it burns with the participation of oxygen from the surrounding space. It comes stably from natural or forced ventilation in the boiler room. The draft is provided by a chimney, the height of which depends on the distance of the device from the central section of the house:

- if it is located less than 1.5 m, then the pipe should rise above the ridge by more than 0.5 m;

- at a distance of 1.5 to 3 m, the same height of the air duct and the top point of the roof is allowed;

- at a distance of more than 3 m, the chimney may even be lower than the ridge, but the angle between them is less than 10°.

To ensure ventilation, the duct must have a minimum number of bends and horizontal sections.

Turbocharged boilers, unlike atmospheric ones, do not have an open burner. Air enters from outside the room through a double (coaxial) chimney.

Important: if the combustion chamber type is open, then the boiler can only be used for heating a private house, because a non-residential premises and a standard chimney are equipped for it.

Basic criteria for choosing a boiler

When choosing a boiler with an atmospheric gas burner, you need to pay attention to the following main characteristics:

- Power;

- Number of circuits;

- Installation method: floor-mounted or wall-mounted;

- The material from which the heat exchanger is made;

- Automation and security

Let us dwell on each of the criteria in more detail, and consider all the main points associated with the given technical characteristics, with the exception of those that have already been discussed above.

Heating unit power

The quality of heating and the creation of a comfortable temperature in the room largely depend on the power of the boiler.

When calculating the boiler power, you need to take into account:

- Room area;

- Room volume;

- Thermal conductivity coefficient of walls, windows and doors.

In order not to dive deeply into numbers and calculations, you can take another, simpler route. It is generally accepted that to heat 10 square meters of housing, 1 kW of boiler power is sufficient for standard ceilings with a height of 2.5 m and insulation of the room. Thus, it is enough to divide the area of the room by 10, and we obtain the theoretically required boiler power.

The resulting figure must be increased by 20% to ensure normal operation of the boiler during peak load periods. To obtain a sufficient volume of hot water, which is especially important for flow-through double-circuit boilers, the power must be increased by 25%.

Material for the manufacture of heat exchanger

The main materials from which the heat exchanger of an atmospheric boiler is made are cast iron, steel, stainless steel and copper. A cast iron heat exchanger has almost no power limitations. It is reliable and durable, thanks to its excellent anti-corrosion properties.

But this also has its own characteristics - cast iron can crack due to the temperature difference at the point of water entry and the heating zone. Design solutions include the prevention of low temperature corrosion by installing a four-way valve.

Cast iron heat exchangers are installed in floor-standing boilers. The products are large in size and weight.

The cast iron heat exchanger has no restrictions on boiler power and is the most reliable and durable

Steel heat exchangers are used by domestic boiler manufacturers due to their low cost. Such heat exchangers do not require installation, they withstand thermal loads well, but at the same time they are significantly inferior to cast iron heat exchangers due to their low corrosion resistance.

A good alternative to steel is a stainless steel heat exchanger. It combines all the positive qualities of steel and cast iron - it is durable, immune to thermal shock, and has high corrosion resistance. But at the same time, boilers with stainless steel heat exchangers are more expensive.

Copper is flexible and conducts heat well. Heat exchangers made from it have many fins and are characterized by a small volume, due to which it is possible to reduce the size and weight of the boiler.

Copper heat exchangers are used in wall-mounted boilers, providing quick heating, which reduces fuel consumption. Due to its compact size and small amount of water, a circulation pump is required to avoid boiling.

Automation and security

Automation ensures safe operation of the boiler, economical fuel consumption, and helps increase the level of comfort when operating the equipment. The cost of automation for a gas boiler is determined by the number and complexity of programs and functions.

Some of them are considered basic and should be present in any gas boiler. They are responsible for preventing gas leaks as a result of various non-standard situations - flame extinction, drop in gas pressure.

There are two types of automation – volatile and non-volatile. The first is considered the most reliable, but requires a connection to the mains and an uninterruptible power supply. The second is considered mechanical, it is simpler and is autonomous.

We recommend: Stove heating of a private home, device options, how to choose the right stove, photo

Non-volatile automation system

It is characterized by autonomy, high maintainability and low price. The temperature range of the thermostat is selected manually using a thermostat, which has a rod in its design that lengthens or shortens depending on the temperature. As a result, the gas supply valve opens and closes.

Non-volatile automation is easy to operate and ensures the operation of basic security systems

The basic automation package includes draft and flame sensors. When the draft decreases or the burner goes out, the gas supply is blocked. Although non-volatile automation is considered simple and reliable, it does not make it possible to operate the boiler in optimal modes, which reduces the service life of the equipment.

Volatile device version

Operating parameters or operating modes are entered on the display or from the remote control, after which the control and regulation systems are launched.

Energy-dependent automation extends the service life of equipment and opens up opportunities for wide comfort control functionality

The principle of its operation is based on the operation of solenoid valves, which are controlled by a microprocessor unit.

Main functions of modern automation:

- Temperature maintenance for a certain time;

- Adjustment of thermal conditions depending on the weather;

- Electronic flame modulation;

- Protection of the heat exchanger from overheating;

- System frost protection;

- Protection against jamming of the circulation pump;

- Self-diagnosis.

The disadvantage of the system is its energy dependence; in the absence of electricity, the equipment is blocked. To ensure full operation, the automation must be connected to an uninterruptible power supply.

How to choose a boiler

When choosing a gas boiler, three main parameters are analyzed: all technical characteristics, a reliable and trusted manufacturer, and cost. Be sure to analyze the room in which the equipment will be installed. The first thing you should pay attention to is the power and functionality of the equipment.

Criteria for choosing wisely

Important characteristics:

- Performance. The calculation is made after analyzing the area of the room and possible heat loss.

- Number of serviced circuits. If space heating and hot water supply are required, choose a double-circuit boiler with a pair of heat exchangers. If DHW is not needed, then a single-circuit boiler is sufficient. The new double-circuit heating devices provide a “Winter/Summer” mode.

- The material from which the heat exchanger is made. Steel or cast iron is used for the primary circuit, and copper and aluminum for the secondary circuit. The service life, thermal conductivity and cost depend on the material.

- Automation. It is provided in a double-circuit turbocharged boiler. There are two types: standard and weather-dependent. New models have built-in remote control units. The model can be additionally equipped with remote notification. Gas consumption depends on the number of automation functions.

The best models of gas boilers are produced by German companies. Italian and French products are in second place in popularity. Russia also began to supply competitive boilers that are low cost.

The most reliable boilers are Baxi, as well as Vaillant Turbo TEC, Viessmann, Vaillant Atmo TEC. In second and third place are models from Neva Lux and Arderia. Korean products from Navien, Hydrosta, Daewoo and Kiturami have low reliability and build quality.

Installation requirements

The highest demands are placed on the installation of atmospheric boilers. Installation and connection are carried out only by representatives of the gas company, with which an agreement is concluded for further maintenance and technical inspection of the equipment. All connecting nodes must be made perfectly, extremely tightly.

You can install a turbocharged boiler yourself. But you need to take into account that the slightest violation will lead to a decrease in performance, and the manufacturer will refuse warranty service

Turbocharged models are not so demanding, but manual connection is also not particularly recommended. Especially if, due to the fault of an inexperienced contractor, water gets into the gas pipeline. There is an important condition - perfect removal of smoke exhaust ducts to the street.

How to calculate the optimal value of the thermal power of a gas boiler?

Why buy a boiler more powerful than required if this will certainly lead to unnecessary costs not only at the time of purchase, but also during operation. On the other hand, giving away a lot of money and freezing in the winter, washing your face with cold or lukewarm water is, to put it in TV serial language, a loss of losses!

The simplest method for selecting the golden mean: 1 kW per 10 m² of serviced area. However, this is very approximate and some important parameters are not taken into account. For example, such as: the climatic coefficient of a particular region, the degree of thermal insulation of the walls, the level of probable heat loss, the volume (and not just the area) of the room, etc.

This means that a more accurate calculation is needed. There are two ways: use publicly available formulas that take into account the above criteria (you have the opportunity to remember your school years) or act more rationally and use a special calculator, which are a dime a dozen on the Internet.

Pros and cons of turbocharged gas boilers

The vast majority of gas boilers in our stores are imported. Mostly European. In our opinion, the rating of the best foreign manufacturers of gas boilers looks like this:

- Wolf (Germany)

- Vaillant (Germany)

- BAXI (Italy)

- Protherm (Slovakia)

- Bosch (Germany)

- Buderus (Germany)

- Navien (Korea)

and some others.

Among our domestic manufacturers of gas boilers, we highlight two factories:

- Zhukovsky Machine-Building Plant (ZhMZ). It produces boilers of the AOGV (single-circuit, heating) and AKGV (double-circuit, heating and domestic hot water) brands.

- LLC "Plant Conord" Located in the city of Rostov-on-Don. It produces gas boilers and heaters CONORD, solid fuel boilers DON, industrial boilers and other equipment.

Why buy a boiler more powerful than required if this will certainly lead to unnecessary costs not only at the time of purchase, but also during operation. On the other hand, giving away a lot of money and freezing in the winter, washing your face with cold or lukewarm water is, to put it in TV serial language, a loss of losses!

The simplest method for selecting the golden mean: 1 kW per 10 m² of serviced area. However, this is very approximate and some important parameters are not taken into account. For example, such as: the climatic coefficient of a particular region, the degree of thermal insulation of the walls, the level of probable heat loss, the volume (and not just the area) of the room, etc.

READ MORE: Which supply valve to choose, types of wall valves, selection criteria and review of the best manufacturers

This means that a more accurate calculation is needed. There are two ways: use publicly available formulas that take into account the above criteria (you have the opportunity to remember your school years) or act more rationally and use a special calculator, which are a dime a dozen on the Internet.

Gas boilers can work only for heating the house (single-circuit boilers) or additionally produce hot water (double-circuit boilers). Your needs are the first thing to consider when choosing the best gas boiler.

Double-circuit boilers are mainly wall-mounted. They are very convenient and take up less space. But their main disadvantage is the need to connect to electricity. This means that it will only work if there is light. And such a boiler should be connected through a voltage stabilizer so that the electronics do not fail due to surges.

Among the floor-standing models there are both single-circuit and double-circuit boilers. They are non-volatile and have high efficiency, but you will have to tinker with the placement of such a boiler.

So everyone has pros and cons. Our rating will help you choose a specific model. And let your home be warm!

Modern models of floor-standing boilers have an efficiency of 88-90% (models with the old configuration - about 85%). As for wall-mounted ones, the same figure is higher - 90-94%. Accordingly, energy consumption in boilers with lower efficiency is higher, which means that energy costs are also higher.

But you cannot evaluate the efficiency of a model only by the installation method - its efficiency is also influenced by the principle of operation. In the latter case, a distinction is made between conventional and condensing boilers.

Almost all floor-standing boilers are convection - they are cheaper and demonstrate lower efficiency. Although at the same time, due to their simpler internal structure, their repairs are cheaper, and this is a plus.

Wall-mounted boilers are more advanced in terms of design, they have more parts, however, repairs in case of breakdown are more expensive

Wall-mounted - can be either convection or condensation. In the latter, the heat generated from heated gases and combustion products is additionally transferred to the coolant. Thus, the heat does not “fly down the chimney”, but is effectively used. The only inconvenience is that it is necessary to equip a condensate drain from the boiler.

At the same time, floor-standing models can also be condensation, but this is a slow-selling product, since their price exceeds 150 thousand rubles.

This criterion is used to determine the reliability of the device.

Specific models traditionally have their own heat exchangers:

- Floor-standing models use reliable and heavy cast iron. It is good because it is not afraid of corrosion, is durable and has a high density and thickness. This allows boilers with a cast iron heat exchanger to operate without interruption for up to 25 years.

- In suspended boilers, it is replaced with light steel or copper. Steel is a cheaper option, but is thin and therefore prone to warping and rusting. Such models will last, if you're lucky, 12-13 years. Copper is more durable and conducts heat better, but is used only in expensive models.

Please note that the statement that wall-mounted boilers are less reliable due to the complexity of their design is nothing more than a myth.

According to the characteristics declared by the manufacturer, the service life of wall-mounted boilers is somewhat shorter, but this does not mean that in life they often break down and quickly fail. When used carefully, they can last as long as floor-standing boilers.

In fact, durability is affected not by the number of parts and structural elements, but by the material of the heat exchanger.

So, it is in floor-standing models that a cast iron heat exchanger is most often installed, which is considered the most durable material. Therefore, their service life differs from wall-mounted boilers in which heat exchangers of lighter materials are mounted.

If you think that the more the better, then you are mistaken. In this case, the functionality of the equipment has nothing to do with the dimensions.

The rule “bigger is better” does not always apply: a small wall-mounted boiler can often have more functionality than large equipment

Surprisingly, but true: more complex wall-mounted boilers are smaller in size than more primitive floor-standing boilers. The first ones are entire mini-boiler houses.

In the design of gas single-circuit and double-circuit wall-mounted boilers, depending on the tasks being solved, the following are used:

- one or two circulation pumps;

- closed expansion tank;

- pressure gauge;

- thermometer;

- air vent;

- safety valve.

READ MORE: Common oleander - a fragrant shrub for your garden

The second ones have a simpler design and require separate installation of an expansion tank and a pump, which in some cases can be completely dispensed with.

If you want to choose a gas boiler wisely, you should take into account the specifics of electricity supply in your region. The non-volatile model will work even in the event of a power outage. If there are problems, choose floor-standing models. About half of them are energy independent.

The only drawback is the piezo horn, which must be done manually. However, in a situation with unstable energy supplies, you can turn a blind eye to this minus for the sake of stable operation of the boiler.

The advantage of non-volatile floor-standing boilers is that they can be used in regions with unstable power supplies. Since any wall-mounted boiler runs on electricity, problems will arise during interruptions

As for wall-mounted boilers, there are no options: they all require connection to the electrical network, and if you want to make the heating system non-volatile, you will have to additionally install a generator or UPS (uninterruptible power supply), which, of course, will result in additional expenses.

The automation of wall-mounted boilers is more advanced, so they are more convenient, safe and easy to use. For example, they are equipped with a frost prevention mode, protection against overheating, pump blocking, lack of traction, and self-diagnosis.

The process of heating water in mounted boilers is fully automated. Starting and stopping equipment, as well as interrupting work in the event of a dangerous situation occurs without the participation of the owners

Among the functional capabilities of floor modifications, gas control and overheating prevention should be mentioned. Auto-ignition is less common.

Here, again, the choice will depend on where the heating system will be installed and how often it will be used:

- Floor-standing boilers can operate with any coolant. Antifreeze is also suitable, so if you need to heat a dacha or a house where you do not live permanently, you should choose floor-mounted configurations with antifreeze as a coolant. This way you won’t have to worry about the system freezing or depressurizing.

- Wall-mounted appliances cannot run on antifreeze. The reason lies in the viscosity and fluidity of the substance, as well as its negative impact on the condition of steel or copper heat exchangers, which are used in mounted models.

If you focus on this criterion and decide whether to choose a floor-standing or wall-mounted model of a gas boiler, which unit is more reasonable to prefer, then floor-standing designs definitely win.

Mounted boilers always (even inexpensive ones) have simulated burners installed, while floor-mounted boilers have one- or two-stage ones.

Let's briefly explain what this means:

- Single stage. Those that can only be in the on or off position, and do not imply intermediate modes.

- Two-stage. They can operate at 50% or 100% power control.

- Modulated. The user can at his own discretion select the operating mode from 20% to 100% power.

The “ideal” mode is considered to be one in which fuel is constantly burned at minimum power. More advanced modulating burners allow you to more accurately set the temperature and use gas more economically.

Installation of floor-standing boilers requires the organization of a boiler room. Installation in a hallway or corridor with organized natural ventilation is acceptable. Most wall-mounted gas units are allowed in kitchens

As for the chimney, in 90% of cases with floor-standing boilers it has to be equipped separately. This is explained by the fact that they are equipped with an atmospheric burner and an open combustion chamber, i.e. the air that is taken from the premises must subsequently be “discharged” outside.

In wall-mounted models, the combustion chamber is closed, so air enters and exits through a coaxial chimney. Floor-standing models with a turbine burner also remove gas processing products using a coaxial system.

Installation of models with a two-pipe chimney is simple and less troublesome, but in case of severe frosts (from -15°C and above), condensation will form in it. This can lead to icing and stopping the heating system.

If hot water preparation is necessary, then it is better to supplement a floor-standing gas boiler with a boiler. You can purchase a floor-standing unit that heats both coolant and hot water, but in this case the quality of preparation is reduced

Power calculation formula

Performing a full calculation of the power of a heating system is difficult and beyond the power of a person who does not have special training. However, there is an easy way to determine power.

It has been experimentally determined that heating 10 m2 of area requires 1 kW of thermal energy. This means that a 24 kW boiler is designed to heat a house of 240 m2, and a room of 150 m2 will require 15 kW of power.

Guided by this ratio, you can quickly and accurately select the right boiler . It is necessary to take into account that it is impossible to make a large reserve of power - the unit will operate abnormally, which will cause the burner to constantly turn on and off.

This mode will create conditions for rapid failure of important components and parts of the boiler.

What to look for when choosing a gas boiler

There are many boiler selection criteria that you can consider before purchasing. If you don’t know enough about the issue, then a smart decision would be to read customer reviews and find out the opinions of experts. If you want to figure it out yourself, then you need to consider the following parameters:

- type of gas boiler (floor-standing, wall-mounted);

- heat exchanger material (steel, cast iron, copper);

- number of circuits;

- installation features;

- serviced area;

- energy dependence;

- power and so on.

Also pay attention to the conditions of use. An apartment and a country house, a store and an office, a warehouse and other facilities will require different gas boilers.

Criteria for choosing between two-circuit and single-circuit equipment

operating principle of a gas floor boiler

When preparing equipment for a heating system, owners often wonder about choosing between a double-circuit boiler and a single-circuit boiler. There is no clear affirmative answer to this question, and the model and class of equipment for heating the coolant are always selected according to the technical requirements of the room in which the system is installed. A gas single-circuit floor-standing boiler solves the dilemma in its favor in the case when the room only requires the use of a heating system. And of course, if necessary, double-circuit equipment is applicable for hot water heating premises.

With reduced needs for hot water, a characteristic indicator of the standard is the need for less than 15 liters of water per minute at a temperature of up to 30 degrees, it is recommended to use equipment with a flow-through water heating system.

If technical standards require the supply of water at a temperature of more than 35 degrees in a room, then floor-mounted double-circuit gas boilers with a boiler are the best option. This kind of equipment can fully provide any country house or cottage with the required volume of hot water.

The best wall-mounted atmospheric gas boilers

Lines from Italy, Korea, and the Czech Republic are considered industry leaders; world-famous brands provide a wide range of items.

BaxiECO4s

The Italian brand offers a range of wall-mounted atmospheric boilers with advanced electronic filling. Heating equipment is made in accordance with environmental safety requirements. Baxi units have an ergonomic design and are distinguished by their reliability, ease of installation and maintenance.

BaxiECO4s24

The model is included in the list of top sellers in 2020. The device is a double-circuit unit with an open combustion chamber, power 9.3-26.3 kW, heated area up to 240 m². The cost varies between 33,500-36,000 rubles.

BaxiECO5 Compact1.24

The fifth generation wall-mounted model is presented in the economy class category. Single-circuit boiler, power 9.3-26.3 kW, dimensions 730x400x298, cost from 31,000 rubles.

Dakon

The products of the Czech manufacturer are designed to help solve problems with home heating and hot water supply. DakonGLEco cast iron models with an atmospheric ejection burner are of particular consumer interest. The equipment is equipped with Honeywell electronics, a draft breaker, and additional additions are provided in the form of room thermostats, external sensors, and antifreeze devices.

NavienAce

The Korean brand offers wall-mounted atmospheric boilers that do not respond to voltage changes and function perfectly in the range of 155-220 volts. The unit is capable of operating at low pressure of gas fuel (within 4-16 mbar) and water (0.1 bar). The minimal dimensions and relative accessibility of the equipment also attract attention. NavienAceATMO double-circuit wall-mounted boilers are equipped with a natural system for removing combustion products, a chip that is triggered by changes in network voltage, and an automatic system that turns on the pump when the temperature drops to 10°C.

New 2020! The D2 series of pressurized combi boilers is already in mass production

June 3, 2019

We present the modernized boilers of the ZEUS Turbo series with supercharging (ZEUS - Turbo).

New for 2020! At numerous requests from our customers, we have launched mass production of modernized boilers of the ZEUS Turbo series with supercharging. The boilers are equipped with reliable and easy-to-control automation, as well as reinforced movable grate bars and a capacious loading hopper.

The boilers are equipped with a boost fan with an intelligent control unit for automatic operation of the air pressurization system with PID regulation. This allows you to supply the required amount of air into the combustion chamber for maximum efficient operation of the boiler and fuel economy.

Designed for heating residential and industrial premises with an area of 50 to 760 m2, equipped with forced circulation water heating systems

DISTINCTIVE ADVANTAGES:

- Solid fuel boiler of shaft type.

- Heat-loaded parts of the boiler are reinforced with steel from 6 to 10 mm, depending on the degree of load.

- The volume of the ash drawer has been significantly increased - from 15 to 35 liters, depending on the power. The volume of the new ash pan is designed for at least a day of boiler operation (depending on the ash content of the coal).

- Slag guides are installed - the slag does not spill past the ash box.

- The boilers are equipped with WPA - 117 boost fans and SP-30 PID control panels (with intelligent speed control). Flue gas sensor included.

- A fundamentally new mechanism for the slag cutter - movable cast iron grates. The grates are designed taking into account the coals used in our conditions. They have a reinforced structure and increased clearances. The new mechanism throws stones and slag into the ash box, thereby ensuring uninterrupted operation of the boiler without stopping for cleaning!

- Burning duration is up to 3 days*.

- Wide range of models: 8-10, 12-20, 22-30, 32-40, 42-54, 56-76 kW.

- The main type of fuel is COAL (black, brown).

- Possibility of installing a heating element unit 6, 9 kW, control panel (optional).

- Thermal manometer, draft regulator (optional).

- Possibility of two-way connection to the heating system (left, right or diagonal). Standard pipes with diameter G2.

- The boiler efficiency is more than 86%.

Sales start in June 2020!

You will find a more detailed description in the product catalog. You can order any product online by filling out the order form on our website or selecting a city near you to purchase in the “Where to Buy” section.

We invite trading wholesale and retail companies to cooperate!

The best floor-standing atmospheric boilers

This segment presents samples of domestic production, Italian and German series.

BaxiSlimEF1.22

The power of the device is 22 kW, the device is optimal for heating an area of up to 200 m², dimensions 850x400x595, sold at a price of 52,000 rubles.

BaxiSlimEF1.61

Model with a power of 60.7 kW, heated area up to 580 m², dimensions 850x400x870, cost within 84,000 rubles.

TitanN30E

Single-circuit non-volatile device with a power of 24 kW, heated area up to 280 m², dimensions 940x295x570, cost varies between 38,000-40,000 rubles.

TitanZ30E

Domestic floor-standing gas installations of the TitanZ series are designed to service autonomous systems with coolant pressure up to 0.3 MPa. The TitanZ30E model with a power of 22 kW of single-circuit design is capable of heating an area of up to 220 m², unit dimensions are 940x295x570, the products are sold at a price of 39,500-41,900 rubles.

RodaKrafterEvoRmod30

The model is single-circuit, belongs to the list of top sellers in 2020. The power of the unit is 31.2 kW, the potential of the heating device is designed to serve an area of up to 300 m², the heat exchanger is cast iron sectional, dimensions 910x450x475, cost from 61,000 rubles.

RodaKrafterEvoRmod60

A new modification of the device with a power of 60.5 kW, a single-circuit model with a sectional cast-iron heat exchanger, is capable of heating an area of up to 550 m². Dimensions 910x450x700, product cost from 83,000 rubles.

comparison table

When choosing a gas boiler for an apartment or house, you should first of all proceed from its technical characteristics. You can compare them using our table.

Model Thermal power, W Efficiency, % Volume of expansion tank, l Natural gas consumption, cubic m/hour Average price, rub.

| Navien DELUXE 13K | 7–13 | 91,7 | 6 | 1,4 | 31 774 |

| Buderus Logamax U072-12K | 5,4–12 | 92 | 8 | 2,1 | 36 995 |

| Bosch Gaz 6000 W WBN 6000-18 C | 5,4–18 | 93 | 2,1 | 35 065 | |

| BAXI ECO-4s 24F | 9,3–24 | 92,9 | 6 | 2,73 | 36 339 |

| Lemax PRIME-V20 | 9–20 | 92,5 | 2,27 | 35 857 | |

| Viessmann Vitopend 100-W A1JB010 | 24 | 91 | 2,77 | 39 227 | |

| Vaillant turboFIT VUW 242/5-2 | 9,7–23,7 | 93,5 | 7 | 2,66 | 39 828 |

| Ariston CARES X 24 FF NG | 11–25,8 | 93,7 | 8 | 2 | 38 025 |

| Protherm Cheetah 23 MTV | 9–24,6 | 93,2 | 5 | 2,9 | 41 568 |

| BAXI LUNA-3 240 Fi | 9,3–25 | 92,9 | 8 | 2,84 | 67 526 |