The need for isolation

Measures to insulate pipes are carried out not only to retain heat if the main is heating or is intended for hot water. Insulation is also necessary in order to achieve the following goals:

- the absence of condensate on the pipes has a beneficial effect on the service life of the pipeline;

- in case of stagnation, that is, if the pipeline has not been used for a long time, the insulation prevents it from freezing in the winter;

- insulation can perform a protective function against corrosion.

In this way, it is possible to increase the pipeline efficiency and service life.

Insulation of hot heating pipes

Communications intended for transporting hot water must be wrapped in materials that have a low thermal conductivity coefficient. This is necessary to ensure that there is no large heat loss along the way from the heating element to the final destination. The following materials are popular:

- Foam-polymer-mineral pipe insulation (PPM) is obtained by foaming polyurethane foam and mixing it with a mineral filler. This type of material is used exclusively for hot water lines. PPM consists of three layers, thanks to which it perfectly maintains the temperature inside the pipe and has high strength, which is important for protection from external mechanical damage.

- Polyurethane foam (PPU) is most often used to enhance the waterproofing properties of communications. A pipe in PPU insulation has good resistance to temperature changes, both internal and external. This material also provides low heat loss - up to 5%. A pipe in PPU insulation is slightly susceptible to corrosion, so it has a long service life.

- Very reinforced insulation (VSI) is ideal for operating pipelines in unfavorable climatic conditions. It gives the line additional resistance to corrosion.

Pipe insulation can be either external or internal. The first is used much more often due to the relative ease of installation, long service life, and ease of replacement. The thickness of the pipe insulation depends on the diameter of the line itself, as well as its purpose.

Pipe insulation with galvanized steel, installation features

Galvanized steel insulation is intended to protect utility networks, pipelines and insulation layers from atmospheric influences, condensation, fires, mechanical damage, and reduce heat losses. It gives the structure a complete aesthetic appearance and extends its service life. It is made from sheet metal with a thickness of 0.55 mm. The service life of the metal casing exceeds the durability of mastic plaster (12 and 5 years, respectively). They are produced in the form of cylinders and shells of different diameters, allowing you to select the optimal solutions for each pipeline.

The length of the shells and cylinders is equal to the length of the outer layer of insulation; an additional allowance of 30-50 mm is made to form a reliable longitudinal seam. To give the structure increased rigidity and an aesthetic appearance, the edges are usually beveled. The dimensions and location of the ridges are selected depending on the outer diameter of the pipe along with the insulation layer.

If the casings come into contact with aggressive environments, acidic and alkaline substances during operation, the surface needs additional treatment: painting with special enamels.

Pipeline insulation with galvanized steel is used in commercial and residential real estate, enterprises, and in cold and hot water supply systems. The performance indicators of the casings include:

- resistance to mechanical loads;

- low thermal conductivity coefficient;

- resistance to moisture and corrosion;

- non-flammability.

During the installation process, the individual segments are connected to each other by snapping special grooves into place. Additional strength and reliability of the structure is provided by bandage tapes or constrictions. Engineering communications have a complex spatial configuration: different geometric shapes, transitions. To simplify the installation of the casing, special shaped elements are used:

- bends,

- tees,

- transition cones,

- plugs, etc.

They allow installation of structures of any complexity.

offers solid molded products and shaped elements of any diameter. Managers will help you choose suitable solutions for each facility. To contact us, use the information provided in the “Contacts” section.

regionizolaciya.ru

Cold water piping materials

Highways that are not exposed to high temperatures require the following types of external treatment:

- Basalt fiber is easy to install and has high speed. In addition, it has a relatively low cost.

- Foamed rubber (FC) is resistant to temperature fluctuations and is also fire resistant. Its porous structure allows the fire to go out on its own when ignited.

- Mineral mats consist of mineral wool and are a large and wide canvas. They are ideal for insulating large diameter pipes. Mineral mats can be stitched, foil or laminated.

- Fiberglass is used exclusively in combination with other insulating materials, such as fiberglass.

- Foamed polyethylene (FPE) is produced in the form of tubes of different diameters. It is environmentally friendly, tolerates temperature fluctuations, does not react with aggressive chemicals, and its use prevents the formation of mold on pipes.

The choice of a specific material for pipe insulation depends on the requirements for it. The modern market is able to provide a large selection of insulation materials. It all depends on the available budget, type of communications and installation skills.

Requirements for materials for thermal insulation

Pipeline insulation technology involves the use of a fairly wide range of materials. There are many factors that go into selecting the most suitable applicant. These include:

- the purpose of a particular highway;

- climatic features of the region;

- coolant temperature;

- location of the route;

- pipeline diameter.

An important factor is operating conditions. For example, for underground communications, insulation materials are selected that are not afraid of constant contact with destructive moisture. If the material will protect heating pipes, then the requirement is different: it should not be attractive to rodents, who like to stay where it is warm and comfortable in winter.

However, that's not all. Regardless of the type, pipe thermal insulation material must meet several requirements; it must:

- ensure the simplest possible installation, regardless of the degree of readiness of the pipeline: just under construction or already in operation;

- have a low thermal conductivity coefficient in order to be able to retain cold and store heat;

- not only not to be afraid, but also not to absorb moisture, which significantly worsens the insulation properties;

- be able to withstand any mechanical influences, chemicals;

- be fire resistant or at least have a “tendency” to self-extinguish;

- have sufficient heat resistance.

The ability to remain effective throughout its stated service life is another important criterion. Not many materials can satisfy all these requirements, so the list of candidates is somewhat limited.

Insulation of heating networks

Heating mains are designed to deliver hot water from the boiler room to the final destination. However, they should not lose heat in the process. Insulation of steel pipes is made from the following materials:

- Mineral wool. It has a low thermal conductivity coefficient and is resistant to combustion. The only drawback of the material is its high cost.

- Polyurethane foam (PPU).

- Expanded polystyrene (EPS) is a special foam plastic that is used for reinforced pipe insulation.

- Foamed polyethylene.

In addition, modern technologies suggest using paint and varnish coating as an insulating material, which has thermal insulating properties.

Materials for the production of insulation for steel pipes

The shell for steel pipes is a universal insulation material, the price of which is quite affordable for all segments of the population - a cylindrical shell made of polystyrene foam, polystyrene foam, polyurethane foam.

Sewer shell has significant advantages over other insulating materials. Among the main advantages of PPS and polyurethane foam for thermal insulation are:

- low thermal conductivity;

- a light weight;

- low water absorption coefficients;

- resistance to microbial insemination;

- fire resistance.

Insulation of external sewer steel pipes with foamed polyethylene and fiberglass is accompanied by mandatory wearing of protective suits. Applying foam glass shells is a quick and easy process, but its price is much higher. Insulation for sewer pipes is also selected according to thickness, diameter, and location of structures.

Gas pipeline insulation

Pipelines for small-diameter flammable substances are most often treated with paint and varnish coatings. While large-diameter gas pipelines require better treatment. It is necessary for protection against corrosion and ultraviolet radiation. There are the following types of pipe insulation:

- Bitumen mastics with various additives, which can be polymer, mineral and rubber. They are stable at low temperatures and have good adhesion to the pipe.

- Tape insulation of pipes with polyethylene or polyvinyl chloride has proven itself in conditions with unfavorable climates.

The main function of insulation for gas pipelines is protection against corrosive and chemically active substances.

Pipe insulation

It is impossible to imagine modern heat and water supply systems without insulation. A competent choice of insulating material guarantees savings, longevity of the system and safety of the systems. Our store offers customers four types of insulating materials, each of which has its own characteristics and advantages.

PPU insulation

At the moment, polyurethane foam is one of the most popular and sought-after materials for thermal insulation. Increasingly, pipes began to be produced with a “built-in” PPU shell.

The durability of polyurethane foam insulation breaks all records - manufacturers claim that even after half a century the insulation will retain all its properties and perform its job efficiently.

The advantage of this type of shell is the ability to work at both high and low temperatures, which is extremely important for our climate. With a low level of moisture absorption, polyurethane foam is not afraid of frost and sudden changes in weather conditions.

VUS insulation

For underground main pipelines, such as gas or oil pipelines, sewer systems, VUS insulation (very reinforced) is used to protect against corrosion and temperature changes. The pipe is insulated in two stages - first - adhesive base - primer. The second is outer, extruded polyethylene, which does not allow moisture to penetrate the steel pipe.

VUS insulation has replaced bitumen insulation, as it has a number of advantages. First of all, the application technology allows us to give a very high-quality result that meets modern GOST standards. This coating ensures high resistance to mechanical damage. In order to destroy the integrity of the insulation, it is necessary to hit a pipe weighing at least 2.1 kg. In our climate, VUS insulation can last at least 30 years, ensuring trouble-free operation of the pipeline.

PPM insulation

Foam polymer (PPM insulation) is a foamed polymer filled with minerals. Excellent for heating networks - after all, such an insulator can be used at temperatures up to 150 degrees and operating pressure up to 2.5 MPa. The peculiarity of this type of insulation is vapor permeability, which means that if moistened, it is capable of self-drying. PPM perfectly insulates the pipe, increases its service life and brings significant savings.

Bitumen-polymer tape LITKOR

LITKOR is a self-adhesive polymer film that performs heat and waterproofing functions. It is made by combining mastic from bitumen and polymers and a base film. Also, a protective anti-agdesion coating is applied to the LITKOR bitumen-polymer tape using a mechanized or manual method. A distinctive feature of this insulating material is its high efficiency with no requirements for surface preparation - you can apply the tape to a cold pipe in winter without additional heating. The mastic layer is very plastic and fills all the irregularities and welds on the pipes. Among other things, LITKOR bitumen-polymer tape is an excellent dielectric.

You can purchase all these types of insulation from us at the best prices - the products offered have the appropriate quality certificates, we guarantee high quality service and fast delivery. Contact our manager and we will answer all your questions.

More detailed information about products and prices can be found using the feedback form on the website

or in the sales department by phone.

Insulation of underground gas pipeline

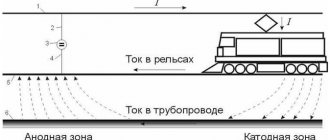

Communications that are located in the soil must have special protection, since they are susceptible to corrosion due to soil moisture, as well as to the effects of stray currents that can arise if roads or power cables are close to each other.

Polyurethane foam is most often used to insulate gas pipes, as it has ideal characteristics for protecting the pipeline located in the soil. It can be mounted in the following ways:

- preliminary insulation, which is applied in the factory during the manufacture of pipes;

- application of insulating materials during installation of communications.

The first method is considered much more reliable, since such lines are more reliable and durable in operation.

Rules for applying anti-corrosion insulation

Corrosion processes destroy metal pipelines at high speed. To prevent destruction, the pipes were initially simply primed. Today, in addition to primers, bitumen-polymer tapes and wrapping films are used to protect the metal surface. Despite the increased costs, such protection is considered economically feasible, since it increases the time between repairs, which is especially important for long-distance pipelines. For these purposes, Litkor, Pirma tape and Polylen film are actively used. However, to ensure effective insulation, not only high-quality insulating material is required, but also its correct installation.

The main operations for pipeline insulation are:

- Preparation of insulating material;

- Pipe preparation;

- Applying primer/primer;

- Application of insulation;

- Quality control of the resulting protective coating.

Cleaning the metal surface, removing protrusions, scuffs and drying are the main technological processes for preparing the pipeline for the application of anti-corrosion material.

Today, more and more often, during the construction of main pipelines, pipes that have undergone insulation under stationary conditions (in the workshop) are installed. Naturally, insulation of this type is superior to insulation in highway conditions. However, if such protection is not available, then Pirma or Litkor tape can be used. To do this, the metal pipe is cleaned from dirt, soot and scale using mechanical and manual means. If there are greasy stains on the pipe, the surface should be degreased. If necessary, dry the surface.

Immediately after cleaning the surface of the pipeline, it is necessary to begin applying insulation. To do this, the primer (primer) is thoroughly mixed to prevent the presence of lumps and other inclusions. The primer layer should be uniform and continuous. Gaps, leaks and bubbles are excluded. The consumption of primer material depends on the surface roughness. Depending on factors, consumption can range from 0.15 to 0.22 l/m2. To obtain an economical and high-quality layer, the primer application machine must be equipped with a rubbing towel, which will prevent the occurrence of streaks and leaks.

Next, depending on the material used (insulating tapes or Polylen 40 or 63 film), the roll of material is installed on the bobbin holders of the machine. However, before directly applying the insulation, it is worth checking and, if necessary, adjusting the tension force of the wrapper or film. You can also adjust the amount of overlap.

Bitumen-polymer tape Litkor, Pirma is applied to the metal surface with a mastic layer to the pipe, with a certain tension. The winding is performed in a spiral manner, eliminating wrinkles, distortions, corrugations, and sagging. The turn in this case is 20-25 mm if the application is single-layer. With a 2+1 application pattern, the overlap is at least 50%. Polylen wrapping film is applied with an overlap of 15-20 mm.

When installing a new roll of insulating anti-corrosion material (Litkor, Pirma, Polylen, etc.), it is recommended to carefully lift the end of the applied insulation by 25-30 cm and lay the beginning of a new insulating roll. It is important to ensure that the material is straightened and does not have wrinkles. To do this, the ends of the canvases must be pressed tightly and carefully smoothed. When performing manual laying, the end of the web is held by hand until a turn is applied from a new roll. The insulated section of the pipeline must be covered with soil no later than 2 hours after applying the insulation.

Installation features

Different types of thermal insulation have different installation technologies:

- Cylinders made of basalt fiber are a composite element, so after their installation it is necessary to secure them with clamps. A protective plastic casing must be placed over the material. Foil basalt cylinders are sealed using aluminum tape and also require additional protection.

- Polyurethane foam is a rigid material that has a “shell” appearance. It is put on the desired pipe and fixed with grooves. Polyvinyl chloride film or aluminum foil is used as a protective material. Such insulation can be installed at any time of the year with minimal humidity. To secure the parts of the “shell” together, a special glue is used, which is used to coat the joints of the grooves. The taped seams are sealed using aluminum tape.

Glass wool and mineral mats are wrapped around the pipe and secured with tape or protective covers.

Do-it-yourself pipe insulation

For DIY pipe insulation, simple materials are used - mineral wool, foam rubber or foamed polyethylene. The last two types are available in the form of a soft casing that is simply put on the pipe.

When doing the work yourself, you need to take into account the following nuances:

- First, the pipes must be glued in a spiral with aluminum tape;

- after which the line is wrapped with insulation;

- The final stage is external fixation using construction adhesive tape.

When doing insulation yourself, it is important to select the material according to its properties, as well as the purpose of the pipeline.