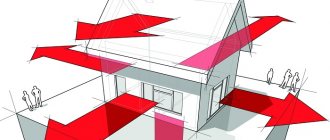

Autonomous heating systems for a private home, created on the basis of gas boilers, are considered the most efficient and economical.

They allow you to solve heating problems in the absence of the ability to connect to centralized networks, and in some cases, users themselves prefer to create their own independent system.

The number of manufacturers producing heating gas boilers is large and constantly growing.

European companies are recognized leaders in this area, but the developments of companies from the countries of the former USSR are beginning to squeeze them out in the market.

The reason for increasing competitiveness is our own conceptual approach to the manufacture of gas boilers, which can be considered using the example of Danko floor-standing models.

Floor-standing single-circuit gas boilers Danko

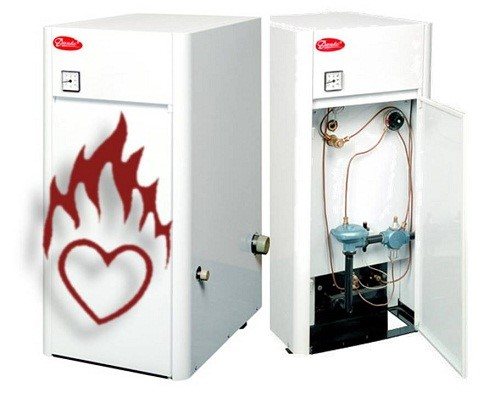

Danko is a brand owned by PJSC Agroresurs, which is based in the Ukrainian city of Rivne.

The company creates heating boilers, guided by the principles of equipment availability, resistance to weather and climatic conditions, technological features of gas and water supply.

The main direction that allowed us to successfully promote our products on the market was the exclusion from the design of all minor and unused parts and assemblies, of which there are too many on European models.

This not only reduces the price, but also reduces the risk of boiler breakdowns or failures, which can become a very serious problem in winter. The company's products are aimed at the mass consumer; the boiler power level is optimal for use in small and medium-sized private homes.

There are non-volatile models that increase the reliability of the heating system, but require some changes in the configuration of the pipelines to ensure natural circulation of the coolant.

Review of the Danko-8 gas boiler after 6 years of use

The Danko-8 gas boiler was installed in 2006 in a private house with an area of 60 m2. Before this, the heating was powered by AGV-70. The need to change the boiler arose for several reasons:

- The old boiler did not provide sufficient temperature in the house.

- Faulty automation.

- The appearance of the AGV-70 and its dimensions did not fit into the room. I wanted something more aesthetic.

Selection and purchase

When choosing a new boiler, I was guided by several points:

- Price. The cost at that time was a little more than $300, although there were cheaper models.

- Compliance with the chimney of a private house.

- Lack of electronics.

- Possibility of independent installation and launch.

- Availability in city stores.

Compared to other similar options, this one looked more reliable. For example, “Aton” seemed half the size and it was hard to believe that using a small heat exchanger it could easily heat the required area.

Installation and launch

I planned to install and connect it myself. The work was carried out in the summer. After purchase and delivery, it took two people to bring it into the house. The unit turned out to be quite heavy even for two.

When connecting, I was guided by the following:

- The heating system in the house is made of two-inch pipes around the perimeter. For a major connection it was necessary to carry out welding work, and after the repair I didn’t really want to do this.

- In the near future it was planned to change the system in order to reduce its volume. Therefore, the connection was made temporary, but, as the proverb says, “there is nothing more permanent than temporary.” Still in use today.

- The circulation of water in the pipes occurred naturally, so there was a large difference between the inlet and outlet temperatures. Most likely, this also greatly influenced the heating efficiency. Therefore, it became necessary to use a pump.

Therefore, for installation I used a 3/4-inch metal-plastic pipe and adapters for moving from the boiler pipes to the system pipes and the pump installed at the inlet.

I did not alter the gas pipe; I connected the boiler through a flexible hose. For the gas outlet to the chimney I used a flexible corrugated pipe.

The first launch was quite intense:

To ignite the boiler, a piezoelectric element is used, which gave a spark when clicked, but the wick ignited after the fifth time. After turning the temperature regulator, gas began to flow to the burner, but did not ignite for quite some time. As a result, the boiler turned on with an unpleasant sound.

After starting the boiler, the worries stopped. The gas burned with a powerful, even and stable flame. I didn’t time the system’s warm-up time, but compared to the AGV-70 it warmed up faster.

Advantages and disadvantages

At the end of the heating season with new equipment, I summed it up:

- Gas consumption has decreased significantly. If earlier more than 500 cubic meters were consumed, now even in the coldest month it is about 300. Although I cannot attribute this merit only to Danko-8, since changes have been made to the system. Forced circulation using a pump made the temperature difference at the inlet and outlet minimal.

- It became much warmer. Even on the coldest days, the temperature in the house did not drop below 23 ºС.

- Trouble-free operation.

Overall I was pleased with the performance of the new boiler.

Advantages:

- I really liked that the KAPE automation makes it possible to regulate the temperature in the system smoothly up to 1 ºС. It is very easy to set what you need, especially with minor weather changes. This is a big plus compared to step adjustment.

- Maintains a stable temperature by switching on/off frequently. At first, this moment seemed suspicious to me. I thought that with this mode of operation the automation would quickly fail. But according to a gas worker friend, it turned out to be the other way around.

- Does not depend on electricity. This is especially true in the private sector, where there are regular interruptions in the quality of electricity (during peak load hours, the voltage is less than 190 V, which is unacceptable for electronic systems).

- Large power reserve for an area of 60 m2.

Flaws:

- I especially don’t like starting a cold boiler. The wick from the piezoelectric element does not light well; you have to click it many times. It is often faster to light a match, but this is not very convenient: the window into which you need to stick it is too small.

- In an awkward position, you need to hold the valve button for 20 seconds while the thermocouple warms up. The spring of the button is quite tight, so after 20 seconds the finger goes numb.

- Loud ignition of the burner on a cold boiler, as gas enters, but does not ignite immediately from the wick.

- When there are strong gusts of wind, the burner sometimes goes out. But this happens rarely and the reason may be not in Danko, but in the chimney. Although this was not noticed with the AGV-70 without automation.

During the first 6 years, Danko worked flawlessly. Before the seventh season, problems arose: in the fall, after the first launch and a short burning, the protection worked. As it turned out later, the reason was the oxidation of the thermocouple and insufficient heating from the wick. After cleaning, the boiler worked for a season without any problems, but before the next season the situation repeated itself.

Results

Knowing all the shortcomings and taking into account the uptime, if I had to make a choice again in 2006, I would most likely purchase this particular boiler.

More reviews on boilers:

- Gas double-circuit boiler in a private house - heated by Vaillant

- Review of the Viessman Vitopend 100-W gas double-circuit boiler after two years of operation

- Combination boiler Teplodar OK 15

- Review of the gas boiler Zhitomir-3 from the Atem company

By Blogsdna

Types

Danko floor-standing boilers can be divided into two groups:

- Single-circuit. They are intended only for supplying coolant to the home heating system.

- Dual-circuit. Capable of preparing hot water for domestic needs simultaneously with the supply of coolant.

Most users believe that double-circuit boilers are much more convenient and efficient than single-circuit boilers. However, this statement is only true for families with a relatively small need for hot water.

The boiler's performance allows for limited hot water consumption; with large water consumption, the temperature will drop, which is inconvenient and uncomfortable for users. Therefore, many people prefer to install single-circuit models and connect an external indirect heating boiler to them.

This addition allows you to significantly increase DHW performance and stabilize the operating mode of the system as a whole.

Danko gas boilers

The owner of the Danko brand is Agroresurs PJSC from Ukraine. The company simultaneously creates several types of heating equipment, the popularity and demand for which among users is steadily increasing.

The production facilities where Danko boilers are manufactured are located in the Ukrainian city of Rivne.

The company set as its goal to create a reliable, durable and durable gas boiler that has all the necessary functionality combined with a low price.

Ukrainian engineers were able to cope with this task, implementing a wide range of affordable and efficient gas units. It was possible to achieve high productivity, reliability, and eliminate unnecessary or unclaimed components and parts.

In parallel with high efficiency, the developers were able to reduce prices, which made Danko units available to a wide range of users.

Danko gas boilers are produced in various structural types, which can be divided into groups according to general characteristics.

By installation type:

- Floor-standing. Installed on a special non-flammable stand or directly on the floor.

- Wall-mounted. Wall-mounted installation, on load-bearing walls or special metal support structures (Ramps).

- Parapet. These are non-volatile units with a hinged installation type. They differ from wall-mounted ones in some features of connection to the chimney and the need to ensure a slope of the heating system pipelines, ensuring natural circulation of the coolant.

By feature set:

- Single-circuit. Designed exclusively for heating the coolant and supplying it to the heating circuit.

- Dual-circuit. Capable of simultaneously heating the coolant and preparing hot water for domestic needs.

By type of combustion chamber:

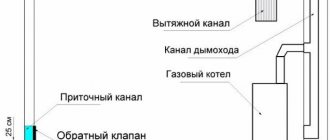

- Open (atmospheric) . Air intake for normal combustion is carried out directly from the room in which the boiler is installed. Smoke is removed naturally using a stove-type draft.

- Closed (turbocharged) . Air intake and smoke removal are performed using a turbocharger fan.

In addition, there are models with a steel or cast iron heat exchanger.

Also, in some series of units, different types of automatic control of the operation of the gas unit can be used:

- Kare (Poland) . Manufactured specifically for installation in Danko boilers. The kit includes a reducer, valves, a thermostat and pressure, draft and boiling sensors.

- Honeywell (USA) . High-quality electromechanical gas supply control units, which are installed in the most advanced models of gas boilers.

- Sit (Italy) . Automatic control units for gas equipment, used in most European models of gas boilers.

The range of Danko boilers is wide; the user has the opportunity to choose the best option for any area and operating conditions.

Advantages and disadvantages

The advantages of Danko floor-standing boilers include:

- The design of the units is optimized for maximum efficient and economical operation in all conditions.

- Boiler components and parts are made of high-quality materials using modern equipment.

- Fuel consumption is reduced by one and a half times compared to products from other companies.

- The units are designed for a long service life.

- Attractive appearance, compact size.

- Relatively low price.

The disadvantages of Danko boilers can be considered:

- Demanding requirements for water quality, the need to use softening filters.

- Requires annual inspection and maintenance.

- There are often cases of random flame extinction due to the backdraft effect.

NOTE!

The disadvantages of Danko boilers can partially be overcome through proper installation, and are partially a specific design feature.

How to choose a boiler for your home

Agree, without understanding technology it is difficult to make the right choice. Especially when there is a huge variety of similar products on the market. Once you look into the store, many questions immediately arise: which boiler is better, domestic or imported? What price is acceptable for this equipment? How economical is the boiler you have chosen?

Of course, for most consumers these issues are not so important; the main thing is the quality and durability of the product.

But, in any case, it is necessary to combine not only the properties described above, but also such characteristics as:

- Energy consumption.

- Power.

- Efficiency.

- Reliability.

- Appearance.

Find out also why you need antifreeze fluid for your heating system.

Imported or domestic

Any product is divided into Russian and European, which is usually taken as a standard. But is this really so?

Yes, we are used to trusting Western products, because they guarantee long service life and reliability of the entire system.

- In the case of the Danko company, this question is not relevant - all boilers are developed using European technologies, which puts them on the same level as famous brands. On the other hand, there is an advantage that for many plays an important role in choosing boilers - cost.

For your information! Many Russian companies can offer analogues to this product, offering identical models outwardly, but they have one distinctive feature - the workflow. Only Danko gas heating boilers have a license to use European technology; domestic organizations are “stingy” to purchase Western developments.

- The boilers of the Ukrainian company Danko are designed for operation in harsh Russian conditions, the entire system is adapted to the use of low-quality gas. Unfortunately, this is not uncommon in our country, so it greatly affects the service life of the boiler.

- Production technology allows for increased heat transfer due to improved insulation. Special sealants are used in all areas of the equipment, which remain in an aggregate state even under high pressure and temperature.

- Gas consumption is reduced due to reduced heat loss. This point is not inherent in every boiler, especially those produced in Russian organizations.

Economical

Note! We have already mentioned that low-quality gas is not an obstacle to the operation of the Danko boiler, but we will say it again - after all, such gas often increased fuel consumption. By choosing a product from a Ukrainian company, you remove this problem from yourself.

Assembly

Leading boiler factories use products from other organizations that specialize in certain parts. That is, one company is engaged in the final point - assembly, and another is engaged in the production of important elements for this process.

Danko gas boiler “in cross-section”

Important! This is worth paying attention to, since most domestic products indicate only one manufacturer's name. Thus, they confirm the use of low-quality elements, which are purchased from small organizations that grind boiler elements with files.

The Danko company has everything included:

- The automation system is supplied from Italian factories.

- A gas heating device is being developed in Poland.

- The copper flow coil is manufactured in Germany.

Using a German product is already half of a successful workflow

- Boiler models are made from high-strength cast iron in the Czech Republic.

As you can see, the Ukrainian ones here are only assembly instructions and setting up the workflow for Russian winters.

Read also about the use of solid fuel heating boilers for summer cottages.

What series and models are floor-standing

The range of Danko floor-standing boilers is wide and includes several series.

Household models include the following lines:

- Danko SR or VSR . This is a series of single- and double-circuit domestic heating boilers with a 3 mm thick steel heat exchanger. Includes models with a power of 8, 10, 12, 15, 18, 20 and 24 kW. They are capable of heating houses with an area of 80 to 250 m2, which corresponds to the usual size of a private house.

- Danko SN and VSN . The units of this series have increased power, ranging from 30-48 kW. The main design features are the same - single- and double-circuit gas boilers with a steel heat exchanger.

There is also a series of Danko gas boilers with a cast iron heat exchanger. They are more massive and heavier due to the dimensions of the cast iron container, and have increased efficiency.

The ability of cast iron to transfer heat is higher than that of steel, which makes boilers more efficient and powerful.

There is a series of boilers for use in large industrial or public premises, the power of which reaches 96 kW. They are capable of heating up to 900 m2, and when connected in a cascade, the capabilities of the units increase accordingly.

Classification

Like many manufacturers of gas boilers, it offers several positions that differ from each other in design and thermal energy generation capacity.

But the main criterion for separation is the installation method, where, as always, there are two types: floor and wall. Both options are on the market today, but statistics show that the Danko floor-standing gas boiler is currently more popular than its wall-mounted counterpart. Why?

- Firstly, it has a large power range: 8-50 kW.

- Secondly, in this category there are single-circuit and double-circuit models.

- Thirdly, this type of heating equipment can operate on both natural gas and a liquefied version.

Let's make a small comparison of different models with the same power; for this we will present you with a table of technical characteristics of Danko gas boilers. To do this, we will use a comparison of a 10 kW device.

| Indicators | Danko-10 | Danko-10V | Danko-10S | Danko-10VS | Danko-10s (liquefied gas) | Danko-10Vs |

| Number of circuits | 1 | 2 | 1 | 2 | 1 | 2 |

| Efficiency | 92 | 91,5 | 92 | 91,5 | 92 | 91,5 |

| Coolant temperature | 90 | 90 | 90 | 90 | 90 | 90 |

| System pressure, MPa | 0,15 | 0,15 | 0,15 | 0,15 | 0,15 | 0,15 |

| Gas consumption m³/h | 1,2 | 1,2 | 1,2 | 1,2 | 0,432 | 0,432 |

| Heat exchanger material | Steel, 3 mm thick | Steel – 3 mm | Steel – 3 mm | Steel – 3 mm | Steel – 3 mm | Steel – 3 mm |

| Combustion chamber type | open | open | open | open | open | open |

In those models where a cast iron heat exchanger is used, the “LS” marking is installed. “OK” models are equipped with Polish automatic equipment and a steel heat exchanger with a wall thickness of 2 mm. That is, there are practically no differences, and all other indicators are the same. The only difference is the power of the heating unit, and accordingly the overall dimensions.

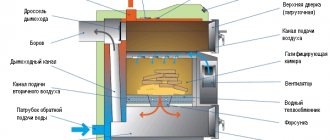

Construction of a Danko gas boiler

Attention! All gas boilers of the Danko brand are energy-independent devices. This made it possible to use this type of equipment in conditions with periodic power outages in consumer homes.

Gas boilers with a closed combustion chamber

There are also models with a closed firebox in the Danko gas boiler model line. This is modern equipment with excellent technical and operational characteristics. For example, the Danko-23 ZKE model. This is a double-circuit boiler, in the design of which two heat exchangers are installed: the first is made of copper, with its help the coolant for the heating system of the house is heated, the second is made of stainless steel for heating water for the hot water system. By the way, the second heat exchanger is a plate design with a larger heating area.

Why did we highlight this model?

- The manufacturer used innovative technologies in its design that affect the quality of operation of the device and economical fuel consumption.

- This device is light weight and compact in size.

- Let's add various functional features of the device. For example, this unit works great under conditions of low gas and water pressure.

- And the last plus is the laconic external design, which allows you to fit the gas boiler into any interior of the room.

Experts generally believe that in the model range of the Danko brand, this particular model is considered the most advanced and perfect today.

Unusual design

Specifications

Let's look at the parameters of Danko floor-standing gas boilers:

| Parameter | Meaning |

| Boiler type | Gas heating |

| Installation method | Floor |

| Fuel type | Natural gas, conversion to liquefied gas possible |

| Heat transfer type | Convection |

| Functionality | Heating, hot water preparation |

| Efficiency | 92 % |

| Unit power | 8-48 kW |

| Power supply | Absent, some models are connected to a single-phase network 220 V 50 Hz |

Master class: cleaning a floor-standing gas boiler

Why is the gas boiler knocking? Why is the heating boiler knocking? Let's look at the main causes of knocking in a gas boiler. Adjusting the flame of the main burner of a gas heating boiler equipped with eurosit automatic equipment. Flushing the heat exchanger of a gas boiler. Spare parts for gas boilers and water heaters in Kotel.

The boiler does not reach temperature.

Adjusting the main burner flame. Search titles only User posts: Separate participant names with a comma. Newer than: Search this topic only Search this section only Display results as topics. Quick search.

Device

The design and structure of Danko gas boilers are based on the latest developments, to which only minor amendments have been made to eliminate unused or minor functions and components. The main elements are the heat exchanger-gas burner connection .

They work in pairs and prepare coolant for the home heating system. Hot water is heated in a secondary heat exchanger due to partial extraction of coolant energy.

The final preparation of the liquid occurs in a three-way valve, which mixes the cooled return flow with the hot coolant in a given proportion, after which the heating agent enters the heating circuit.

Smoke removal occurs naturally using draft in the chimney, and circulation is provided either by an external pump or it occurs naturally.

Gas floor-standing boiler Danko 12 C / SR (KSG-12) for heating

Gas heating boiler Danko 12 C/CP with a power of 12 kW with Sit (Italy) and is intended for heating a house or other premises with a total area of up to 110 m2. Danko KSG (SR) steel gas boilers are manufactured with a vertical flue for exhaust gases, the diameter of which is only 110 mm , which is a feature and very convenient when installing the boiler. The main welded tubular heat exchanger is made of high-quality steel with a thickness of 3 mm. The heat exchanger gas ducts are made of a larger number of smoke tubes into which screw turbulators are inserted. As a result, this helps to ensure maximum temperature selection of the exhaust flue gases, which in turn ensures rapid heating of the coolant in the heat exchanger and maximum boiler efficiency. To complete the boilers, the following are used: automatic safety and regulation: SIT; imported injection low-flame burners made of high-quality heat-resistant stainless steel, which ensure complete combustion of gas and a stable flame even when the gas pressure drops to 635 Pa. Boilers of this series do not require any additional maintenance or consumables. The above parameters allow us to say with confidence that Danko gas steel boilers are completely environmentally friendly. In modern gas supply conditions, Danko energy-saving boilers ideally meet user requirements. When installing a circulation pump, more uniform heating of the heating system is achieved, thus ensuring indoor comfort with less gas consumption.

Danko boilers are notable for the fact that all models:

- have a 3 mm steel heat exchanger;

- operate on natural gas, but at the same time have the ability to convert to liquefied (cylindered) gas;

- non-volatile, i.e. do not depend on the source of electricity;

- have a vertical chimney arrangement, which significantly saves space when installing the boiler;

- silent in operation;

- work ideally at nominal or high gas pressure in the network;

- have automatic safety and regulation “Sit” (Italy), which not only makes it easier to start the boiler, but also ensures high safety;

- imply the presence or absence of a hot water supply (DHW) function;

- designed for operation in open and closed heating systems;

- fully adapted to various working conditions in Russia;

- have a 3-year warranty, which is provided not only for the boiler itself, but also for its components;

- have a unique design, patent protection and quality certificates of the Russian Federation.

Design of the gas heating steel boiler Danko 8CP...18CP The boiler is made in the form of a floor-mounted rectangular cabinet, the front side of which is closed by a door that provides access to start the boiler into operation. The stamped welded steel flue is used to remove combustion products and stabilize the draft in the combustion chamber. Cleaning of the smoke pipes of the boiler body is carried out with the cover of the decorative casing and flue removed. The decorative casing is stamped steel, coated with protective enamel.

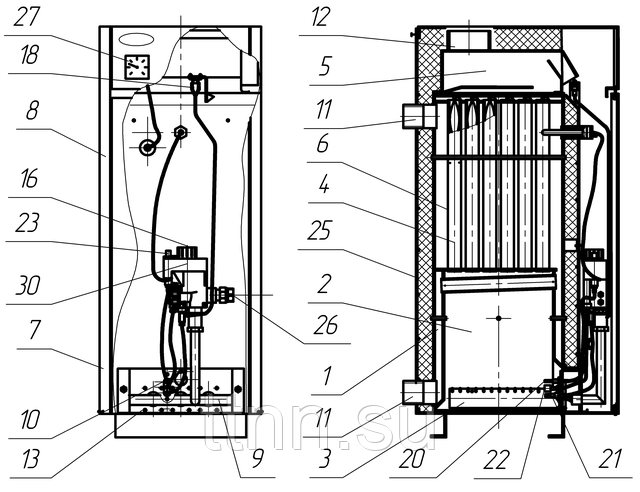

1 - body; 2 - firebox; 3 — main burner; 4 - convective flue; 5 - gas duct; 6 - smoke pipes; 7 — decorative casing; 8 - door; 9 - collector; 10 — inspection hole; 11 — pipes for connection to the heating system; 12 — exhaust pipe for combustion products; 13 — burner device; 16 — thermostat; 18 — traction sensor; 20 – piezoelectrode; 21 – thermocouple; 22 — pilot burner; 23 — piezo button; 25 — thermal insulation; 26 — pipe for connection to the gas main; 27 — temperature indicator; 30 – automatic (gas valve) 630 EUROSIT

Automation “Sit” (Italy) - multifunctional gas supply regulator consisting of a thermostatic control device with a thermostat; piezo lighter; traction sensor; ignition burner with thermocouple and electrode.

Please check availability when ordering.

User manual

The boiler operates automatically. The user is only required to maintain the cleanliness of the body, fill and drain water from the system and start the boiler when necessary.

Temperature adjustment is carried out in operating mode, according to the user’s own feelings. The boiler is started either using a piezo ignition system or manually using the principle of a gas stove. To turn on the boiler using piezo ignition, you need to turn the knob to the ignition position.

The thermostat knob must be turned until it aligns with the “asterisk” icon and at the same time pressed in all the way.

Press the piezo ignition button several times to light the burner, but hold the thermostat knob for another 10-15 seconds . If the attempt is unsuccessful, repeat the procedure.

To service and repair the boiler, you should call a technician from the service center. Independent tampering with the structure will automatically void the warranty agreement.

Download instructions

Download instructions for the Danko floor-standing gas boiler.

Basic faults

The most common malfunctions of Danko gas boilers, experts and ordinary users include problems with the burner and gas consumption.

Cases of flame attenuation (failure), characteristic of boilers with an atmospheric burner, are often noted. In addition, the injectors often become clogged with soot, soot and other combustion products. Excessive gas consumption occurs due to the appearance of a layer of scale in the primary heat exchanger.

It acts as a thermal insulator, reducing the efficiency of heat transfer. The user notices that the coolant temperature has dropped and increases the flame burning mode.

This causes the heating of the outer surface of the heat exchanger to become stronger, which causes rapid failure of the unit.

The solution to the problem is the use of softening water filters (as a preventive measure) and periodic washing of the heat exchanger, for which you need to invite a technician from the service center.

Basic malfunctions, why does the boiler go out?

The main malfunction of the Danko floor-standing gas boiler is spontaneous extinguishing of the burner.

It can be caused by various reasons:

- Stopping the gas supply (in the main line, or simply forgot to open the gas tap on the boiler itself).

- There were problems with gas equipment - breakdown of automation, failure of the gas valve, other problems.

- Reverse draft in the chimney, strong wind or drafts inside the room.

If the gas supply is interrupted, you should contact the gas service and obtain the necessary information. If problems arise with gas equipment, you must call a technician from a service center who is authorized to perform such work.

Dealing with drafts or backdrafts is more difficult, since they are often caused by external reasons that cannot be influenced. In any case, it is necessary to ensure high-quality and stable air exchange in the room, to eliminate drafts and sudden changes in the direction of air flows.

It is also necessary to monitor the condition of the chimney and promptly clean it from soot and soot.

Danko boilers

_______________________________________________________________________________

_______________________________________________________________________________

I want to buy a boiler in the near future. I'm interested in Danko 16 (cast iron). The main question is that descriptions often describe the limited service life of models with heat exchangers made of steel; if I nevertheless purchase a device with a cast iron heat exchanger, will this extend the service life and is it significant? And in general, is cast iron reliable? By the way, what type of automation do you recommend? Are there any problems with the discrepancy between our gas and the imported equipment that is used? Cast iron heat exchangers last much longer than steel ones. The heat exchanger is constantly exposed to moisture mixed with acids from combustion products, which leads to corrosion. Corrosion increases significantly if the heat exchanger is not warmed up after start, as described in the data sheet (condensate). Another factor is burnout. Salts in the coolant water tend to settle on the walls of the heat exchanger in places of greatest heating. This further increases the heating of the wall and ultimately leads to burnout. Naturally, the thicker the steel of the heat exchanger, the longer the boiler will live. A cast iron heat exchanger is much more durable in this regard. On the other hand, cast iron is not a ductile material and for its long service life you need to properly make the heating system and, first of all, the replenishment. What is the difference between the new version of the Danko 18 boiler and the later one, in the number of burners? The number of burners is the same: Danko-18 - 3 burners of 8 kW (total power 24 kW). I have a Danko double-circuit parapet boiler 7 UHF. They took it for heating. If I want to turn off the heating and switch it to hot water. Do I need to turn off the pump and turn off the taps? We consume hot water from the boiler. I want to turn it off for the day until the evening. In order to save money. Turn off the pump, close the taps (the expansion tank must communicate freely with the unit), open the small circle tap (if any). When the heating is on, we have a very hot pump that pumps water into the radiators, should this be the case or not? The pump should not be hot, especially if it is on the return line. Most likely it doesn't work for you. If the pump is on the supply side right next to the boiler, then naturally it will be hot as the hot pipe from the unit heats up. In general, it is not advisable to install a pump for supply, because its wear increases. Help me figure out the boiler. A couple of weeks ago I bought a parapet Danko 10 mustache, bought it second hand, turned on the heating, it heats well (about 150 liters, but it doesn’t matter), but the hot water is generally cold, or rather hot water runs off the radiator and then cold. I brought the unit up to 85 degrees, made a very thin stream (almost dripping), you can hold your hand. I called the technicians and they said that these models are not designed for hot water (DHW). I talked to people and it seems like the water is normal, of course there is no pressure, but there is boiling water. If anyone has encountered this, please tell me, otherwise it can’t be understood, and I bought it because of the hot water. Regarding the taps, this is already clear; I immediately connected it that way so that it could be adjusted. After all, I heated the water in the system to 85 degrees, and the hot water flows in a very thin stream, well, logically, everything should work. Why then is a second circuit needed in this device? This model produces only 3.6 l/min. hot water at a temperature of 35 degrees, it is enough to just wash your face and wash the dishes in the kitchen, under one condition, if the distance is no more than 10 meters from consumption and the tube with a diameter of 15 mm. You mentioned that you bought it second hand, the question is, has it been previously used? If so, then the water from the tap comes out in a thin stream. Does this bother you? This means that the second circuit of the heat exchanger contains copper tubes, and so they are most likely clogged with scale; it is necessary to rinse the second circuit with anti-scale, as is written in the instructions. And it is best to prevent scale from building up by installing a polyphosphate filter on cold water at the entrance to the boiler. If, after all, the unit is new and the hot water flows in a thin trickle, you need to look for an obstacle in the pipelines, perhaps there is rust across the coil or the cold or hot water pipeline itself is clogged, regardless of whether it is before or after the boiler. If the hot water supply was made from PPR (polypropylene pipes), then in such cases the craftsman who laid the cold or hot water pipeline for you, independently, overexposed the hot iron and when connecting two ends, for example, an angle and a straight one, the passage hole decreased in diameter, then Of course, the water will flow in a thin trickle. This can be easily checked by disconnecting both ends and blowing air through your mouth; if air does not pass through, then it is. The question concerns the Danko gas boiler. If it's not difficult, give me some advice. An automatic system with a Eurosit 630 burner is installed. Everything works perfectly. Only when the water in the apparatus cools down and the main burners turn on, a rather noisy bang occurs, i.e. the gas ignites with a delay. I checked the pilot burner jet, it is clean (it’s working for the first winter). I tried to add gas to the pilot burner, but there was no particular reaction to unscrewing the adjustment screw (gas can only be added slightly). I feel like I still need to add gas to the pilot burner, but nothing works. What can be done in this situation. Thanks in advance. If you add Eurosit 630 on the block, and there is no proper result, then unscrew the igniter tube, see how the gas flows and clean the nozzle, you can slightly enlarge the hole. Malfunction of the parapet boiler Danko-12.5 US. Recently it started knocking. It has been working since the beginning of winter, installed on an old heating system (pipes D. 76mm, length only about 58 m, temperature difference between supply and return is a couple of degrees). An Oasis CN-25/4 pump is installed. The return filter was cleaned and a significant amount of black deposits of a mixed soft and hard consistency were found, difficult to wash off from hands. It knocks when heating and cooling in the temperature range from 55 to 60 degrees, regardless of whether the burner is on or not. If you turn the pump off and on, the frequency of the knocks increases significantly for a couple of seconds. What could this be and what should I do? Or is this normal? The pipes have sagged and it looks like there is air in the CO, check the slopes. The new parapet boiler Danko-10 BC goes out and the gas is wasted. Does the factory give any kind of guarantee and how to find a specialist? Automation - 630 EuroSit. It seems that the automation should block the gas outlet. I found the following ways to find the problem myself: 1. Tighten the contacts (I can’t see what to tighten) 2. Reduce the draft in the chimney (by the way, the gas workers didn’t allow caps on the top of the pipes, I had to remove them) 3. Block off some kind of inspection window, where is this in this model? 4. Turn the igniter over - you have to climb inside. And all this was written according to the 15 kW model, but is my 10 VS the same? Replacing the gas valve will help. Please tell me how to set up the EuroSit 630 automation on a Danko 12 kW floor-standing boiler. I installed Eurosit instead of automatic Kare. On 2 it reaches 40 g. and the burner turns off, cools down to 35 degrees and lights up again. I tried turning off the pump and accelerating to 90 degrees. boiler. Heated up to 75 degrees. on 7 and turned off the automation completely. Maybe the gear on the EuroSit 630 is not set correctly? One of two things: either the thermometer is lying or the location where the thermal balloon is installed is 90 degrees. A Danko floor-standing boiler is in operation. Does not reach temperatures above 60 degrees! There were no problems until it got cold outside, -22 outside at home, 23-24 degrees, that’s the maximum! There is too much water in the system - 250-300 liters! What do you advise? Automation Eurosit 630, while the temperature at home is normal 23-24! I have a lot of water in the system, when they installed it I didn’t know that I had to take the volume of water into account! If I can’t come up with anything, will I have to either change the device, or remove half of the registers and mount them with polypropylene, and aluminum radiators? The boiler has an automatic system with modulated gas supply to the burner. That is, maximum and minimum power. And if the heating needs of your home fit into this range, then there is no point in letting the burner go out. The only thing that is required is the correct setting of the maximum and minimum individually. It is factory set to standard incoming gas pressure. And locally, this value may differ significantly from the required 180 - 200 mm in. Art. We installed and connected a Danko gas boiler with automatic Kare, it works great on the igniter, but as soon as you add power to the burner, it goes out completely, yesterday it went out within 5 minutes, today it works for about 20 minutes and goes out completely. Anyone who has encountered this problem, please advise. A time constant of 10-15 minutes corresponds to the heating time of the boiler head with poor draft or a very narrowed chimney. There is enough cross-section at the igniter, but when the burner is turned on, the tip overheats due to weak draft. Alternatively, reduce the burner power by turning off the gas valve to the burner. Let the burner burn barely. If this helps, then it's a matter of cravings. Check the water temperature regulator. It may be set to a very low temperature, after reaching which the device turns off. The pilot light should be lit. In this case, you just need to set the regulator to a higher temperature. The unit will turn off later. There is no media circulation due to air in the system. In operation there is a Danko floor-standing boiler, NOVA-820 automation. I set the temperature to 55 degrees. the boiler turns on and heats the coolant either to 65, then to 70 degrees, then to 60 degrees, and then cools down to 49, then to 40, or even lower. It also happens that it doesn’t start the first time. The draft is normal, the wick is burning, the area including the basement is 300 sq.m. The device has been working for a couple of months, the house has just been built, the windows are plastic, the walls are insulated with expanded clay blocks and are lined with brick, this is about heat loss. Check that the thermostat temperature probe is positioned correctly and that the pilot light is lit. The thermocouple on the automatic Kare, Danko boiler, the electromagnet stopped working. What is the reason and how to eliminate it? Look at the pilot light flame. If it is weak, then clean the jet. Try adjusting the position of the thermocouple in the pilot flame. If this does not help, then the thermocouple needs to be replaced. The Danko boiler is malfunctioning, it has gone out, attempts to restart it do not yield anything - I press the gas supply button, light the wick with a match, hold it for a minute, release it - the wick immediately goes out. I called the gas workers - they said that they would arrive tomorrow evening or even the day after tomorrow, but as luck would have it, it was -15 outside. I'm afraid the system won't freeze. The device is gas, 10 kW, with Polish automatic kaletka, the circulation is natural, but there is a pump. Tell me what can be done before the gas workers arrive to prevent the system from freezing. The flame does not reach the 3 mm thermocouple, as it was before - I don’t know, but everything worked for many years. I heated the thermocouple with a candle flame, then the unit worked until the candle burned out, then turned off. How can I clean it without taking it out? Everything there is so closed and uncomfortable that I can’t even see the thermocouple itself. The igniter nozzle is clogged and needs to be cleaned. A Danko 15 gas boiler is in operation. The problem is that the burner and wick go out. The boiler was launched in November 2020. Experts came 4 times to fix something, it took from a couple of weeks to a month. They say there are no problems, everything clean and new works well. Gas pressure, etc. Everything is okay. It’s good that it’s still under warranty, but once it runs out, it probably won’t be very good. With the main burner on, light the piece of paper, then after extinguishing it, present it to the draft sensor; if smoke goes into the unit, then the draft is due to something else. If smoke comes into the house or intermittently, then into the device, it means there is no draft in the chimney, it is necessary to insulate the chimney and, if necessary, add a pipe, thus creating normal draft in the chimney. The thing is that these models are designed to save money and the smoke pipes are made with a smaller diameter of 25mm, while in other models they reach 32-45mm. This is where the problem lies, that the heat does not escape to the street, like with other units. Gas parapet boiler Danko 12.5 us. It burns on the wick and everything is fine, but as you increase it, it goes out, what is the possible reason? Who knows? Well, everything has already been sorted out. The first step is to check the pressure in the gas pipeline before entering the boiler. If it is low, then the device does not have enough gas to turn on the main burner, so the wick will go out. Here you need to adjust the inlet pressure automatically. Call the gas workers, have them measure the pressure, it should be from 1.0 to 1.7 kPa. If it is less than 1.0, say 0.3-0.5, then there is no need to adjust anything, you need to look for where the pressure is lost at the inlet to the unit. A Danko 10 parapet single-circuit boiler with automatic Kare was installed, it has been in service for about 5 years, but this year a problem arose, from the beginning of the heating season it worked normally for about three months, and then it just turned off. We found a problem - suction of burnt gas, since the air exhaust pipe burned out in one place. We stuck the pipe out further - the device works, but now it is impossible to reduce the temperature - on the 5,6,7 divisions - it works like a clock, but as soon as I set it to at least 4, it immediately turns off. Tell me, please, what is the reason? First of all, do the boiler maintenance (cleaning): the pilot tube, the nozzle, the pilot itself, and the thermocouple. After that, see how well the automation supplies gas to the ignition burner (over 5 years, the valve could become clogged, the igniter flame is weak). If after cleaning the flame is weak, try increasing the flow with the adjusting screw. If this does not work, replace the valve. If the pilot flame is good, you need to look for the cause in the chimney, gas exchange is disrupted. A Danko gas boiler with Eurosit automatics is installed, it is on 2, when the main burner is operating, a sound comes out, like a boiling kettle (whistle) and quiet tapping. The pump is turned on at 1. When the pump is turned on to the 3rd position, the sound of the boiler does not change, the circulation is good because the pipes warm up well throughout the house, the collector can be easily held by hand, even when the device is turned on at 3-4 kW. The system has been in operation for a year, the system is open, but a maximum of 5-8 liters of water were added over the entire heating season. The pump screen is clean because I flushed the system before installing the new unit. What is the sound coming from and what should I do? It is very important to measure the inlet pressure when entering the automation. It should be 1.3-1.kPa. If it is more than 1.3 (for example, 2.0-2.5 kPa), then high gas pressure affects the operation of the boiler when the main burner is on. If the device is new, then remove the top cover and check the screw turbulators. They must fit freely into the smoke pipes. Maybe some kind of turbulator, when heated, expands and scrapes along the body of the smoke pipe. If the device has not been serviced, clean the smoke pipes and screw turbulators. And also on SIT automation. If the regulator is at 2, then this should correspond to a temperature of 50 degrees. If 80-90, then the thermostat is knocked down, as a result of which the temperature in the unit is high and such knocking noises can be made. 1 is 40 degrees, the remaining numbers are added in order by 10 degrees. Danko gas boiler malfunction. It turns on and works, but as soon as I turn on the pump, it immediately goes out along with the wick. Tell me the reason, please? I called the repairman, but he’ll be there in a week, we’ll freeze. The boiler is non-volatile. Turning on the heating system pump can only affect the operation of the main burners and then only the frequency of on-off cycles. The system pump cannot affect the operation of the pilot burner. They installed a Danko -12.5 UVS parapet boiler; upon purchase they said that it could be used for both heating and showering. The installer came and said that it was not suitable for a shower. Maybe you can install some kind of pump or you still need to buy a boiler. Model 12.5 UVS has a DHW circuit with a water flow rate of 270 l/hour (dT - 35 degrees). This is enough for a shower. How does the master justify his words? Perhaps you didn't quite understand it correctly? For the summer period, for example, I am convinced that a boiler is more suitable; for winter, the device is more economically profitable. The boiler may not be very powerful, but for a house of 80 sq/m there was enough power in the cold - 25 set the regulator from 4 - to 6 out of 7 possible, in 2020 it was warm sometimes even hot, this year I installed a pump and flushed the system, changed the open expander like 25 liters per closed 14 liters, experts installed it, for some reason the device does not produce the same warmth that it had that year. I have no idea what can be done about this, and I don’t know if the pump was installed correctly in the system, connected immediately after the device, could power be lost because of this? The first thing that comes to mind is that along with installing the pump, you also increased the volume of the system, added pipes and radiators. But you don’t mention this, which means we will assume that the volume of water in the system remains the same. There is no consensus on where it is better to install the pump on the supply or return, both have their place. Most likely, this is not the problem, but the speed of water flow in the system. For proper operation of the automation, normal hysteresis, or the temperature difference between supply and return, must be at least 10 degrees. It may be like this for you, you installed a pump, increased the flow rate, the water does not have time to cool down in a full cycle and comes into the unit at a high temperature. The temperature sensor (thermal cylinder) gives a signal that there is no need to heat the water. Try simply reducing the flow, set the pump speed to unity.

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers

- Electric boilers

- Boiler error codes

- Troubleshooting boilers

- Gas water heaters

- Malfunctions and repairs of geysers

- Water heaters

- Troubleshooting water heaters

- Repair of indirect heating boilers

- Troubleshooting electric convectors

_______________________________________________________________________________

- BAXI ECO FOUR

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

- BAXI LUNA

Peculiarities. Installation and assembly. Automation components.

- BAXI MAIN FOUR

Technical specifications. Installation. Adjustment and checking. Maintenance.

- BAXI SLIM

Adjustment and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

- BAKSI - REPAIR

After starting, a malfunction appeared. It doesn’t want to turn on, it worked for two years, now the whole display lights up, just like when the boiler is turned on, when the self-diagnosis mode is in progress, then it clicks, turns off for miles and seconds and turns on the whole display again. It turned on once, but it gives error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me, what could it be?

- BAXI - OPERATION

In operation, the Baxi main four 240 boiler shuts down with error E35 (stray flame). Tell me what to do? First season in operation.

- BAXI - SETTINGS

We installed and connected the Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW device?

- BOSCH - REPAIR

Bosch 6000 24 kW boiler, single-circuit with built-in three-way valve. The boiler sensor does not see it and gives an error. Tell me how to do it so that it doesn’t give an error and works normally for both the heating and the boiler?

- BOSCH - ADJUSTMENTS

If you turn off the DHW flow sensor, maybe it will be possible to reprogram it into a single-circuit device through menu L3?

- ARDERIA - REPAIR

We installed an Arderia esr 2.13 ffcd boiler. If my coolant pressure drops slightly by a couple of notches over 2-3 days, could the reason be a faulty three-way valve (there are no leaks from the radiators)?

- ARDERIA - ADJUSTMENTS

The gas boiler Arderia 2.35 is in operation. Tell me about reducing power. I heard something about modulation, fan speed, etc. Is it really possible to reduce power?

_______________________________________________________________________________

- BUDERUS FLOOR

We installed and connected the Buderus Logano G234-WS-44 kW boiler, automatic Logomatic 4211. Heating is based on cylinders without hot water, and the jets for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the outside temperature was +16+18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and the red button light on the front wall came on. We pressed the button, turned the power back on and everything worked. This happened several times, then the boiler was turned off completely for the summer, what could be the problem?

- BUDERUS WALL

In the single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is used for DHW?

- VAILLANT - REPAIR

Tell me, for Vaillant wall-mounted gas boilers, are there real/actual differences for the better in the new generation turboTEC plus VU/5-5 compared to /3-5?

- VAILLANT - ADJUSTMENTS

There is a malfunction in the boiler, the green LED (power) is flashing, the instructions say that the thermal protection has tripped, the green indicator is flashing, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is fine.

- DAEWOO

In operation there is a double-circuit gas boiler Daewoo Gasboiler with an electronic panel. When the DHW is turned on, the heating heats up, the operating mode is summer. I removed the three-way valve, there is no dirt or wear. It seems that the board does not control the three-way valve. How to check?

- ELECTROLUX

The Electrolux Basic Xi wall-mounted boiler has been installed and connected. A problem began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts it gave error E1. How can I fix it?

- KOREA STAR

Koreastar boiler malfunction. The heating works perfectly, the hot water comes intermittently, when you turn on the hot water tap, cold water comes out first, then boiling water. After a few seconds it’s cool, then boiling water again. What could be the problem?

- FERROLI

Malfunction of the Ferroli Domiproject 24 boiler - I set it to 60-70 degrees, it switches to minimum combustion, does not turn on, does not turn off. Restart is unstable. No pattern emerges. What to do?

- JUNKERS

In operation, a Junkers euroline gas boiler, when hot water is turned on, gas ignites, then goes out, and so on several times. If you turn it on while the heating is running, the water heating starts immediately. Tell me, please, what could be the problem?

- NAVIEN

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. It is not possible to adjust the fan run-on. I set it to 30 seconds, but still 2 minutes. spins.

- OASIS

Malfunction of the Oasis ZRT18 boiler. The unit starts, the gas lights up, then goes out. It lights up again and then goes out (this happens three times). Then it lights up and works fine. It doesn't give any error. What is the reason?

- SAUNIER DUVAL

Malfunction of the Senor Duval gas boiler - the water pressure sensor shows 0.0, the indicator flashes red, the hot water does not heat up, but the water pressure in the apartment is good. How to fix the problem?

- VIESSMANN

Where should a condensate trap be installed in a coaxial chimney? The boiler wh1d with a closed combustion chamber is located at a distance of 1 m from the wall.

- WESTEN

Problem starting the Westen Pulsar D boiler. Piezo ignition works, but there is no flame, error E01 after a crackling sound. I moved the fork around.

- BERETTA

The Novella floor-standing gas boiler is blocked - the green lights on the panel are on and nothing else happens. How to fix?

- ARISTON

An Ariston gas wall-mounted boiler has been installed and connected, which does not hold pressure at all: while cooling the heated water, the pressure drops to zero, although water is regularly filled. What about the pressure?

- SIME

Metropolis dgt 25 bf boiler malfunction. The hot water supply has stopped working, the heating is working, it does not display an error. What do you advise?

- SOLLY

Please tell me how to solve the problem. The Solly Standard boiler, whenever you try to turn it on or hot water, displays a GS error.

- WOLF

Wolf boiler in operation. Lately it has begun to behave strangely: during the pause between starts, it turns on the burner for one second five times, and 70 degrees appears on the display. Where to look for a problem?

- ACV

ACV Wester Line works very unstable: it often crashes, makes a characteristic knock and stalls when starting, but at times everything is fine. The unit is almost new, what's wrong with it?

- DEMRAD

In the gas boiler Demrad, the gas supply to the burner stopped. The piezo element clicks, but there is no ignition. There is nothing wrong with the gas stove, there is gas. What is the reason?

- KITURAMI

The Kiturami world boiler is malfunctioning and stops periodically. I clean the flame sensor and the unit works fine for a while, but soon the same thing happens again. He also began to smoke heavily. Maybe the problem is that the chimney is short, and it needs to be lengthened?

_____________________________________________________________

- IMMERGAZ - ERRORS

Errors of Nike Star, Eolo Star/Mini, Mythos boilers. Malfunctions of boilers with the possibility of automatic unlocking.

- IMMERGAZ - REPAIR

My boiler systematically raises the temperature to 80 degrees in winter mode. I called the repairman three times. He said that many models have this problem and suggested installing a programmer, but it’s not certain that it will help. Tell me how to solve this problem and will this programmer help?

- AOGV

Models 11.6; 17.4; 23.2; 29.3 kW. Specifications. Control elements of the automation unit. Installation and maintenance. Malfunctions and their elimination.

- AOGV - REPAIR

The AOGV gas boiler was installed and put into operation. Problem with hot water supply. The heat exchanger was washed. Less than a month has passed and the water is not flowing again. We put a filter on the water, but time passed, and again there was no hot water. What kind of breakdown could this be?

- AGV

Installation and installation. Start-up and adjustment. Malfunctions and ways to eliminate them.

- AKGV

Technical specifications. Installation and connections. Startup and operating procedure. Automatic adjustments.

- NEVA LUX

The boiler Neva Lux 7023 is malfunctioning. It gives error E7 twice a month. But after reboot it still works. Now it gives error E6. It will work for 15 minutes and turn off. What could it be?

- ROSS

Design and automation unit. Ignition order. Malfunctions and repairs.

- ATEM ZHYTOMYR

Tell me, is it possible that due to low gas pressure the Atem Zhytomyr boiler goes out, a click occurs and goes out. What is the problem? Is it possible to temporarily disable automation and how?

- LEMAX

We installed a Lemax KSG-12.5 Premium gas boiler. After turning off the main burner, a clicking sound occurs after a couple of minutes, what is the reason? Tell me?

- KEBER

A KS-G gas boiler of 250 sq.m. was installed and connected. m. When ignited, it does not turn off, the temperature rises, if I am not mistaken, automatic Arbat 1. The flame is not regulated - it is too large. What to do?

- LIGHTHOUSE

I installed the Mayak gas boiler and connected it. It works fine. But the reason is this. When it works on unit it squeaks a lot, if you turn the knob 2-7 the squeak disappears. Tell me, what could it be?

- DANKO

We installed and connected a Danko gas boiler with automatic Kare, it works great on the igniter, but as soon as you add power to the burner, it goes out completely, yesterday it went out within 5 minutes, today it works for about 20 minutes and goes out completely. Has anyone encountered this problem?

- GAZLUX

The gaseko 18 boiler is in operation. When hot water is turned on, the pressure in the system drops after replenishment, the pressure reaches 3 bar. Have to reset. What's wrong, how to fix it?

- NOVA FLORIDA

Water often boils in the boiler, causing it to fail due to overheating. The heat exchanger was recently washed, the system is not clogged. What's the matter?

- RINNAI

Rinnai 167 RMF boiler malfunction. Recently I started showing error 14. How can I fix the problem?

- CELTIC

The Celtic DS boiler heats up to 45 degrees and sits all day, does not turn off and does not heat the batteries, sometimes it shows error A3. How can I fix this problem?

- MORA

The hot water pressure in the Mora Top boiler has dropped. What is the reason?

- MASTER GAS SEOUL

The Seoul gas wall-mounted boiler stopped turning on due to a no-ignition error. How can it be eliminated? What exactly went wrong?

Price range

Danko floor-standing boilers represent a wide group of models, which expands the price range. If you do not take into account powerful samples intended for heating large areas, then the cost of floor-standing boilers is in the range of 20-67 thousand rubles.

The price of a particular model depends on the set of functions and design features.

Before purchasing, you need to decide on the type of chimney, since this is an important factor influencing the choice of a particular model.

NOTE!

The chimney is not included in the basic package and must be purchased separately.